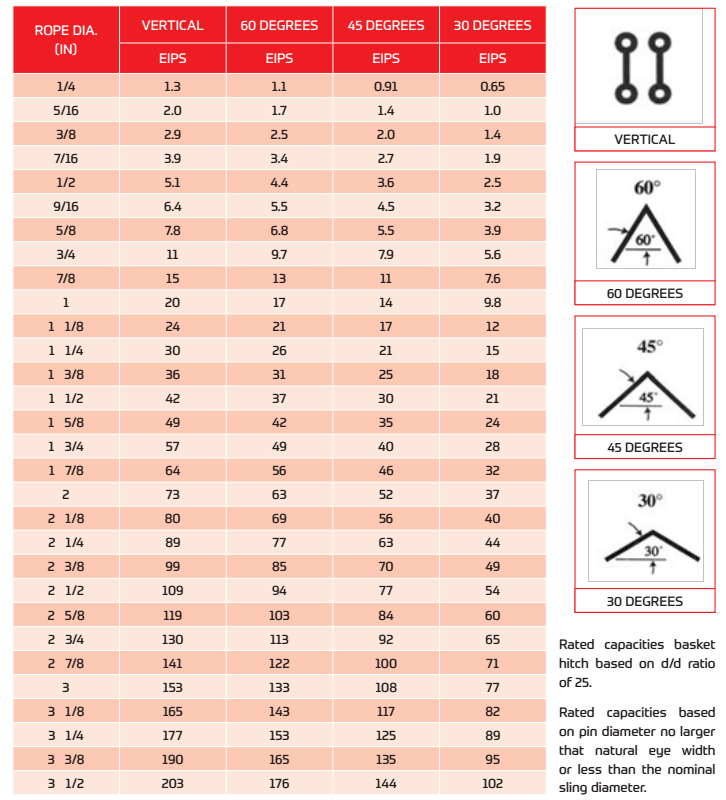

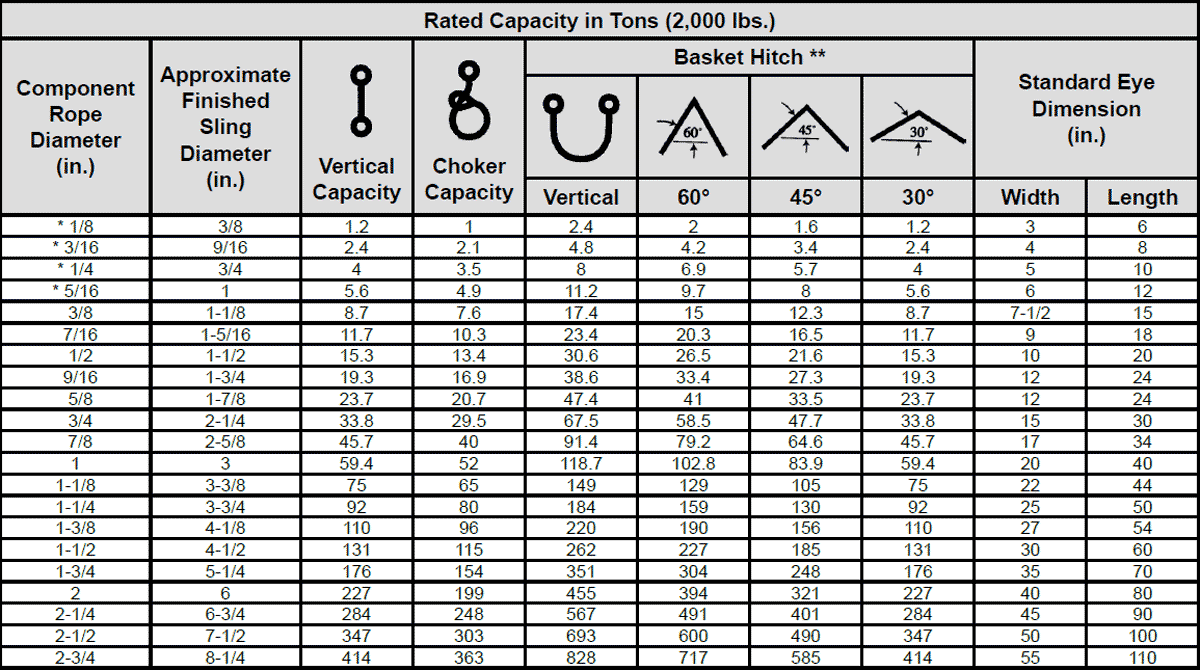

Wire Rope Sling Capacity Chart

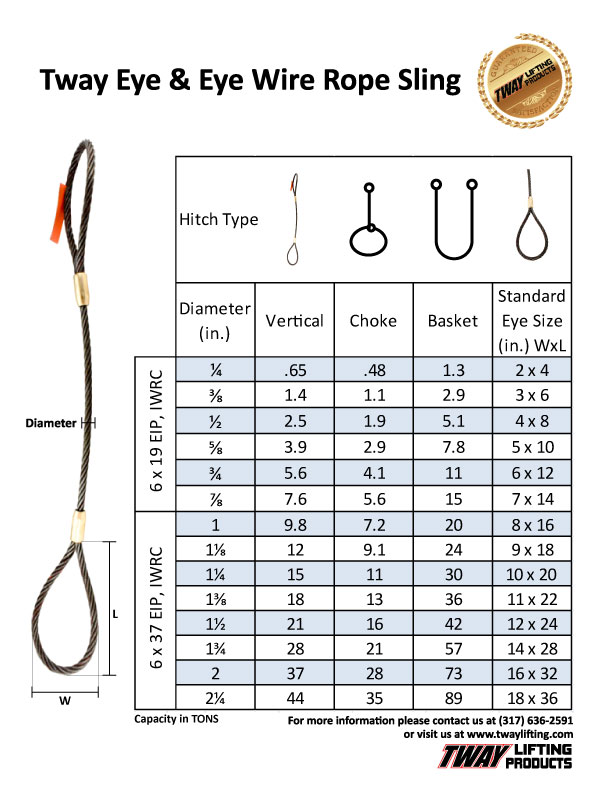

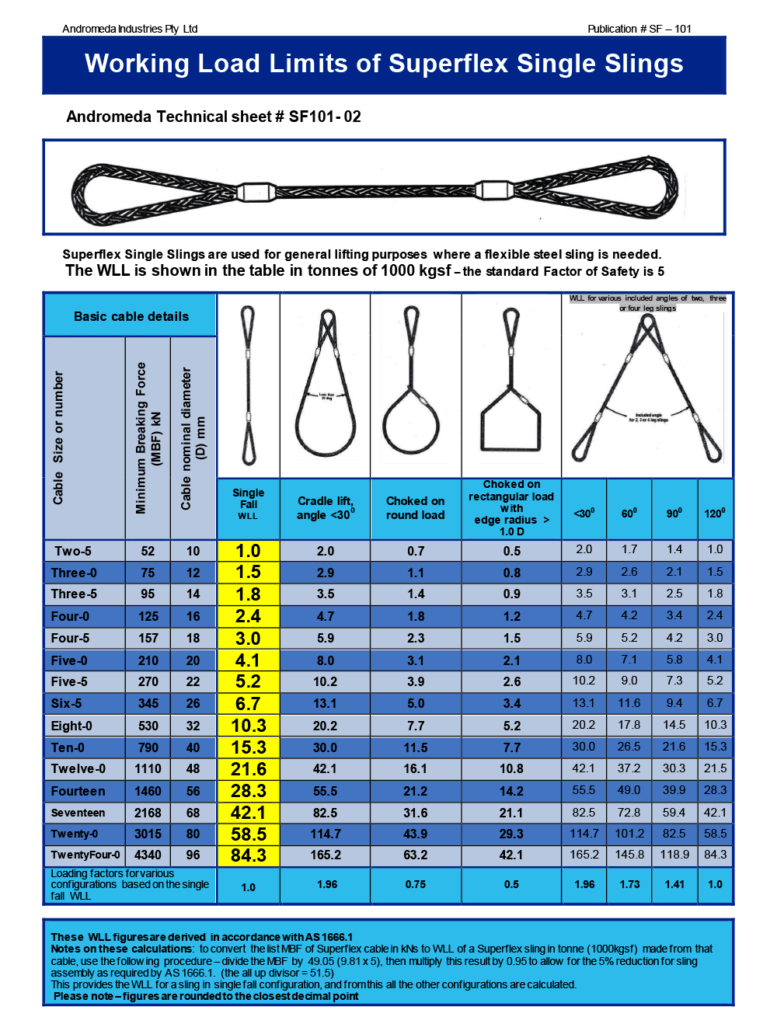

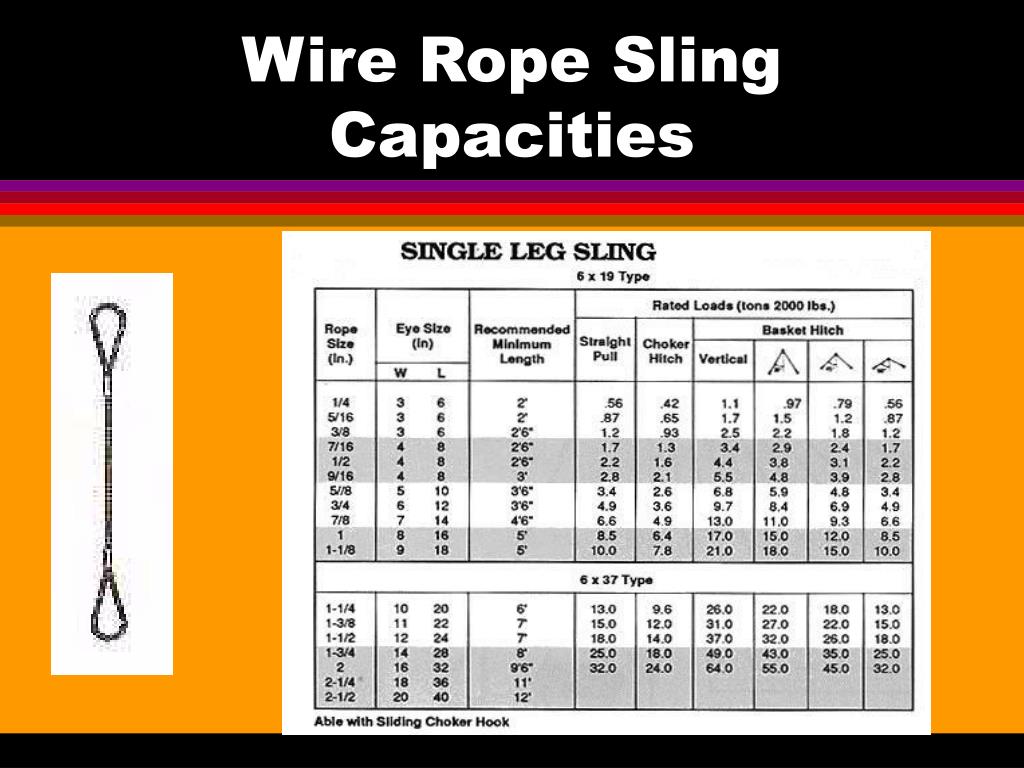

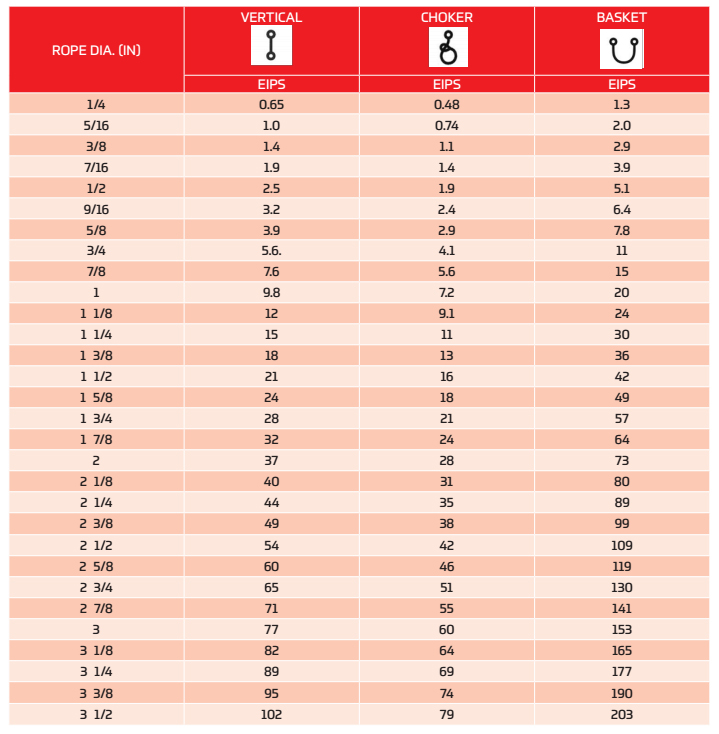

Wire Rope Sling Capacity Chart - Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. For choker hitch, the angle of. • type of hitch being used when lifting the load. Web rated capacity in tons of 2,000 lbs. The contact surface diameter divided by the rope diameter is designated d/d ratio as described in fig. • diameter of the item being lifted where the sling is attached. Rated capacities shown apply only to 6x19 and 6x37 classification wire rope. The listed capacities of wire rope slings/assemblies in this catalog are based on the industrial standard of a 5 to 1 design factor. Web wire rope products may be proof tested upon request. • eficiency of the end termination or eye splice. If they contain swaged terminations and will be used as a sling, they will be 100% proof tested. Basket hitch capacity based on minimum d/d ratio of 25/1. For choker hitch, the angle of. The rated capacities for wire rope slings are based on a design factor of 5 per asme b30.9. Web rated capacity in tons of 2,000 lbs. Tables 18, 19, and 20 are based on the d/d ratios indicated below. Web the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used in the sling and other factors that affect the overall strength of the sling, including: The scale below shows the relative position of the sling. • diameter of the item being lifted where the sling is attached. Web the symbols below represent load or support surfaces in contact with the rope sling. Sling weight = (length x per foot weight) + zero base weight. Web the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope. Rated capacities shown apply only to 6x19 and 6x37 classification wire rope. Web the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number of parts of rope in slin g and number of sling legs) and sling application components (angle of legs, type of hitch, d/d ratios, etc.) • diameter of. Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. • diameter of the item being lifted where the sling is attached. Web how to measure an eye & eye, eye & thimble, or thimble & thimble single leg sling, single leg slings, are measured as illustrated. • eficiency of the end termination or eye splice. Web the factors listed below afect the capacity of a wire rope sling: Sling weight = (length x per foot weight) + zero base weight. If they contain swaged terminations and will be used as a sling, they will be 100% proof tested. Tables 18, 19, and 20 are based on. Web wire rope products may be proof tested upon request. Tables 18, 19, and 20 are based on the d/d ratios indicated below. The rated capacities for wire rope slings are based on a design factor of 5 per asme b30.9. Web the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency,. Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. If they contain swaged terminations and will be used as a sling, they will be 100% proof tested. Tables 18, 19, and 20 are based on the d/d ratios indicated below. Web the factors listed below afect. For choker hitch, the angle of. Web the factors listed below afect the capacity of a wire rope sling: If they contain swaged terminations and will be used as a sling, they will be 100% proof tested. Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter.. Web wire rope load limits. • type of hitch being used when lifting the load. For choker hitch, the angle of. Web rated capacity in tons of 2,000 lbs. Web the symbols below represent load or support surfaces in contact with the rope sling. Web wire rope & slings. Basket hitch capacity based on minimum d/d ratio of 25/1. The scale below shows the relative position of the sling constructions shown in this catalog as they pertain to abrasion resistance and flexibility. Web the symbols below represent load or support surfaces in contact with the rope sling. * zero base weight includes oblong link, thimbled eyes and sling hooks. For choker hitch, the angle of. Web rated capacity in tons of 2,000 lbs. • eficiency of the end termination or eye splice. This is the method used to determine the working load limit (wll) of a sling: Tables 18, 19, and 20 are based on the d/d ratios indicated below. The rated capacities for wire rope slings are based on a design factor of 5 per asme b30.9. Web wire rope load limits. Web the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number of parts of rope in slin g and number of sling legs) and sling application components (angle of legs, type of hitch, d/d ratios, etc.) Sling weight = (length x per foot weight) + zero base weight. Web the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used in the sling and other factors that affect the overall strength of the sling, including: If they contain swaged terminations and will be used as a sling, they will be 100% proof tested.

Tway 1/2" Eye & Eye Wire Rope Sling

Super Flex Wire Rope Slings Aluminium Ferrules Lifting Absolute

Wire Rope Sling Capacity Chart

Wire Rope Sling Capacity Chart

Wire Rope Sling Capacity Chart

Wire Rope Sling Capacities All Rigging Co. Rigging Equipment

WireRopeSlingCapacityCharts.pdf Rope Braid

Wire Rope Sling Capacity Chart

Wire Rope Sling Capacities All Rigging Co. Rigging Equipment

Wire Rope Sling Capacity Chart

Web How To Measure An Eye & Eye, Eye & Thimble, Or Thimble & Thimble Single Leg Sling, Single Leg Slings, Are Measured As Illustrated Below.

• Type Of Hitch Being Used When Lifting The Load.

Rated Capacities Shown Apply Only To 6X19 And 6X37 Classification Wire Rope.

Web The Factors Listed Below Afect The Capacity Of A Wire Rope Sling:

Related Post: