X Bar R Chart

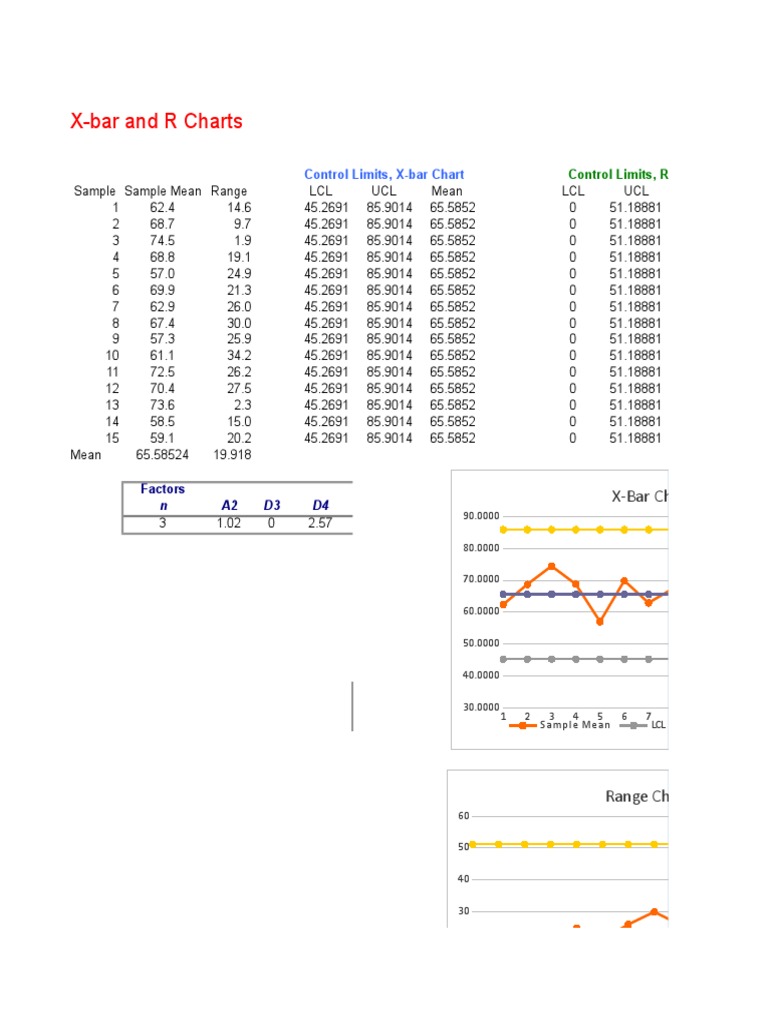

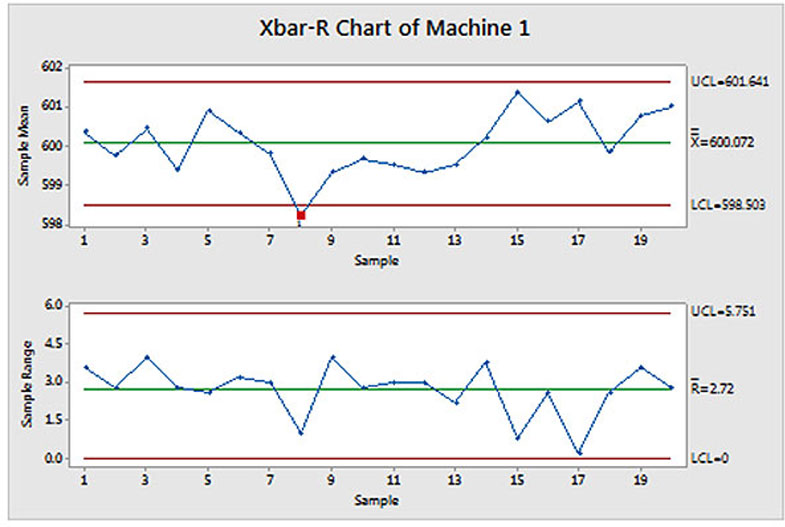

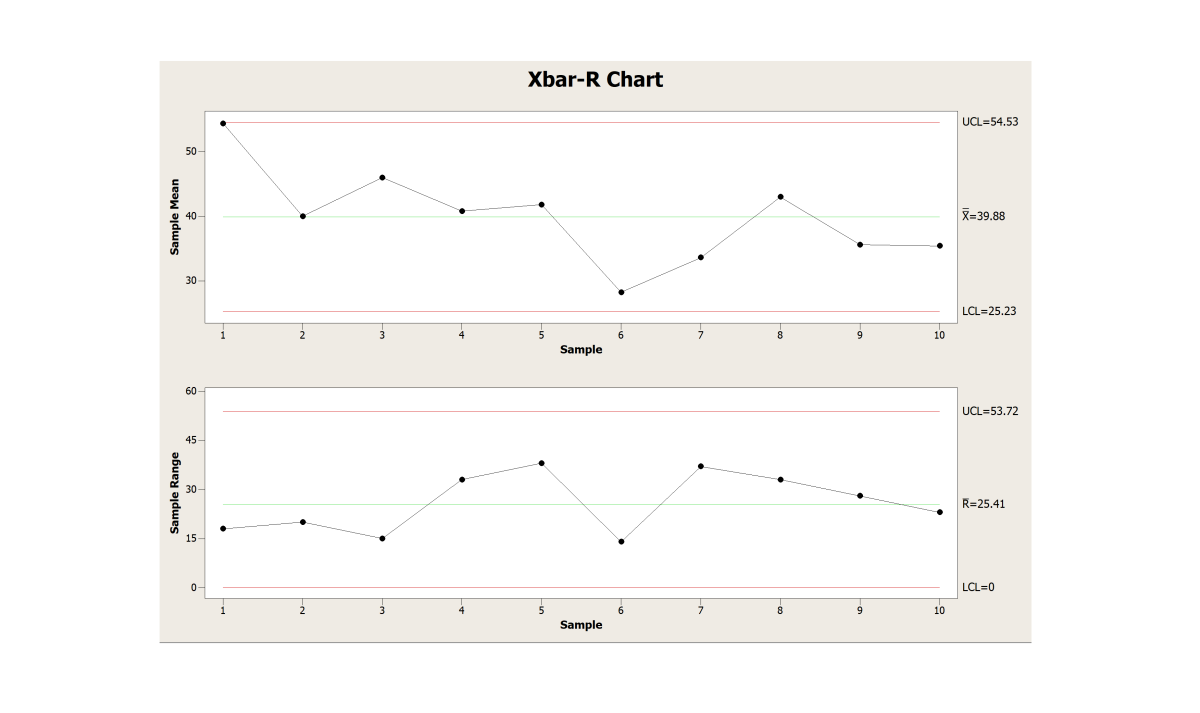

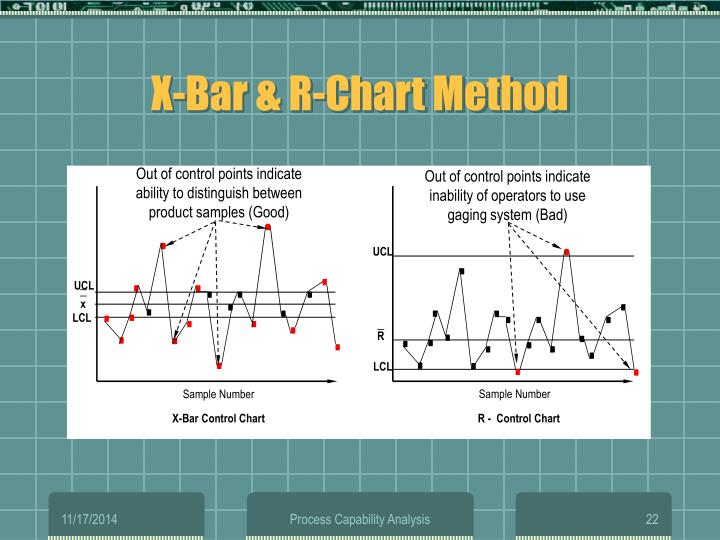

X Bar R Chart - Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). Once we compute the control limits for the range chart, we will study the range chart. The control limits for the chart depends on the process variability, \bar { r } rˉ. Selection of the appropriate control chart is very important in control chart mapping; Web statistical process control provides a mechanism for measuring, managing, and controlling processes. The centerline represents the average of all the 10 subgroup averages = 22.95. The sample size cannot vary. The data should be collected in a random and consecutive manner. Before you interpret the xbar chart, examine the r chart to determine whether the process variation is in control. The r chart plots the subgroup ranges. The centerline represents the average of all the 10 subgroup averages = 22.95. The mean of the first subgroup of 23.2, 24.2, 23.6, 22.9, 22.0 = 23.18. The r chart plots the subgroup ranges. The data must be continuous. Notice the first data point in the xbar chart is the mean of the first subgroup. The centerline represents the average of all the 10 subgroup averages = 22.95. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. The data. Examine the r chart to determine whether the process variation is in control. If the r chart is not in control, then the control limits on the xbar chart are not accurate. For example, if your sample size was 7, you would use 0.419, 1.924 and 0.076, respectively, for a2, d4, and d3. The control limits for the chart depends. Web statistical process control provides a mechanism for measuring, managing, and controlling processes. The r chart plots the subgroup ranges. The centerline represents the average of all the 10 subgroup averages = 22.95. Web here is the table where the value of the constants are taken from based on the size of the subgroup or sample. The sample size cannot. Web here is the table where the value of the constants are taken from based on the size of the subgroup or sample. The data should be collected in a random and consecutive manner. Selection of the appropriate control chart is very important in control chart mapping; The r chart plots the subgroup ranges. The data must be continuous. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). The sample size cannot vary. In statistical process control (spc), the and r chart is a type of. The data must be continuous. Before you interpret the xbar chart, examine the r chart to determine whether the process variation is in control. Once we compute the control limits for the range chart, we will study the range chart. Web x̅ and r chart. Web x bar r charts are the widely used control charts for variable data to. The sample size cannot vary. Determine an appropriate subgroup size and sampling. The mean of the first subgroup of 23.2, 24.2, 23.6, 22.9, 22.0 = 23.18. Examine the r chart to determine whether the process variation is in control. The upper control limit (ucl) = 3 sigma above the center line = 23.769. Web here is the table where the value of the constants are taken from based on the size of the subgroup or sample. If the range chart is not in control, the control limits for the \bar { x } x ˉ chart will have no meaning. Notice the first data point in the xbar chart is the mean of. The upper control limit (ucl) = 3 sigma above the center line = 23.769. Web when working with an xbar and r chart, we begin with the r chart. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call. Selection of the appropriate control chart is very important in control chart mapping; Notice the first data point in the xbar chart is the mean of the first subgroup. Web x̅ and r chart. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. If the r chart is not in control, then the control limits on the xbar chart are not accurate. Web statistical process control provides a mechanism for measuring, managing, and controlling processes. The centerline represents the average of all the 10 subgroup averages = 22.95. The sample size cannot vary. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). Examine the r chart to determine whether the process variation is in control. The data must be continuous. The mean of the first subgroup of 23.2, 24.2, 23.6, 22.9, 22.0 = 23.18. Web here is the table where the value of the constants are taken from based on the size of the subgroup or sample. Once we compute the control limits for the range chart, we will study the range chart. Determine an appropriate subgroup size and sampling. Web when working with an xbar and r chart, we begin with the r chart.

Difference Between XBar and RChart and How They Are Used ROP

X Bar Control Chart PresentationEZE

Control Limits for xbar r chart show out of control conditions

Control Limits for Individual Sample Yields limits that differ from

XBar & R Chart Template Rev PDF Descriptive Statistics

X Bar R Chart Template Chart Examples

Xbar R Control Chart Quality Gurus

How to Create an XbarR Chart in Minitab 18 ToughNickel

X Bar And R Chart

Xbar and R Chart Formula and Constants The Definitive Guide

The Upper Control Limit (Ucl) = 3 Sigma Above The Center Line = 23.769.

For Example, If Your Sample Size Was 7, You Would Use 0.419, 1.924 And 0.076, Respectively, For A2, D4, And D3.

The R Chart Plots The Subgroup Ranges.

The Data Should Be Collected In A Random And Consecutive Manner.

Related Post: