Welding Charts

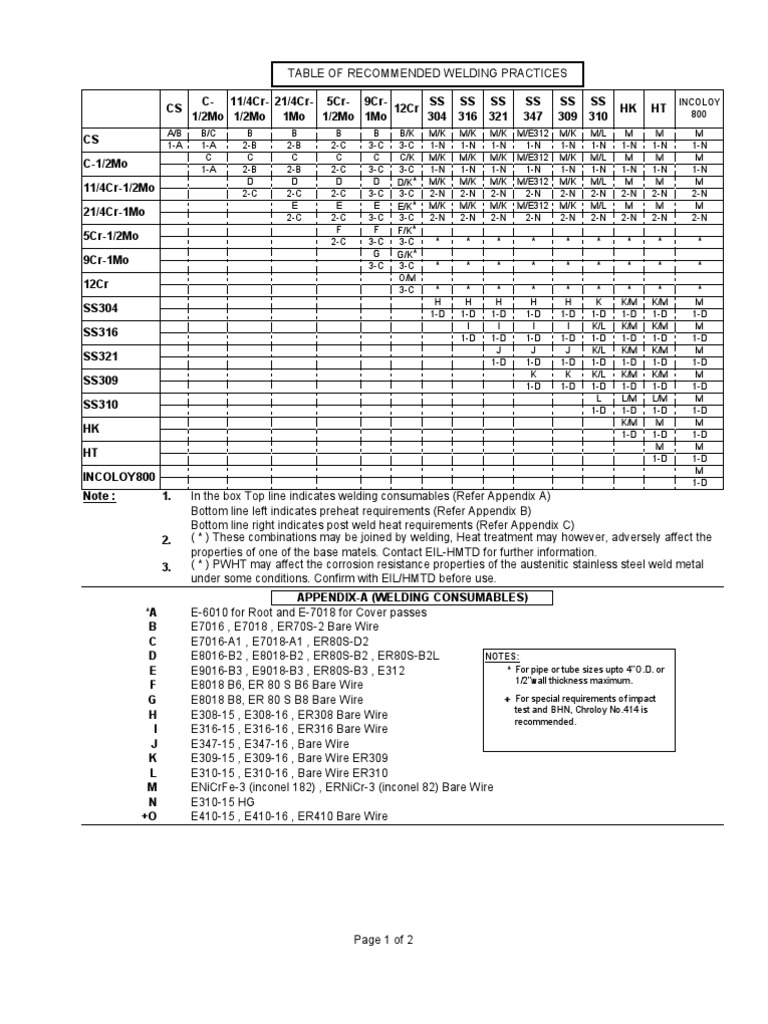

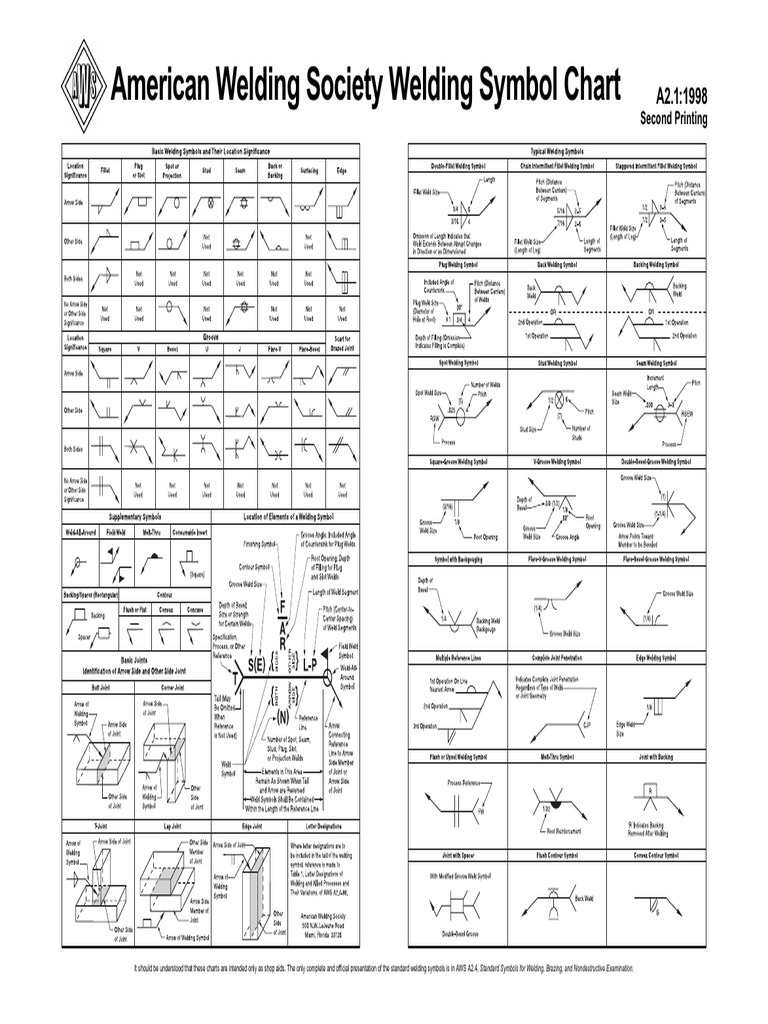

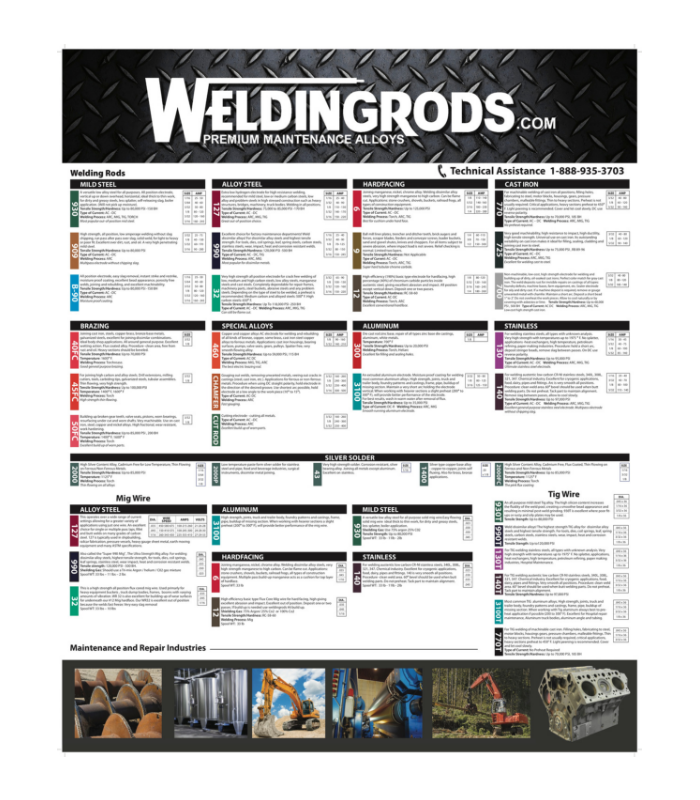

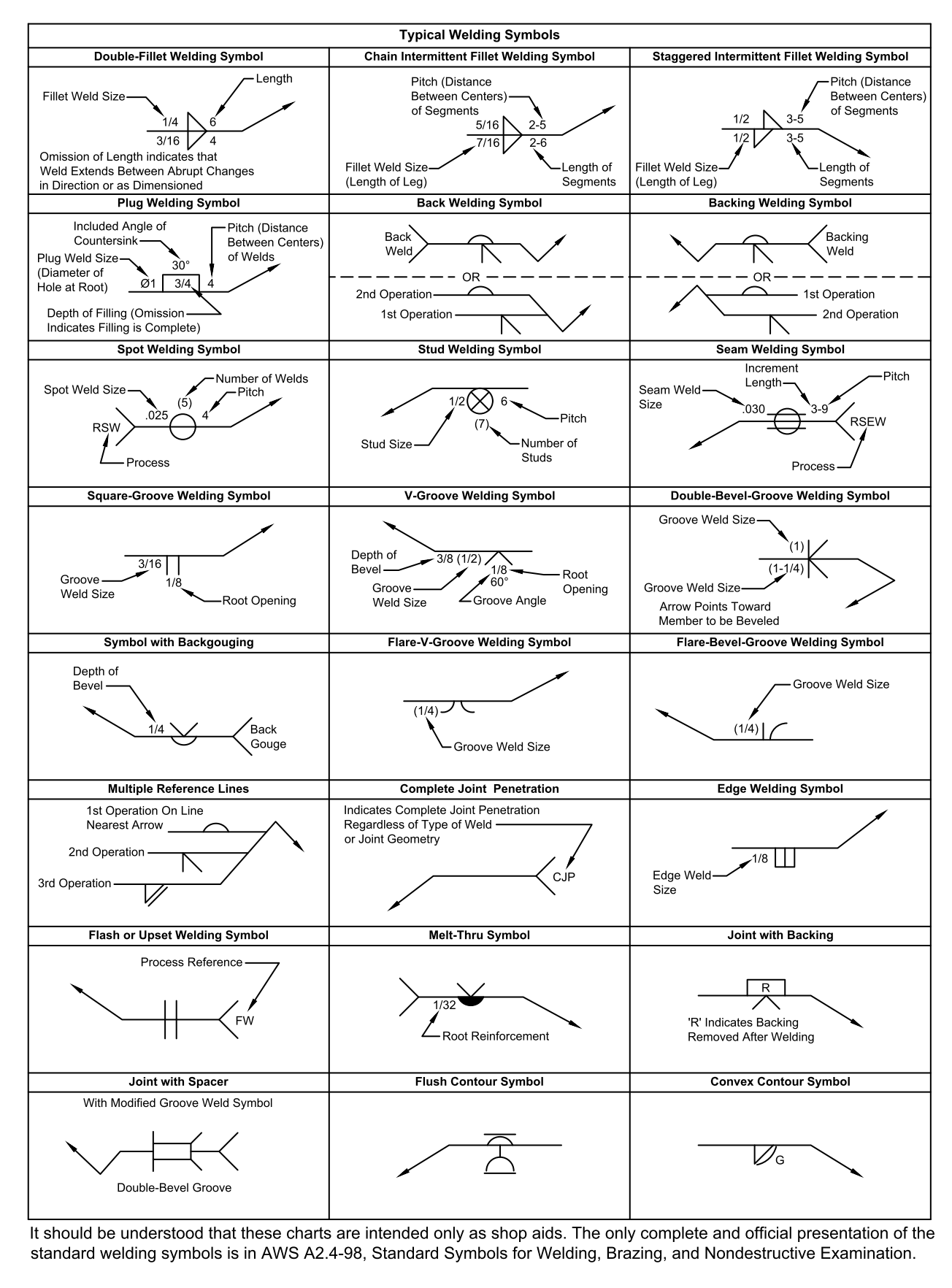

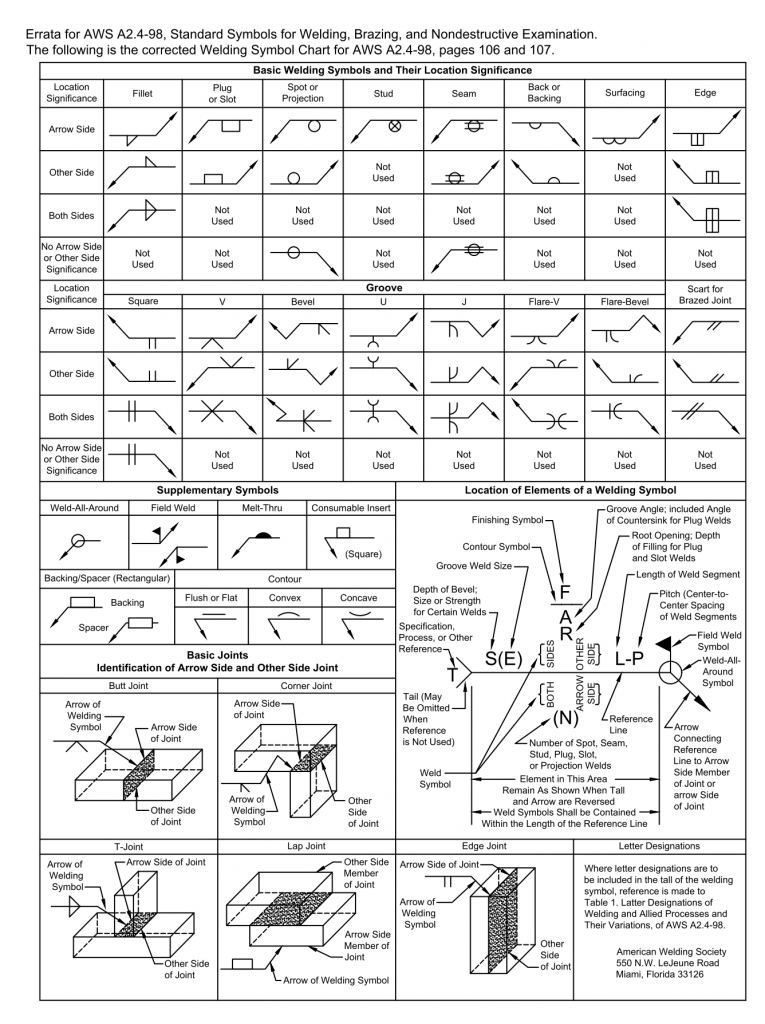

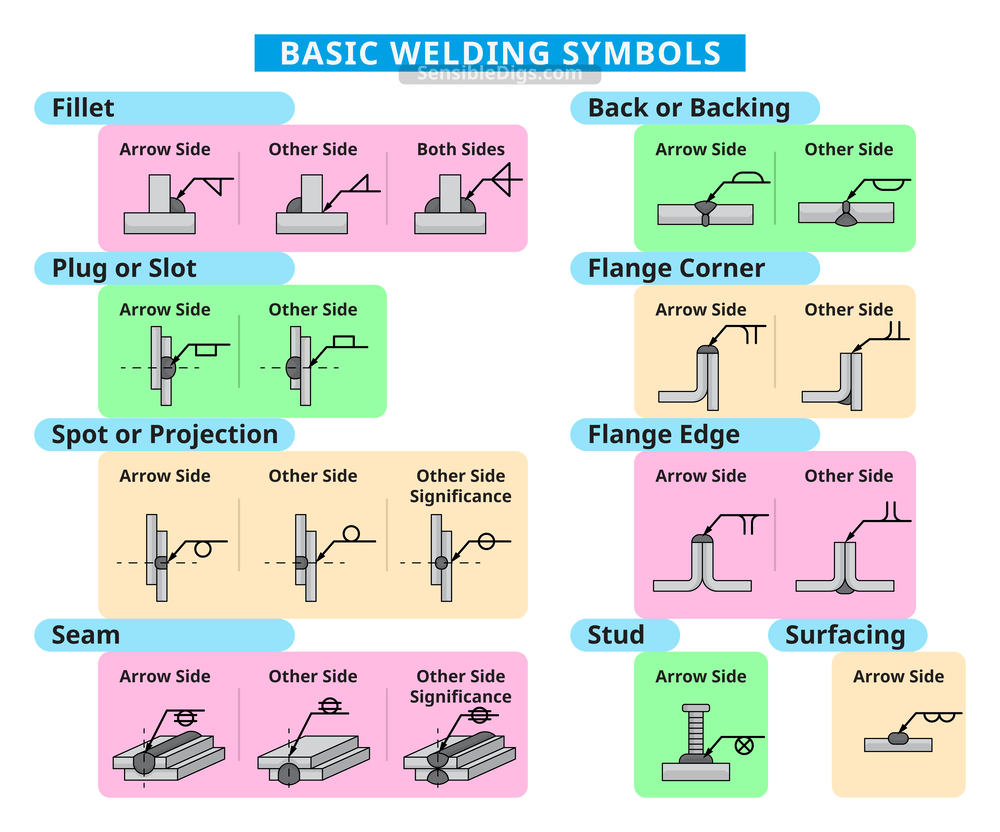

Welding Charts - Welding symbol for fillet weld It is composed of standard elements including a weld symbol, arrow line, and reference line, and uses any of the applicable supplementary symbols to effectively complement such. You just have to pay attention… normal bead: Good penetration into the base, flat profile, appropriate width, and ties in well at the ends.; Web name double sided v butt double sided bevel butt double sided u butt weld symbol Web becoming a professional welder is rewarding and provides a lifelong opportunity to enjoy fulfilling employment worldwide. Web all the weld symbols, weld sizes, pitch, weld length are placed on the reference line. Generally, there is no specific requirement for the position of the arrow line relative to the weld, as shown in figures 4(a) and (b). Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. Web another way to check your mig settings is to inspect the weld bead. However, sooner or later you will be faced with drawings you’re required to weld from. It is composed of standard elements including a weld symbol, arrow line, and reference line, and uses any of the applicable supplementary symbols to effectively complement such. Web becoming a professional welder is rewarding and provides a lifelong opportunity to enjoy fulfilling employment worldwide. 3. Good penetration into the base, flat profile, appropriate width, and ties in well at the ends.; Web all the weld symbols, weld sizes, pitch, weld length are placed on the reference line. You just have to pay attention… normal bead: Web another way to check your mig settings is to inspect the weld bead. Web the table presents some of. Web becoming a professional welder is rewarding and provides a lifelong opportunity to enjoy fulfilling employment worldwide. Good penetration into the base, flat profile, appropriate width, and ties in well at the ends.; Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for. Web the table presents some of the most commonly used welding symbols. However, sooner or later you will be faced with drawings you’re required to weld from. It usually involves preparing the edge pieces to form one of the groove weld shapes like v, bevel, u, j, flare v, flare bevel or no preparation at all with square edges to. 3 cross joint of double fillet weld. It usually involves preparing the edge pieces to form one of the groove weld shapes like v, bevel, u, j, flare v, flare bevel or no preparation at all with square edges to form a square groove. However, sooner or later you will be faced with drawings you’re required to weld from. Web. It usually involves preparing the edge pieces to form one of the groove weld shapes like v, bevel, u, j, flare v, flare bevel or no preparation at all with square edges to form a square groove. Welding symbol for fillet weld 3 cross joint of double fillet weld. It is composed of standard elements including a weld symbol, arrow. It will tell you what it needs. Web another way to check your mig settings is to inspect the weld bead. Web all the weld symbols, weld sizes, pitch, weld length are placed on the reference line. Good penetration into the base, flat profile, appropriate width, and ties in well at the ends.; It is composed of standard elements including. Web the table presents some of the most commonly used welding symbols. It will tell you what it needs. It is composed of standard elements including a weld symbol, arrow line, and reference line, and uses any of the applicable supplementary symbols to effectively complement such. However, sooner or later you will be faced with drawings you’re required to weld. It is composed of standard elements including a weld symbol, arrow line, and reference line, and uses any of the applicable supplementary symbols to effectively complement such. It will tell you what it needs. Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post. Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. Welding symbol for fillet weld It usually involves preparing the edge pieces to form one of the groove weld shapes like v, bevel, u, j, flare v, flare bevel or. You just have to pay attention… normal bead: Web name double sided v butt double sided bevel butt double sided u butt weld symbol It will tell you what it needs. It is composed of standard elements including a weld symbol, arrow line, and reference line, and uses any of the applicable supplementary symbols to effectively complement such. Web another way to check your mig settings is to inspect the weld bead. Web becoming a professional welder is rewarding and provides a lifelong opportunity to enjoy fulfilling employment worldwide. Web the table presents some of the most commonly used welding symbols. Welding symbol for fillet weld Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. Good penetration into the base, flat profile, appropriate width, and ties in well at the ends.; Web all the weld symbols, weld sizes, pitch, weld length are placed on the reference line. 3 cross joint of double fillet weld.Welding Chart the complete reference guide to welding Pipe (Fluid

Printable Welding Charts

Printable Welding Charts

Printable Weld Symbol Chart

Printable Welding Symbols Chart

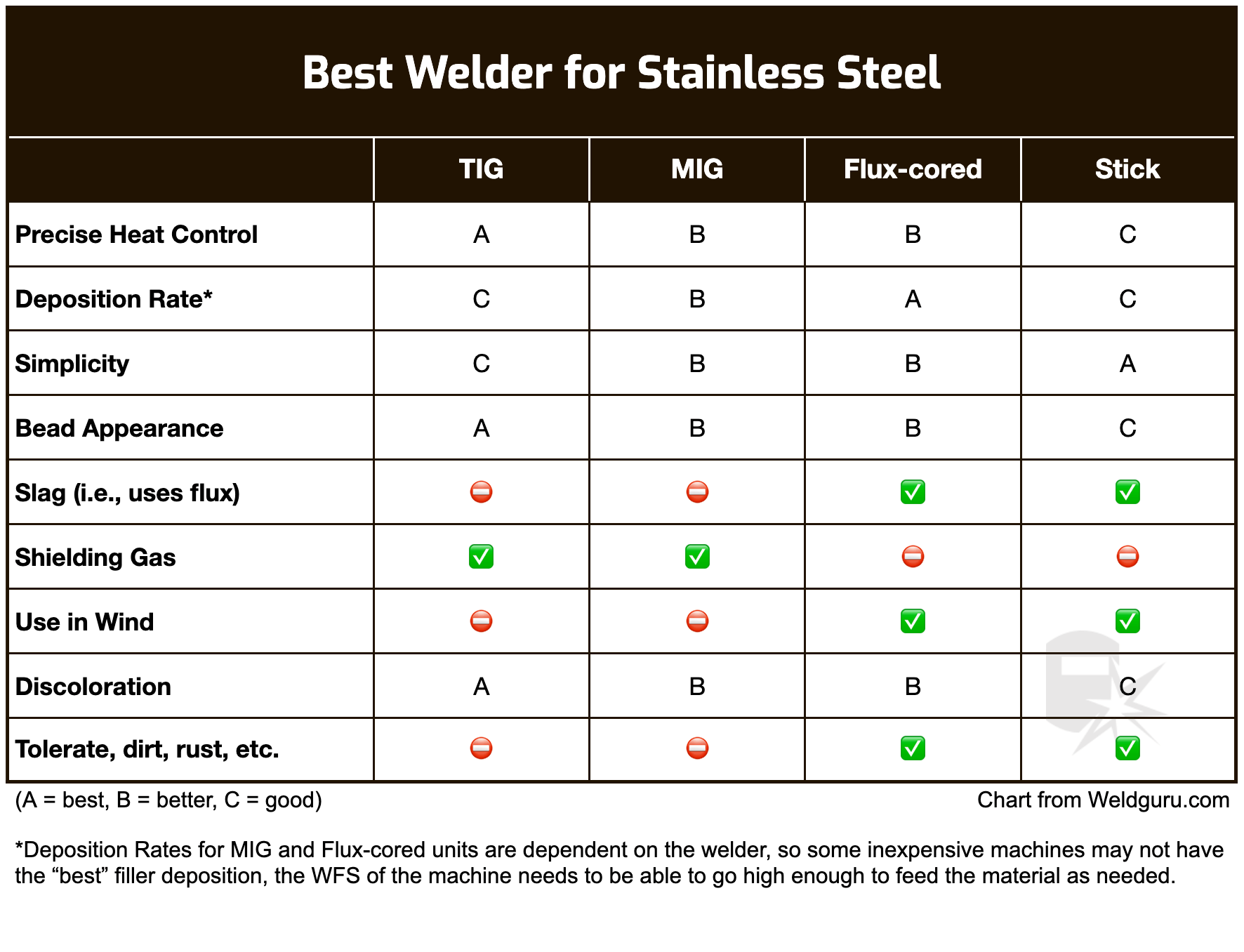

How to Weld Stainless Steel A Complete Guide

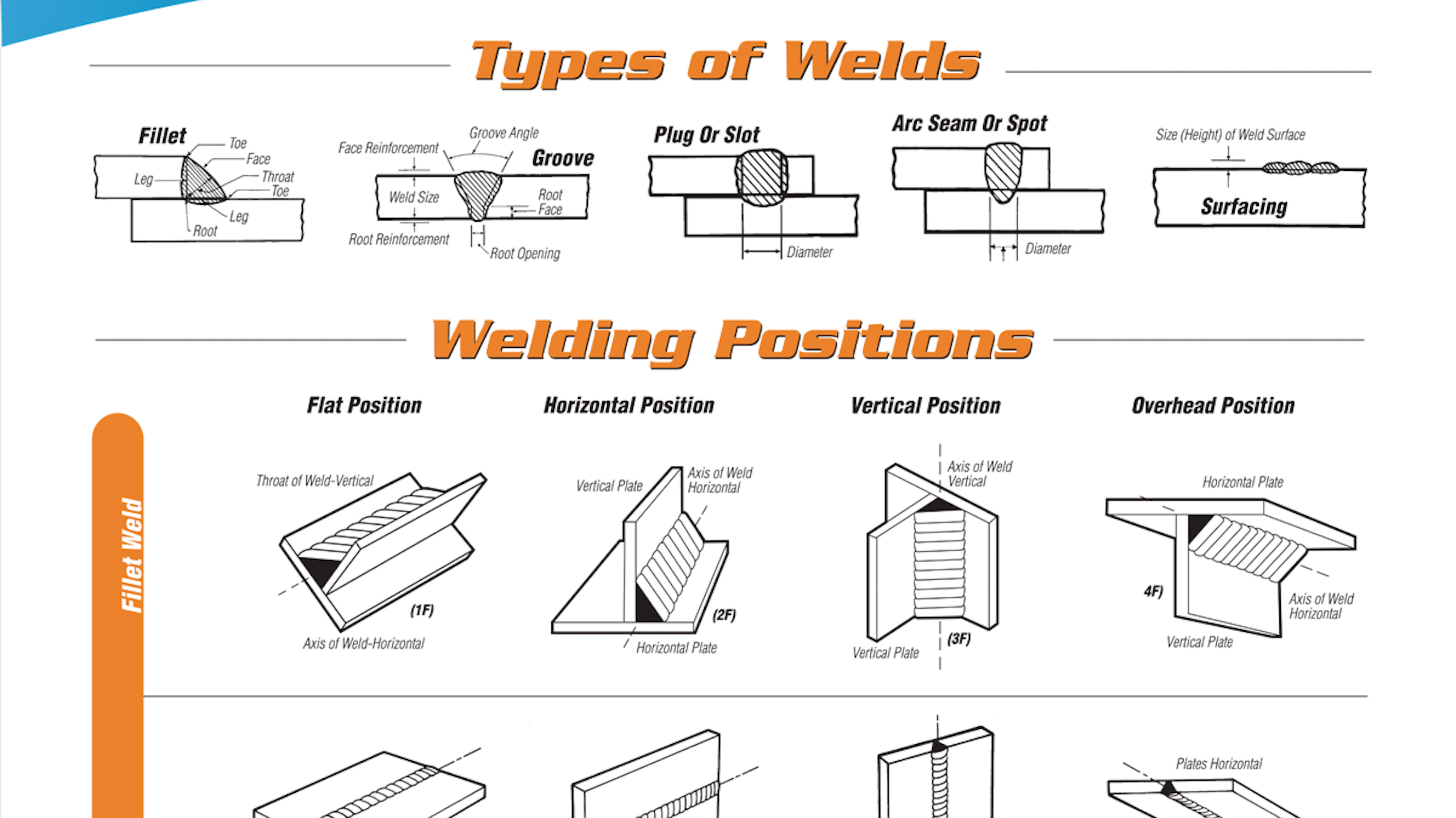

Welding Types and Positions poster Fleet Maintenance

Tig Welding Settings Chart

Welding Symbols Chart Printable

Welding Symbols Diagrams & Types (Fully Explained) Sensible Digs

Generally, There Is No Specific Requirement For The Position Of The Arrow Line Relative To The Weld, As Shown In Figures 4(A) And (B).

However, Sooner Or Later You Will Be Faced With Drawings You’re Required To Weld From.

It Usually Involves Preparing The Edge Pieces To Form One Of The Groove Weld Shapes Like V, Bevel, U, J, Flare V, Flare Bevel Or No Preparation At All With Square Edges To Form A Square Groove.

Related Post: