Bioreactor Design

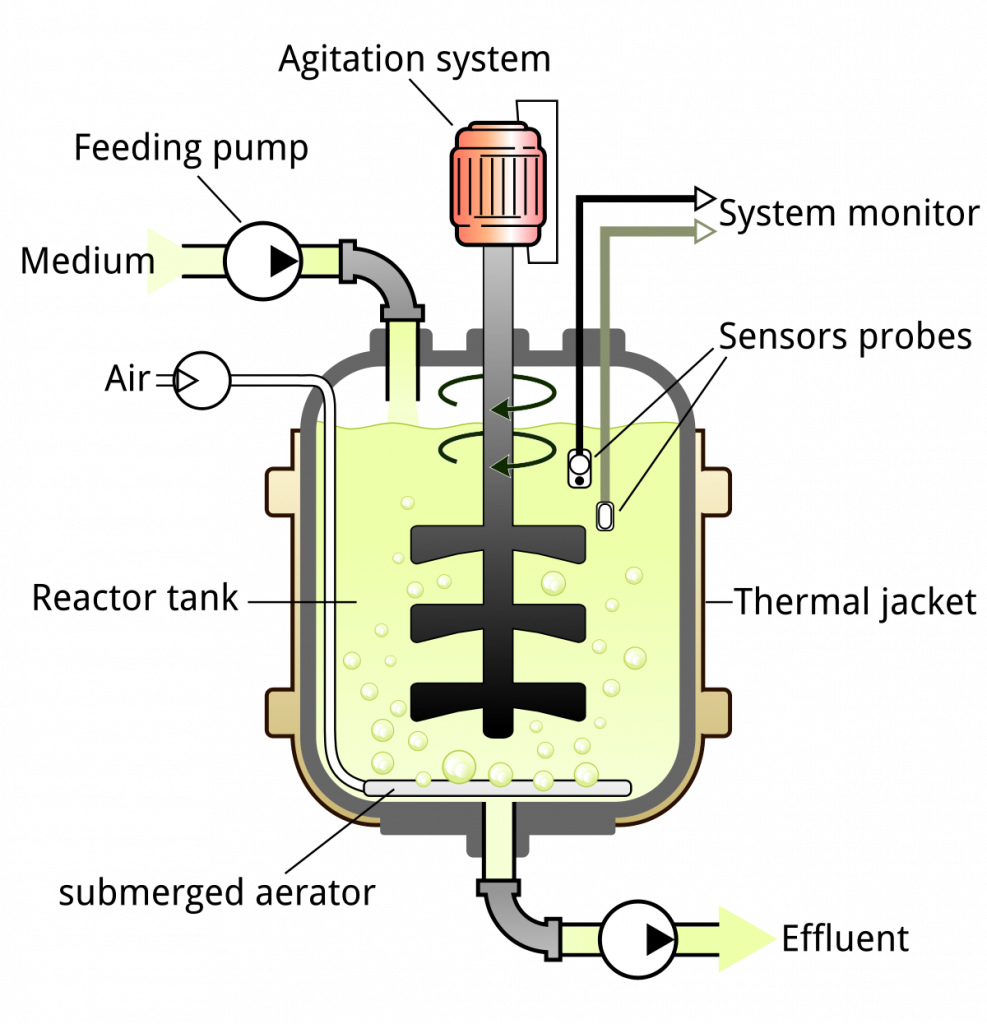

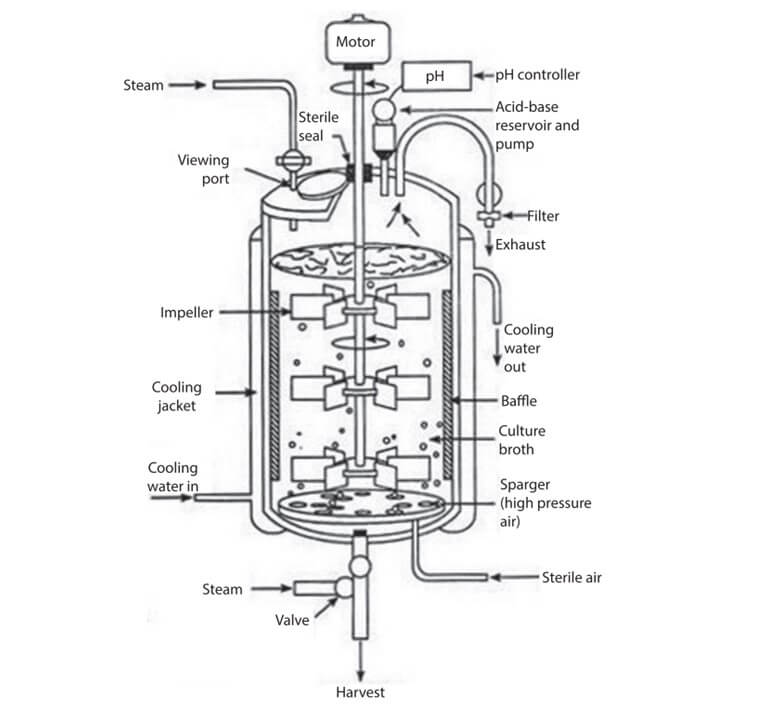

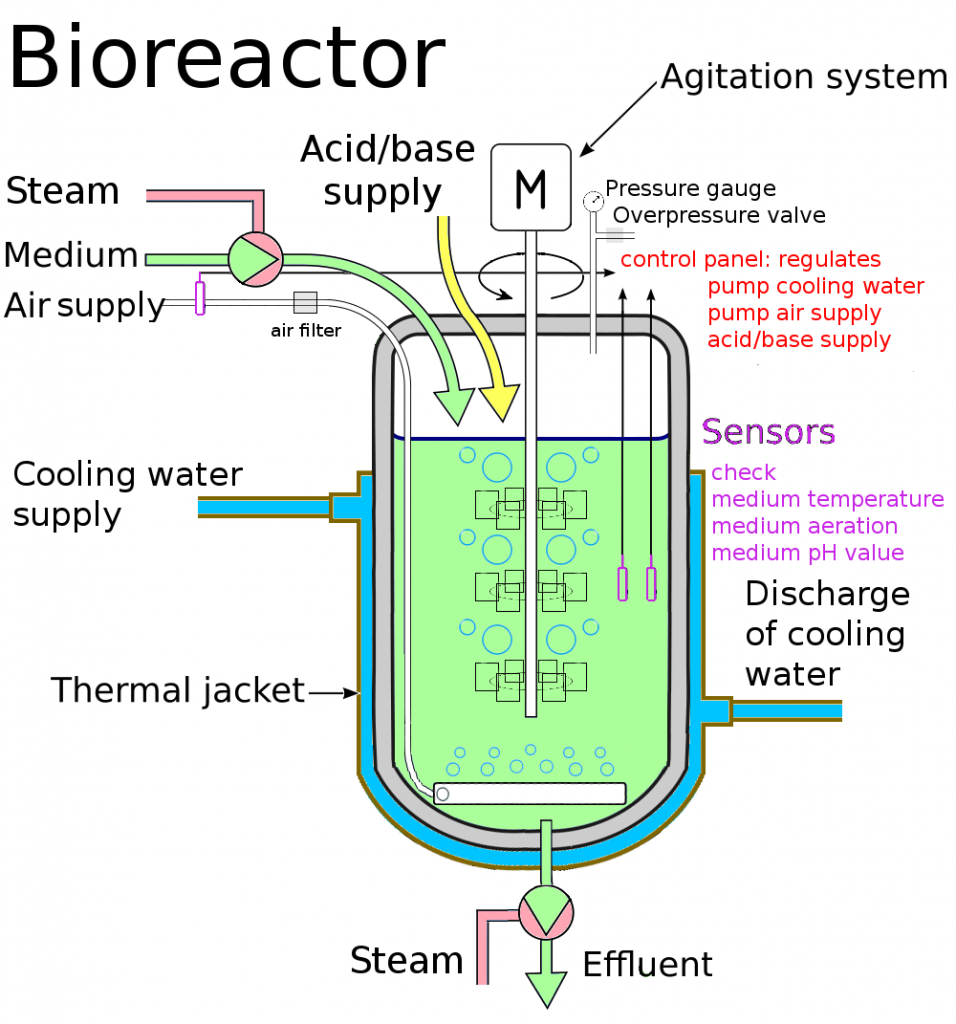

Bioreactor Design - The bioreactor system provides a biomimetic physiological platform by delivering nutrients, eliminating cellular waste products, supplying oxygen and. The design and mode of operation of a bioreactor are based on the production of an organism, optimum conditions required for desired product formation, product value, and its scale of production. Published online by cambridge university press: Web a bioreactor is any manufactured device or system that supports a biologically active environment. A background to bioreactor design requirements is first introduced followed by general considerations of rotating reactor concepts. A good bioreactor design will help to improve productivity and provide higher quality products at lower prices. Web the design of the bioreactor for a specific biological process is determined by a variety of considerations including: In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically. Web computational fluid dynamics (cfd) modeling in bioreactor design can reduce wet testing by simulating bioreactor geometry, fluid flow, and design and positioning of components. Web this chapter reviews the progress made in developing and applying rotating reactors for bioprocessing, focusing on whole cell fermentation and biotransformations. A good bioreactor design will help to improve productivity and provide higher quality products at lower prices. Mainly special demands, such as gentle agitation and aeration without cell damage, The design and mode of operation of a bioreactor are based on the production of an organism, optimum conditions required for desired product formation, product value, and its scale of production.. In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically. Mainly special demands, such as gentle agitation and aeration without cell damage, The properties of the biological agent — cells (s) or enzyme (s) — the nature of the raw material or substrate, the properties and desired. A background. Web the design of the bioreactor for a specific biological process is determined by a variety of considerations including: The design and mode of operation of a bioreactor are based on the production of an organism, optimum conditions required for desired product formation, product value, and its scale of production. In one case, a bioreactor is a vessel in which. In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically. Web the design of the bioreactor for a specific biological process is determined by a variety of considerations including: Web a bioreactor is any manufactured device or system that supports a biologically active environment. The design and mode of. The bioreactor system provides a biomimetic physiological platform by delivering nutrients, eliminating cellular waste products, supplying oxygen and. Web the design of the bioreactor for a specific biological process is determined by a variety of considerations including: A good bioreactor design will help to improve productivity and provide higher quality products at lower prices. Web this chapter reviews the progress. The properties of the biological agent — cells (s) or enzyme (s) — the nature of the raw material or substrate, the properties and desired. Web the design of the bioreactor for a specific biological process is determined by a variety of considerations including: Web this chapter reviews the progress made in developing and applying rotating reactors for bioprocessing, focusing. A good bioreactor design will help to improve productivity and provide higher quality products at lower prices. Mainly special demands, such as gentle agitation and aeration without cell damage, A background to bioreactor design requirements is first introduced followed by general considerations of rotating reactor concepts. Web this chapter reviews the progress made in developing and applying rotating reactors for. A background to bioreactor design requirements is first introduced followed by general considerations of rotating reactor concepts. The bioreactor system provides a biomimetic physiological platform by delivering nutrients, eliminating cellular waste products, supplying oxygen and. Web this chapter reviews the progress made in developing and applying rotating reactors for bioprocessing, focusing on whole cell fermentation and biotransformations. Web the design. A good bioreactor design will help to improve productivity and provide higher quality products at lower prices. Web the design of the bioreactor for a specific biological process is determined by a variety of considerations including: Published online by cambridge university press: The bioreactor system provides a biomimetic physiological platform by delivering nutrients, eliminating cellular waste products, supplying oxygen and.. A background to bioreactor design requirements is first introduced followed by general considerations of rotating reactor concepts. Web this chapter reviews the progress made in developing and applying rotating reactors for bioprocessing, focusing on whole cell fermentation and biotransformations. Web a bioreactor is any manufactured device or system that supports a biologically active environment. Web the design of the bioreactor. Published online by cambridge university press: A background to bioreactor design requirements is first introduced followed by general considerations of rotating reactor concepts. In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically. Web a bioreactor is any manufactured device or system that supports a biologically active environment. The properties of the biological agent — cells (s) or enzyme (s) — the nature of the raw material or substrate, the properties and desired. Web the design of the bioreactor for a specific biological process is determined by a variety of considerations including: A good bioreactor design will help to improve productivity and provide higher quality products at lower prices. The design and mode of operation of a bioreactor are based on the production of an organism, optimum conditions required for desired product formation, product value, and its scale of production. Mainly special demands, such as gentle agitation and aeration without cell damage,

Good Bioreactor Design How It Creates An Outstanding User Experience

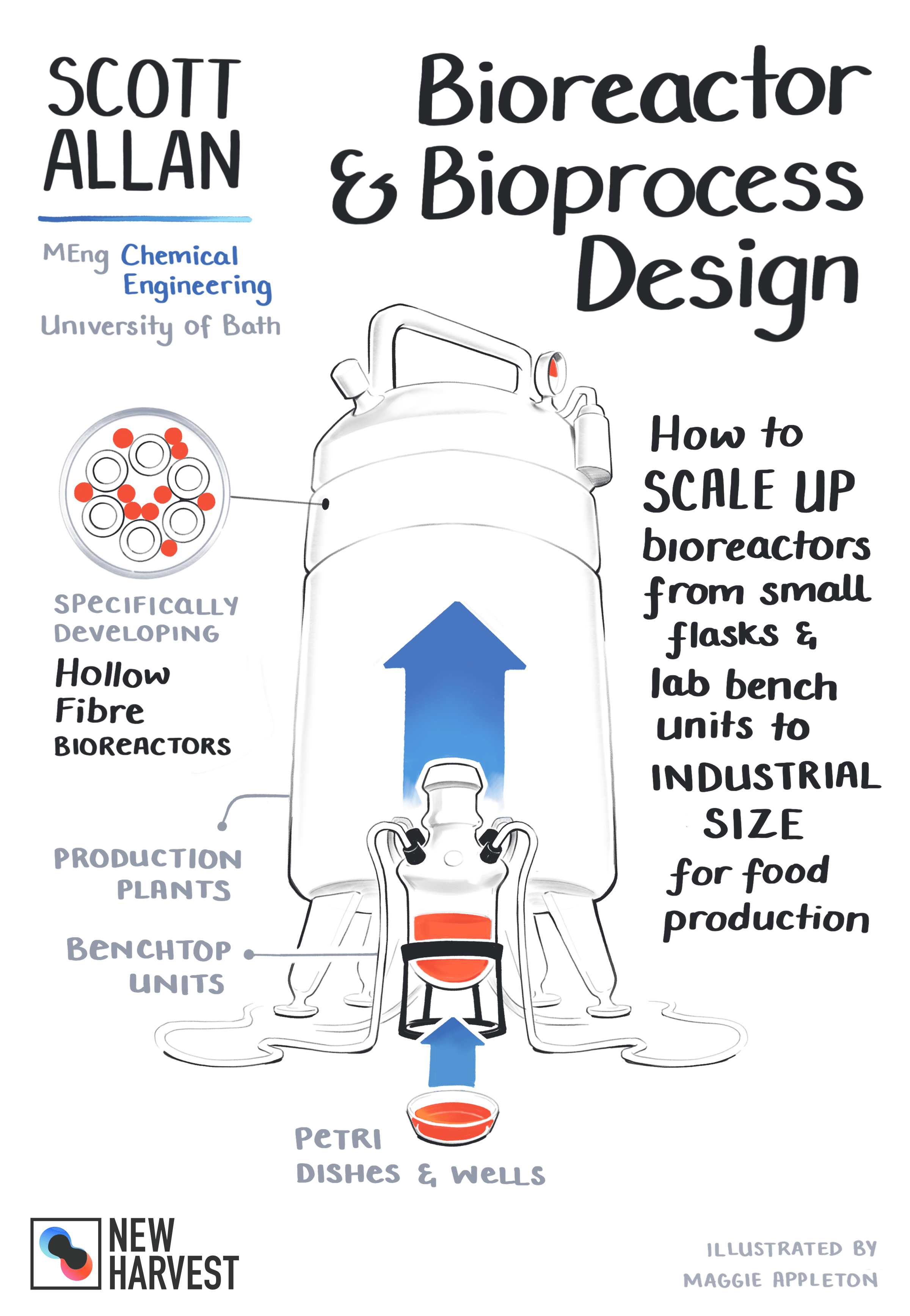

Bioreactor & Bioprocess Design

Bioreactor Design and Operation of Micropropagation Glycol Jacketed

bioreactor parts and their functions Kylie Payne

Bioreactor Definition, Design, Principle, Parts, Types, Applications

ClearLogic Membrane Bioreactor (MBR)

Bioreactor Insanitek

Fibrous Bed Bioreactor

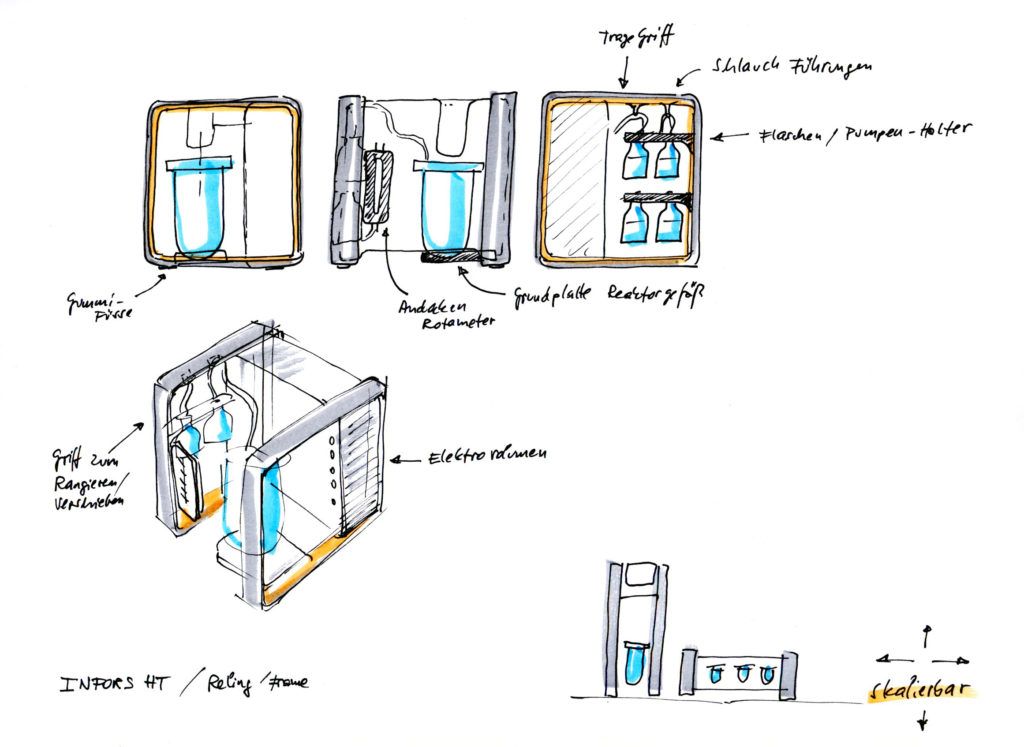

Techfors The pilot bioreactor for bioprocess professionals INFORS HT

Bioreactor Parameter, Parts, Types, and Application • Microbe Online

The Bioreactor System Provides A Biomimetic Physiological Platform By Delivering Nutrients, Eliminating Cellular Waste Products, Supplying Oxygen And.

Web This Chapter Reviews The Progress Made In Developing And Applying Rotating Reactors For Bioprocessing, Focusing On Whole Cell Fermentation And Biotransformations.

Web Computational Fluid Dynamics (Cfd) Modeling In Bioreactor Design Can Reduce Wet Testing By Simulating Bioreactor Geometry, Fluid Flow, And Design And Positioning Of Components.

Related Post: