Worm Wheel Gear Design

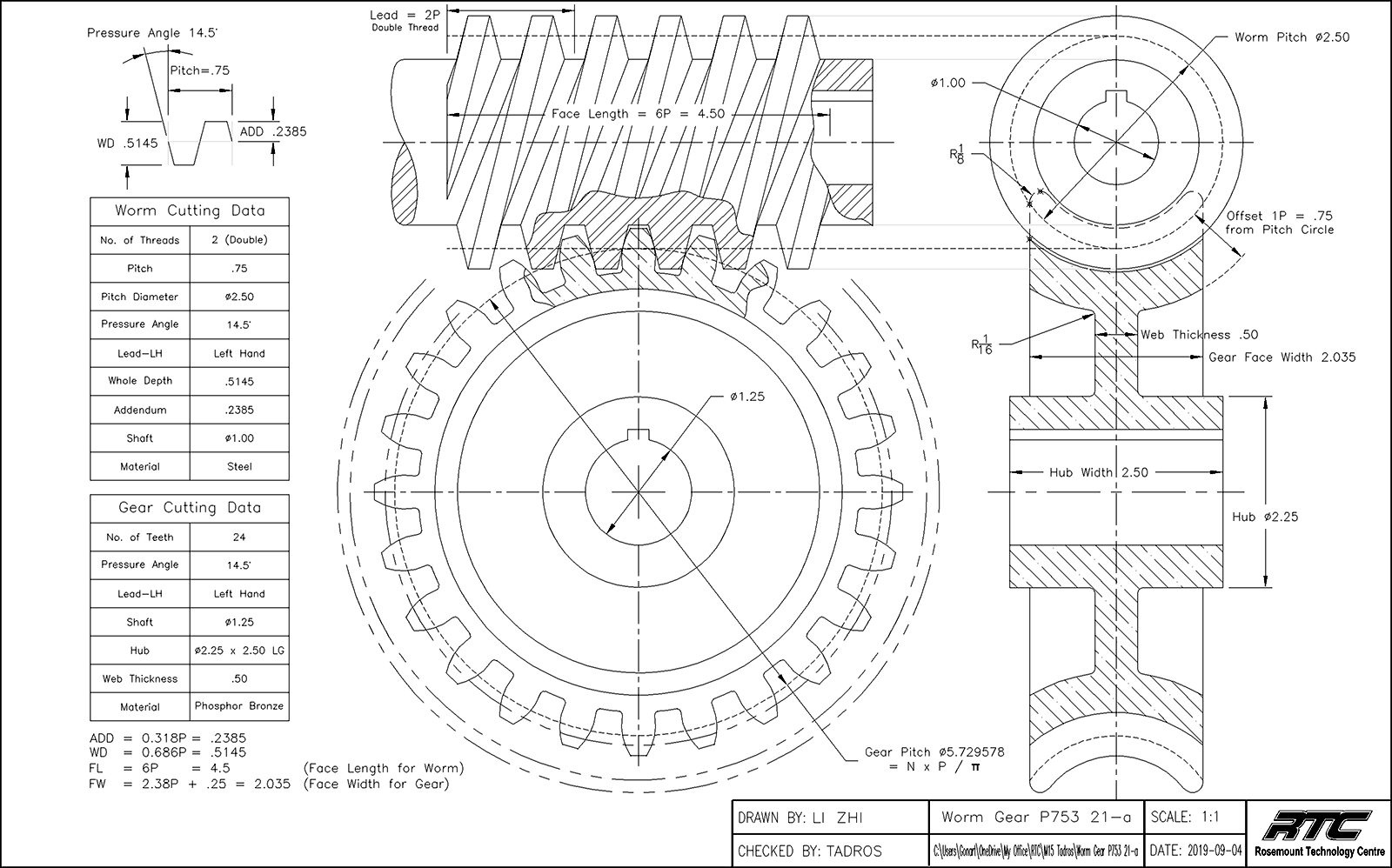

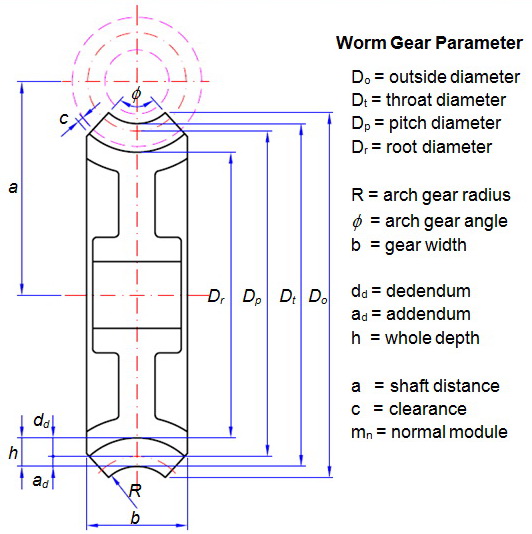

Worm Wheel Gear Design - Zar3+ provides an additional input window for modifications of tooth height factors and profile shift. Web the range of geared motors encompasses all gear unit types from helical, offset shaft, helical bevel, helical worm up to worm geared motors. If gear life is not given: Web we are a gear manufacturing company in wildwood, fl, that’s committed to manufacturing custom gears that meet the highest standards of precision and performance. We also offer stock duplex. The efficiency of a worm gear. L = lead of a worm which is the distance any one thread advances in a single revolution. Web worm gears are a type of mechanical power transmission system that consist of a worm (a threaded shaft) and a gear (known as the worm wheel or worm. Not only can it eliminate abnormal tooth contact due to incorrect assembly, but it also provides for the forming of. Web a worm gearbox is a type of gearbox that uses a combination of shafts, worm gears, bearings and toothed wheels to produce movement. Web khk stock worms and worm wheels are available in modules 0.5 to 6 and in speed ratios of 1/10 to 1/120, made in a variety of materials and styles. Web this worm gear design tutorial will discuss up to the selection of the module and pitch and the calculation of the number of teeth, pitch circle diameter and centre. They can be used to. Web the range of geared motors encompasses all gear unit types from helical, offset shaft, helical bevel, helical worm up to worm geared motors. If gear life is not given: Design of bevel gear method 1: Zar3+ provides an additional input window for modifications of tooth height factors and profile shift. Not only can it eliminate abnormal tooth contact due to incorrect assembly, but it also provides for the forming of. Web this worm gear design tutorial will discuss up to the selection of the module and pitch and the calculation of the number of teeth, pitch circle diameter and centre to centre distance. If gear life is not given: Web. Design of bevel gear method 1: The geared motors have a range. L = lead of a worm which is the distance any one thread advances in a single revolution. Web worm gear design parameters. However, the tooth surface is produced in a concave shape in order to improve the surface contact area with the. Web design of worm and worm wheel. Web khk stock worms and worm wheels are available in modules 0.5 to 6 and in speed ratios of 1/10 to 1/120, made in a variety of materials and styles. Web we also specialize in repairing crane wheels, pumps, rolls, screws and barrels, cutting equipments, gearboxes and gears. We know how important this. The geared motors have a range. Web khk stock worms and worm wheels are available in modules 0.5 to 6 and in speed ratios of 1/10 to 1/120, made in a variety of materials and styles. If gear life is not given: The efficiency of a worm gear. Web a worm drive is a gear arrangement in which a worm. Not only can it eliminate abnormal tooth contact due to incorrect assembly, but it also provides for the forming of. Web worm gear design parameters. We also offer stock duplex. Web the range of geared motors encompasses all gear unit types from helical, offset shaft, helical bevel, helical worm up to worm geared motors. Web the worm wheel is similar. Not only can it eliminate abnormal tooth contact due to incorrect assembly, but it also provides for the forming of. Web we also specialize in repairing crane wheels, pumps, rolls, screws and barrels, cutting equipments, gearboxes and gears. Web the range of geared motors encompasses all gear unit types from helical, offset shaft, helical bevel, helical worm up to worm. Web a worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm wheel (which is similar in appearance to a spur gear). Web a worm gearbox is a type of gearbox that uses a combination of shafts, worm gears, bearings and toothed wheels to produce movement.. Web worm and wormgear design equations and calculator. We also offer stock duplex. Web united gear works has over 55 years of experience repairing gearboxes, pumps, and gears. Not only can it eliminate abnormal tooth contact due to incorrect assembly, but it also provides for the forming of. Web a worm gearbox is a type of gearbox that uses a. As a design manual, this. However, the tooth surface is produced in a concave shape in order to improve the surface contact area with the. Zar3+ provides an additional input window for modifications of tooth height factors and profile shift. Web we also specialize in repairing crane wheels, pumps, rolls, screws and barrels, cutting equipments, gearboxes and gears. Web khk stock worms and worm wheels are available in modules 0.5 to 6 and in speed ratios of 1/10 to 1/120, made in a variety of materials and styles. Design of bevel gear method 1: We know how important this equipment is for you and our services are available. Web united gear works has over 55 years of experience repairing gearboxes, pumps, and gears. We also offer stock duplex. Web this worm gear design tutorial will discuss up to the selection of the module and pitch and the calculation of the number of teeth, pitch circle diameter and centre to centre distance. If gear life is not given: The pitch line velocity is ideally up to 30 m/s. Web worm and wormgear design equations and calculator. Not only can it eliminate abnormal tooth contact due to incorrect assembly, but it also provides for the forming of. They can be used to. L = lead of a worm which is the distance any one thread advances in a single revolution.

globoid worm gear design siunitfordisplacementinphysics

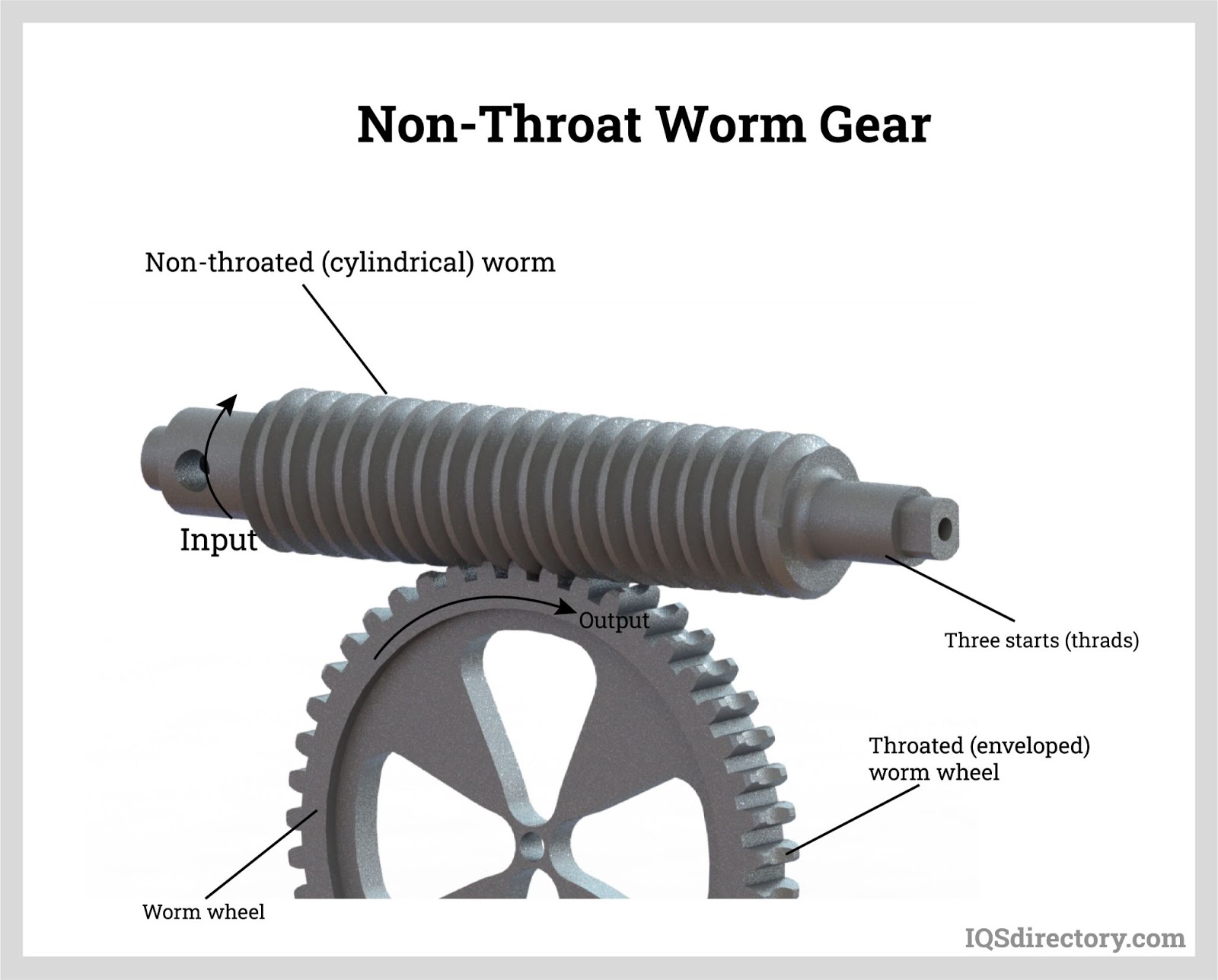

Worm Gear What Is It? How Is it Made? Types Of, Uses

Model of worm wheel with separate detail and marked regions of the

mechanical engineering Worm Gear and Worm Shaft for 2 axis

How Worm Gear Motors Work

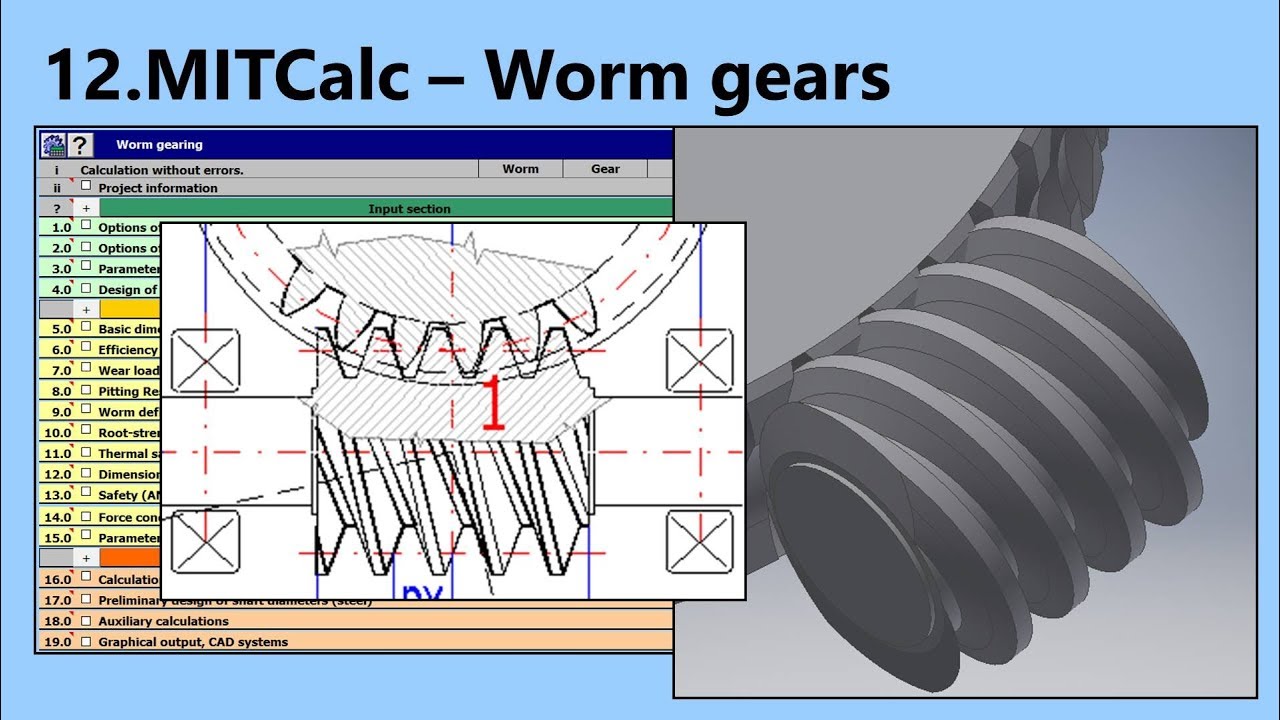

Worm Gear Calculation and Design (MITCalc12) YouTube

Worm gear design calculation pdf to excel dpoksystems

Worm Gear What Is It? How Is it Made? Types Of, Uses

Worm Gear Design Calculation Pdf File rangmillionaire

Worm Gearing Design Standards, Proportions, and Materials

United Gear Works Has The Experience To Rebuild &.

Web We Are A Gear Manufacturing Company In Wildwood, Fl, That’s Committed To Manufacturing Custom Gears That Meet The Highest Standards Of Precision And Performance.

Web Worm Gear Design Parameters.

Web A Worm Gearbox Is A Type Of Gearbox That Uses A Combination Of Shafts, Worm Gears, Bearings And Toothed Wheels To Produce Movement.

Related Post: