P Chart Example

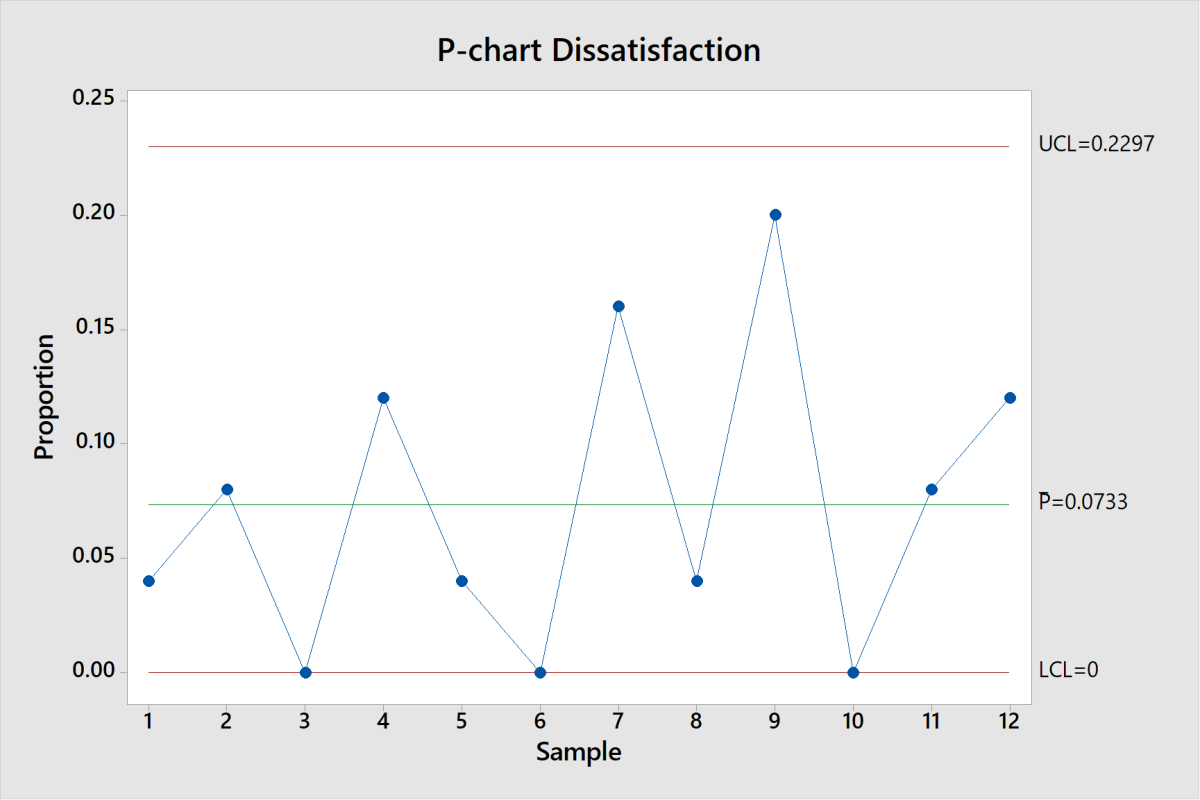

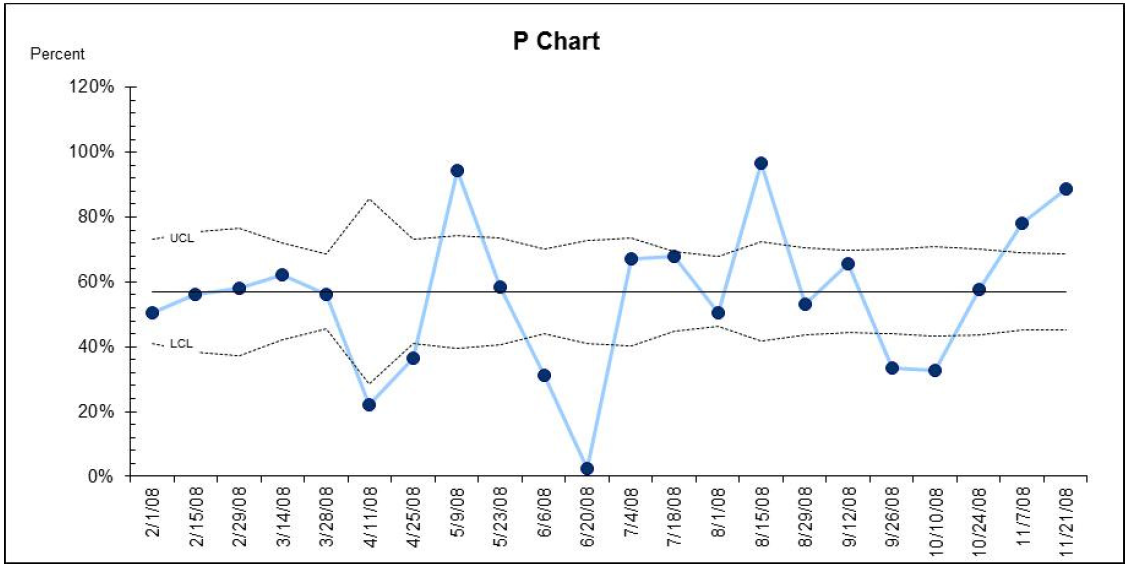

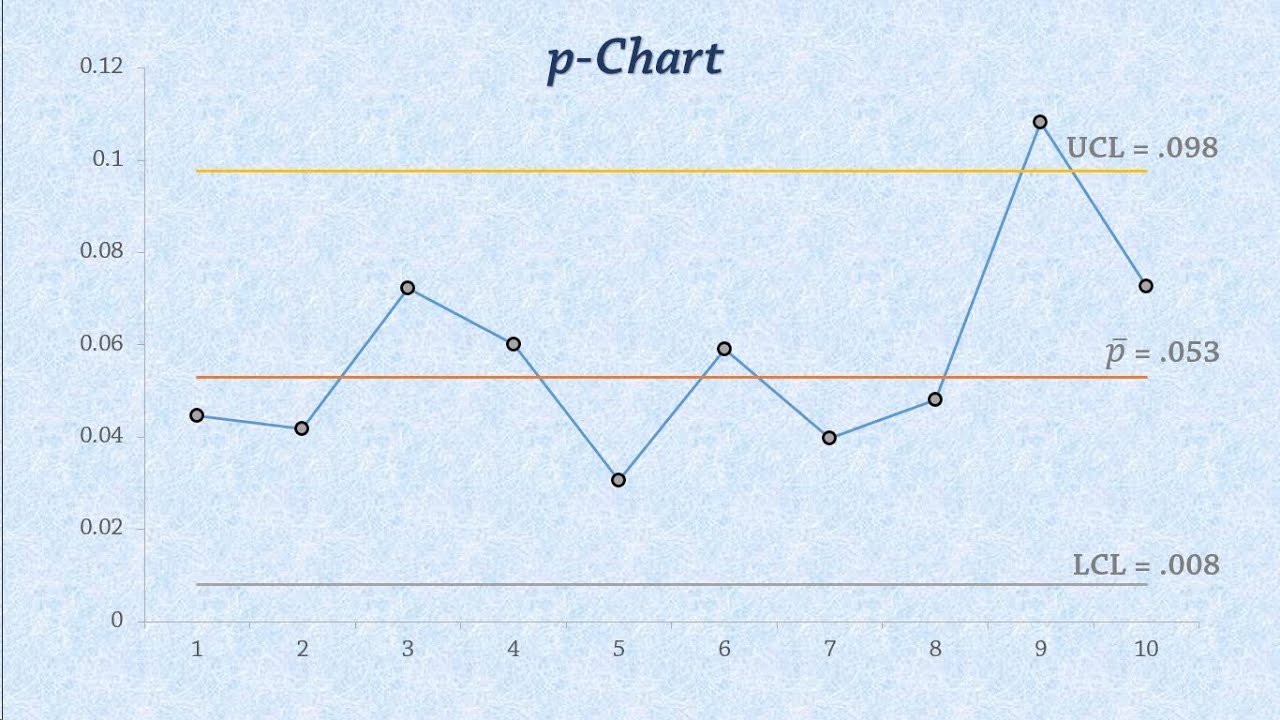

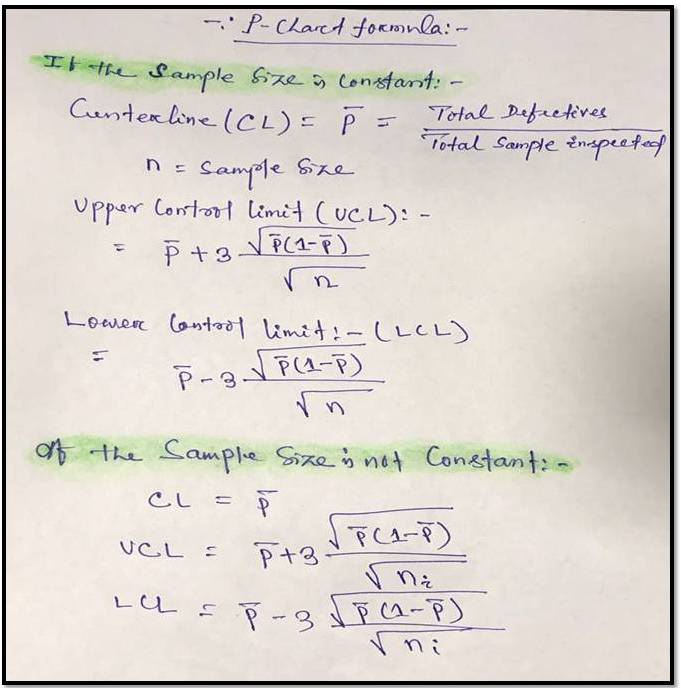

P Chart Example - The call center supervisor aims to assess the effectiveness of the customer call answering process. P charts can be used when the subgroups are not of equal size. The steps in how to construct a p control chart were introduced along with how to handle varying subgroup sizes. This guide shows you the steps involved in constructing a p chart. Compare systems before and after a major change. The supervisor for a call center wants to evaluate the process for answering customer phone calls. Equal and unequal sample sizes are discussed. Web control charts dealing with the proportion or fraction of defective product are called p charts (for proportion). Qi macros will do the math and draw the graph for you. The lines are located at: The steps in how to construct a p control chart were introduced along with how to handle varying subgroup sizes. Key output includes the p chart and test results. Web p chart is one of the quality control charts used to assess trends and patterns in counts of binary events (e.g., pass, fail) over time. Qi macros will do the. Web p chart is one of the quality control charts used to assess trends and patterns in counts of binary events (e.g., pass, fail) over time. Web control charts dealing with the proportion or fraction of defective product are called p charts (for proportion). Web complete the following steps to interpret a p chart. The lines are located at: First,. Key output includes the p chart and test results. The lines are located at: For 21 days, the supervisor tracks the total number of incoming calls and the count of unanswered calls. A numerical example will now be given to illustrate the above mentioned principles. Select p chart on qi macros menu. Web a p chart is a type of statistical control chart used to monitor the proportion of defective units in a process over time. The lines are located at: Web this month’s publication looked at p control charts. Create a p chart using qi macros. A p chart is established by the supervisor to monitor the proportion of unanswered calls. Add text, shapes, and lines to customize your flowchart. Key output includes the p chart and test results. The supervisor for a call center wants to evaluate the process for answering customer phone calls. Assess the need for stratification into subgroups, like location, employee, or time of day. The p chart is often referred to as a fraction defective chart. On each wafer 50 chips are measured and a defective is defined whenever a misregistration, in terms of horizontal and/or vertical distances from the center, is recorded. It is based on the binomial distribution where each unit has only two possibilities (i.e. Select p chart on qi macros menu. Show whether the system is stable (i.e. The supervisor records the. P control charts are used to monitor the variation in the fraction of defective items in a group of items. The location of chips on a wafer is measured on 30 wafers. Qi macros can calculate them for you! It is particularly useful when dealing with binary outcomes (e.g., pass/fail, defect/no defect) in a sample of varying sizes. A p. This guide shows you the steps involved in constructing a p chart. Web the crime records division (crd) acts as the texas state control terminal for eight state and national criminal justice programs and is responsible for the administration of these programs, providing critical operational data to law enforcement and criminal justice agencies in texas and nationwide. Web complete the. Web the crime records division (crd) acts as the texas state control terminal for eight state and national criminal justice programs and is responsible for the administration of these programs, providing critical operational data to law enforcement and criminal justice agencies in texas and nationwide. Average number of nonconformities per unit. The p chart is used to evaluate process stability. The p chart is often referred to as a fraction defective chart. Compare systems before and after a major change. Qi macros will do the math and draw the graph for you. Web a p chart is a type of statistical control chart used to monitor the proportion of defective units in a process over time. Web complete the following. The p chart is often referred to as a fraction defective chart. We first define the term attributes as used in quality control terminology. Web example of p chart? Add text, shapes, and lines to customize your flowchart. P charts can be used when the subgroups are not of equal size. The supervisor records the total number of incoming calls and the number of unanswered calls for 21 days. Web a p chart is a type of statistical control chart used to monitor the proportion of defective units in a process over time. Average number of nonconformities per unit. Equal and unequal sample sizes are discussed. Qi macros will do the math and draw the graph for you. Web the p chart is one of four attribute control charts used to evaluate the stability of a process over time using counted data. For a sample subgroup, the number of defective parts is counted and plotted as either a percentage of the total subgroup sample size, or a fraction of the total. There is a difference between a defect and defective, as there is between a nonconformity and nonconforming unit. Detect sudden changes in systems, which can be attributed to a cause. It helps track glitches down by monitoring the ratio of stuff with defects batch by batch across time. P charts are used when the subgroups are not equal in size and compute control limits based on the binomial distribution.

Example Of P Chart Calculation chartcentral

P Chart

PCharts for Statistical Process Control MITE MMC Institute for

How to Create a PChart in Minitab 18 ToughNickel

Example P chart Quality Improvement East London NHS Foundation Trust

Statistical Process Control Control Charts for Proportions (pchart

P Chart Excel Template Formula Example Control Chart Cal.

P chart example PresentationEZE

Control Limits for p chart, traditional approach Smarter Solutions, Inc.

P Chart Calculations P Chart Formula Quality America

Compare Systems Before And After A Major Change.

Key Output Includes The P Chart And Test Results.

Qi Macros Can Calculate Them For You!

For 21 Days, The Supervisor Tracks The Total Number Of Incoming Calls And The Count Of Unanswered Calls.

Related Post: