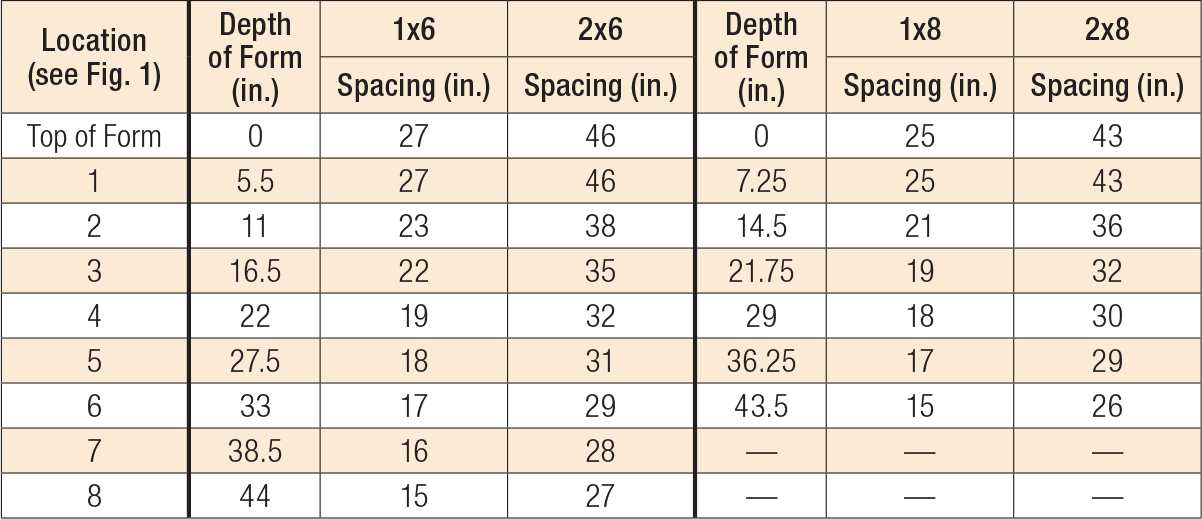

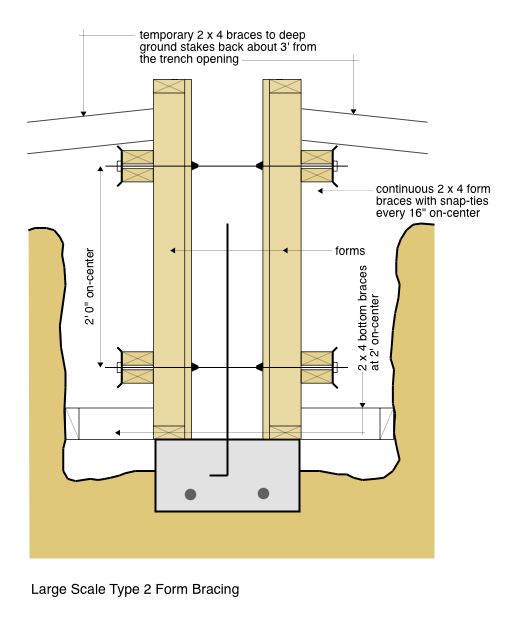

Snap Tie Spacing Chart

Snap Tie Spacing Chart - Web home / standard snap tie. Web the snap tie spacing calculator helps calculate the appropriate distances between snap ties based on several critical factors, including the properties of the. Please use decimals for dimensions. Dayton superior a4h hex head snap ties are manufactured with hot forged integral 1/2 hex shaped heads. Web the most common snap tie spacings being used with the jahn forming system are shown below. Web the proper tie head position is at the midpoint or higher of the omni wedge slot. Web a3 standard snap tie is manufactured with either hot or cold forged integral heads and is equipped with flats or crimps to prevent turning in the concrete during breakback. A strongback bracket hooks onto. Web the most common snap tie spacings being used with the jahn forming system are shown below. This calculator is for estimates of materials purchases only; Jahn® a bracket is utilized to hold a. The tielock bracket hooks the tie loop, while securely holding the 2×4 lumber walers. Web enter the information about your structure and formwork to estimate your material needs. Load ratings and application details. 3/4” plywood thickness, face grain perpendicular to walers. Standard snaptie, standard snap tie, Web the maximum recommended spacing for wts used with 1x, 2x and 1 1/4 thick forms is outlined in the tables below. Web form ties, common and uncommon. Standard 16” waler spacing with 2x4 lumber. Web the most common snap tie spacings being used with the jahn forming system are shown below. 3/4” plywood thickness, face grain perpendicular to walers. Web in practice, the snap tie spacing calculator allows construction professionals to input values for wall width, wall height, tension, length between tie. Web the maximum recommended spacing for wts used with 1x, 2x and 1 1/4 thick forms is outlined in the tables below. For each formwork design the appropriate form. Web the maximum recommended spacing for wts used with 1x, 2x and 1 1/4 thick forms is outlined in the tables below. The tables give spacing guidelines for various form heights. A safety factor of 2 has been applied to determine sage working loads (swl) of ties. Web the proper tie head position is at the midpoint or higher of. A strongback bracket hooks onto. The tielock bracket hooks the tie loop, while securely holding the 2×4 lumber walers. Snap ties are used to hold. We used single waler system but didn't put a tie in every hole. For each formwork design the appropriate form tie is. Web this diagram is based on: When it is desired to. Web the most common snap tie spacings being used with the jahn forming system are shown below. Standard 16” waler spacing with 2x4 lumber. Load ratings and application details. Standard 16” waler spacing with 2x4 lumber. For each formwork design the appropriate form tie is. Web recommended snap tie spacing for rate of pour at 2 feet per hour at 70° plywood deflection is the limiting factor in the diagrams above. Web the most common snap tie spacings being used with the jahn forming system are shown below. Web. Web form ties, common and uncommon. A safety factor of 2 has been applied to determine sage working loads (swl) of ties. Web the proper tie head position is at the midpoint or higher of the omni wedge slot. Web a snap tie spacing calculator is a tool used in construction to determine the appropriate spacing between snap ties on. Web enter the information about your structure and formwork to estimate your material needs. Web the most common snap tie spacings being used with the jahn forming system are shown below. Web this diagram is based on: Load ratings and application details. Jahn® a bracket is utilized to hold a. A safety factor of 2 has been applied to determine sage working loads (swl) of ties. Please fill out the form below with dimensions and specs. Web a snap tie spacing calculator is a tool used in construction to determine the appropriate spacing between snap ties on concrete forms. Load ratings and application details. Web a4h hex head snap tie. Please fill out the form below with dimensions and specs. Web a4h hex head snap tie. Web hex head measures 1/2” across flats. Web this diagram is based on: Pour pressure of 450 psf with l/360. For each formwork design the appropriate form tie is. Web form ties, common and uncommon. Web typical tie spacing is 16”x24” for most concrete walls. Plywood was drilled the standard 8, 16 ect. All final form work design should be signed off by the appropriate project engineer. Web this estimating tool is to help determine product quantities. The tielock bracket hooks the tie loop, while securely holding the 2×4 lumber walers. Web the maximum recommended spacing for wts used with 1x, 2x and 1 1/4 thick forms is outlined in the tables below. When it is desired to. 3/4” plywood thickness, face grain perpendicular to walers. Web the most common snap tie spacings being used with the jahn forming system are shown below.

WT Wedge Form Tie Simpson StrongTie

Snap Tie Spacing For Concrete Wall Forms

Snap Tie Spacing Chart

Custom Snap Ties — Steel Dog

Snap Tie Spacing For Concrete Wall Forms

Snap Tie Spacing Calculator Online

Scaffolding Federal OSHA Tie Spacing DH Glabe & Associates

Snap Tie Spacing For Concrete Wall Forms

SnapCoil™ Tie — Steel Dog

Concrete Snap Tie Spacing

Web In Practice, The Snap Tie Spacing Calculator Allows Construction Professionals To Input Values For Wall Width, Wall Height, Tension, Length Between Tie.

Web Home / Standard Snap Tie.

For Different Rates Of Pour And/ Or Other Tie Spacing, Contact A Dayton Superior.

Standard Snaptie, Standard Snap Tie,

Related Post: