Factory Process Flow Chart

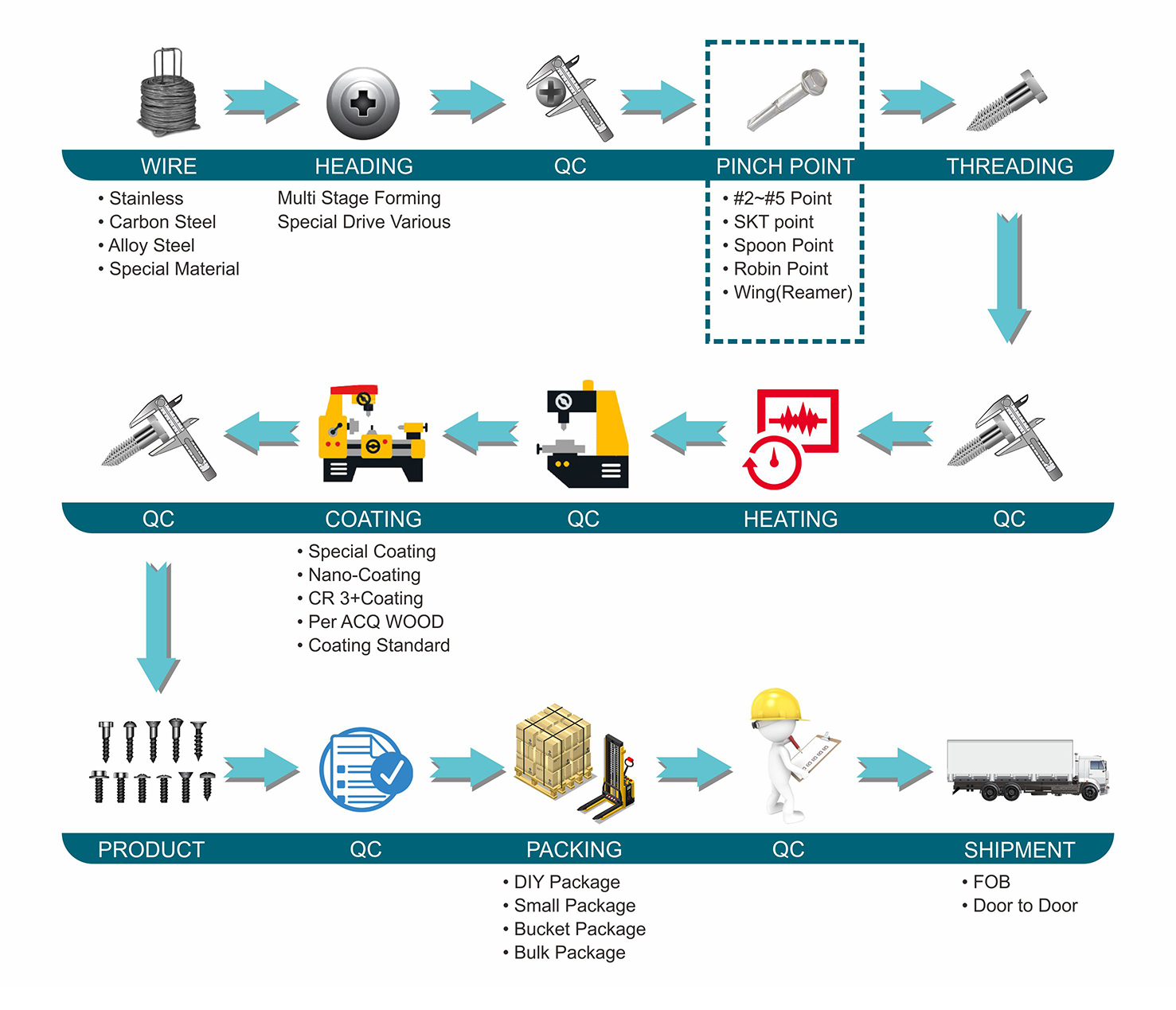

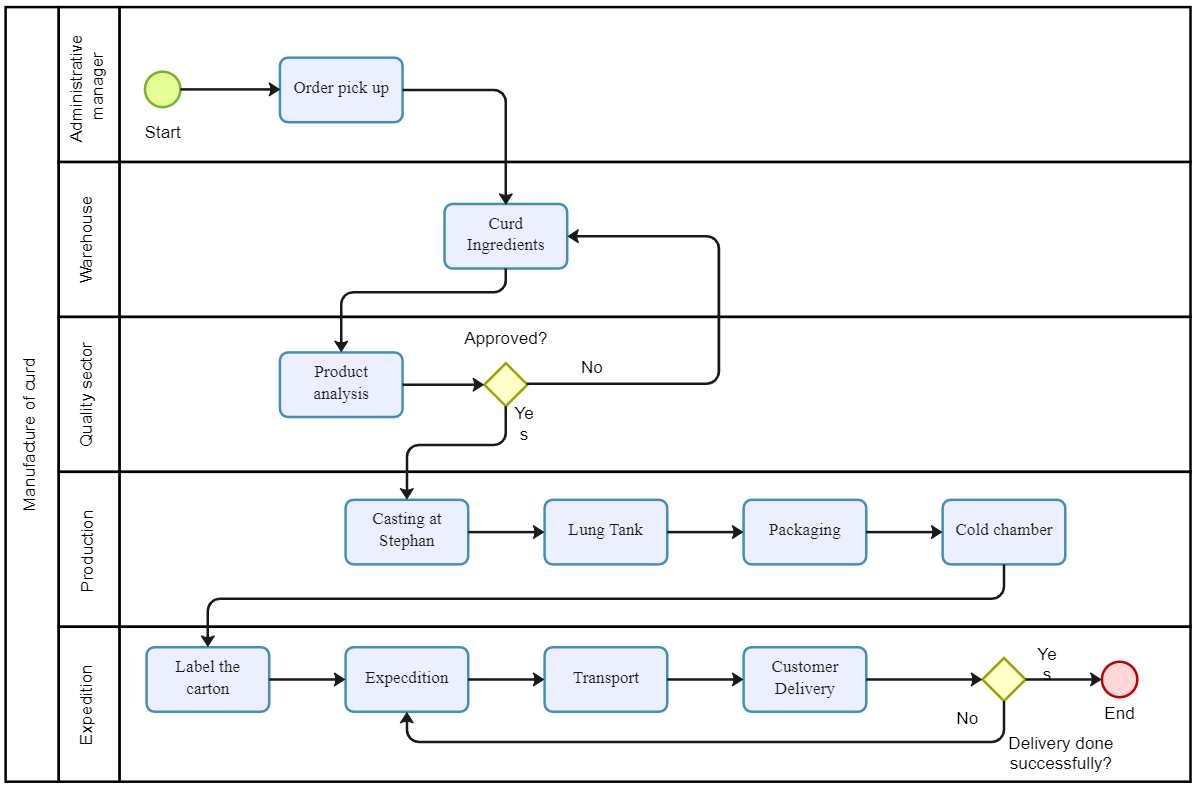

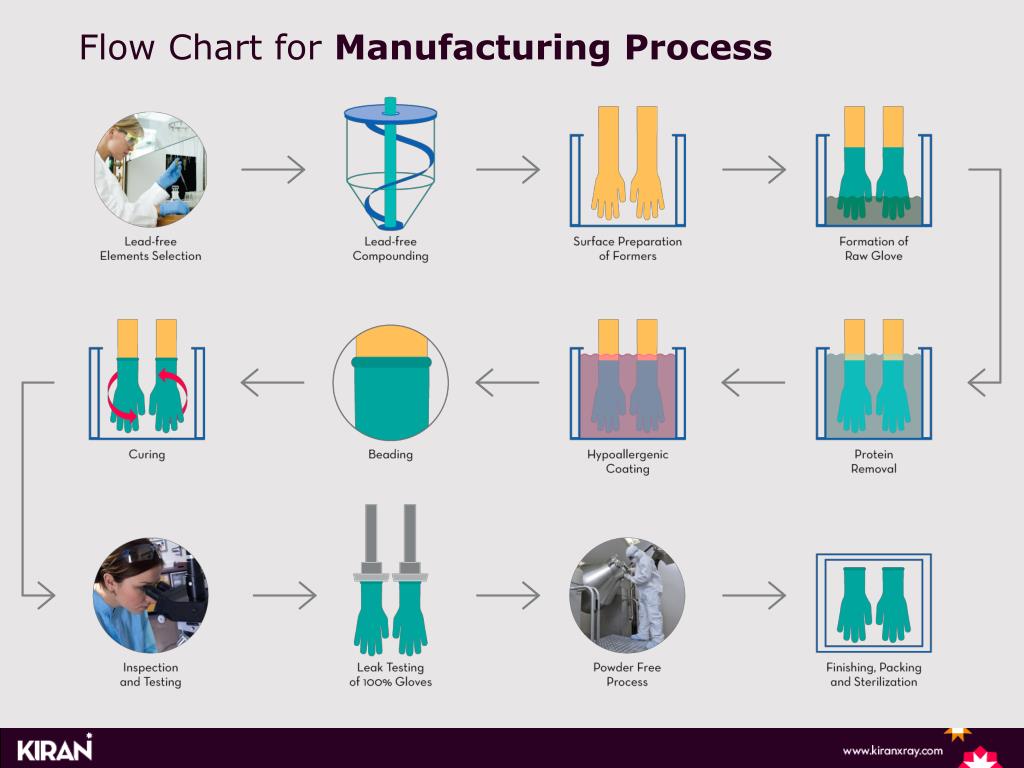

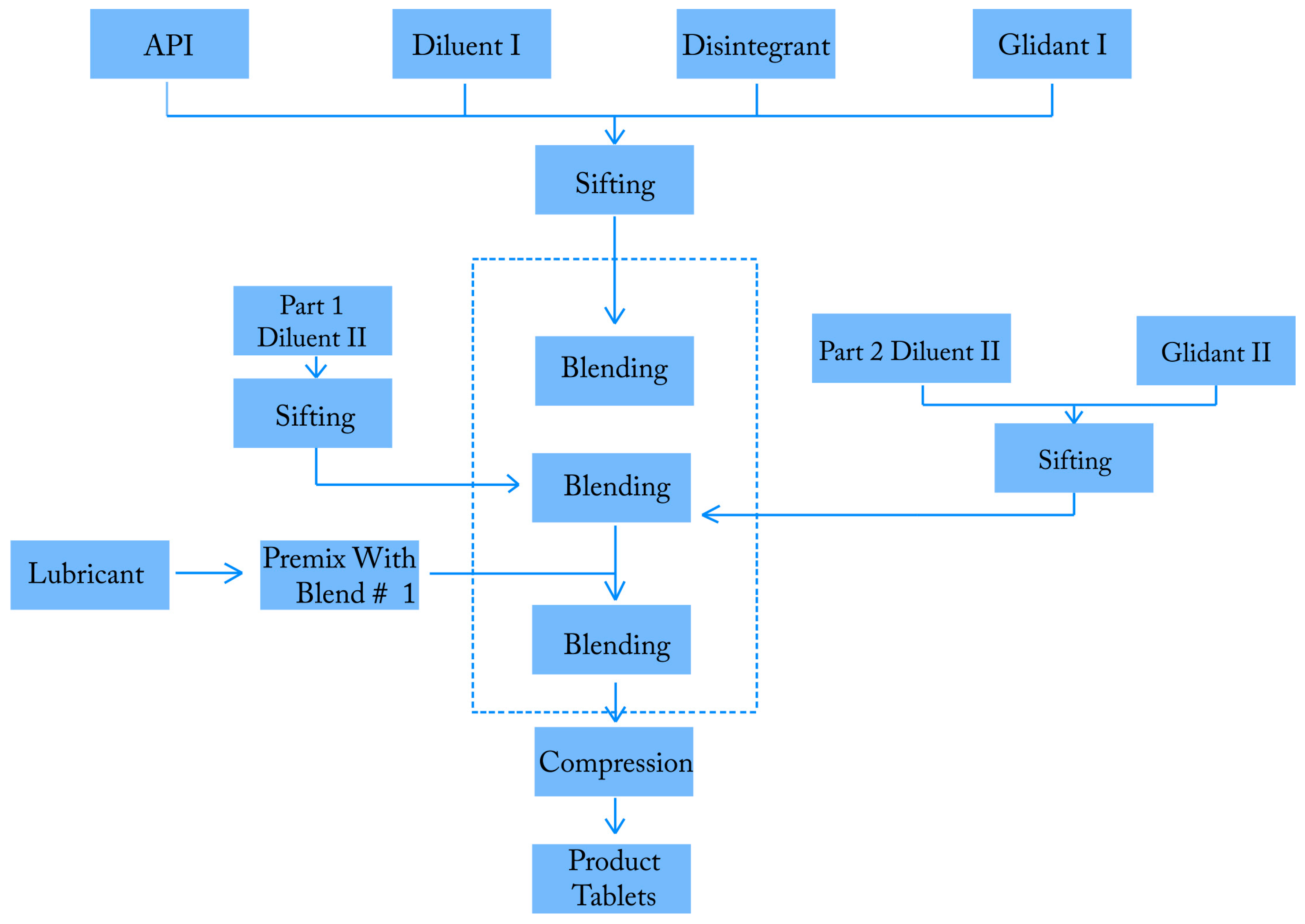

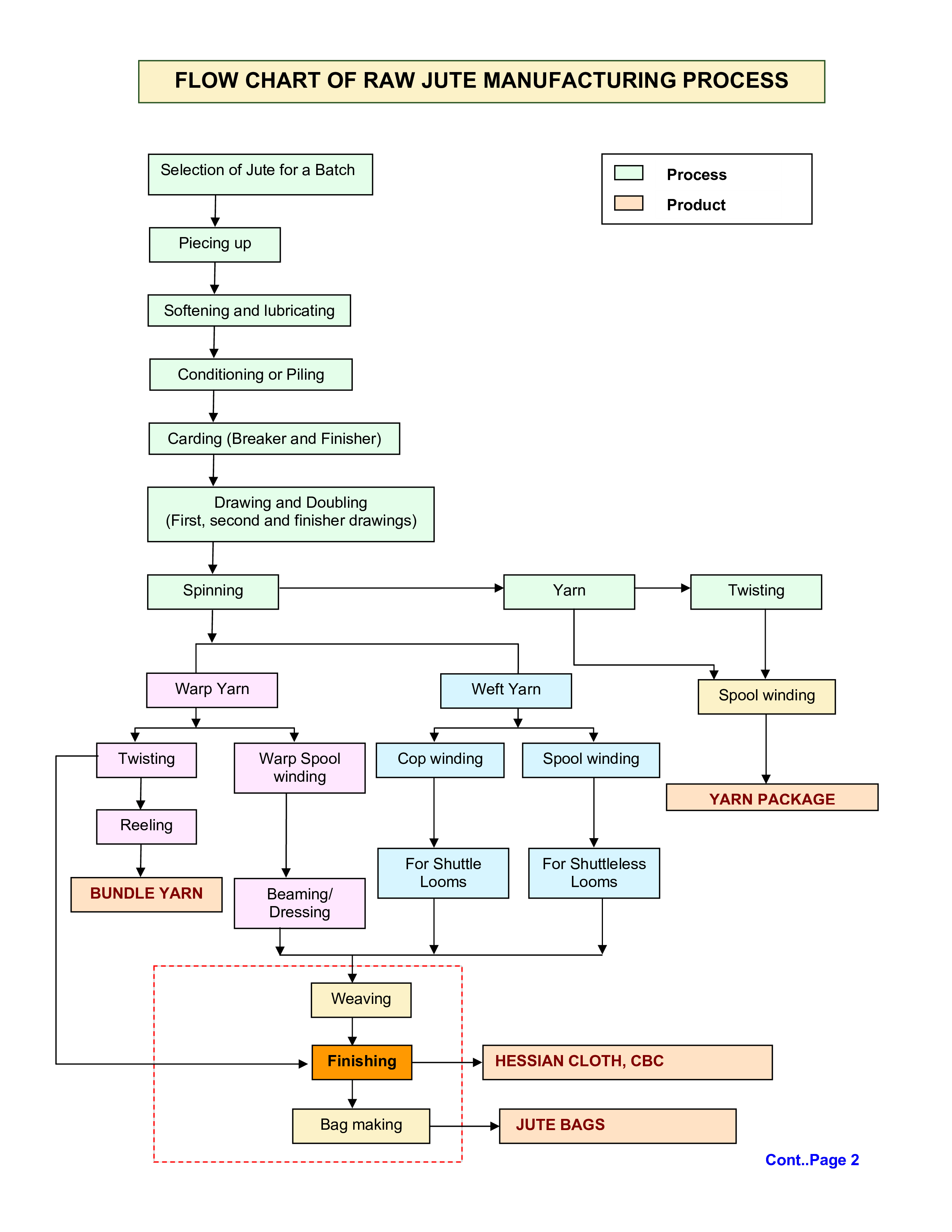

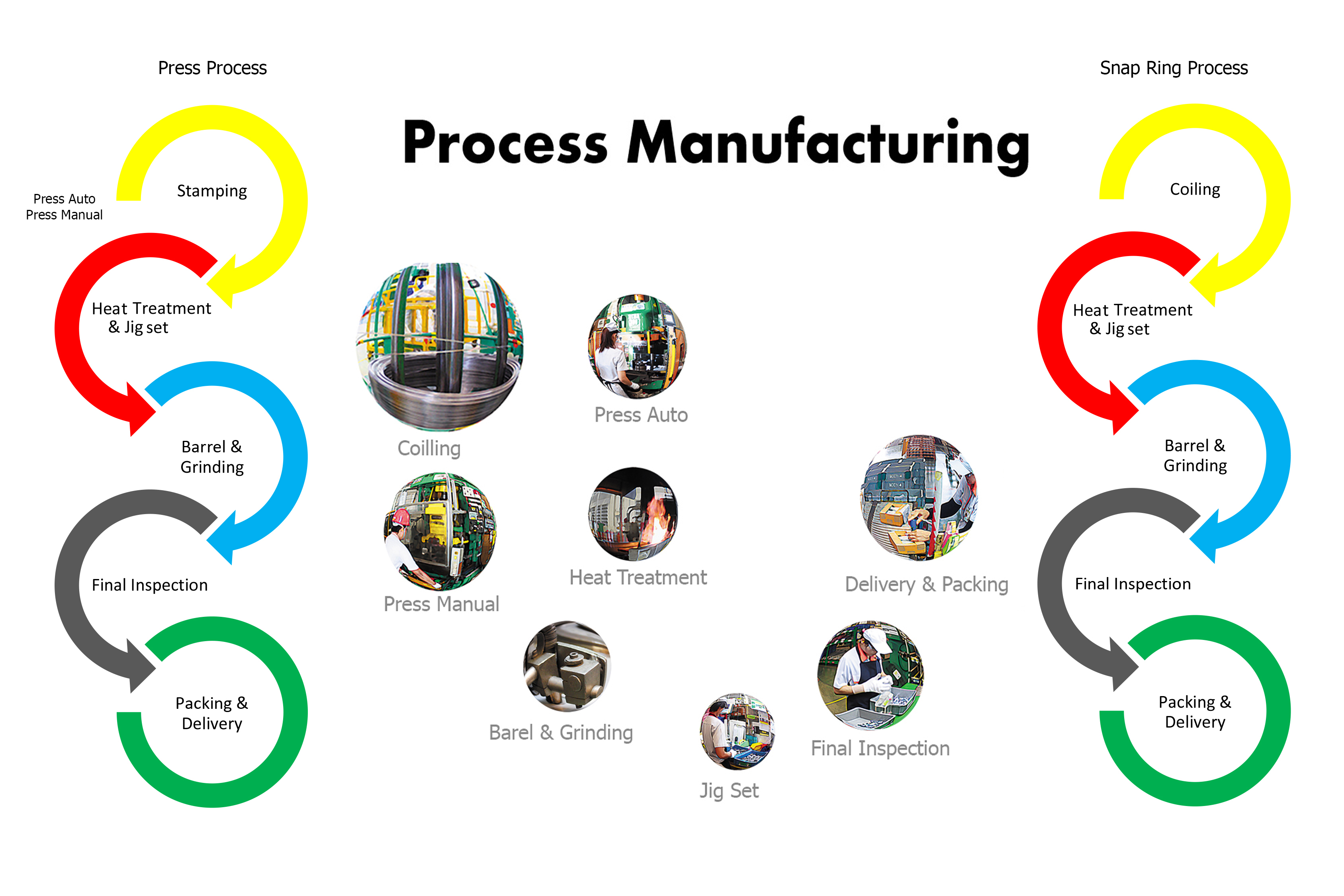

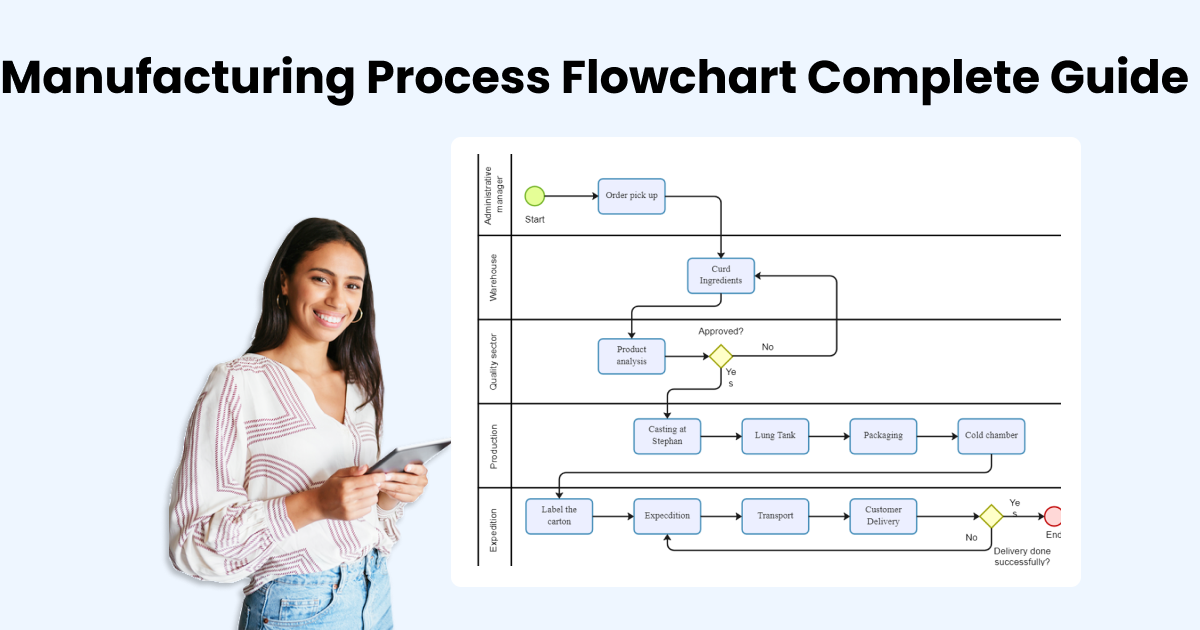

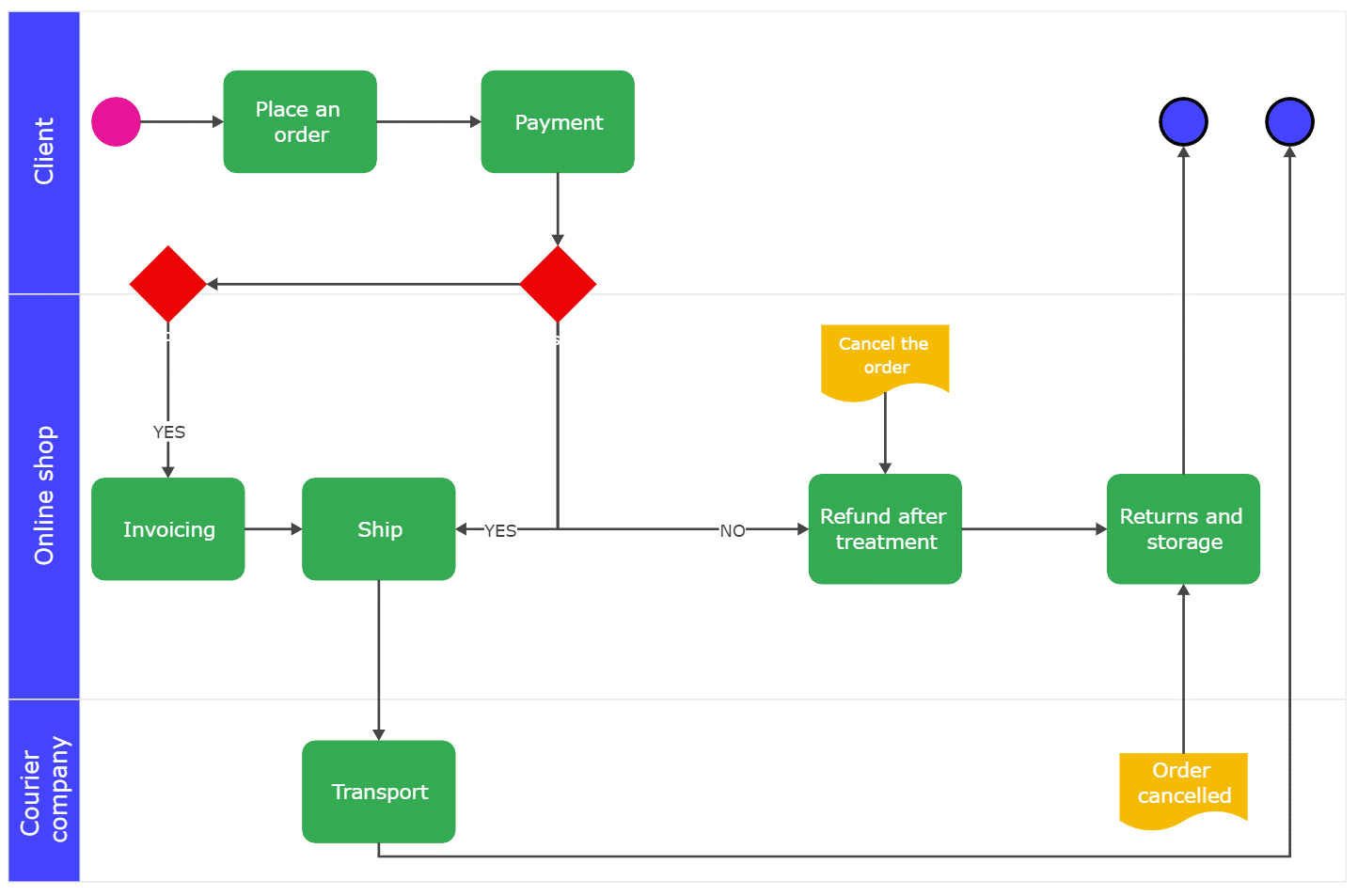

Factory Process Flow Chart - It is also called an outline process chart. Once the materials have been inspected, they are stored in a designated location until they are needed for production. Web manufacturing processes are ideally suited for analysis via flow charting, due to the consistent, logical, linear flow of such processes, with standard operating instructions, defined decision points and specific inputs and outputs. Amg industries identified a specific part, a ford finger exhaust tip that was experiencing production challenges and was comprised of a highly repetitive task. Nevertheless, it does not cover. Web a process flow chart is the first step in any process improvement effort. It's most often used in chemical engineering and process engineering, though its concepts are sometimes applied to other processes as well. A production order defines which material is to be produced in which quantity, time, and way. Web a process flow chart, also known as a process map or process flow diagram, is a visual representation of a process in a business. Explaining how to perform a process. Inspecting raw materials is the next step, checking quality and quantity to ensure they meet the required specifications. It uses symbols and arrows to show the flow of tasks and decisions that are involved in completing the process from start to finish. Web manufacturing process flowcharts are commonly used by managers to simplify the training and orientation of production employees.. Web a flowchart is a visual representation of the sequence of steps and decisions needed to perform a process. Open this template to view a detailed example of a manufacturing flow diagram that you can customize to your use case. Web a process flow chart, also known as a process map or process flow diagram, is a visual representation of. Want to create your own process map? Web an integrated framework using vsm, ahp and topsis for simplifying the sustainability improvement process in a complex manufacturing process. J eng des technol 2019; Once the materials have been inspected, they are stored in a designated location until they are needed for production. It’s used to document a process, improve a process. It helps to organize tasks in chronological order and identify essential steps, such as manufacturing & assembly, quality assurance, inspection,. This allows anyone to view the flowchart and logically follow the process from beginning to end. Flow charts and various process flow diagrams (pfd) fill countless pages in quality management manuals. It’s used to document a process, improve a process. Steps are linked by connecting lines and directional arrows. Digitalization has had a profound impact on the manufacturing sector, enabling businesses to optimize processes, improve quality and reduce costs. Identify process inefficiencies and opportunities for improvement. It is also called an outline process chart. This approach helps minimize losses by assuring better quality. Want to create your own process map? In the bike company, production orders are used to start and control bicycle production. Identify process inefficiencies and opportunities for improvement. Web a comprehensive manufacturing flow chart provides an overarching view of the entire production process. This approach helps minimize losses by assuring better quality. Web visualize the manufacturing flow for a product. Web a process flow chart is the first step in any process improvement effort. It is also called an outline process chart. Want to create your own process map? Boost efficiency, eliminate waste, and enhance communication among teams. It is also called an outline process chart. Flow charts and various process flow diagrams (pfd) fill countless pages in quality management manuals. Amg industries identified a specific part, a ford finger exhaust tip that was experiencing production challenges and was comprised of a highly repetitive task. It shows the stages, equipment used and quality control checks where you’ll check. Web the operation process chart is a basic & easy to implement tool of method study. This allows anyone to view the flowchart and logically follow the process from beginning to end. Opc is a useful tool during lean manufacturing implementation. A tailored chart of accounts helps organize costs into appropriate general ledger accounts, which makes analyses and reporting more. Process orders are always scheduled when the order is created. It's most often used in chemical engineering and process engineering, though its concepts are sometimes applied to other processes as well. Digitalization has had a profound impact on the manufacturing sector, enabling businesses to optimize processes, improve quality and reduce costs. It is also called an outline process chart. It. Amg industries identified a specific part, a ford finger exhaust tip that was experiencing production challenges and was comprised of a highly repetitive task. Manufacturing accounting is best prepared using automated software. Each step in the sequence is noted within a diagram shape. Digitalization has had a profound impact on the manufacturing sector, enabling businesses to optimize processes, improve quality and reduce costs. This approach helps minimize losses by assuring better quality. Process orders are always scheduled when the order is created. Web a process map or flowchart describes the flow of materials and information, displays the tasks associated with a process, shows the decisions that need to be made along the chain and shows the essential relationships between the process steps. Explaining how to perform a process. Web an integrated framework using vsm, ahp and topsis for simplifying the sustainability improvement process in a complex manufacturing process. The operation process chart helps to understand the process overview of the shop floor, optimize processes as well as improve plant layout. Furthermore, by assigning production scheduling profiles, you can optimize and partially automate various. It uses symbols and arrows to show the flow of tasks and decisions that are involved in completing the process from start to finish. Web here, we’ll discuss the major manufacturing trends that will change the industry in the coming year. Web a comprehensive manufacturing flow chart provides an overarching view of the entire production process. Nevertheless, it does not cover. A tailored chart of accounts helps organize costs into appropriate general ledger accounts, which makes analyses and reporting more meaningful.

Manufacturing Flow Chart Template

Understanding Manufacturing Process Flowcharts (With Examples)

Manufacturing Process Flow Chart Template

PPT Flow Chart for Manufacturing Process PowerPoint Presentation

Manufacturing Process Flow Chart Template

Manufacturing Process Planning Flow Chart Examples

Manufacturing Process Flow Chart Templates at

12+ Flow Chart Manufacturing Process Robhosking Diagram

Understanding Manufacturing Process Flowcharts (With Examples)

Understanding Manufacturing Process Flowcharts (With Examples)

Web A Flowchart Is A Picture Of The Separate Steps Of A Process In Sequential Order.

You Can Also Drag And Drop Standard Icons And Symbols To Lay Out For New Flowchart Making.

Open This Template To View A Detailed Example Of A Manufacturing Flow Diagram That You Can Customize To Your Use Case.

Web You Can Precisely Select And Process The Process Orders In Your Area Of Responsibility In Reporting And Mass Processing.

Related Post: