C Chart Six Sigma

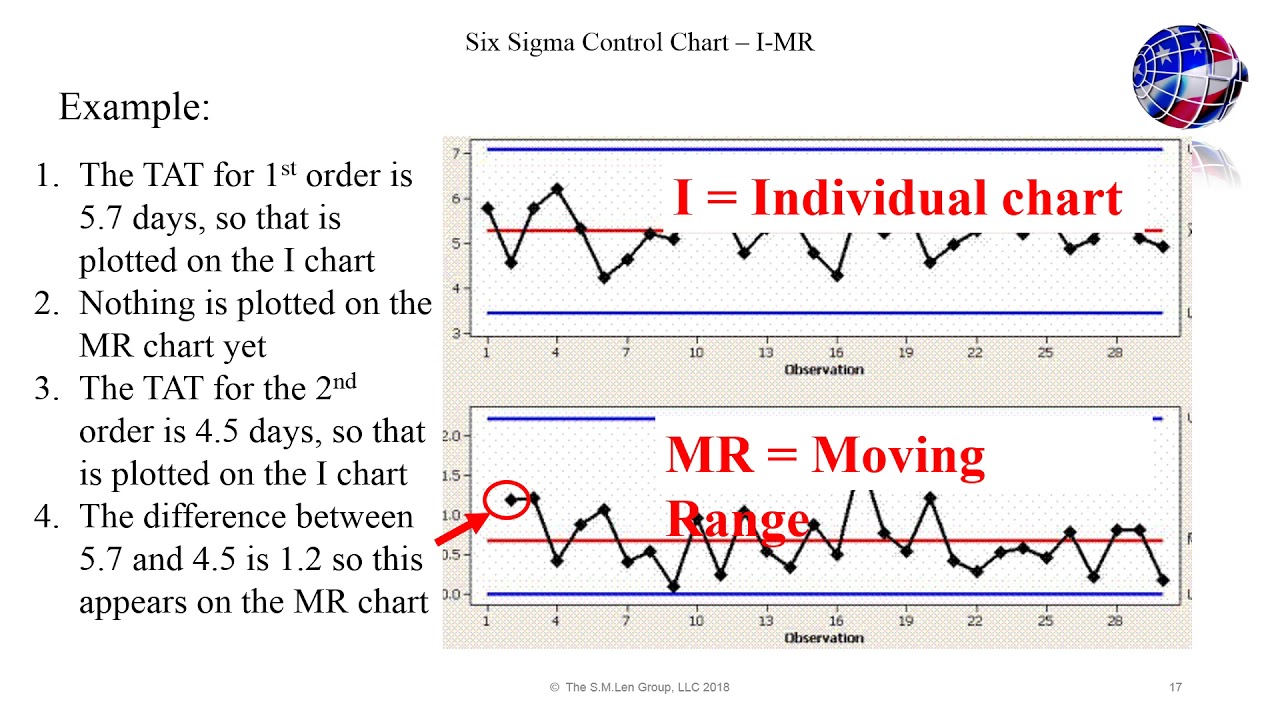

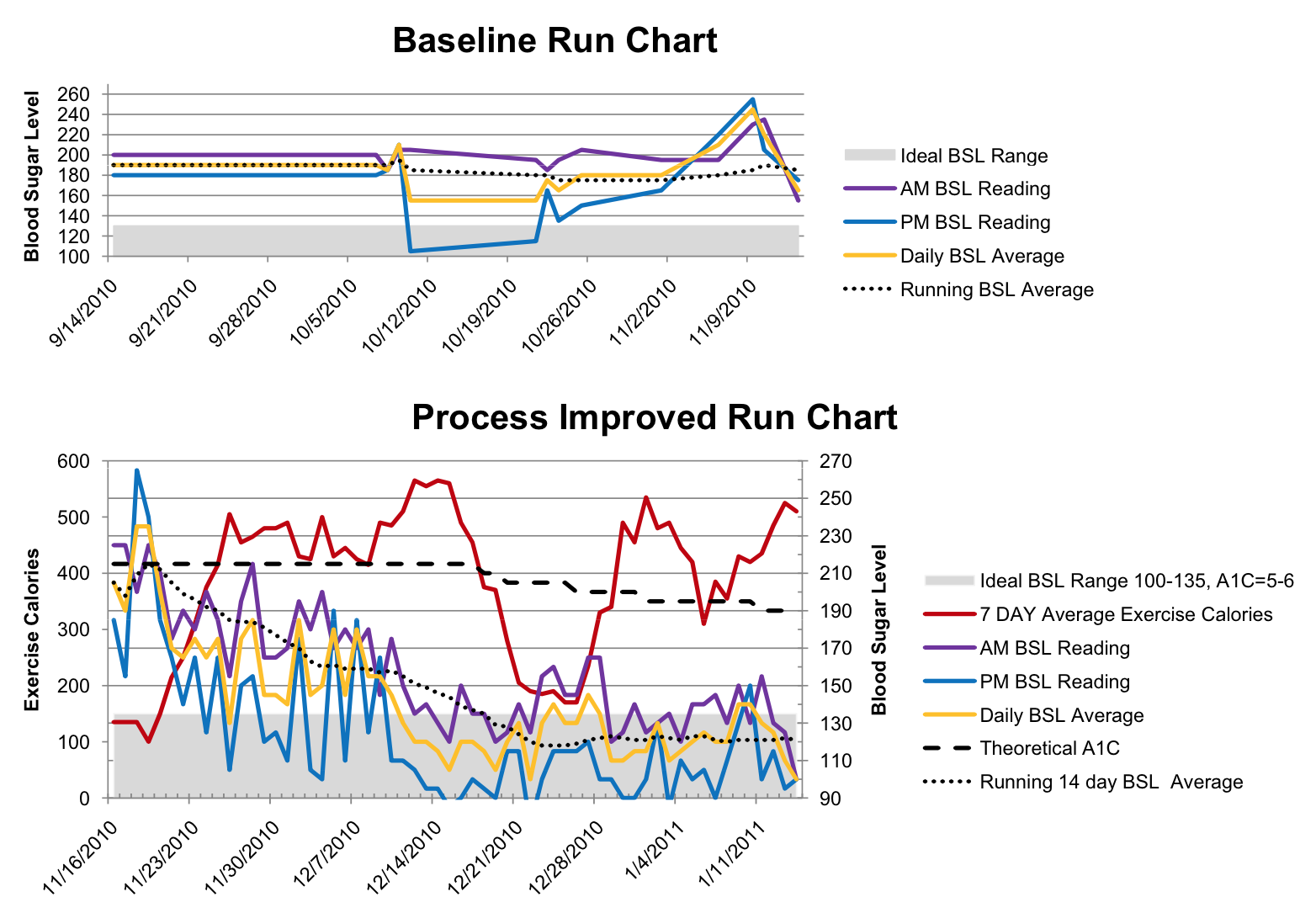

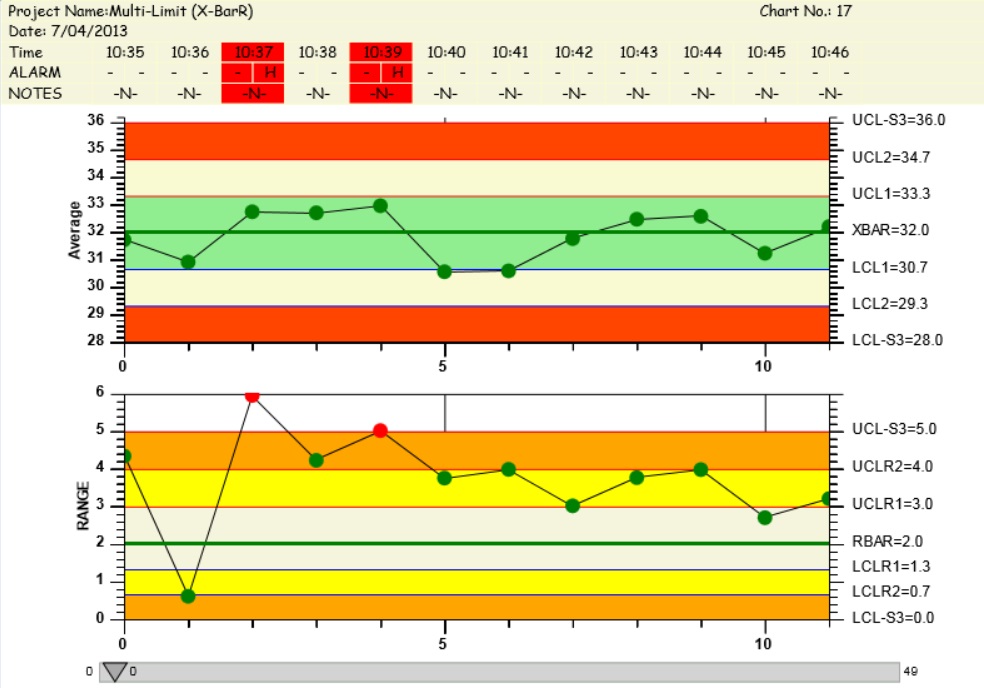

C Chart Six Sigma - C chart is also known as the control chart for defects (i.e., counting the number of defects). A control chart is also known as the shewhart chart since it was introduced by walter a shewhart. Constant (fixed) sample size (subgroup size) develop upper and lower control limits (ucl and lcl) and. Web what are control charts? Control charts dealing with the number of defects or nonconformities are called c charts (for count). It is also occasionally used to monitor the total number of events occurring in a given unit of time. It shows data points in a time series or a sequence, with a centreline indicating the process average and upper and lower limits representing acceptable variation. This “unit” is commonly referred to as an inspection unit and may be “per day” or “per square foot” of some other predetermined sensible rate. Web the control chart is a graph used to study how a process changes over time. They are used extensively during the measure and analyze phases of the dmaic approach to understand process capabilities and identify sources of variation. Web we can use 4 types of control charts if we have a distinct data type: Web a six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. Only after our method is. C chart is one of the quality control charts used to track the. Web the primary. Web what is a control chart in six sigma? By this, we can see how is the process behaving over the period of time. To view the process behavior or to hear the voice of the process, a control chart is initially employed (vop). Web control charts play a crucial role in the six sigma methodology by enabling statistical process. Web the c chart is a control chart for the number of nonconformities (defects or concerns) per inspection unit. We can also call it as process behavior chart. Constant (fixed) sample size (subgroup size) develop upper and lower control limits (ucl and lcl) and. Control charts are a simple yet powerful tool that helps us understand if a process is. Web what are c charts. When to use c chart: This chart is used when the number of samples of each sampling period is essentially the same. C chart, n chart, np chart, and u chart. Web what is a control chart in six sigma? There are four types of attribute charts: There is a difference between a defect and defective, as there is between a nonconformity and nonconforming unit. It generally monitors the number of defects in consistently sized units. Every item in the sample is evaluated for only the number of defects, flaws, or occurrences, etc. Well, it is a graphical tool that. Web what are c charts. In the control chart, these tracked measurements are visually compared to decision limits calculated from probabilities of the actual process performance. Only after our method is. The plot shows the # of defects. Web the primary statistical process control (spc) tool for six sigma initiatives is the control chart — a graphical tracking of a. The control limits are ±3σ from the centerline. C chart is one of the quality control charts used to track the. Web the control chart is a graph used to study how a process changes over time. C chart is especially used when there are high opportunities for defects in the subgroup, but the actual number of defects is less.. The c chart is especially easy to make because the number of defects is plotted directly on the control chart. Only after our method is. When to use c chart: C chart, n chart, np chart, and u chart. To view the process behavior or to hear the voice of the process, a control chart is initially employed (vop). Web the primary statistical process control (spc) tool for six sigma initiatives is the control chart — a graphical tracking of a process input or an output over time. By this, we can see how is the process behaving over the period of time. The plot shows the # of defects. Web a six sigma control chart is a simple. Web the control chart is a graph used to study how a process changes over time. C chart is one of the quality control charts used to track the. This “unit” is commonly referred to as an inspection unit and may be “per day” or “per square foot” of some other predetermined sensible rate. A control chart always has a. Evaluates the stability of counted data; Web an ultimate guide to control charts in six sigma. This “unit” is commonly referred to as an inspection unit and may be “per day” or “per square foot” of some other predetermined sensible rate. The chart can track the number of defects per unit, whether there is. Web a six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. Web what are control charts? C chart, n chart, np chart, and u chart. When to use c chart: The control limits are ±3σ from the centerline. The c chart is used when the data can only be whole numbers, as in counting, it is known as attribute, or discrete data. It is also occasionally used to monitor the total number of events occurring in a given unit of time. To view the process behavior or to hear the voice of the process, a control chart is initially employed (vop). Control charts are a simple yet powerful tool that helps us understand if a process is “stable or in control.” control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. By this, we can see how is the process behaving over the period of time. Well, it is a graphical tool that helps organisations understand the nature of process variation. C chart is also known as the control chart for defects (i.e., counting the number of defects).

Six Sigma Green Belt Introduction to Control Charts

C Chart Six Sigma

10 C CHART IN SIX SIGMA, SIX CHART SIGMA IN C Chart & Formation

6 Sigma Conversion Table PDF

C Chart Six Sigma

Six Sigma Green Belt Introduction to Control Charts

22 C CHART IN SIX SIGMA, IN C CHART SIX SIGMA Chart & Formation

C & U charts Sixsigma DSI Lean Six Sigma Glossary Term

What is Control Charts in Six Sigma and How to Create them?

![]()

Control Charts Six Sigma Ppt Powerpoint Presentation Icon Show Cpb

They Are Used Extensively During The Measure And Analyze Phases Of The Dmaic Approach To Understand Process Capabilities And Identify Sources Of Variation.

Web Six Sigma Control Charts Are Significant In Monitoring And Controlling Process Variation Within The Six Sigma Methodology.

Only After Our Method Is.

It Generally Monitors The Number Of Defects In Consistently Sized Units.

Related Post: