Pipe Flow Capacity Chart

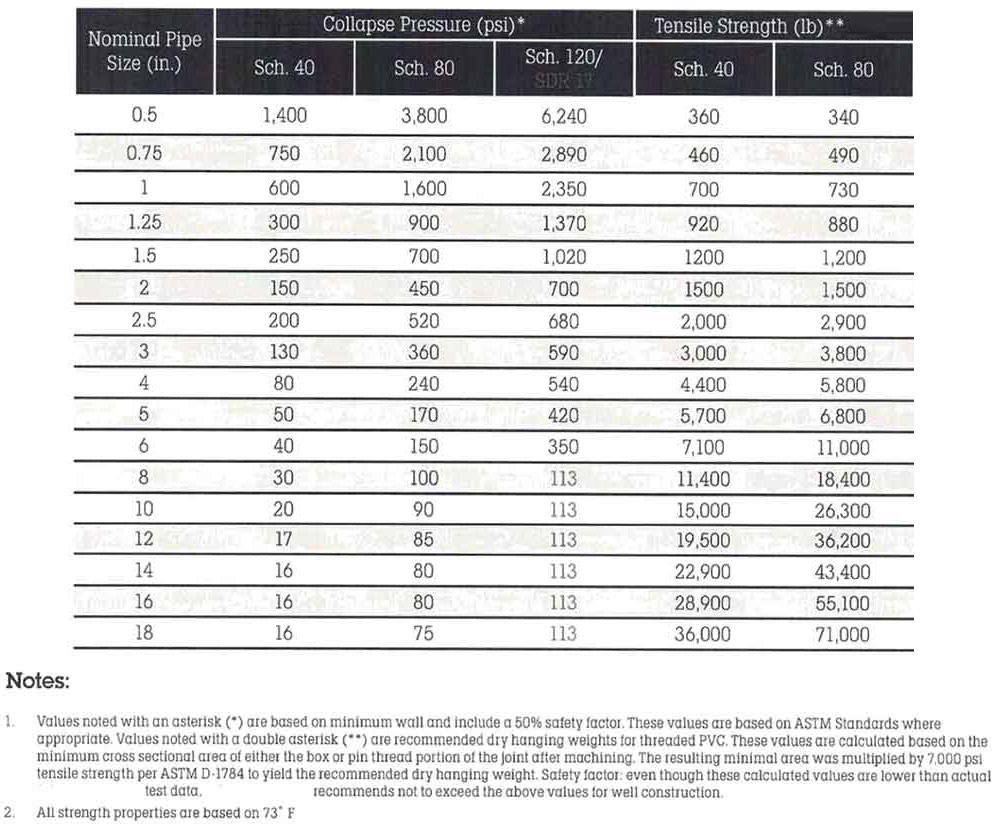

Pipe Flow Capacity Chart - The diagrams below can be used for design of sewage and wastewater gravity conveying systems. Web velocity head in the table below can be used to calculate the minor loss in schedule 40 steel pipes with water flow. Web pipe to carry maximum predicted flow, at a given slope, without flooding. A comparison of pipe diameters with different surface roughness coefficients is an important design consideration. Web the following chart contains the maximum recommended flow rates at the given pressure for ansi schedule 40 pipe. The spreadsheet shown below uses s.i. The excel formulas then calculate water flow rates for the entered pipe sizes and lengths. What is the pressure (psi) drop per 100 ft length of pipe and the flow velocity? Web fluide design inc., 5764 monkland avenue, suite 311, montreal, quebec, canada h4a 1e9 tel: The diagram above and table below are for steel pipes schedule 40. Web velocity head in the table below can be used to calculate the minor loss in schedule 40 steel pipes with water flow. Relative capacity between larger and smaller pipes. Data given in based on the nps tables given by ansi b36.10m and includes pipe wall thickness, outside diameter, nominal diameter. This chart is applicable for designing compressed air systems.. Web a mannings formula pipe flow calculator for square and circular pipes. This calculator is a helpful tool for everyone who needs to know the exact volume of water in a pipe. Web free online flow rate calculator which helps you calculate the flow rate of any pipe given its diameter and liquid/gas velocity or its height and width (for. Pressure less than 1 1/2 psig. We begin with some results that we shall use when making friction loss calculations for steady, fully developed, incompressible, newtonian flow through a straight circular pipe. Psi/100' = 11 velocity = 32,000 fpm. The diagram above and table below are for steel pipes schedule 40. This calculator is a helpful tool for everyone who. You only need to know the diameter of the pipe, the material it's made of, its length, and the drop in height. Web the following chart contains the maximum recommended flow rates at the given pressure for ansi schedule 40 pipe. Web the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and. Our guide provides handy tables of approximate water flow rates based on pipe size, helping you estimate capacity quickly and easily. Major and minor loss must be summarized for calculating the total head loss in the system. Web fluide design inc., 5764 monkland avenue, suite 311, montreal, quebec, canada h4a 1e9 tel: This chart is applicable for designing compressed air. The spreadsheet shown below uses s.i. You only need to know the diameter of the pipe, the material it's made of, its length, and the drop in height. The excel formulas then calculate water flow rates for the entered pipe sizes and lengths. Data given in based on the nps tables given by ansi b36.10m and includes pipe wall thickness,. We begin with some results that we shall use when making friction loss calculations for steady, fully developed, incompressible, newtonian flow through a straight circular pipe. Web this pipe volume calculator estimates the volume of a pipe as well as the mass of a liquid that flows through it. Pressure less than 1 1/2 psig. Web unfortunately, recommendations aren't that. Web this spreadsheet allows for entering the hazen williams coefficient for the proper pipe material, the pressure drop, and the pipe diameter (s) and length (s) of interest. This chart is applicable for designing compressed air systems. Data given in based on the nps tables given by ansi b36.10m and includes pipe wall thickness, outside diameter, nominal diameter. This calculator. Relative capacity between larger and smaller pipes. We begin with some results that we shall use when making friction loss calculations for steady, fully developed, incompressible, newtonian flow through a straight circular pipe. Web calculate fluid velocity and volume flow in pipes and tubes. A comparison of pipe diameters with different surface roughness coefficients is an important design consideration. Web. Web unfortunately, recommendations aren't that straightforward because you also need to account for water pressure, material friction and more. Gtls) today reported results for the second quarter ended june 30, 2024. The diagram above and table below are for steel pipes schedule 40. Web pipe to carry maximum predicted flow, at a given slope, without flooding. What is the pressure. Web pipe to carry maximum predicted flow, at a given slope, without flooding. Web fluide design inc., 5764 monkland avenue, suite 311, montreal, quebec, canada h4a 1e9 tel: Major and minor loss must be summarized for calculating the total head loss in the system. Web pipe diameter calculation for known flow rate and velocity, in closed round pipe, applicable for liquids and gases The spreadsheet shown below uses s.i. The diagrams below can be used for design of sewage and wastewater gravity conveying systems. Shankar subramanian department of chemical and biomolecular engineering clarkson university. Specific gravity of natural gas 0.6. Calculate flow rate from pressure. A comparison of pipe diameters with different surface roughness coefficients is an important design consideration. 6800 lbs per hour of steam flow in a 2 1 / 2 inch pipe at 100 psig pressure. Relative capacity between larger and smaller pipes. One mbh is equivalent to 1000 btu's per hour (0.29 kw = 0.29 kj/s) Solve for part full pipe flows, or size a pipe with a known design flow. Web this spreadsheet allows for entering the hazen williams coefficient for the proper pipe material, the pressure drop, and the pipe diameter (s) and length (s) of interest. Pressure less than 1 1/2 psig.

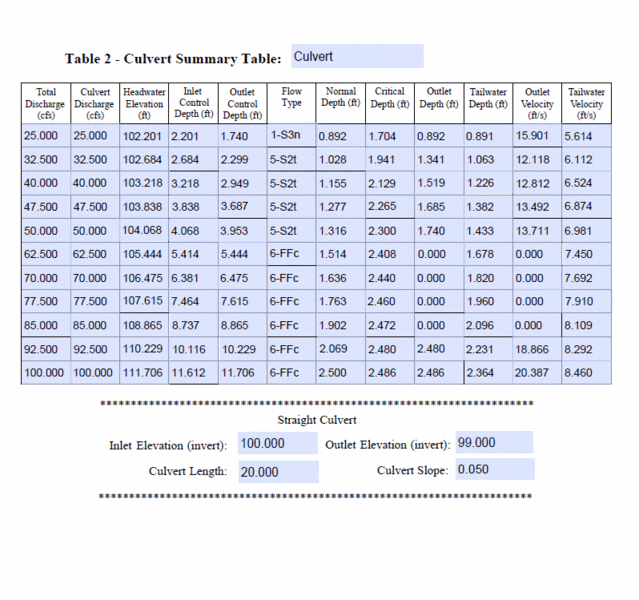

Culvert Pipe Flow Capacity Chart

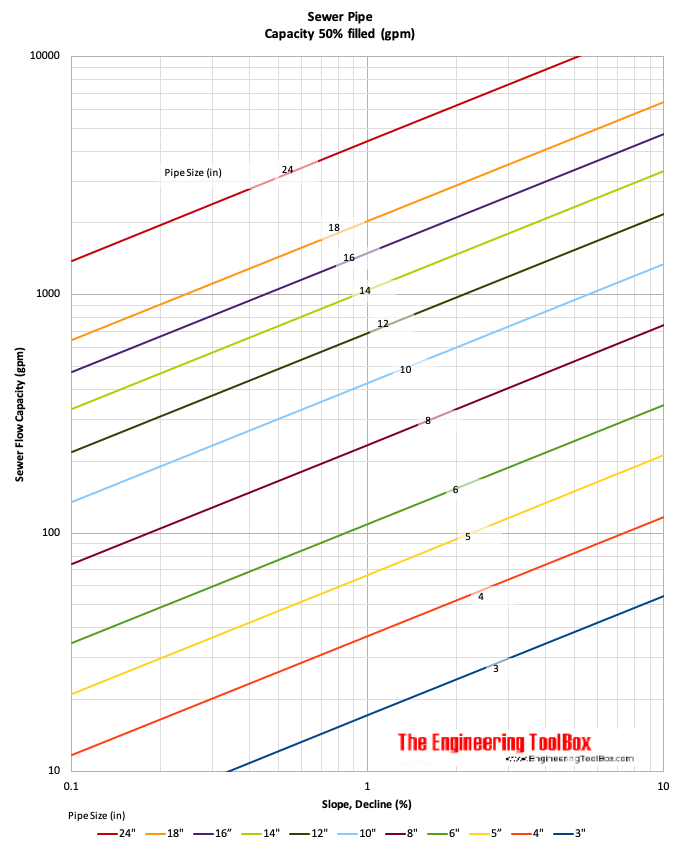

Sewer Pipes Capacities vs. Slope

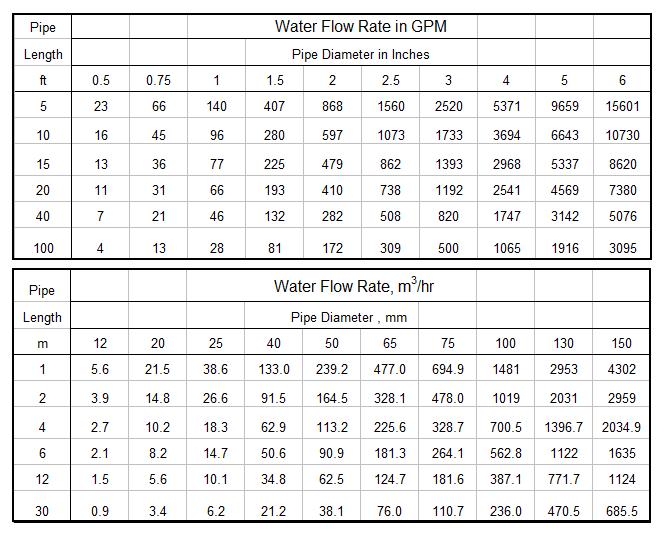

Water Flow Rate for Pipe Sizes with Excel Spreadsheets

Water flow pipe sizes

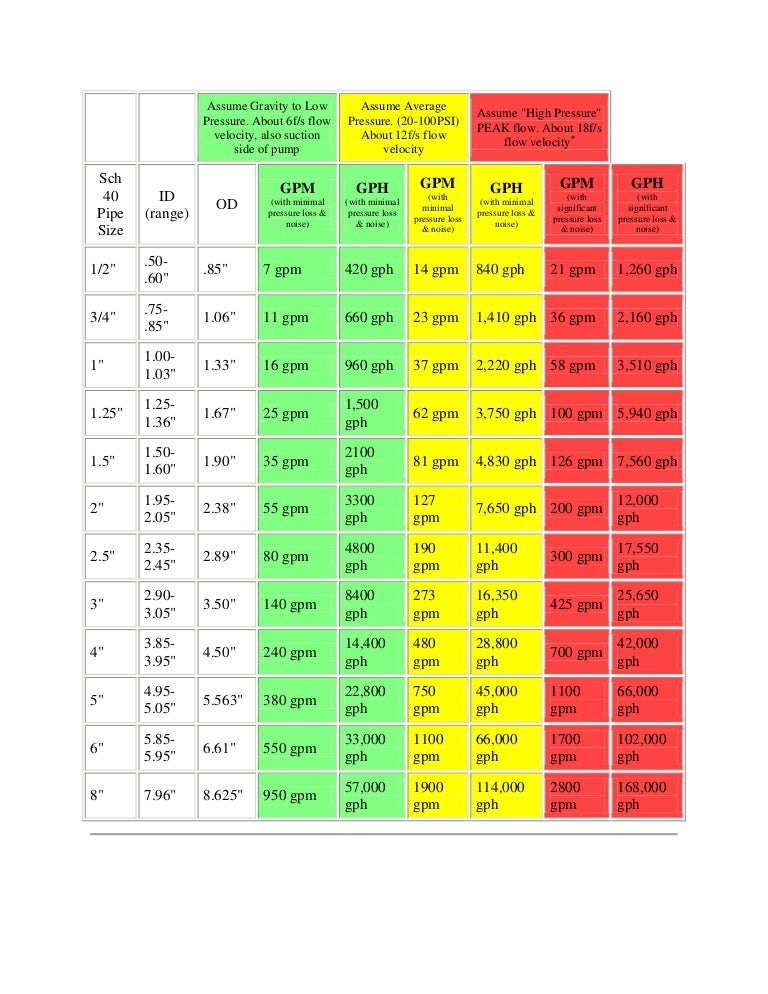

Water Pipe Diameter Flow Rate Chart

PVC Pipe Flow Chart

21 Best Pipe Flow Chart Gpm

Schedule 40 Pvc Pipe Flow Chart A Visual Reference of Charts Chart

PIPE CAPACITY CALCULATIONS STEP BY STEP & EXCELSHEET Drilling Manual

Culvert Pipe Flow Capacity Chart

Web Free Online Flow Rate Calculator Which Helps You Calculate The Flow Rate Of Any Pipe Given Its Diameter And Liquid/Gas Velocity Or Its Height And Width (For A Rectangular Pipe) And Velocity.

Gtls) Today Reported Results For The Second Quarter Ended June 30, 2024.

Volumetric Flow Rate Q = Π D.

Data Given In Based On The Nps Tables Given By Ansi B36.10M And Includes Pipe Wall Thickness, Outside Diameter, Nominal Diameter.

Related Post: