Dust Collector Cfm Chart

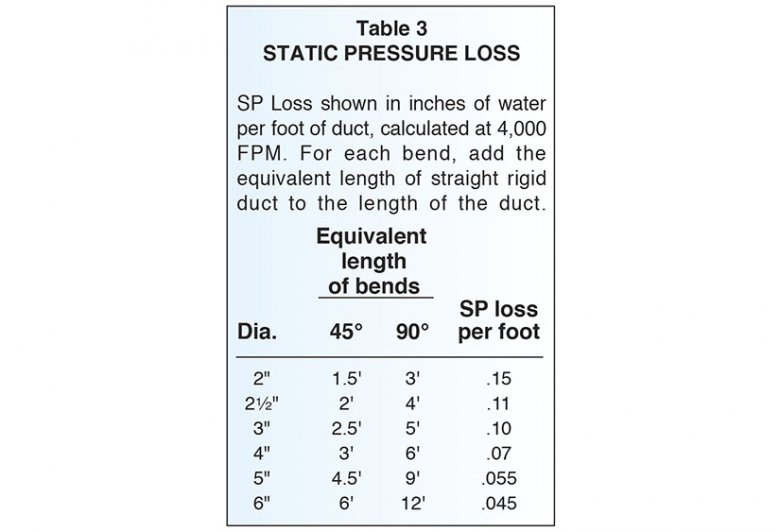

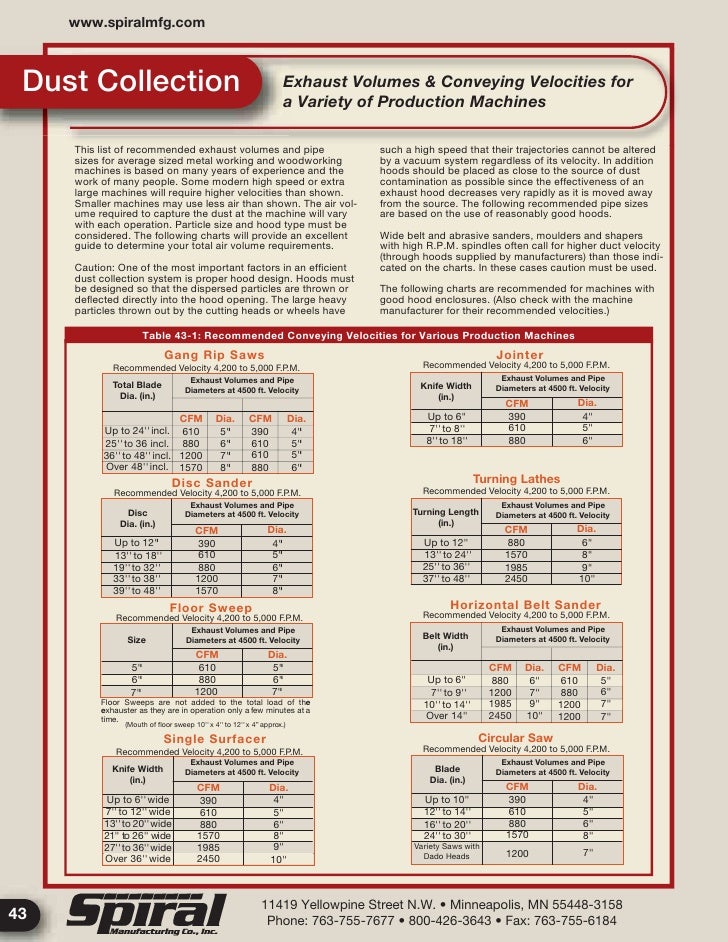

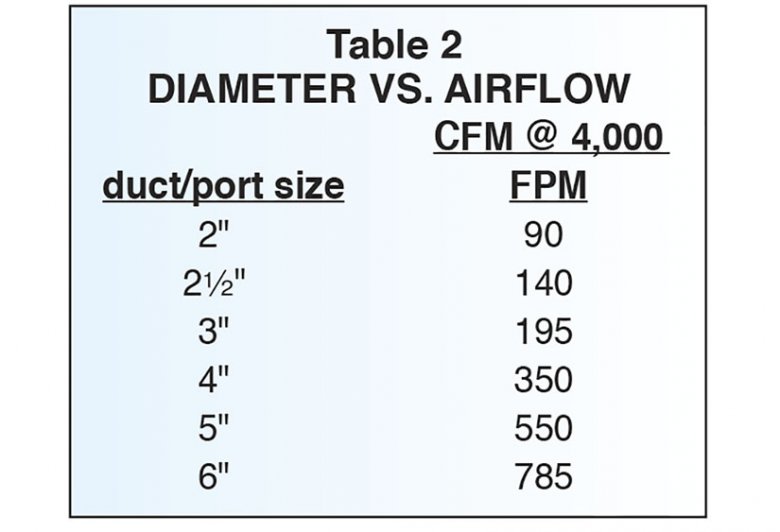

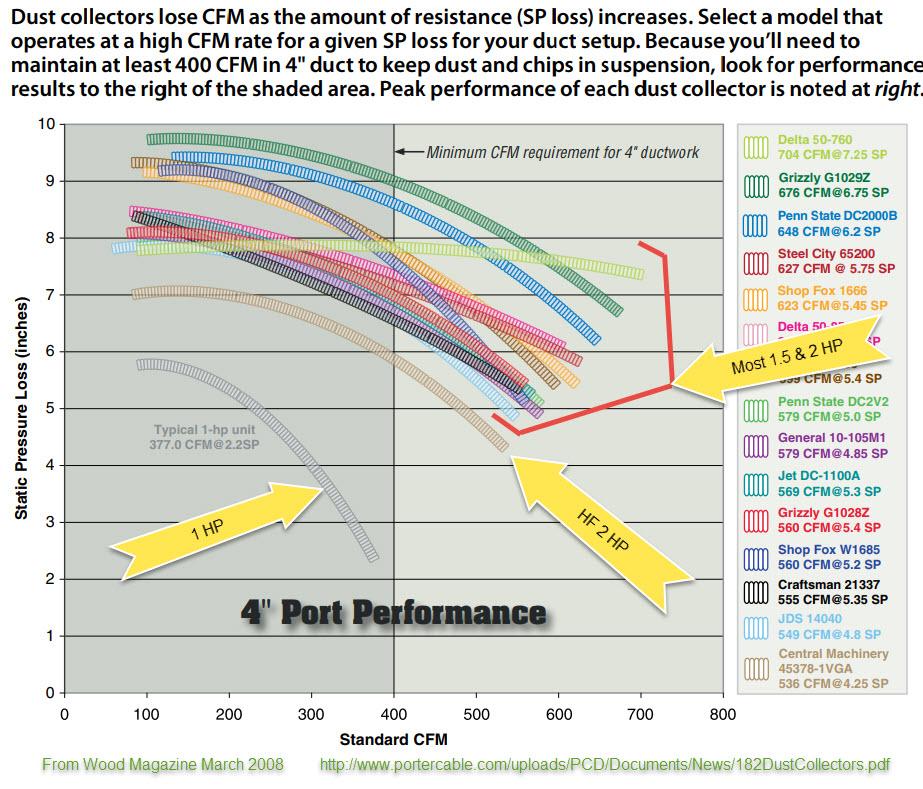

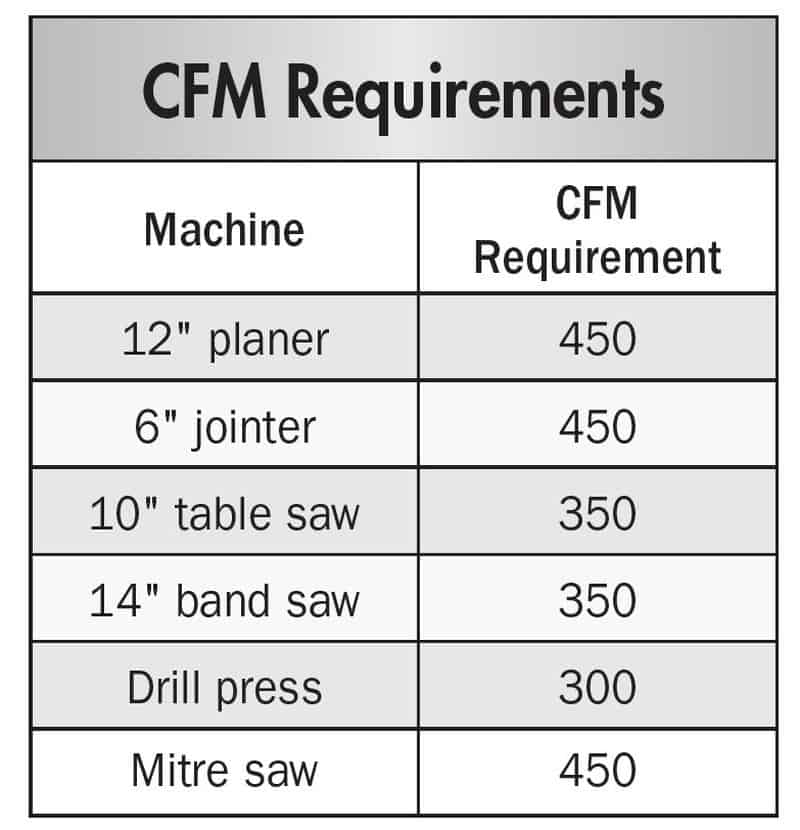

Dust Collector Cfm Chart - Use the cfm and static pressure to compare the performance of your dust collector. Web to properly size a dust collector, we need to know your cfm requirements and at what static pressure your system will be operating. The horsepower (hp) of the motor, and the cubic feet per minute (cfm) of airflow the unit is capable of generating. Web the typical method for determining what size dust collector to purchase involves finding the static pressure (sp) of your ductwork, the airflow in cubic feet per minute (cfm) required to move dust from your tools, and plotting those two numbers on the fan curve for a given dust collector. Web our approach to calculating dust collection cfm, including the top questions to ask an engineering firm to identify the right solution. Then there are those calculations required to determine the proper dust collector, duct sizes, and system layout. For systems carrying woodshop dust and chips, engineers recommend minimum air velocity of 4,000 fpm in branch lines (that's about a 45 mph breeze) and 3,500 fpm in the main duct. Read on to learn how to account for tool size, length of runs, blast gates, and more. This is a measure of airflow, or how much air the dust collector is able to move each minute. System resistance (sp) duct velocity use the chart. Read on to learn how to account for tool size, length of runs, blast gates, and more. Input cfm input velocity (fpm) ideal round duct diameter duct friction in straight duct. Web ducting calculators and air volume converter. A high cfm rating is definitely a plus, according to branum. Web many dust collection systems suffer due to poor ductwork designs. It’s this cfm value that determines how efficient a dust collection system is, and understanding its intricacies is vital. Web to help you decide which woodworking dust collectors would be the best fit for your workshop, laguna tools has included detailed performance and technical data about each machine in our online catalog. Your cfm requirements are determined by the size. System resistance (sp) duct velocity use the chart. The horsepower (hp) of the motor, and the cubic feet per minute (cfm) of airflow the unit is capable of generating. Please contact us with your requirements. Web chart below to estimate the cfm requirements (example: Web to help you decide which woodworking dust collectors would be the best fit for your. Your cfm requirements are determined by the size of the enclosure that it must clean and the volume of dust you produce. Web to properly size a dust collector, we need to know your cfm requirements and at what static pressure your system will be operating. Web in addition to the size of the collector, you'll find two important ratings:. Input cfm input velocity (fpm) ideal round duct diameter duct friction in straight duct. Web unfortunately, setting up a system can seem perplexing, what with complicated terms, such as fan curve, static pressure, cubic feet per minute (cfm), and airflow velocity. This is a measure of airflow, or how much air the dust collector is able to move each minute.. The higher the airflow, the greater the capability of the collector. If a machine has multiple dust ports, the total cfm for the machine is the sum of all of the ports. Your cfm requirements are determined by the size of the enclosure that it must clean and the volume of dust you produce. The horsepower (hp) of the motor,. Web the typical method for determining what size dust collector to purchase involves finding the static pressure (sp) of your ductwork, the airflow in cubic feet per minute (cfm) required to move dust from your tools, and plotting those two numbers on the fan curve for a given dust collector. Use the cfm and static pressure to compare the performance. Web a dust collector cfm calculator is a specialized computational tool that determines the volume of air (in cubic feet per minute or cfm) required to efficiently remove dust particles using a dust collector system. Web a dust collector pulls air through hose or duct at an airflow volume measured in cubic feet per minute (cfm). Web the airflow rate. If a machine has multiple dust ports, the total cfm for the machine is the sum of all of the ports. That means the dust collector would have to deliver 1,335 cfm after it overcomes the resistance level. Read on to learn how to account for tool size, length of runs, blast gates, and more. For systems carrying woodshop dust. Web a dust collector pulls air through hose or duct at an airflow volume measured in cubic feet per minute (cfm). These rates will vary, depending on the size of the machine, with larger units providing greater airflow capacities. You need 1,335 cfm at 8 resistance (also known as static pressure, measured in inches of water gauge). Web unfortunately, setting. Web once you know the cfm and resistance, you can purchase the proper collector. That means the dust collector would have to deliver 1,335 cfm after it overcomes the resistance level. Input cfm input velocity (fpm) ideal round duct diameter duct friction in straight duct. Web it is best to do the following calculations before you purchase your dust collector or the necessary ductwork. Check your instrument manuals for accurate measurements. The more cfm a collector can generate, the farther it pulls dusty air. Duct velocity (fpm) proper size of duct; Web in addition to the size of the collector, you'll find two important ratings: Measure air flow for each tool. Web a dust collector cfm calculator is a specialized computational tool that determines the volume of air (in cubic feet per minute or cfm) required to efficiently remove dust particles using a dust collector system. If a machine has multiple dust ports, the total cfm for the machine is the sum of all of the ports. Web the airflow rate of the dust collector, measured in cubic feet per minute (cfm), is a good gauge of its efficiency. Web the typical method for determining what size dust collector to purchase involves finding the static pressure (sp) of your ductwork, the airflow in cubic feet per minute (cfm) required to move dust from your tools, and plotting those two numbers on the fan curve for a given dust collector. Remote and led drum light are standard. In the world of industrial dust collection, cfm, or cubic feet per minute, stands as the cornerstone. Use the cfm and static pressure to compare the performance of your dust collector.

CFM to Duct size chart Woodworking shop projects, Wood shop, Dust

Dust Collection Cfm Chart

Dust Collector Cfm Chart Raptor Blast Systems T Ttex / A good blower

Figure Dustcollection Needs By The Numbers WOOD Magazine

Dust Collection Research Dust Collection Basics

Dust collection help The Shop Wood Talk Online

Dust Collectors for the Home Shop Canadian Woodworking

Dust Collector Cfm Chart Time For A Dust Collector This dust

Dust Collection Cfm Chart Printable Templates Free

Dust Classification Chart

Web Many Dust Collection Systems Suffer Due To Poor Ductwork Designs.

Your Cfm Requirements Are Determined By The Size Of The Enclosure That It Must Clean And The Volume Of Dust You Produce.

Web To Help You Decide Which Woodworking Dust Collectors Would Be The Best Fit For Your Workshop, Laguna Tools Has Included Detailed Performance And Technical Data About Each Machine In Our Online Catalog.

It’s This Cfm Value That Determines How Efficient A Dust Collection System Is, And Understanding Its Intricacies Is Vital.

Related Post: