X Bar And R Control Chart

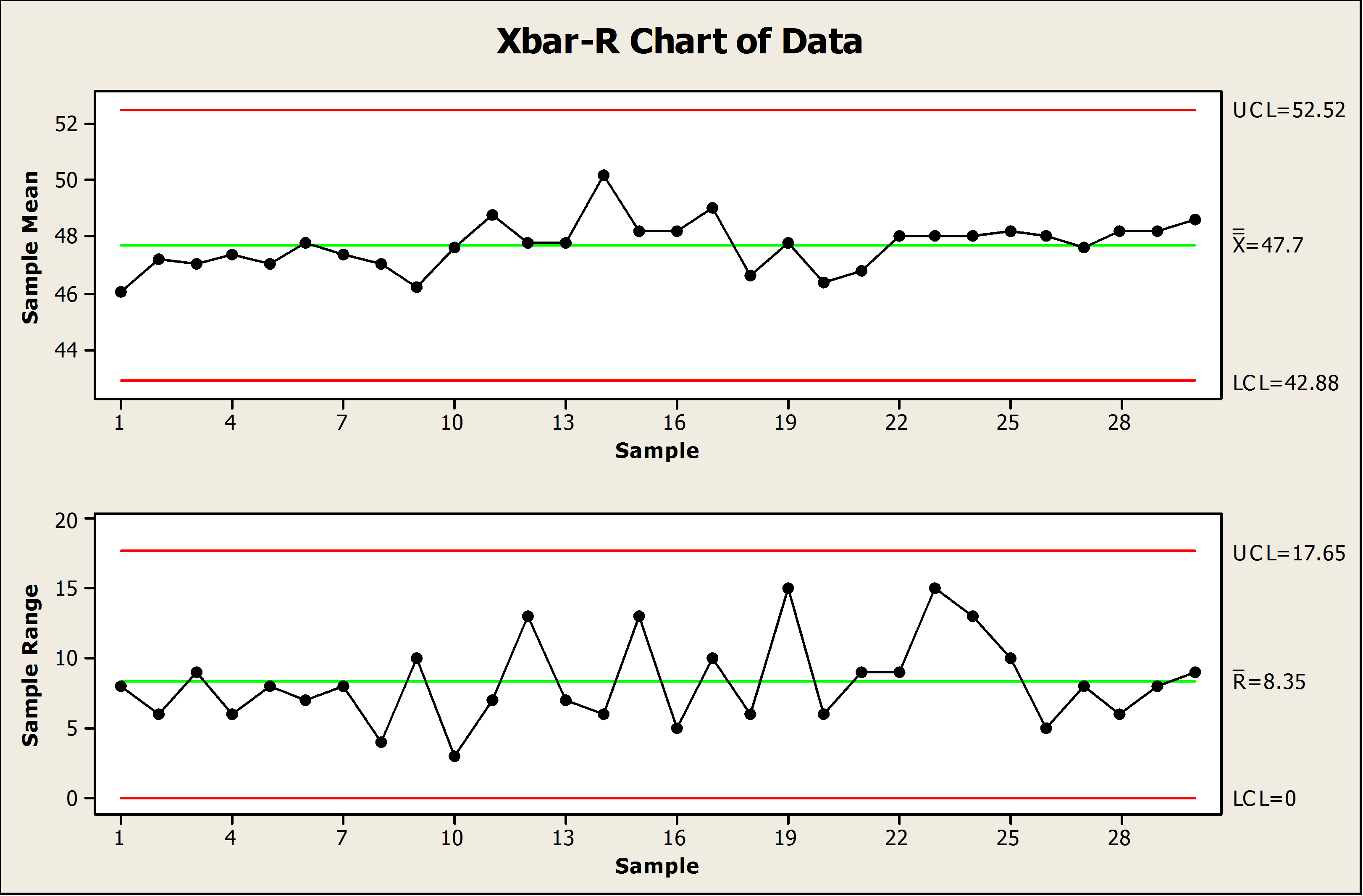

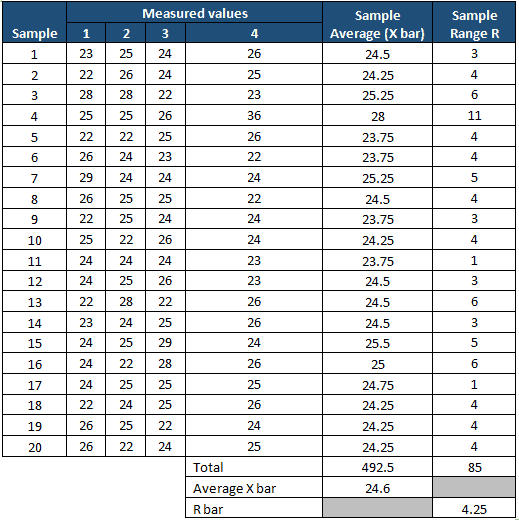

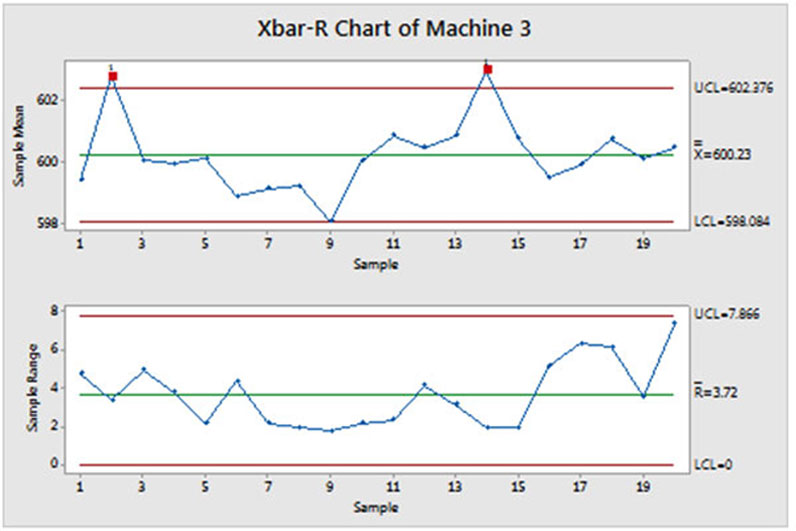

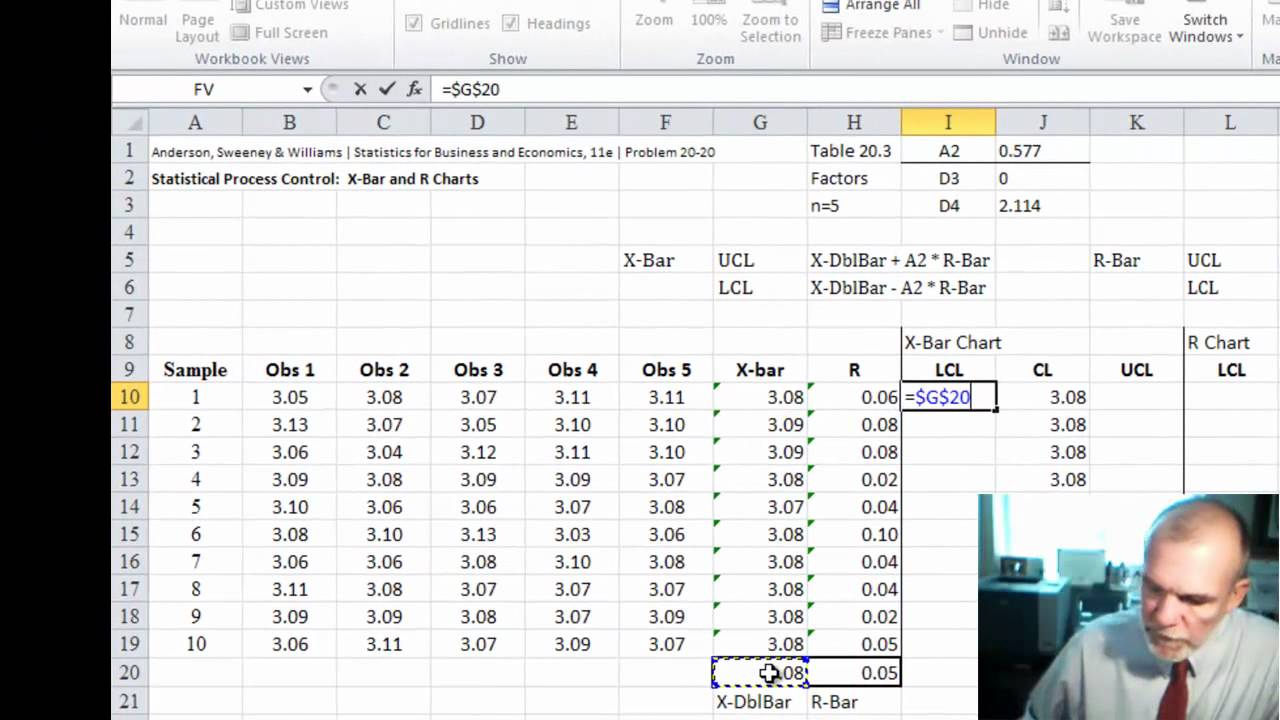

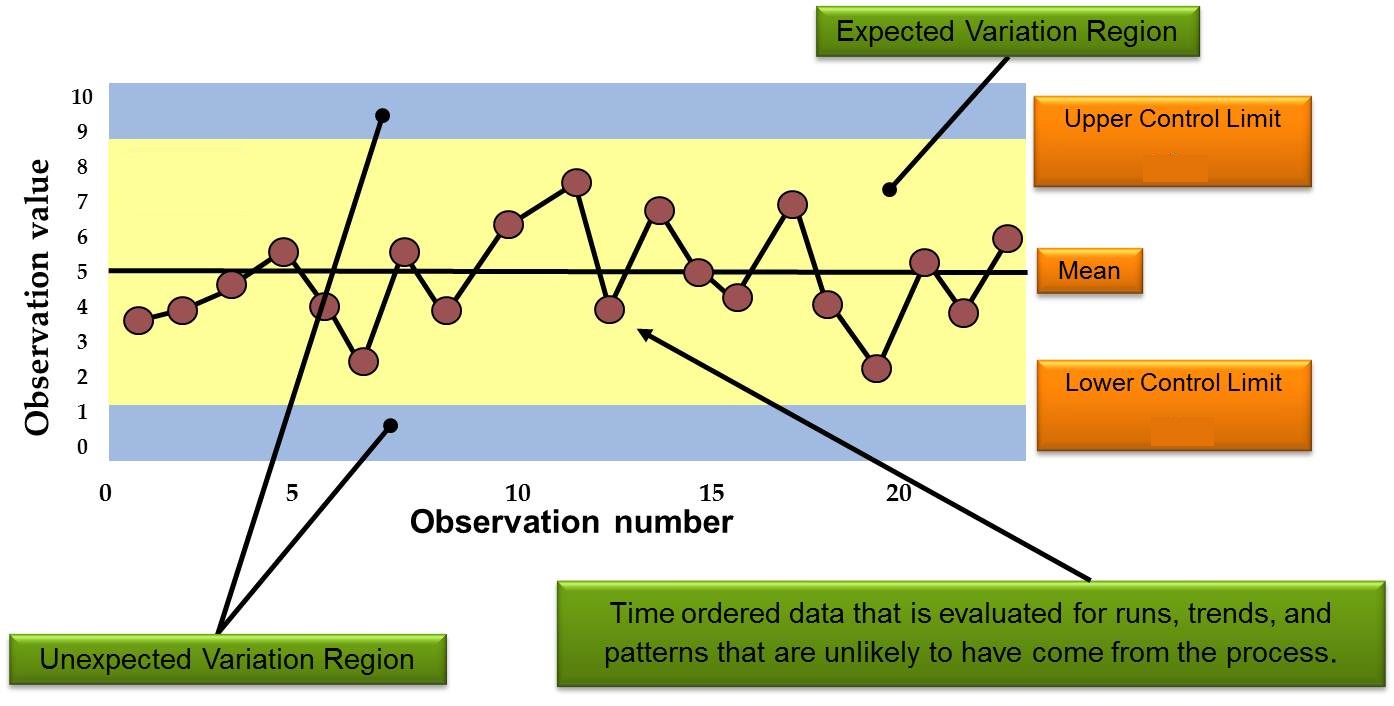

X Bar And R Control Chart - The control limits on the x bar consider the. To add the additional data to this chart, click sigmaxl chart. The mean or average change in a process over time from subgroup values. This is currently a stable catapult process. Web this is not difficult and by following the 8 steps below you will have a robust way to monitor the stability of your process. Web the florida bar journal, june 1997. Ten things to know when using the individuals control charts; Comprehend, visualize, and interpret zoning code in the following ways:. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables. Consists of two charts displaying central tendency and variability. Web the xbar & r chart is the most commonly used control chart. Subgroups 21 to 25 were added afterwards. Determine the sample size, n,. Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. Web the florida bar journal, june 1997. Orange county has adopted the gridics 3d zoning map, text, and property data platform. Web the florida bar journal, june 1997. This publication examined two comments that. The control limits on the x bar consider the. Consists of two charts displaying central tendency and variability. Ten things to know when using the individuals control charts; The target mean, the standard deviation of the samples, and the sample size. Consists of two charts displaying central tendency and variability. Orange county has adopted the gridics 3d zoning map, text, and property data platform. To add the additional data to this chart, click sigmaxl chart. Web this is not difficult and by following the 8 steps below you will have a robust way to monitor the stability of your process. This publication examined two comments that. Web when working with an xbar and r chart, we begin with the r chart. Web armed with this background we can now develop the \(\bar{x}\) and \(r\) control. This publication examined two comments that. The target mean, the standard deviation of the samples, and the sample size. Web this is not difficult and by following the 8 steps below you will have a robust way to monitor the stability of your process. Comprehend, visualize, and interpret zoning code in the following ways:. Subgroups 21 to 25 were added. The control limits on the x bar consider the. Subgroups 21 to 25 were added afterwards. Web this is not difficult and by following the 8 steps below you will have a robust way to monitor the stability of your process. Web the florida bar journal, june 1997. The mean or average change in a process over time from subgroup. The control limits for the chart depends on the process variability, \bar { r }. Subgroups 21 to 25 were added afterwards. Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. This is currently a stable catapult process. To add the additional data to this chart, click sigmaxl chart. Web the florida bar journal, june 1997. The target mean, the standard deviation of the samples, and the sample size. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables. The mean or average change in a. The control limits on the x bar consider the. Web when working with an xbar and r chart, we begin with the r chart. The target mean, the standard deviation of the samples, and the sample size. Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. The average range is $$. Web when working with an xbar and r chart, we begin with the r chart. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables. Subgroups 21 to 25 were added afterwards. The mean or average change. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables. To add the additional data to this chart, click sigmaxl chart. The average range is $$. Web armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. This is currently a stable catapult process. The mean or average change in a process over time from subgroup values. The control limits for the chart depends on the process variability, \bar { r }. Consists of two charts displaying central tendency and variability. Web the florida bar journal, june 1997. The control limits on the x bar consider the. Determine the sample size, n,. Web when working with an xbar and r chart, we begin with the r chart. Ten things to know when using the individuals control charts; Comprehend, visualize, and interpret zoning code in the following ways:. The range (r) chart shows the variation within each variable (called subgroups). Subgroups 21 to 25 were added afterwards.

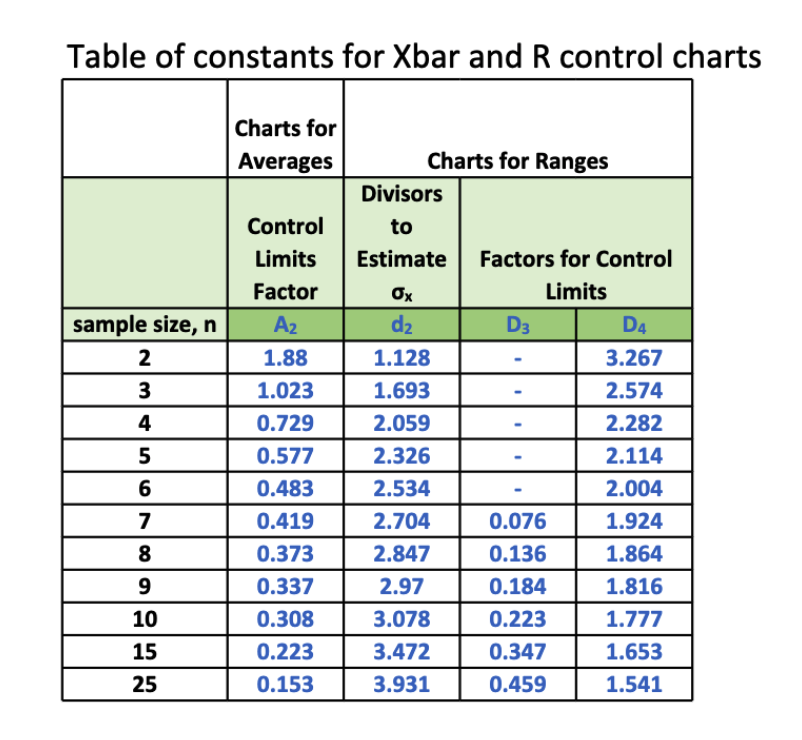

Solved Table of constants for Xbar and R control charts

Statistical Process Control (SPC) Christian Gould

X Bar R Control Charts

Difference Between XBar and RChart and How They Are Used ROP

XBarR Control Charts YouTube

Xbar R Control Chart Quality Gurus

After discussing the several aspects and uses ofXbar and R Charts, we

Control Limits for xbar r chart show out of control conditions

Xbar and R Chart Formula and Constants The Definitive Guide

Control Chart X Bar

Web This Is Not Difficult And By Following The 8 Steps Below You Will Have A Robust Way To Monitor The Stability Of Your Process.

Orange County Has Adopted The Gridics 3D Zoning Map, Text, And Property Data Platform.

The Target Mean, The Standard Deviation Of The Samples, And The Sample Size.

This Publication Examined Two Comments That.

Related Post: