Welding Weaving Patterns

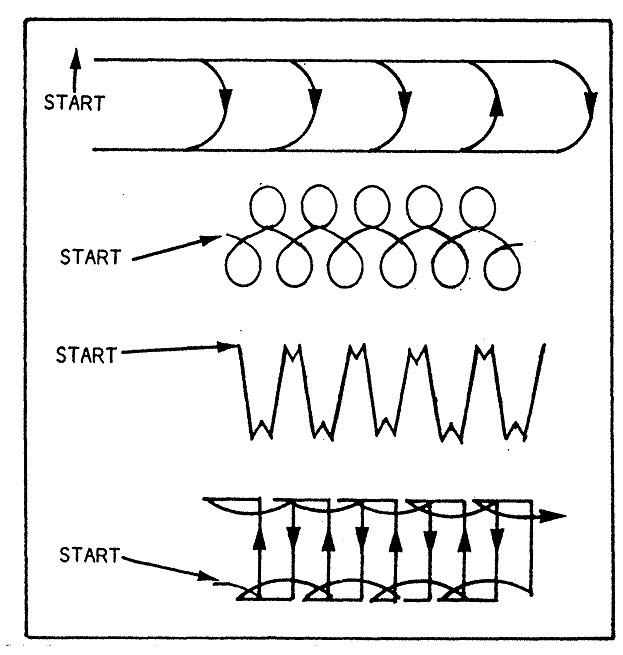

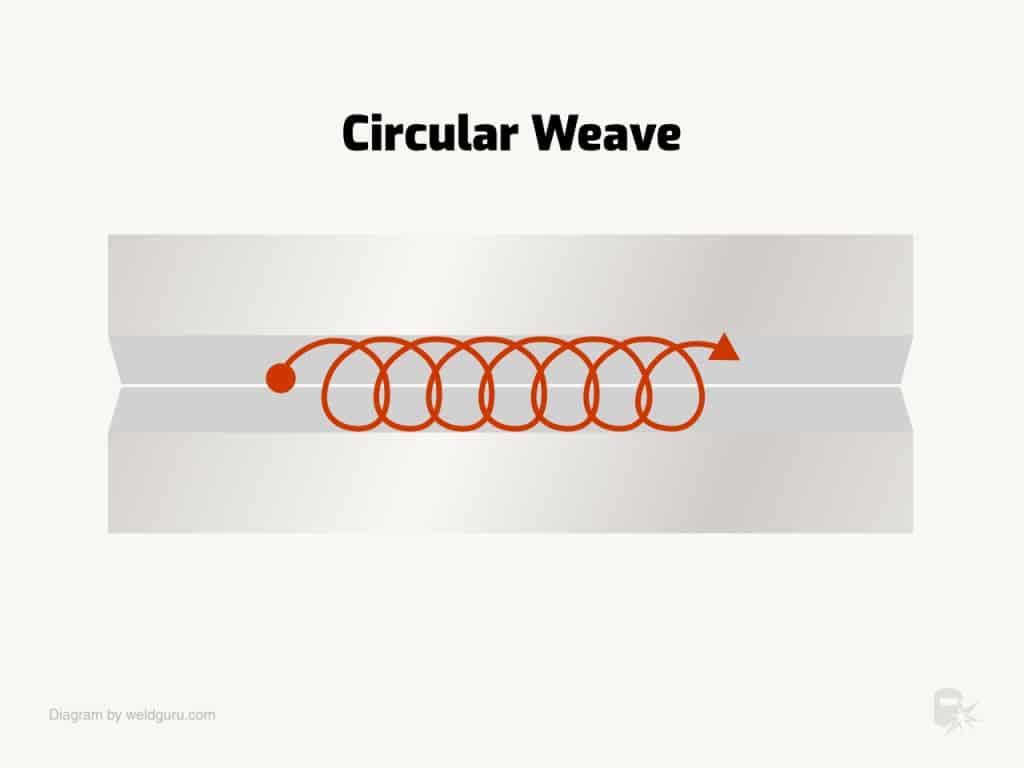

Welding Weaving Patterns - Web generally speaking, there are two main welding bead techniques and patterns: Web weave welding is achieved by offsetting the motion of the weld arc as it moves along the weld path, making it ideal for filling wide, flat joints or welding thick. This motion allows you to make cover welds over stringer beads, otherwise known. What is the correct traveling angle for vertical? Web weaving pattern is one such example where to cover the portion of welding the most commonly observed iterations are single weave pattern and the zigzag. However, once you decide to create weld. Walking the cup and freehand. Web weave bead patterns. When it comes to mig welding a properly set up machine is the most. The weaving welding technique involves making a series of overlapping circles with the electrode as you. Creates smooth and durable welds on thicker materials, versatile for all weld positions, ideal. Web extensive weaving can result in porous welds. Web weave patterns offer several advantages in mig welding and find extensive applications in various welding scenarios: Web weaving pattern is one such example where to cover the portion of welding the most commonly observed iterations are single. We’ll hit on the latter in a bit, but right now let’s focus on the former. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. Web use the correct wire diameter. Weaving is an arc welding technique which allows for filling a wide, flat joint or. Web generally speaking, there are two main welding bead techniques and patterns: However, once you decide to create weld. Web weave patterns offer several advantages in mig welding and find extensive applications in various welding scenarios: Web use the correct wire diameter. Use a wire brush or grinder to remove. Web use the correct wire diameter. Web depending on the welding position, you might choose not to weave when welding because of the welder’s angle to the joint. However, once you decide to create weld. The weaving welding technique involves making a series of overlapping circles with the electrode as you. Weave bead welding is exactly as it sounds; You use this motion to make cover. Web depending on the welding position, you might choose not to weave when welding because of the welder’s angle to the joint. Web weave bead patterns. Weaving increases the weakening of the weld metal with the original metal and should be minimized when welding alloy steels. The most common sticking welding pattern is. What is the correct traveling angle for vertical? The dots indicate pause points that apply additional heat and metal at the edge of the bead where it is most needed. Web weaving pattern is one such example where to cover the portion of welding the most commonly observed iterations are single weave pattern and the zigzag. Deals of the dayshop. Weaving increases the weakening of the weld metal with the original metal and should be minimized when welding alloy steels. Web there are basically two ways to weave a tig weld: Web beads and patterns for vertical welds. We’ll hit on the latter in a bit, but right now let’s focus on the former. Web the six common mig welding. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. Comfort is the golden rule. Web weave bead patterns. These patterns significantly impact the final. Web weave bead welding involves making a weaving pattern in order to cover a larger surface area. Weave bead welding is exactly as it sounds; Web weave welding is achieved by offsetting the motion of the weld arc as it moves along the weld path, making it ideal for filling wide, flat joints or welding thick. Weaving increases the weakening of the weld metal with the original metal and should be minimized when welding alloy steels. This. What is the correct traveling angle for vertical? Comfort is the golden rule. The dots indicate pause points that apply additional heat and metal at the edge of the bead where it is most needed. Web generally speaking, there are two main welding bead techniques and patterns: Web weave welding is achieved by offsetting the motion of the weld arc. Web depending on the welding position, you might choose not to weave when welding because of the welder’s angle to the joint. Web extensive weaving can result in porous welds. However, once you decide to create weld. Weaving increases the weakening of the weld metal with the original metal and should be minimized when welding alloy steels. Use a wire brush or grinder to remove. The most common sticking welding pattern is the weave. Web use the right technique. When it comes to mig welding a properly set up machine is the most. Wire diameter depends on the size of weld you’re looking for and the thickness of the steel you want to weld. Comfort is the golden rule. What amperage do you use for vertical welding? The dots indicate pause points that apply additional heat and metal at the edge of the bead where it is most needed. Web use the correct wire diameter. Web generally speaking, there are two main welding bead techniques and patterns: Web beads and patterns for vertical welds. Web weave bead patterns.

MIG Welding Weave Patterns Super Helpful Guide & Review

MIG Welding Weave Patterns Super Helpful Guide & Review

4 Beginner MIG Welding Patterns to Master Today Beginner Welding Guide

DIFFERENT TYPES OF WEAVING USED IN THE PROCESS OF WELDING Nikit

Weaving in welding A comprehensive guide to weave patterns

What weave pattern you like most? Diy welding, Welding, Welding and

WEAVING IN THE WELDING OPERATION Weld World

Welding Techniques

6 Essential MIG Welding Patterns To Master

6 Essential MIG Welding Patterns To Master

Weaving Is An Arc Welding Technique Which Allows For Filling A Wide, Flat Joint Or Welding Thick Metals By Adding A Weave Pattern To.

These Patterns Significantly Impact The Final.

This Motion Allows You To Make Cover Welds Over Stringer Beads, Otherwise Known.

You Will Make A Weaving Pattern In Order To Cover A Larger Area.

Related Post: