X Bar R Chart Example

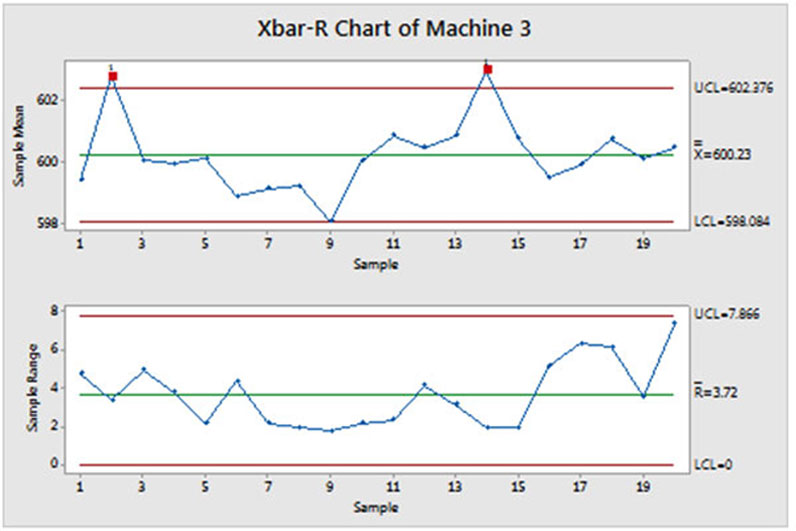

X Bar R Chart Example - I showed how we can derive the xbar and r chart constants, d 2. Simply copy your data into the table and select the measurements. The xbar chart will then be created for you online. Let us understand how to make xbar chart and r chart with the help of an example. Three machines manufacture camshafts for three shifts each day. Examine the r chart to determine whether the process variation is in control. A quality engineer at an automotive parts plant monitors the lengths of camshafts. But is there a difference between them? Use this control chart to monitor. Suppose an engineer wants to monitor a manufacturing. Used for measurement data assumes population is normally distributed upper and lower control limits usually 3 standard deviations above and below. Use this control chart to monitor. A quality engineer at an automotive parts plant monitors the lengths of camshafts. Let us understand how to make xbar chart and r chart with the help of an example. Are they complementing. I showed how we can derive the xbar and r chart constants, d 2. Used for measurement data assumes population is normally distributed upper and lower control limits usually 3 standard deviations above and below. Let us understand how to make xbar chart and r chart with the help of an example. Are they complementing each other like peanut butter. But is there a difference between them? A quality engineer at an automotive parts plant monitors the lengths of camshafts. Use this control chart to monitor. Web steps in constructing the xbar chart. Example of an xbarr chart (average and range chart) created by qi. A quality engineer at an automotive parts plant monitors the lengths of camshafts. Used for measurement data assumes population is normally distributed upper and lower control limits usually 3 standard deviations above and below. The xbar chart will then be created for you online. Three machines manufacture camshafts for three shifts each day. Input your data set into. Used for measurement data assumes population is normally distributed upper and lower control limits usually 3 standard deviations above and below. Are they complementing each other like peanut butter and jelly, or are. Find the mean of each subgroup xbar (1), xbar (2), xbar (3)… xbar (k) and the grand mean of all subgroups using:. Three machines manufacture camshafts for. You will find the chart listed under may different names, including: Suppose an engineer wants to monitor a manufacturing. Are they complementing each other like peanut butter and jelly, or are. Find the mean of each subgroup xbar (1), xbar (2), xbar (3)… xbar (k) and the grand mean of all subgroups using:. Simply copy your data into the table. Suppose an engineer wants to monitor a manufacturing. But is there a difference between them? Whenever a value on a control chart is beyond the upper control limit (ucl) or lower control limit (lcl), the process is said to. Example of an xbarr chart (average and range chart) created by qi. Examine the r chart to determine whether the process. A quality engineer at an automotive parts plant monitors the lengths of camshafts. Examine the xbar chart to determine whether the process mean is in control. Are they complementing each other like peanut butter and jelly, or are. Web steps in constructing the xbar chart. You will find the chart listed under may different names, including: Are they complementing each other like peanut butter and jelly, or are. Examine the r chart to determine whether the process variation is in control. Input your data set into. A quality engineer at an automotive parts plant monitors the lengths of camshafts. Whenever a value on a control chart is beyond the upper control limit (ucl) or lower control. Let us understand how to make xbar chart and r chart with the help of an example. You will find the chart listed under may different names, including: Web this article provides a foundation for readers to use to derive and build their own xbar and r chart. Web steps in constructing the xbar chart. But is there a difference. Find the mean of each subgroup xbar (1), xbar (2), xbar (3)… xbar (k) and the grand mean of all subgroups using:. Use this control chart to monitor. Suppose an engineer wants to monitor a manufacturing. Whenever a value on a control chart is beyond the upper control limit (ucl) or lower control limit (lcl), the process is said to. You will find the chart listed under may different names, including: Used for measurement data assumes population is normally distributed upper and lower control limits usually 3 standard deviations above and below. Let us understand how to make xbar chart and r chart with the help of an example. Are they complementing each other like peanut butter and jelly, or are. I showed how we can derive the xbar and r chart constants, d 2. Examine the xbar chart to determine whether the process mean is in control. Example of an xbarr chart (average and range chart) created by qi. Simply copy your data into the table and select the measurements. Examine the r chart to determine whether the process variation is in control. But is there a difference between them? Web steps in constructing the xbar chart. Input your data set into.

X Bar R Chart Template Chart Examples

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

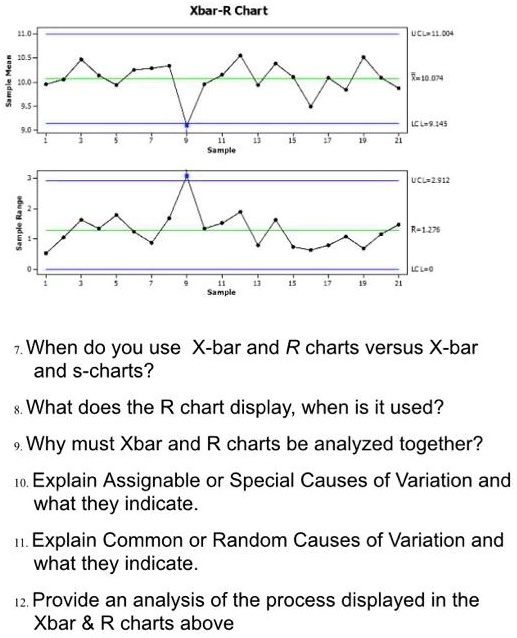

SOLVED XbarR Chart WMAA FJO 074 LEIR When do you use Xbar and R

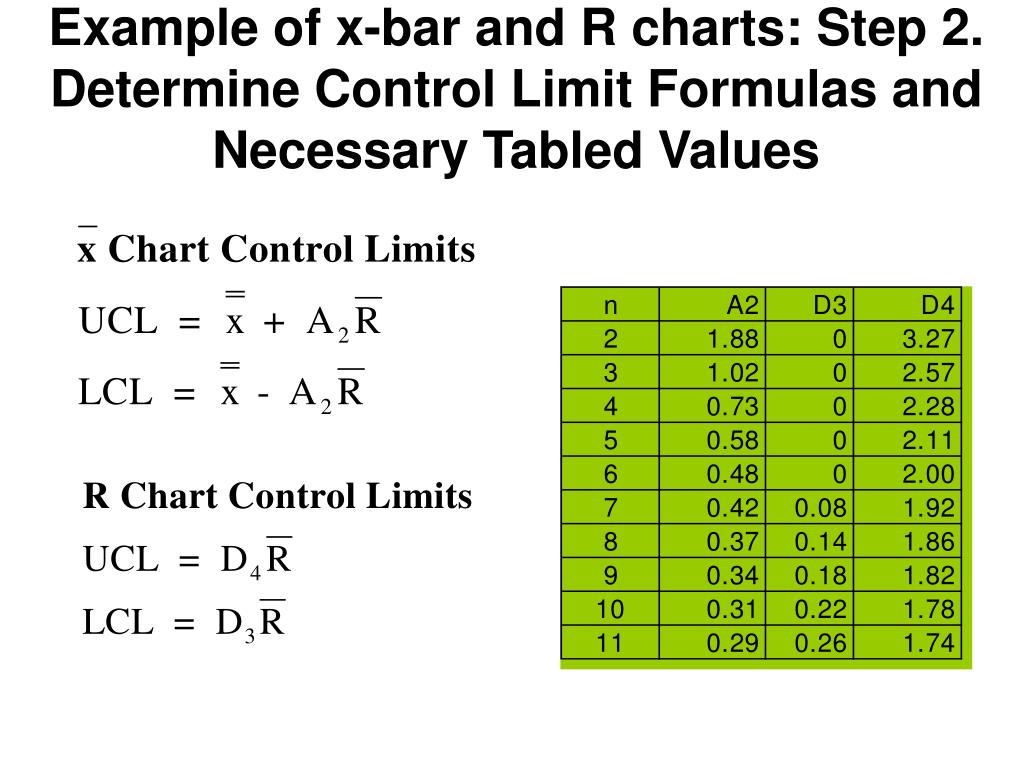

Xbar and R Chart Formula and Constants The Definitive Guide

Control Limits for Individual Sample Yields limits that differ from

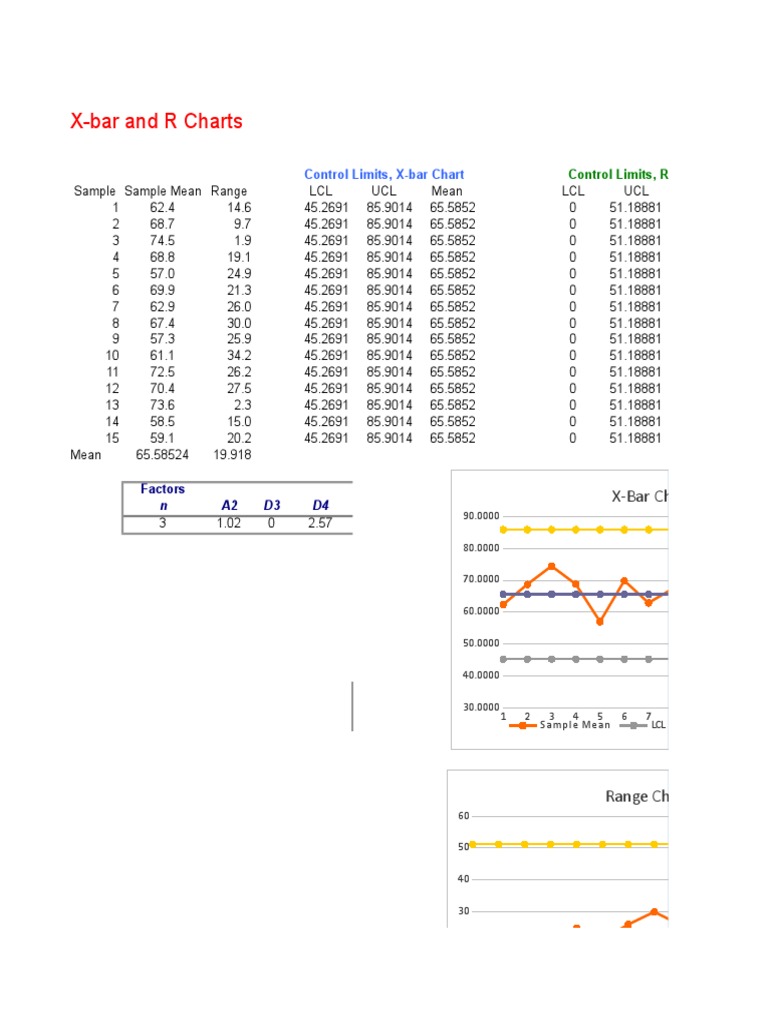

XBar & R Chart Template Rev PDF Descriptive Statistics

X Bar R Chart Example

How To Analyze Xbar And R Charts Chart Walls

Control Limits for xbar r chart show out of control conditions

XBar and R Charts Definition

Three Machines Manufacture Camshafts For Three Shifts Each Day.

A Quality Engineer At An Automotive Parts Plant Monitors The Lengths Of Camshafts.

Web This Article Provides A Foundation For Readers To Use To Derive And Build Their Own Xbar And R Chart.

The Xbar Chart Will Then Be Created For You Online.

Related Post: