Wire Draw

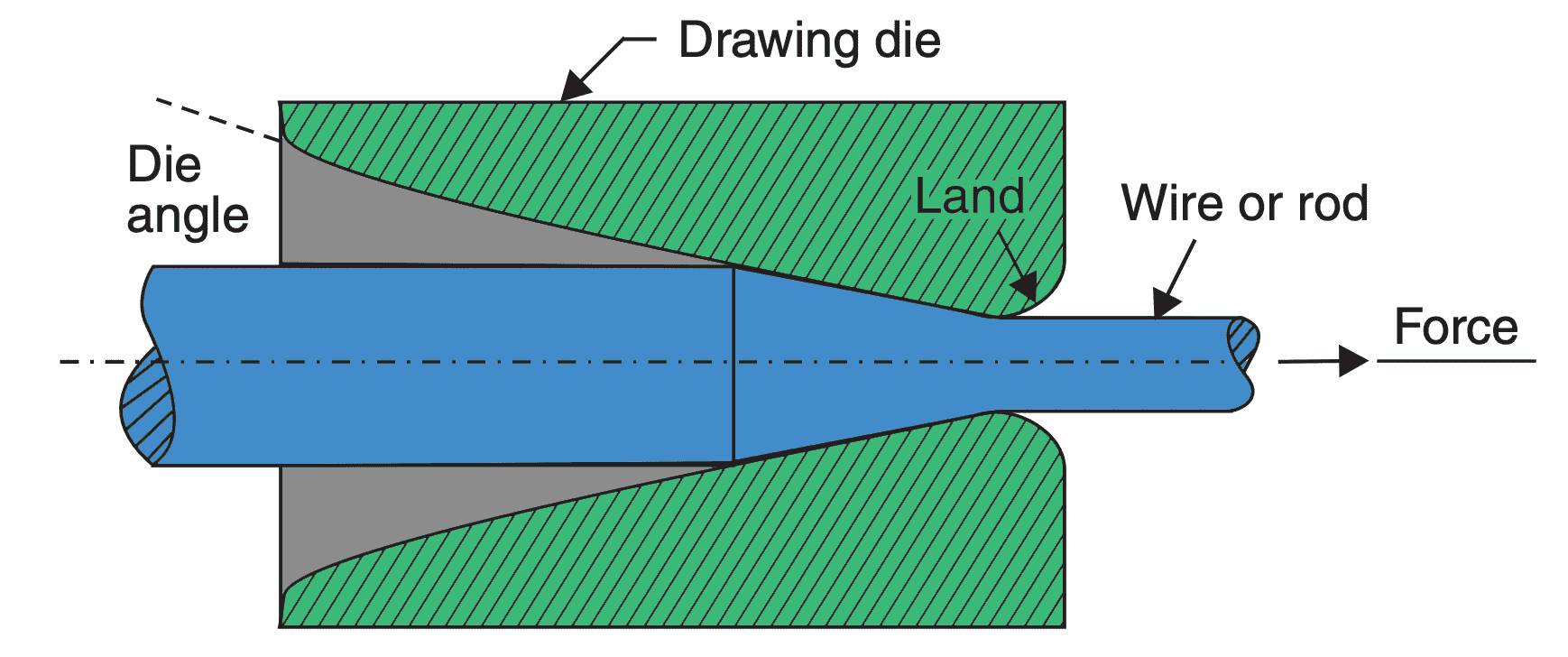

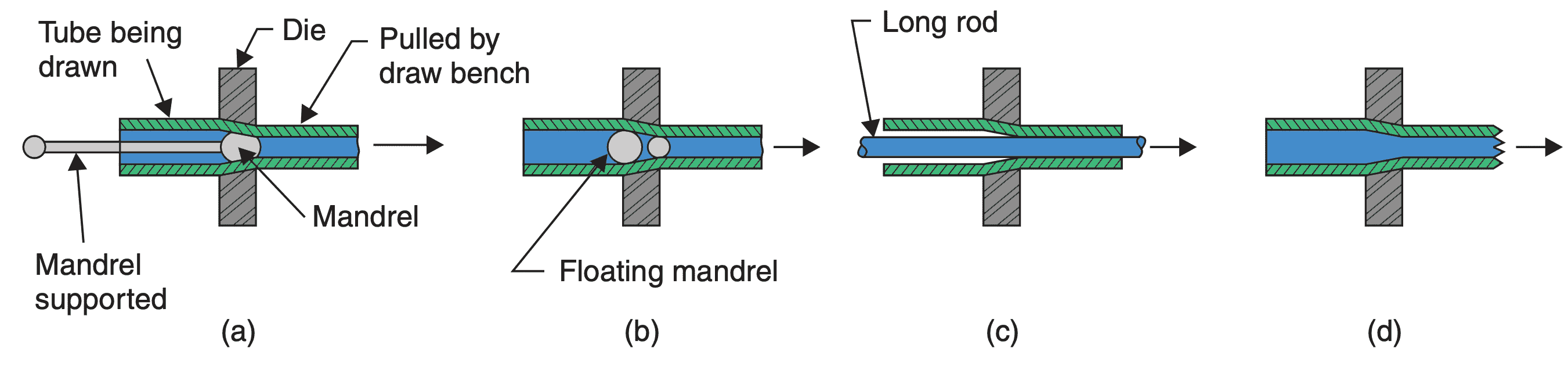

Wire Draw - The block, made to revolve by an electric motor, pulls the lubricated rod through the die, reducing it. Web updated 11:02 am pdt, july 28, 2024. Forging is the plastic, or permanent, changing of a metal shape. Web in metal works, wire drawing and tube drawing is a stretching of a metal or plastic or even glass material to the desired shape in continuous products such as wires and tubes. Modern wire drawing process is similar to the one used centuries ago, however, significant developments have taken place in the machines and the dies. Described as a “lifeguard” by european media, the man drew loud cheers. Web wire drawing is done on continuous drawing machines which consist of multiple draw dies, separated by accumulating drums between the dies. This process is a type of forging. The first known use of wiredraw was in 1598. To draw or stretch forcibly : Ignoring friction and redundant work we can write the draw pressure as: The products are characterized by. 1598, in the meaning defined at sense 1. Polygon spoke with legendary pokémon artist. Nanterre, france (ap) — a man drew hoots and whistles when he stripped down to his tiny briefs and dove in the olympic pool sunday to retrieve a wayward. Complete the wire in your barbed wire drawing. Let us discuss more details about this metalworking process in detail. It is an ancient plastic processing technology. The products are characterized by. These plates were made of hardened steel with several holes through which wire would be drawn to make it longer and thinner. The closer to the handle you mark, the larger the loop will be. Draw the sharp ends on your barbed wire fence drawing. Forging is the plastic, or permanent, changing of a metal shape. See more words from the same year. Polygon spoke with legendary pokémon artist. Web measure and cut your piece of gold or silver wire. Prices taken at time of publishing. Let us discuss more details about this metalworking process in detail. The process is clearly explained in detail. Web bar or wire drawing is a deformation process in which the work piece in the form of cylindrical bar or rod is pulled through. Forging is the plastic, or permanent, changing of a metal shape. Web the selection of wire drawing dies depends on various factors, including the material to be drawn, wire diameter, required tolerances, surface finish, production volume, and cost considerations. In drawing wire, the required deformation is accomplished by drawing the wire through the conical bore section of the die, hereby. Web wire drawing, with the assistance of wire drawing machines, is essential in various cable manufacturing scenarios, including power cables, communication cables, and automotive wiring. Web wire drawing is a cold plastic deformation process by which the diameter of a rod or a wire is reduced and its length is increased by pulling the workpiece through a calibrated hole of. This technique not only reduces the diameter of the wire. Complete the wire in your barbed wire drawing. Web wire drawing is a cold plastic deformation process by which the diameter of a rod or a wire is reduced and its length is increased by pulling the workpiece through a calibrated hole of a conical die. In drawing wire, the. This process is a type of forging. The process is clearly explained in detail. The gathering bloomburrow collector boosters. Web wire drawing, with the assistance of wire drawing machines, is essential in various cable manufacturing scenarios, including power cables, communication cables, and automotive wiring. Let us discuss more details about this metalworking process in detail. Web bar or wire drawing is a deformation process in which the work piece in the form of cylindrical bar or rod is pulled through a converging die. Twist the pliers away from you and rotate your wrist as far as possible. See how thick metal rods are pulled through progressively smaller die diameters to create long strands of. The. Begin your barbed wire fence drawing. Web the winning numbers in saturday evening’s drawing of the powerball game were: Add the rest of the points. Figure 1 shows the basics of the drawing process. Web wire drawing is a cold plastic deformation process by which the diameter of a rod or a wire is reduced and its length is increased. Web this lecture describes the fundamentals of wire drawing including working principle, mechanism, calculation of various parameters, advantages, disadvantages. The tandem wire drawing machine made in 1880 made continuous wire drawing production. Web the important parameters which affect the wire drawing force are the drawing ratio, die angle, material flow stress, friction etc. Web measure and cut your piece of gold or silver wire. Put the wire between the pliers' jaws and line it up with your mark. Complete the wire in your barbed wire drawing. Each drum, called a capstan or block, is motor driven to provide the proper pull force to draw the wire stock through the upstream die. Web drawing plates and dies. The gathering bloomburrow collector boosters. Forging is the plastic, or permanent, changing of a metal shape. This technique not only reduces the diameter of the wire. Drawing metal wire through a drawplate offers you the flexibility of a variety of diameters of wire without having to carry a large stock. These plates were made of hardened steel with several holes through which wire would be drawn to make it longer and thinner. Download a pdf of wire drawing process. Web bar or wire drawing is a deformation process in which the work piece in the form of cylindrical bar or rod is pulled through a converging die. Web wire drawing is done on continuous drawing machines which consist of multiple draw dies, separated by accumulating drums between the dies.

How to Draw Barbed Wire YouTube

How To Draw Barbed Wire, Step by Step, Drawing Guide, by Dawn DragoArt

fine(work) live video of wire drawing machine YouTube

What is Wire Drawing, Tube Drawing and Making? ExtruDesign

how to draw wires in autocad Wiring Diagram and Schematics

How to Draw Realistic Barbed Wire YouTube

wire drawing setup

How to draw Wire drawings

Wire Drawing 3 (c) Barbara Gilhooly annealed steel wire 24" x 24

What is Wire Drawing, Tube Drawing and Making? ExtruDesign

To Draw Or Stretch Forcibly :

In Drawing Wire, The Required Deformation Is Accomplished By Drawing The Wire Through The Conical Bore Section Of The Die, Hereby Reducing The Diameter Through Plastic Deformation.

Web The Selection Of Wire Drawing Dies Depends On Various Factors, Including The Material To Be Drawn, Wire Diameter, Required Tolerances, Surface Finish, Production Volume, And Cost Considerations.

Figure 1 Shows The Basics Of The Drawing Process.

Related Post: