Wind Turbine Design Blades

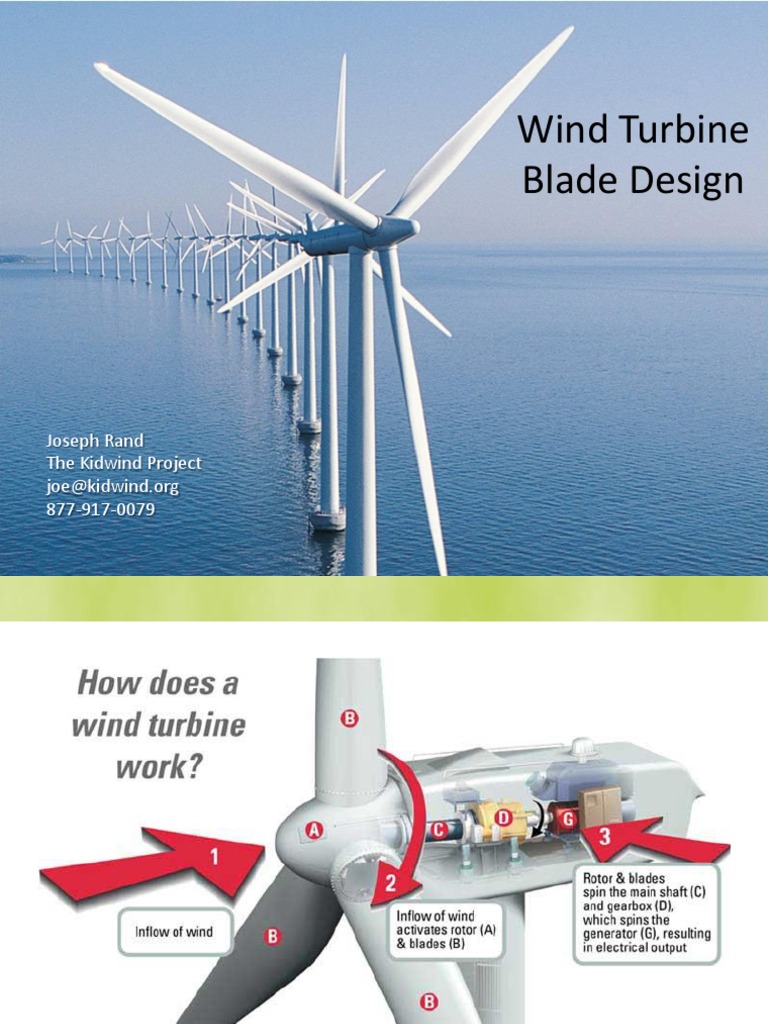

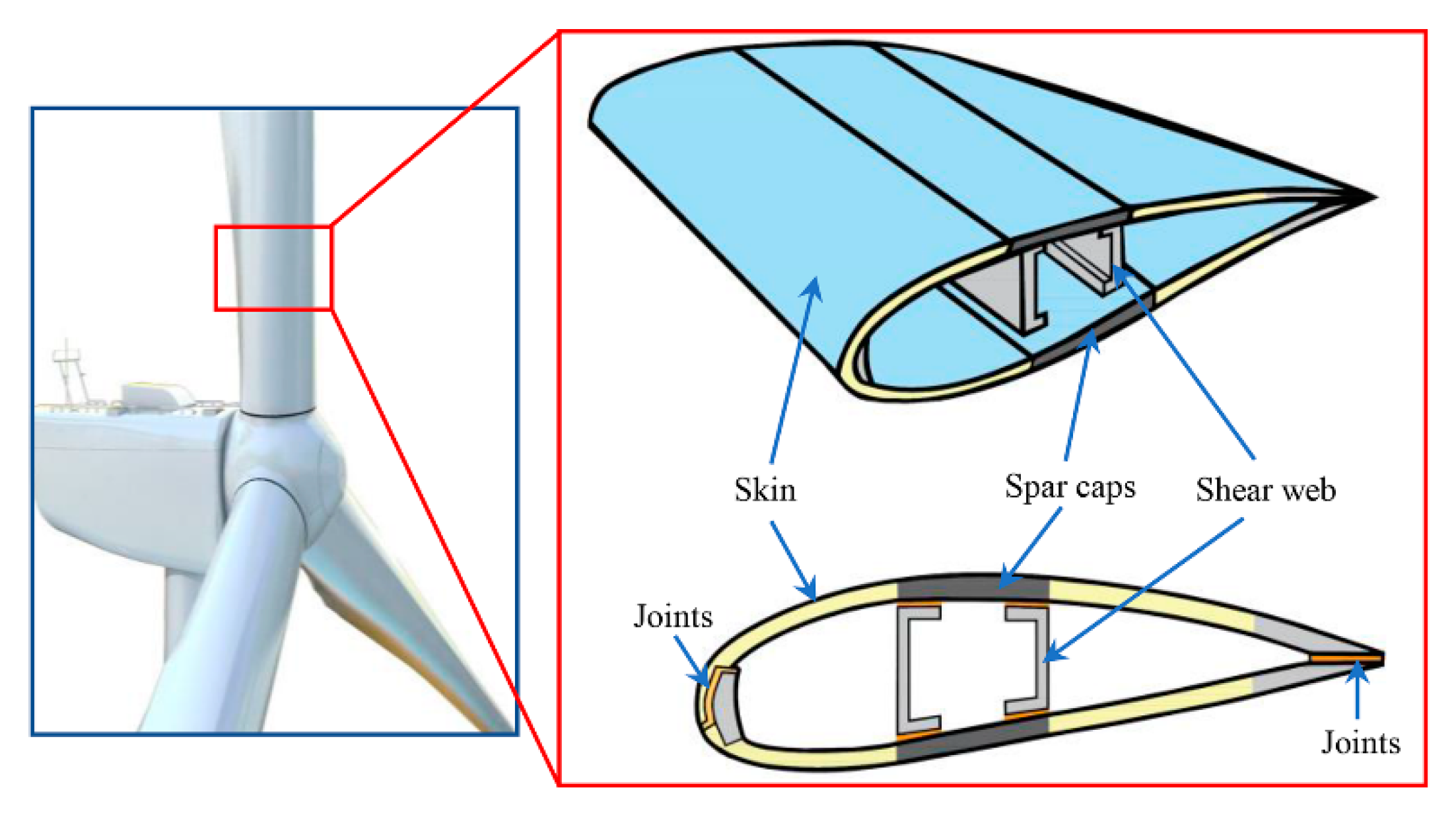

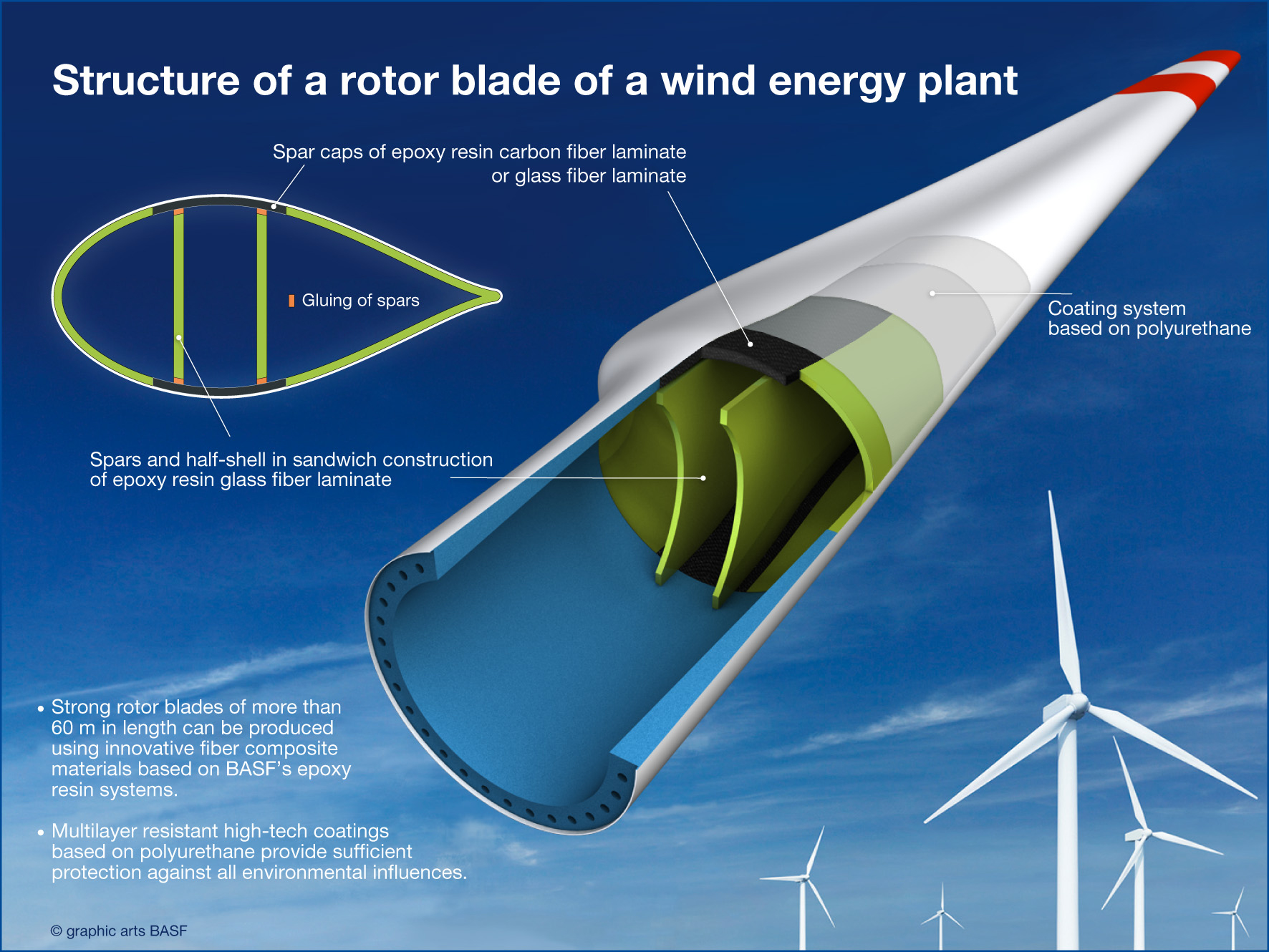

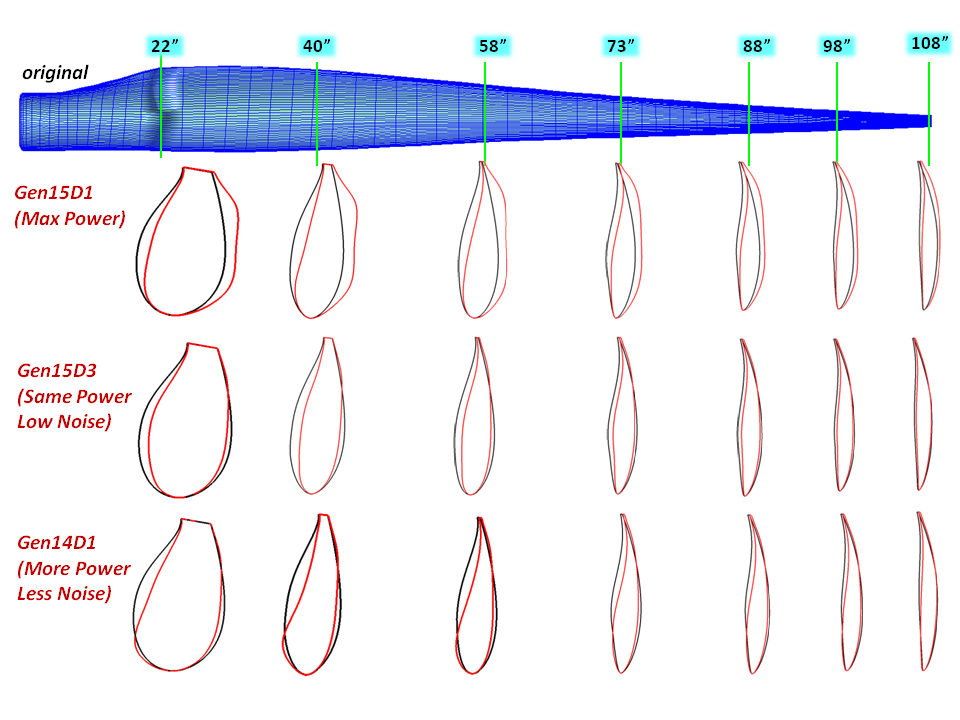

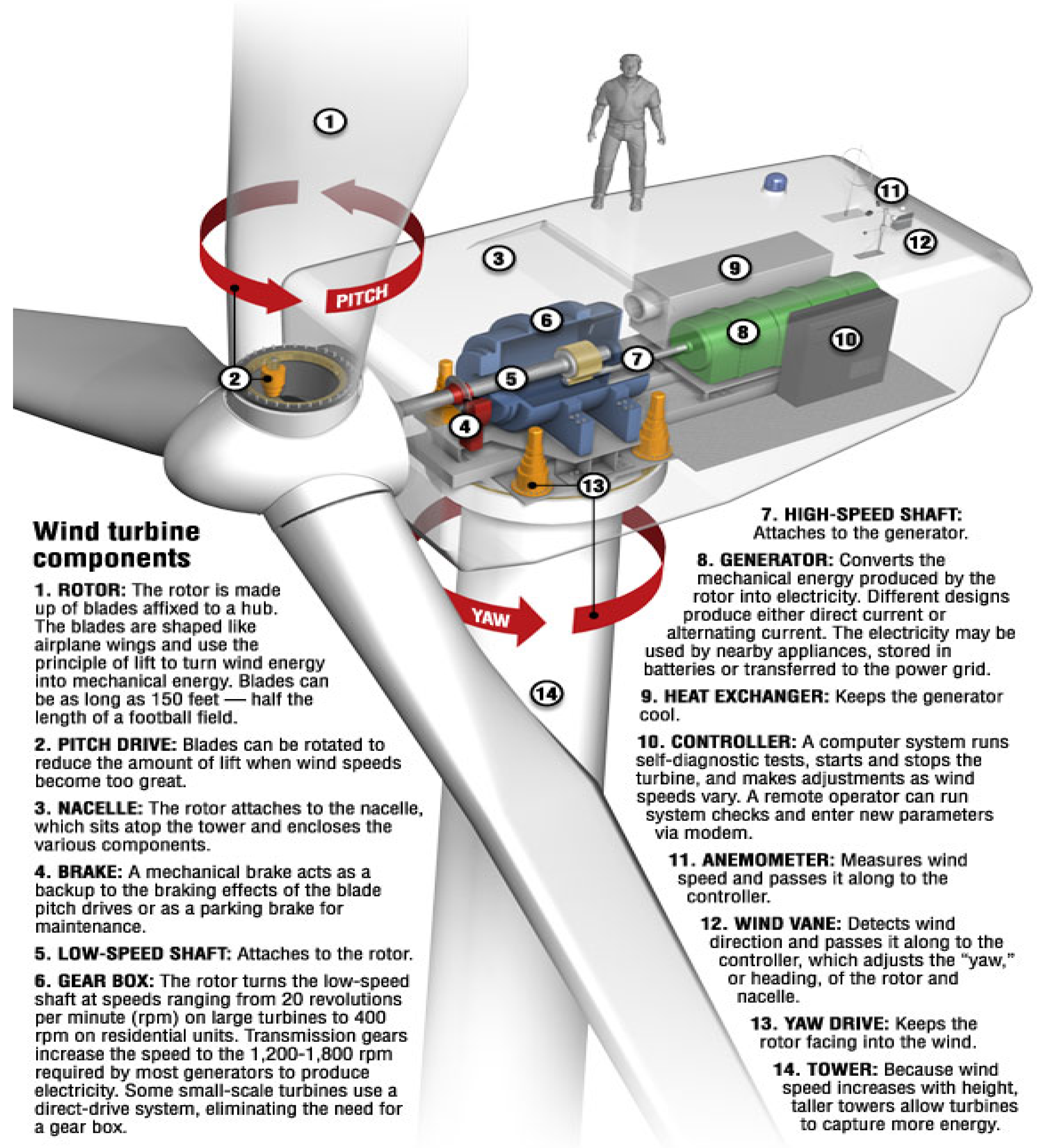

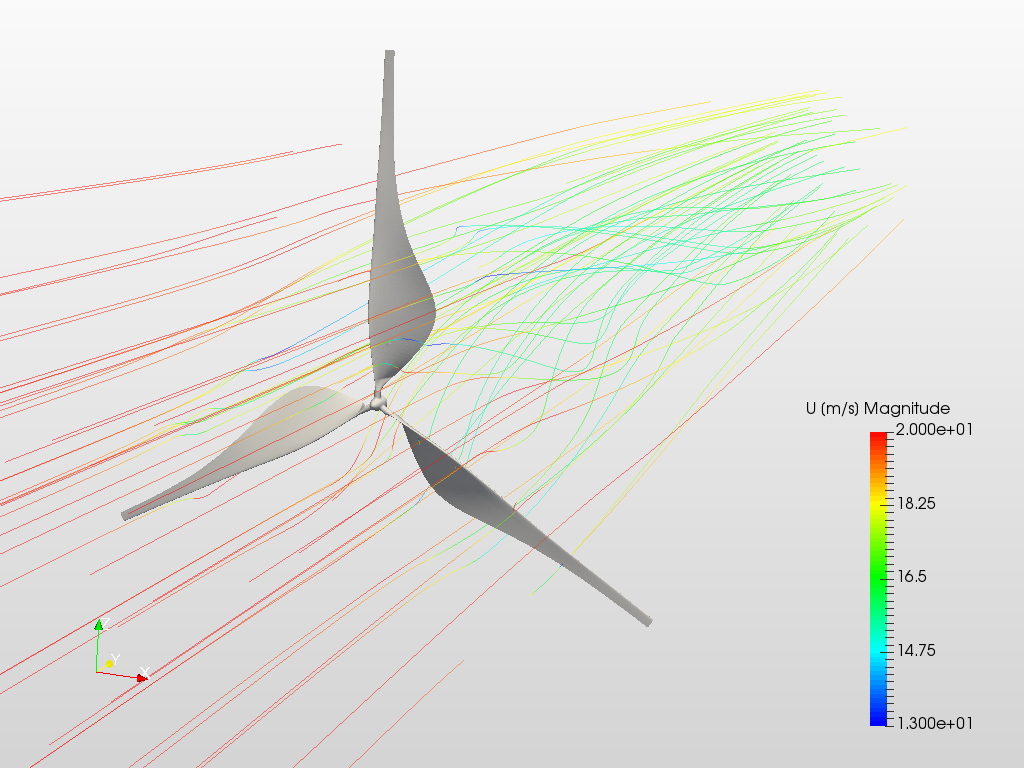

Wind Turbine Design Blades - Web this study investigated the meteorological conditions leading to ice formation on wind turbines in a coastal mountainous area. Web an overview of the current and future trends in wind turbine blade structural design process is presented. The blade was transported 218 kilometers. The part, made and installed by ge vernova, had broken three days earlier, and no one really knew why. The maker of a massive wind turbine blade that broke apart. Web most wind turbines face the wind—and there is a good reason for that. The main design principles and failure mechanisms of blades in operation are assessed and explained through an industry point of. Web proven wind turbine blade designs, efficient wind power. Web the design philosophy for rotor blades (as with all fibre reinforced polymer structures) began with large safety factors and addressing simple issues of linear elastic behaviour. First, the numerical analysis model of spar cap damage was established based on the continuous damage mechanics model, the puck criterion, and the cohesive zone. Higher tower ⇒ higher wind speed because of vertical shear. Larger swept area ⇒ larger power capture. Since the 1980s, wind turbine developers have been using what is called the danish concept for their designs—three blades, positioned upwind (i.e., facing the wind), that are engineered to keep facing the wind to maximize energy production. Web the design process for wind. The conventional shapes are popular due to their proven track records and ease of manufacture. Designs of current horizontal axis wind turbine (hawt) blade tips vary depending on the scale but are for the most part simple shapes within the blade plane. Web this study investigated the meteorological conditions leading to ice formation on wind turbines in a coastal mountainous. Generating lift and drag when they move through the air, airfoils play a key role in improving the aerodynamic performance. Lm wind power began producing wind turbine blades in 1978, and although the basic blade design hasn’t changed, we have continued working on developing the world’s longest wind blades. Web zhu, shen, and sørensen ( 2014) presented an integrated method. The blade was transported 218 kilometers. Web a detailed review of design loads on wind turbine blades is offered, describing aerodynamic, gravitational, centrifugal, gyroscopic and operational conditions. Web retrospect, the last 30 years of thermosetting composite wind turbine blade development yielded three distinct structural concepts: The design method starts with determining the wind turbine’s particular needs, such as the intended. The conventional shapes are popular due to their proven track records and ease of manufacture. The design method starts with determining the wind turbine’s particular needs, such as the intended power output and operating circumstances. Web the idea that a wind turbine blade could break apart and spread thousands of pieces of foam and fiberglass across the south shore never. The blade was transported 218 kilometers. The monolithic skin monocoque concept (based on ulrich hutter’s pioneering design (1959)), the single shear web design, and the double shear web or box spar concept (see figure 1). Discover the role of blade length, aerodynamics, materials, and ongoing challenges in harnessing wind energy. Web an overview of the current and future trends in. Web composite materials are ideal for producing wind turbine blades because of their strength, light weight, and ability to be tailored to provide the precise mechanical properties needed for any. Web the design of a wind turbine blade is a compromise between aerodynamic and structural considerations. The maker of a massive wind turbine blade that broke apart. Web designing wind. Wind turbine blade design is a complicated procedure that combines engineering, aerodynamics, and materials science. Since the 1980s, wind turbine developers have been using what is called the danish concept for their designs—three blades, positioned upwind (i.e., facing the wind), that are engineered to keep facing the wind to maximize energy production. Larger swept area ⇒ larger power capture. Web. A preliminary investigation by ge found that the vineyard wind blade that broke off, falling into the ocean and littering nearby beaches, was due to a “manufacturing deviation. The conventional shapes are popular due to their proven track records and ease of manufacture. Web most wind turbines face the wind—and there is a good reason for that. Web retrospect, the. Web the design process for wind turbine blades involves the use of computational fluid dynamics (cfd) codes, such as windse, to simulate wind turbine or wind farm performance, optimize designs, and quantify uncertainty. To increase the power generating capacity of a turbine, blades must grow in length (power captured by a turbine is proportional to the square of blade length).. Web an overview of the current and future trends in wind turbine blade structural design process is presented. Web retrospect, the last 30 years of thermosetting composite wind turbine blade development yielded three distinct structural concepts: Web proven wind turbine blade designs, efficient wind power. Web central to the effectiveness of a wind turbine is its blade design and the materials used in their construction. Web the design philosophy for rotor blades (as with all fibre reinforced polymer structures) began with large safety factors and addressing simple issues of linear elastic behaviour. Lm wind power began producing wind turbine blades in 1978, and although the basic blade design hasn’t changed, we have continued working on developing the world’s longest wind blades. Web designing wind blades. The monolithic skin monocoque concept (based on ulrich hutter’s pioneering design (1959)), the single shear web design, and the double shear web or box spar concept (see figure 1). Generating lift and drag when they move through the air, airfoils play a key role in improving the aerodynamic performance. Web a detailed review of design loads on wind turbine blades is offered, describing aerodynamic, gravitational, centrifugal, gyroscopic and operational conditions. Designs of current horizontal axis wind turbine (hawt) blade tips vary depending on the scale but are for the most part simple shapes within the blade plane. Web the design of a wind turbine blade is a compromise between aerodynamic and structural considerations. The conventional shapes are popular due to their proven track records and ease of manufacture. Web the idea that a wind turbine blade could break apart and spread thousands of pieces of foam and fiberglass across the south shore never came to mind for members of town administration and the. Since the 1980s, wind turbine developers have been using what is called the danish concept for their designs—three blades, positioned upwind (i.e., facing the wind), that are engineered to keep facing the wind to maximize energy production. The blade was transported 218 kilometers.wind,,turbine,,blade,,design wind,,turbine,,blade,,design Wind

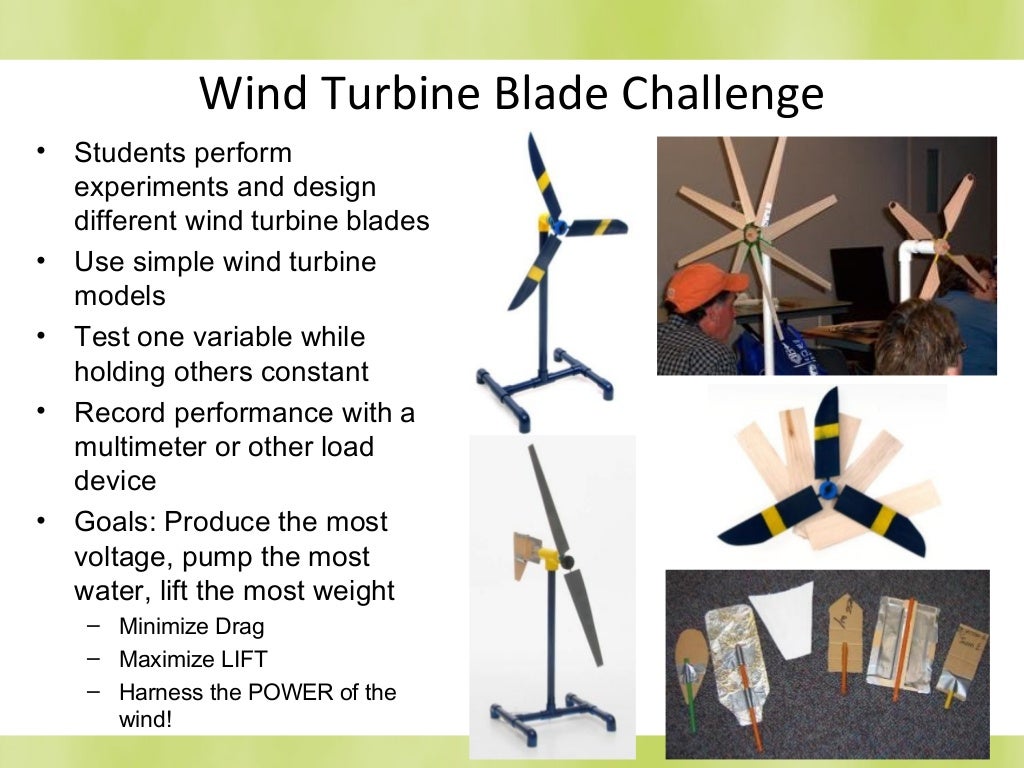

Homemade Wind Turbine Blade Design Homemade Ftempo

Wind Turbine Blade Design Dimensions

All Things Wind Turbine Blade Inspection

Wind Turbine Blade CRAFT Tech

Wind Turbine Blade Design Dimensions

Wind turbine blade design

Energies Free FullText Wind Turbine Blade Design

PPT Wind turbine blade design using FEM PowerPoint Presentation, free

Wind turbine blade design calculations Renewable energy

Web Most Wind Turbines Face The Wind—And There Is A Good Reason For That.

Web Composite Materials Are Ideal For Producing Wind Turbine Blades Because Of Their Strength, Light Weight, And Ability To Be Tailored To Provide The Precise Mechanical Properties Needed For Any.

The Design Method Starts With Determining The Wind Turbine’s Particular Needs, Such As The Intended Power Output And Operating Circumstances.

Size Grows More Than Power Rating.

Related Post: