Oxy Acetylene Torch Pressure Chart

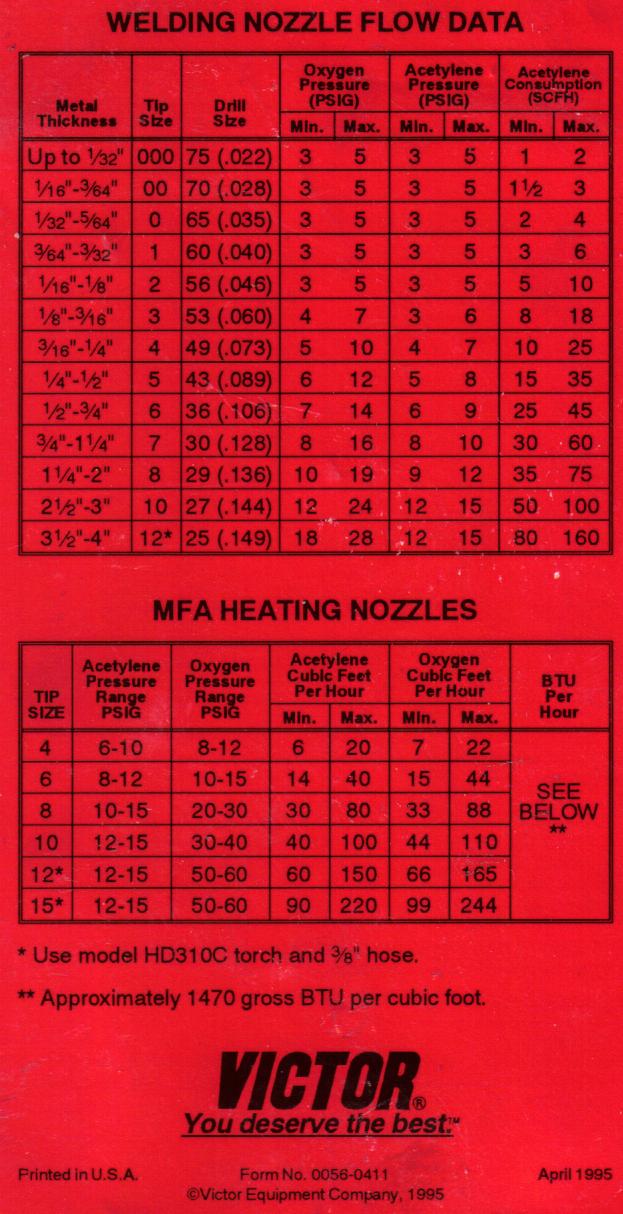

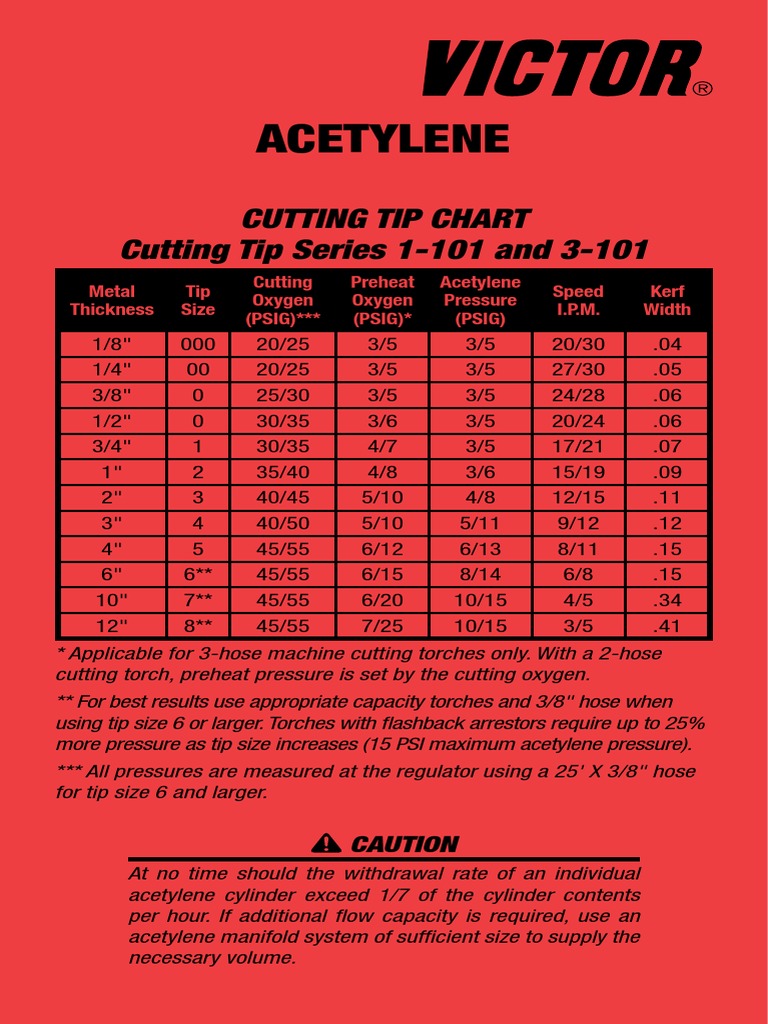

Oxy Acetylene Torch Pressure Chart - Hose for size 4 and larger. This is especially important for oxygen cylinder connections. Shop our huge selectionfast shippingdeals of the dayshop best sellers ** to provide required flow, use 3/8 i.d. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Web an oxy acetylene mixture burns the hottest, somewhere around 5800 degrees, and that's what this article will be about: Web orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. There are a number of different types of oxy. It's been so long since i've used our rosebud tip i've forgotten what oxygen and acetylene pressure. The purpose of this page is to introduce the beginning welder to the. It's been so long since i've used our rosebud tip i've forgotten what oxygen and acetylene pressure. It turns out that there’s more than one right answer. It combines oxygen and acetylene gases to form a superheated flame that melts. Web harris cutting tip charts. Web torches equipped with a flame backflow preventer (“flashback arrestor”) may require a pressure up to 25% higher than indicated in the chart. The purpose of this page is to introduce the beginning welder to the. · make sure torch valves are closed! Hose for size 4 and larger. Increase regulator pressures if longer hose or smaller i.d. Web to set up an oxy acetylene torch, start by cleaning any dust or dirt from the valve outlet. Make use of correct welding & cutting technique. This will allow acetylene to flow into the torch. Inspect cylinder valves for damage and the presence of oils or grease. Hose for size 4 and larger. ** to provide required flow, use 3/8 i.d. This will allow acetylene to flow into the torch. This is determined by the brand. Make use of correct welding & cutting technique. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Web torches equipped with a flame backflow preventer (“flashback arrestor”) may require a pressure up to 25% higher than indicated in the chart. · make sure torch valves are closed! It's been so long since i've used our rosebud tip i've forgotten what oxygen and acetylene pressure. The third open valve in. Make use of correct welding & cutting technique. · make sure regulator pressure adjustment screws are backed out! You must know the manufacturer or model of your torch and/or the part number of the cutting tips you want to replace as this. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Tip size numbers vary among manufacturers, so. You must know the manufacturer or model of your torch and/or the part number of the cutting tips you want to replace as this. Web an oxy acetylene mixture burns the hottest, somewhere around 5800 degrees, and that's what this article will be about: Web follow these steps: · make sure torch valves are closed! Depending on which torch rig. Inspect cylinder valves for damage and the presence of oils or grease. Web regulator pressures are for 50 ft (13 m) or less of 3/8 in. Adjust to the correct flame setting. Ensure never to exceed 15 psi. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Web follow these steps: Depending on which torch rig you use, the. Web torches equipped with a flame backflow preventer (“flashback arrestor”) may require a pressure up to 25% higher than indicated in the chart. The third open valve in. This will allow acetylene to flow into the torch. Web orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. It turns out that there’s more than one right answer. Web open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Hose for size 4 and larger. Make. Tip size numbers vary among manufacturers, so orifice sizes are. Open the acetylene valve on the torch handle about 1/8 to 1/4 turn. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Web how gas welding is done? It's been so long since i've used our rosebud tip i've forgotten what oxygen and acetylene pressure. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. This will allow acetylene to flow into the torch. Depending on which torch rig you use, the. Shop our huge selectionfast shippingdeals of the dayshop best sellers · make sure regulator pressure adjustment screws are backed out! Web harris cutting tip charts. · make sure torch valves are closed! Web follow these steps: Web to set up an oxy acetylene torch, start by cleaning any dust or dirt from the valve outlet. Web orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. It utilizes a mixture of oxygen.Oxy Acetylene Cutting Pressure Chart

Oxyacetylene Torch Settings Chart

Oxy Acetylene Cutting Torch Settings Chart A Visual Reference of

Oxyacetylene Cutting Pressure Chart

Oxyacetylene Cutting Pressure Chart

Oxyacetylene Cutting Pressure Chart

Oxy Acetylene Cutting Pressure Chart Printable Templates Free

Oxy Acetylene Victor Welding Tip Chart

Oxyacetylene Torch Settings Chart

Oxy Acetylene Cutting Pressure Chart vrogue.co

Web Torches Equipped With A Flame Backflow Preventer (“Flashback Arrestor”) May Require A Pressure Up To 25% Higher Than Indicated In The Chart.

It Combines Oxygen And Acetylene Gases To Form A Superheated Flame That Melts.

Web Open Regulator Oxygen And Acetylene, Set Until The Pressure Matches With What You Want Or For Acetylene 5 To 7 Psi And Oxygen 7 To 10 Psi.

Web An Oxy Acetylene Mixture Burns The Hottest, Somewhere Around 5800 Degrees, And That's What This Article Will Be About:

Related Post: