Xbar And R Chart

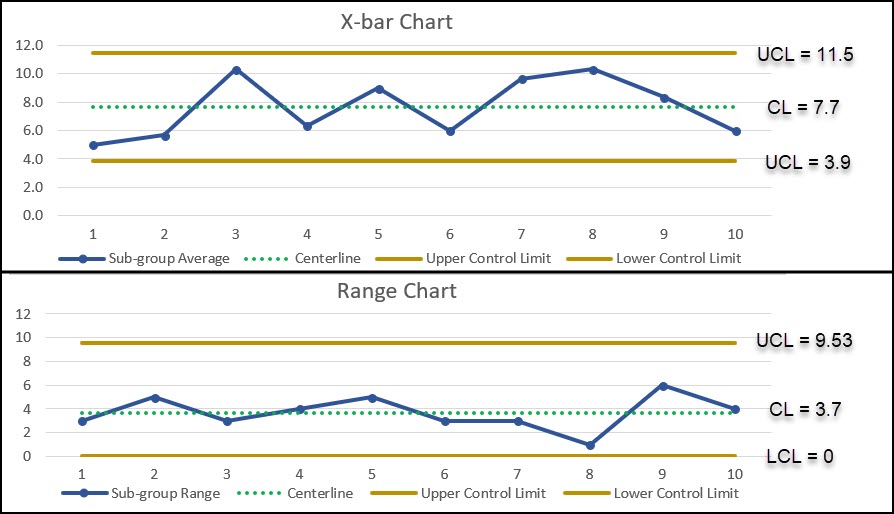

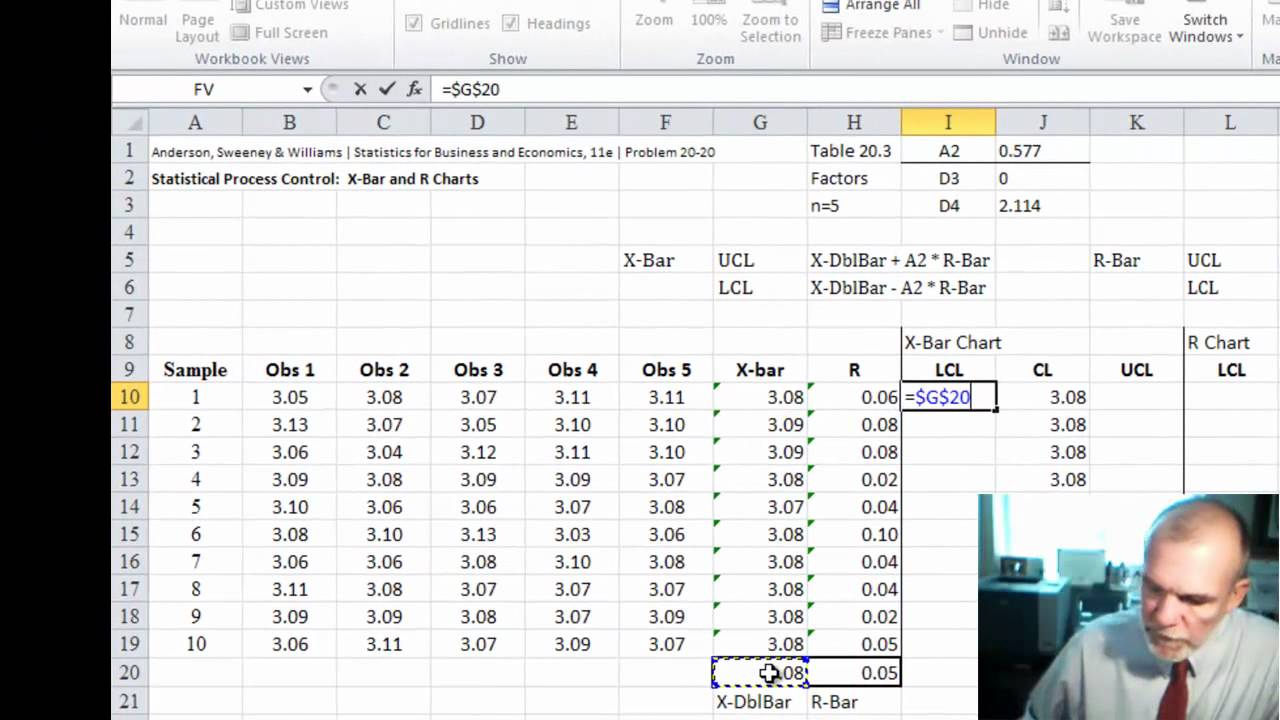

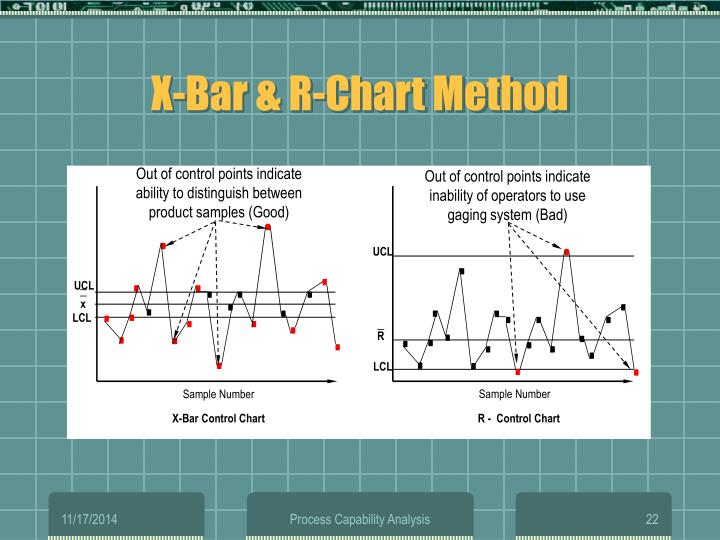

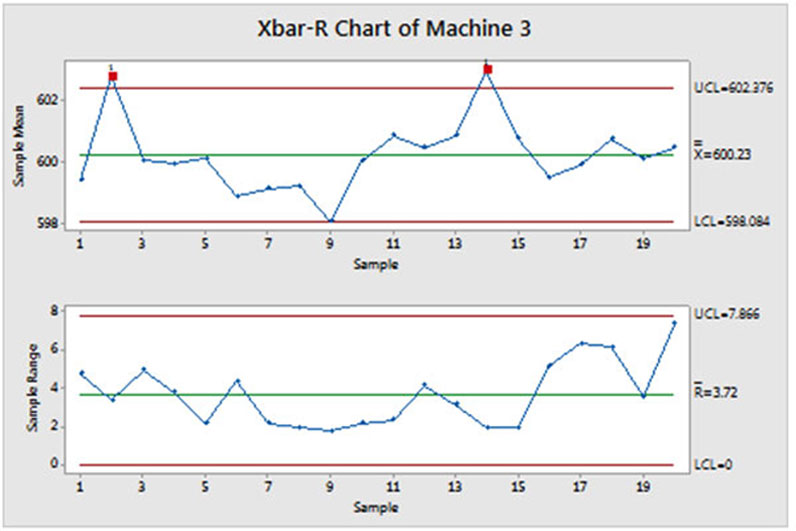

Xbar And R Chart - Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. Please let me know if you find it helpful! Web the mean of \(r\) is \(d_2 \sigma\), where the value of \(d_2\) is also a function of \(n\). At the start of each hour, you collect five samples from the production line and measure a quality characteristic, x. → we will learn step by step, with one example of the manufacturing process variation. Web example of control chart: Armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. The xbar chart examines the variation between subgroups suppose you are making a product. Examine the xbar chart to determine whether the process mean is in control. Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. Armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. Of course, more samples and more frequent measurements is better statistically. The. The xbar chart examines the variation between subgroups suppose you are making a product. Of course, more samples and more frequent measurements is better statistically. First the r chart is constructed. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. If the r chart validates that the process variation is in. Please let me know if you find it helpful! Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. An estimator of \(\sigma\) is therefore \(r / d_2\). Collect initial set of samples. Using the smart, intuitive system, these visual snapshots are just two clicks away. Examine the r chart to determine whether the process variation is in control. Examine the xbar chart to determine whether the process mean is in control. Using the smart, intuitive system, these visual snapshots are just two clicks away. Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for. The control limits on both chats are used to monitor the mean and variation of the process going forward. Of course, more samples and more frequent measurements is better statistically. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a. Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. If the r chart validates that the process variation is in statistical control, the xbar chart is constructed. The control limits on both chats are used to monitor the mean and variation of the process going forward. They provide. Consider the cost of sampling, required resources, and balance with minimizing time (and produced units) between measurements. Web the mean of \(r\) is \(d_2 \sigma\), where the value of \(d_2\) is also a function of \(n\). An estimator of \(\sigma\) is therefore \(r / d_2\). They provide continuous data to determine how well a process functions and stays within acceptable. Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. Collect initial set of samples. Armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. The range (r) chart shows the variation within each variable (called subgroups). If the r chart validates that. The range (r) chart shows the variation within each variable (called subgroups). The xbar chart examines the variation between subgroups suppose you are making a product. Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. Web the mean of \(r\) is \(d_2 \sigma\), where the value. Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. Using the smart, intuitive system, these visual snapshots are just two clicks away. → in this example, we will learn how to make a control chart. First the r chart is constructed. Process that is in statistical. The control limits on both chats are used to monitor the mean and variation of the process going forward. Consider the cost of sampling, required resources, and balance with minimizing time (and produced units) between measurements. First the r chart is constructed. Examine the xbar chart to determine whether the process mean is in control. Web what are x bar r control charts? They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Collect initial set of samples. Determine the sample size, n, and frequency of sampling. Using the smart, intuitive system, these visual snapshots are just two clicks away. Armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. Examine the r chart to determine whether the process variation is in control. Identify which points failed each test. Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits.

Statistical Process Control (SPC) CQE Academy

Control Limits for Individual Sample Yields limits that differ from

X Bar R Chart Example

Xbar R Control Chart Quality Gurus

XBarR Control Charts YouTube

Xbar and R Chart Formula and Constants The Definitive Guide

X Bar R Chart Template Chart Examples

Control Limits for xbar r chart show out of control conditions

X Bar And R Chart

How To Analyze Xbar And R Charts Chart Walls

Web Example Of Control Chart:

→ In This Example, We Will Learn How To Make A Control Chart.

At The Start Of Each Hour, You Collect Five Samples From The Production Line And Measure A Quality Characteristic, X.

Web In Statistical Process Control (Spc), The ¯ And R Chart Is A Type Of Scheme, Popularly Known As Control Chart, Used To Monitor The Mean And Range Of A Normally Distributed Variables Simultaneously, When Samples Are Collected At Regular Intervals From A Business Or Industrial Process.

Related Post: