Chip Load Chart

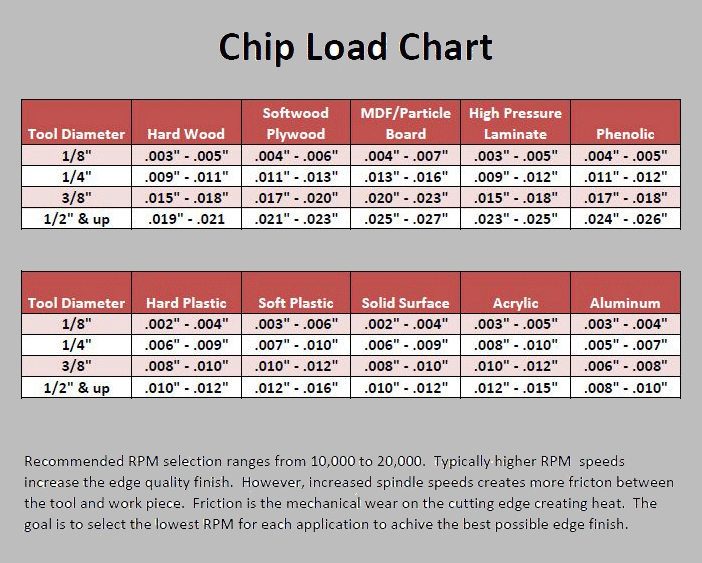

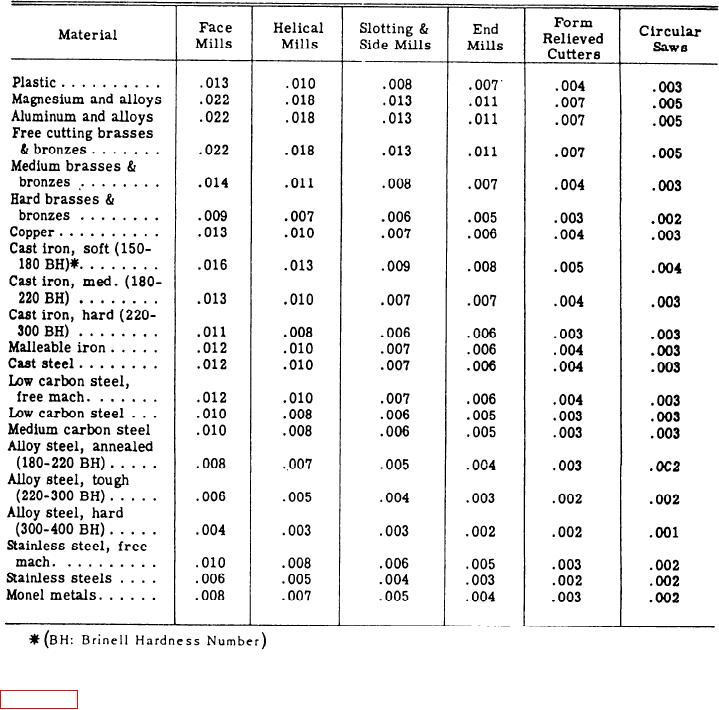

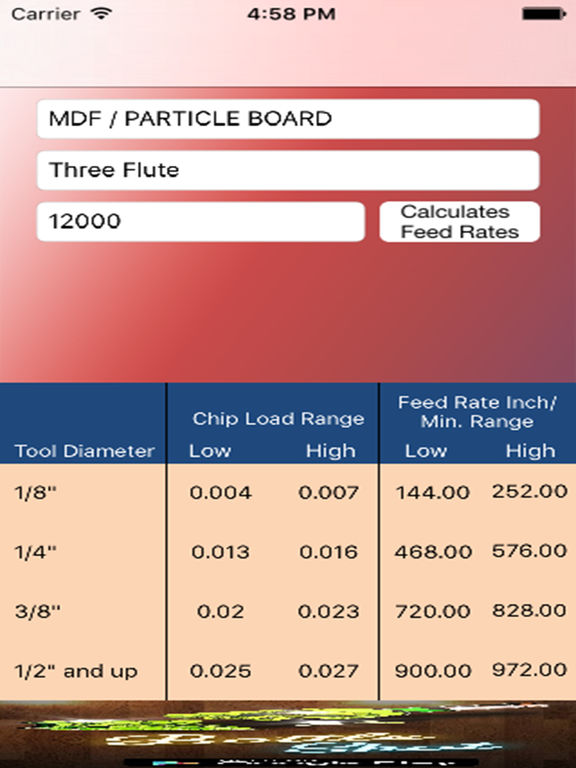

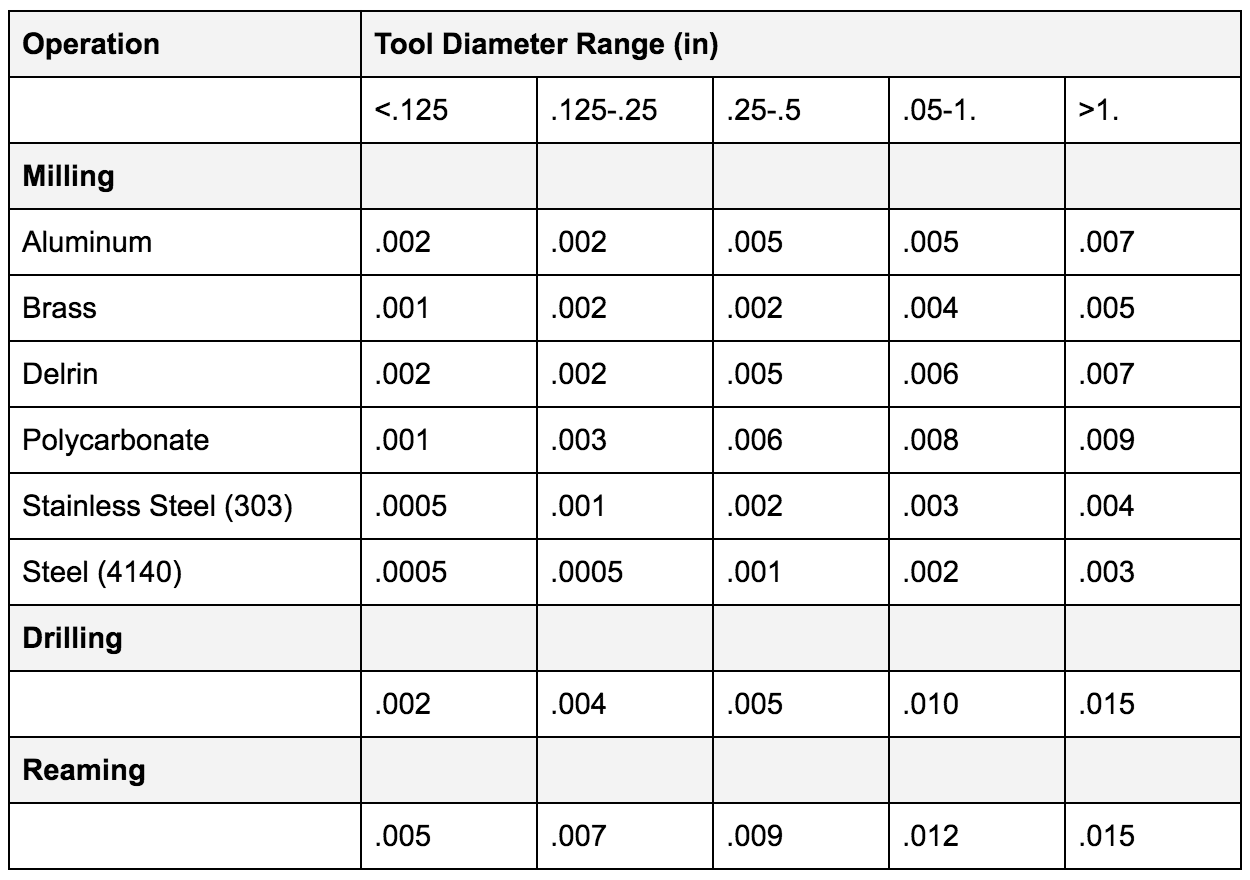

Chip Load Chart - Web the proper size chip removes heat from the tooling surface, extending the tool life and quality of cut. The chip load per tooth can be calculated using the formula: Chip load = feed rate (inches per minute) / (rpm x number of. Use the calculator to determine approximate settings. Web chip load is defined as the thickness of the chips removed during a machining operation. Web the chip load calculator is used to determine the chip load per tooth (cpt) during milling operations. Learn how to use the chart, calculate chip load,. Proper chip sizes also are important to prevent tool breakage and injury. Compare the recommended values for different tool diameters and. Web this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. \ [ \text {chip load} = \frac {\text {feed rate}} {\text {rpm} \times \text {number. Chip load = feed rate / (rpm x number of teeth) printer friendly. Web the chip load calculator is used to determine the chip load per tooth (cpt) during milling operations. Web peak toolworks chip load calculator makes it easy to determine feed speed, knife. Web the optimal chip load is between.007 and.012 and is highlighted in green below. Importance of proper chip load. Effects of excessive chip load. Web chip load is defined as the thickness of the chips removed during a machining operation. Enter tool diameter, number of flutes, surface speed and chip load to get. Web here's some useful data on machine settings to achieve the desired chipload for good performance of moulders and jointers with various types of wood and sheet goods. Find sfm, ipm, rpm, and more here. Are you using a harvey tool? The chip load per tooth can be calculated using the formula: Find recommended chip load values for different cutter. Web the proper speed and feed help improve tool life and remove material at the optimal rate. These recommendations do not apply to thicker material or techno cnc tools with long. Importance of proper chip load. \ [ \text {chip load} = \frac {\text {feed rate}} {\text {rpm} \times \text {number. It is a part of how tools perform in. Chip load = feed rate / (rpm x number of teeth) printer friendly. Web here's some useful data on machine settings to achieve the desired chipload for good performance of moulders and jointers with various types of wood and sheet goods. Web what is a chip load chart and how do i use it? Use the calculator to determine approximate. Chip load = feed rate / (rpm x number of teeth) printer friendly. Web find the optimal feed rate and rpm for your cnc cutting tool and material combination using this chip load chart. Web a chip load chart is used for determining proper feed rates when cutting various materials and using various tools. Importance of proper chip load. Web. Effects of excessive chip load. Chip load = feed rate / (rpm x number of teeth) printer friendly. Web the chip load calculator is used to determine the chip load per tooth (cpt) during milling operations. Proper chip sizes also are important to prevent tool breakage and injury. Effects of inadequate chip load. \ [ \text {chip load} = \frac {\text {feed rate}} {\text {rpm} \times \text {number. Web the optimal chip load is between.007 and.012 and is highlighted in green below. Learn how to use the chart, calculate chip load,. Chip load is the thickness of the material being removed each time the cutting edge of the tool passes through the. Web. Compare the recommended values for different tool diameters and. If there is too little of a chip load you risk burning out the tool, too high of a chip load and you risk. Web the chip load calculator is used to determine the chip load per tooth (cpt) during milling operations. The chip load per tooth can be calculated using. Web peak toolworks chip load calculator makes it easy to determine feed speed, knife marks per inch and chip load per tooth. Web what is a chip load chart and how do i use it? Effects of excessive chip load. Web chip load is defined as the thickness of the chips removed during a machining operation. Web this handy cnc. Web the proper size chip removes heat from the tooling surface, extending the tool life and quality of cut. Learn how to use the chart, calculate chip load,. If there is too little of a chip load you risk burning out the tool, too high of a chip load and you risk. Web the chip thinning factor (ctf) enables you to calculate the feed per tooth that will yield the desired chip load. Chip load is the thickness of the material being removed each time the cutting edge of the tool passes through the. Web this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Web chip loads are based on material thickness of average size for cutting edge length of tool. Chip load = feed rate / (rpm x number of teeth) printer friendly. Importance of proper chip load. Are you using a harvey tool? Web the proper speed and feed help improve tool life and remove material at the optimal rate. Web using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Web what is a chip load chart and how do i use it? These recommendations do not apply to thicker material or techno cnc tools with long. Chip load = feed rate (inches per minute) / (rpm x number of. Find recommended chip load values for different cutter diameters and workpiece materials with our calculator or charts.

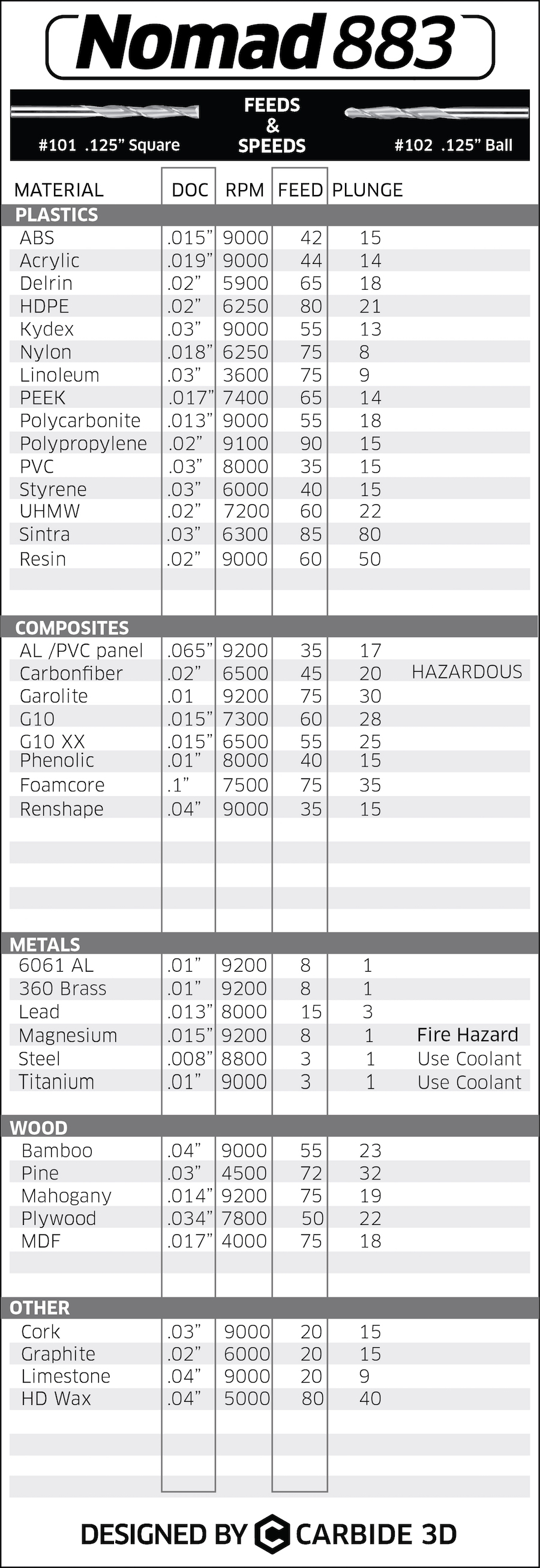

Origin/consistency of chipload Shapeoko Carbide 3D

Hall Manufacturing Solutions

Table Chip Loads

App Shopper CNC Chip Load Calculator (Utilities)

Chip Load Chart For Machinists

Feeds & Speeds Explained MEKANIKA

Metal Machining How To Improve Finish through Speeds & Feeds

The chip load on that chart per teeth, so if as three flutes, you times

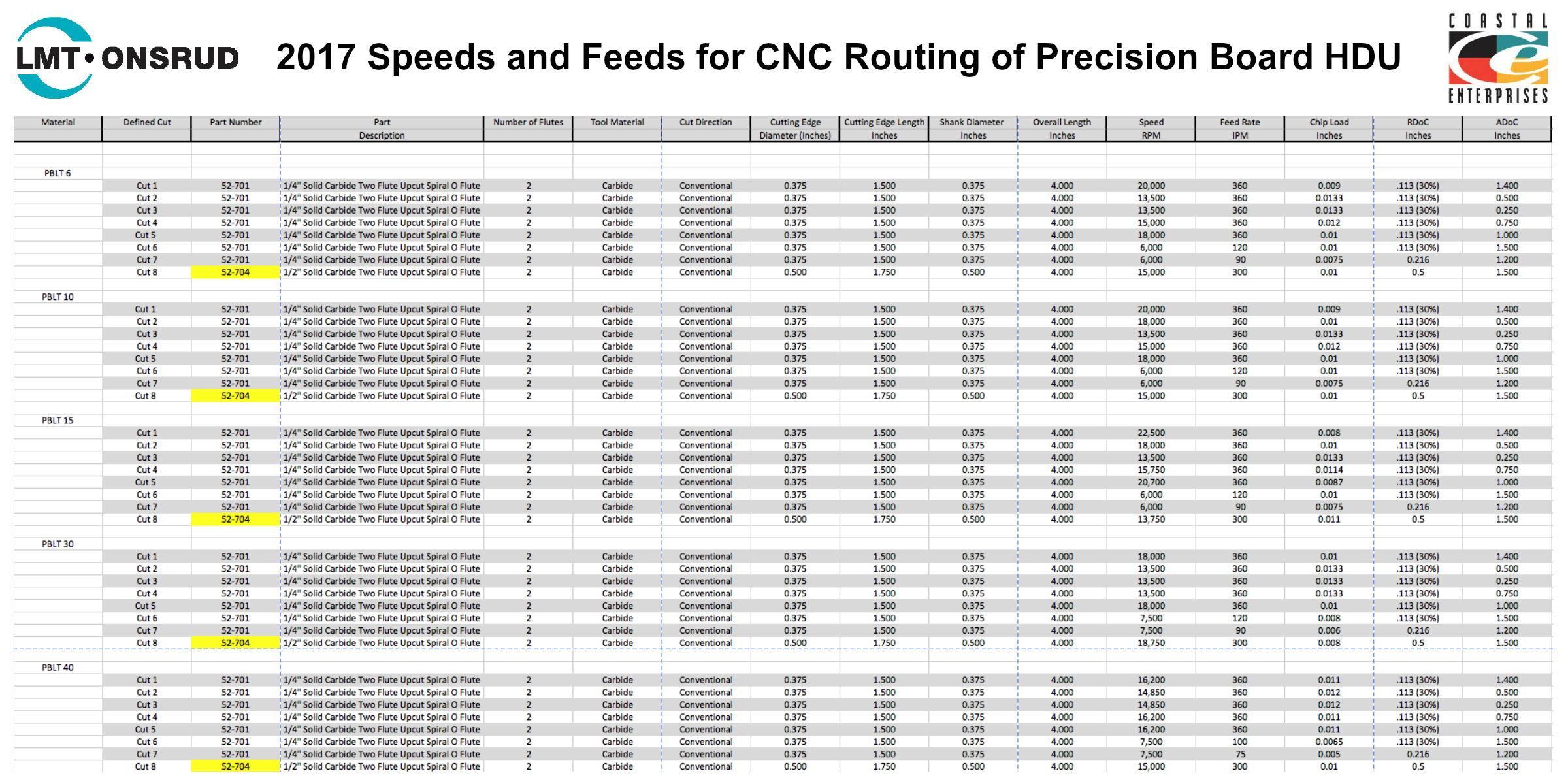

Updated Speeds and Feeds for Precision Board HDU Coastal Enterprises

Fusion Blog

Web Find The Optimal Feed Rate And Rpm For Your Cnc Cutting Tool And Material Combination Using This Chip Load Chart.

Effects Of Inadequate Chip Load.

Learn What Chip Load Is, How To Calculate It, And How To Use It For Milling.

Enter Tool Diameter, Number Of Flutes, Surface Speed And Chip Load To Get.

Related Post: