Mig Weld Settings Chart

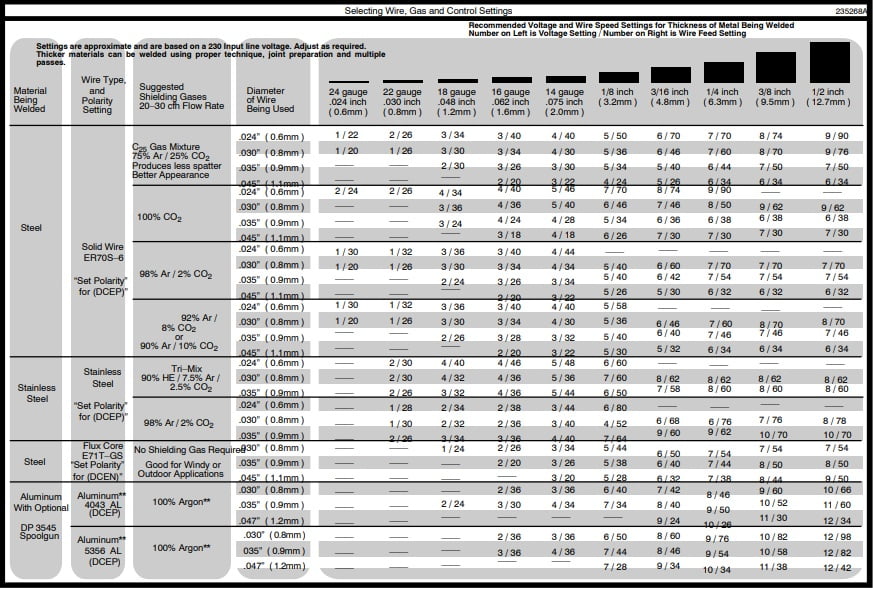

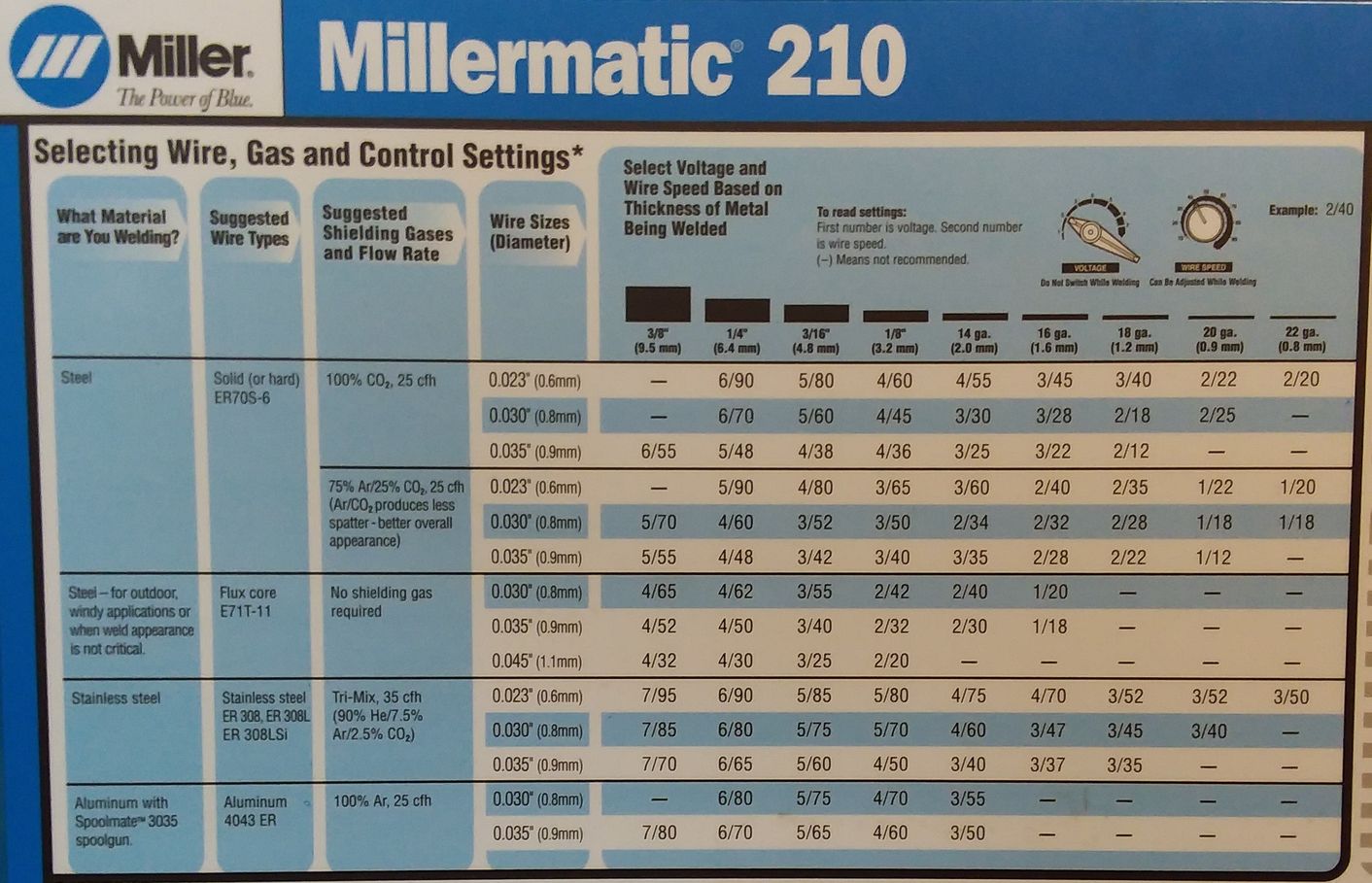

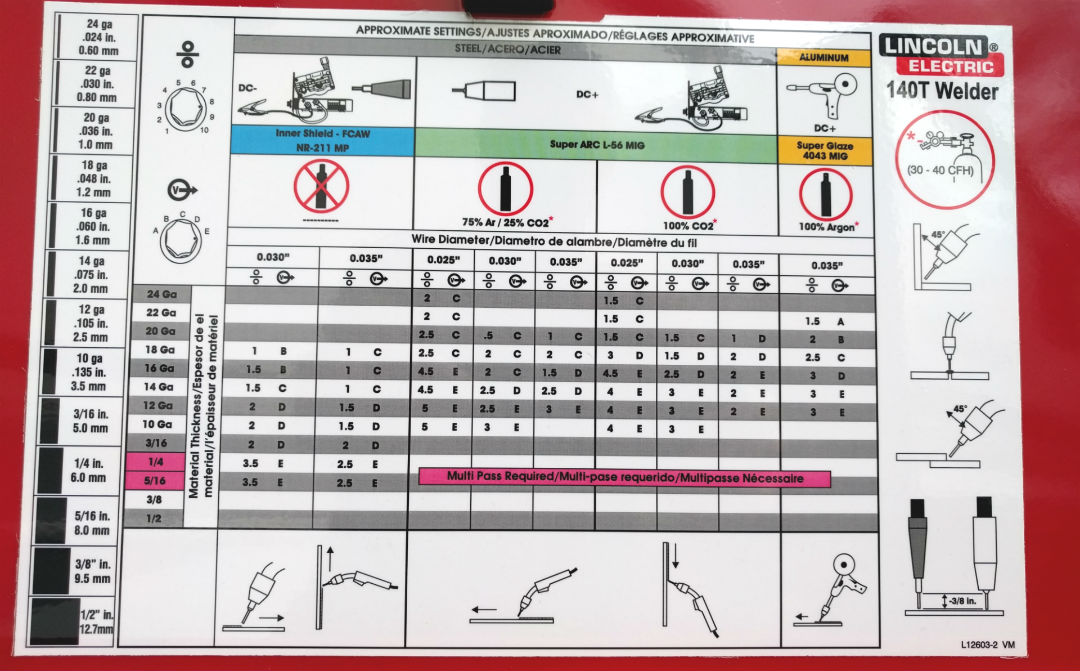

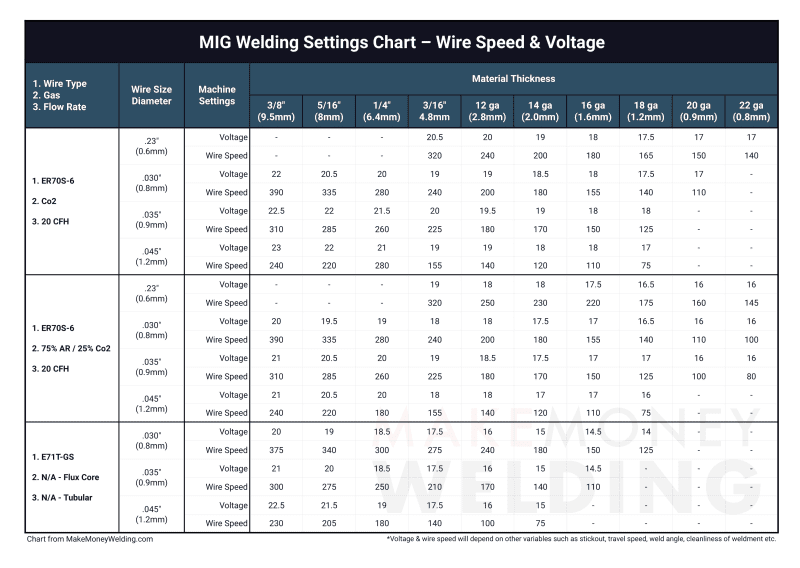

Mig Weld Settings Chart - Web here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web most people buy the mig welder machine, but they need to learn the correct and the proper settings and the suitable parameters for the new mig welder. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. Quick pointers to refine your skills and results. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. How thick is the metal you want to weld? Stainless steel mig welding settings chart. However, not all welders use the same settings, so you should read your welder’s manual. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. View full size chart here. You can get this information welding. Use these tips to get the best mig welds. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon. You can get this information welding. View full size chart here. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. How thick is the metal you want to weld? But before using these values, we suggest that you have a decent understanding of your preferred metal. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that melts and deposits the workpiece metal in the weld joint. View full size chart here. But before using these values, we suggest that you have a decent understanding. The most common metals welded with the mig process include mild steel, stainless steel, and aluminum. Quick pointers to refine your skills and results. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination,. Although this welding method might not be for stylish pieces, it saves time and money. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. Two separate knobs control these on most mig welders. If you have a project that involves metals you might have to use mig. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web most people buy the mig welder machine, but they need to learn the correct and the proper settings and the suitable parameters for the new mig welder. View full size chart here. This section will examine. Web most people buy the mig welder machine, but they need to learn the correct and the proper settings and the suitable parameters for the new mig welder. Web using the correct mig welding settings can make or break the quality of your finished product. View full size chart here. Choosing the right wire, shielding gas & gun. That is. Web most people buy the mig welder machine, but they need to learn the correct and the proper settings and the suitable parameters for the new mig welder. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Two separate knobs control these on most mig welders. But before using these values, we. Also, consider the amperage settings and the task at hand. This section will examine the voltage and wire speed and shielding gas flow. Web mig welding settings: That is why we are here to provide the right concept about the mig welder settings with a chart to make your weld solid and accurate. The ultimate mig welding guide. Web miller mig welding settings charts. Web the two main settings on a mig welder are wire speed and voltage. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. That is why we are here to provide the right concept about the mig welder settings with a chart to make your weld. What material are you welding? The ultimate mig welding guide. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that melts and deposits the workpiece metal in the weld joint. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Web most people buy the mig welder machine, but they need to learn the correct and the proper settings and the suitable parameters for the new mig welder. Quick pointers to refine your skills and results. Web mig welding settings: Web using the correct mig welding settings can make or break the quality of your finished product. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. After you have determined the thickness and type of material, selected a proper shielding gas and electrode, and cleaned the surface, it is time to set up your machine. Are you welding indoors or outdoors? Web how big is the job? Web miller mig welding settings charts. There are many mig setting charts available from manufacturers that all vary. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld.

How To MIG Weld Aluminum Beginners Guide (with Chart)

Mig Welding Settings Chart

Mig Welding Settings Chart

aluminum mig welding settings chart

MIG Welder Settings Explained (with Chart) Weld Guru, 42 OFF

MIG Welder Settings Explained (with Chart) Weld Guru

Mig Welding Setting Chart

Best Welder for Beginners? 19 Smart Reasons for MIG • WelditU

Important MIG Welder Settings You Need to Know (with Chart)

MIG Welding Gas Pressure Settings (with Charts)

If You Have A Project That Involves Metals You Might Have To Use Mig Welding.

Also, Consider The Amperage Settings And The Task At Hand.

There Might Be Variations With The Settings Depending On The Manufacturer.

Web The Two Main Settings On A Mig Welder Are Wire Speed And Voltage.

Related Post: