Welding Rods Chart

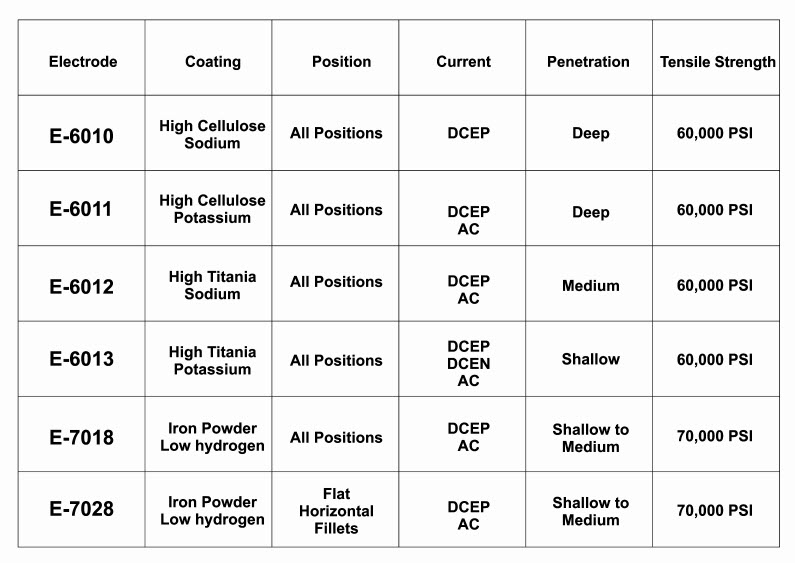

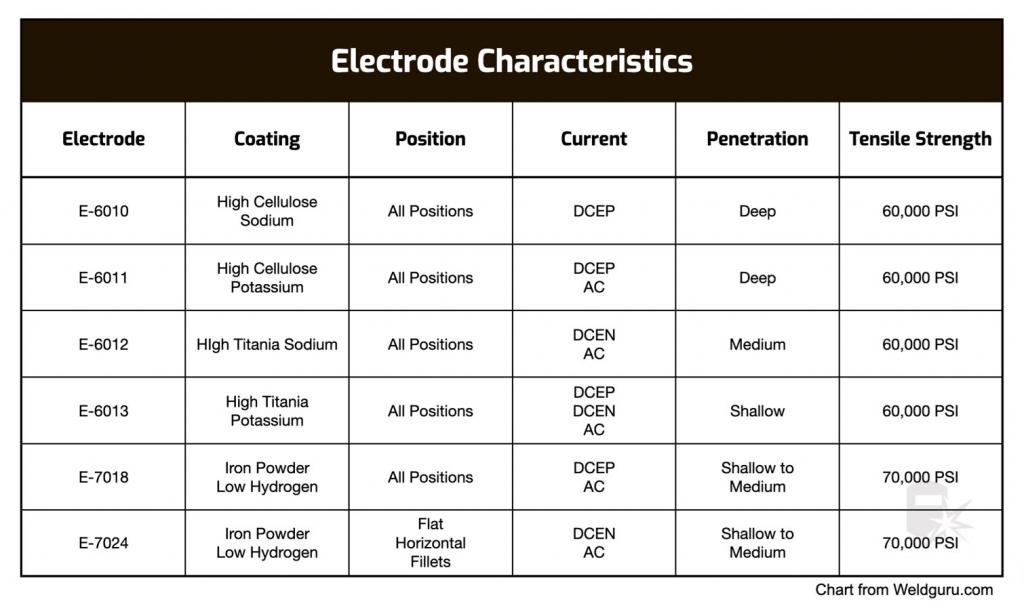

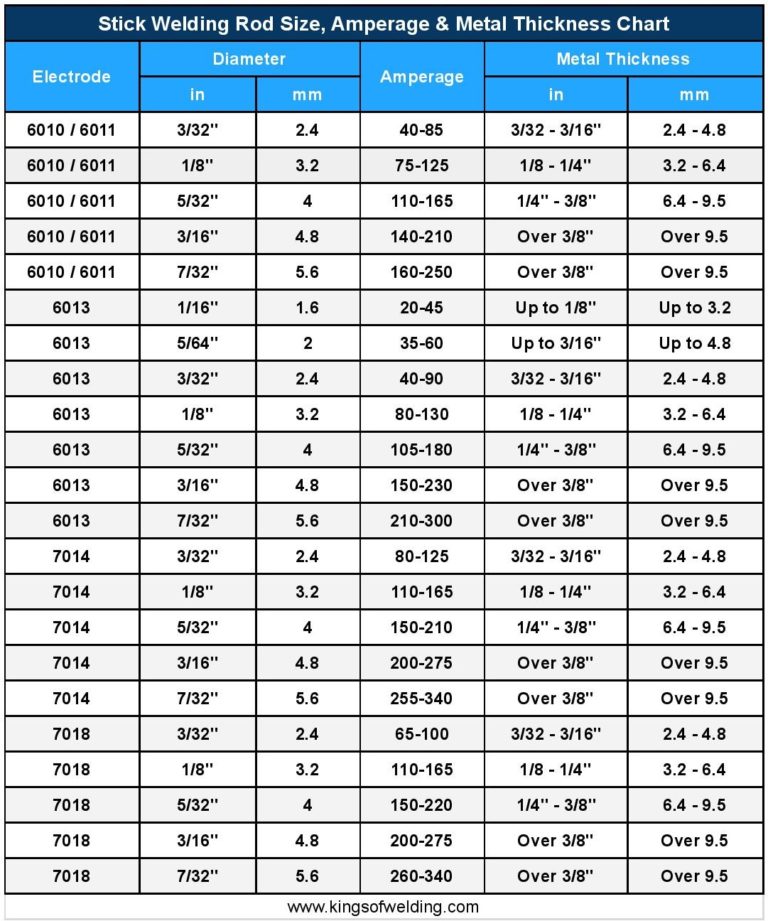

Welding Rods Chart - Web the welding rod electrode identification system for smaw stainless steel is set up as follows: We have gone into this in more detail below. E indicates electrode for arc welding. Web home » mechanical engineering » different types of welding rods & their uses [explained] pdf. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Based on welding process types, welding rods are classified for: Typically, welding electrode types are made of a metal alloy that matches or complements the materials being welded. If you need this article in pdf form, you can download it at the. Web our powerful calculator let's you easily determine which stick electrode you need. One cable from your welding machine is clamped to the 'work', and the other cable which also comes from the arc welding machine is for the rod holder. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. What are the most common stick rods for home. Web below is a chart of the different types of stick welding rod and explanations of what the different numbers mean. Typically,. Web home » mechanical engineering » different types of welding rods & their uses [explained] pdf. Instead, you would choose the largest electrode to give you a perfect 1/8″ fillet weld. This chart provides valuable information on which rod size to use for different metal thicknesses and welding positions. The type of welding rod you choose depends on your needs,. What do welding rod size numbers mean? One cable from your welding machine is clamped to the 'work', and the other cable which also comes from the arc welding machine is for the rod holder. How to build welding lead reels. Web below is a chart of the different types of stick welding rod and explanations of what the different. Based on welding process types, welding rods are classified for: In this article, you will learn what are different types of welding rods in welding? How to build welding lead reels. This chart provides valuable information on which rod size to use for different metal thicknesses and welding positions. Which arc welding rods should i use? Web home » mechanical engineering » different types of welding rods & their uses [explained] pdf. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. What to consider before selecting a stick welding rod type? For example, the esab 6013 electrodes, having a 2.5mm diameter and 350mm. Web for example, if the part you’re working on calls for a 1/8″ (3.2 mm) fillet weld, but the material is 1/2″ (12.7 mm) thick, you would not want to use a 5/32″ (4 mm) electrode. Web home » mechanical engineering » different types of welding rods & their uses [explained] pdf. How to measure the diameter of a welding. Plus you'll get the most complete welding rod chart on the internet in pdf! E indicates electrode for arc welding. What do welding rod size numbers mean? Now, let’s break down some different size types for jobs with different metals: In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable one for. Web you can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. Let’s delve deeper into the importance of selecting the correct rod size. Almost all fusion welding processes require welding electrode to create the weld metal. Metal project to be welded, or 'work'. Web these six. Instead, you would choose the largest electrode to give you a perfect 1/8″ fillet weld. In one of these packets, there are about 277 rods. In this article, you will learn what are different types of welding rods in welding? Web the welding rod electrode identification system for smaw stainless steel is set up as follows: Web if you are. Web for example, if the part you’re working on calls for a 1/8″ (3.2 mm) fillet weld, but the material is 1/2″ (12.7 mm) thick, you would not want to use a 5/32″ (4 mm) electrode. How to measure the diameter of a welding rod. If you need this article in pdf form, you can download it at the. Web. They are designed to melt and provide filler material during the welding process. What to consider before selecting a stick welding rod type? Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. Based on welding process types, welding rods are classified for: Web you can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. What’s the difference between welding rods, electrodes, and filler metal? In this article, you will learn what are different types of welding rods in welding? Now, let’s break down some different size types for jobs with different metals: Plus you'll get the most complete welding rod chart on the internet in pdf! This chart provides valuable information on which rod size to use for different metal thicknesses and welding positions. What do welding rod size numbers mean? Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Web these six different types of welding rods are the most uses and quite popular in the welding industry. How to build welding lead reels. Metal project to be welded, or 'work'. Web this chart should serve as a guide for all your welding rod size needs and will provide education and knowledge about the selection process as well.

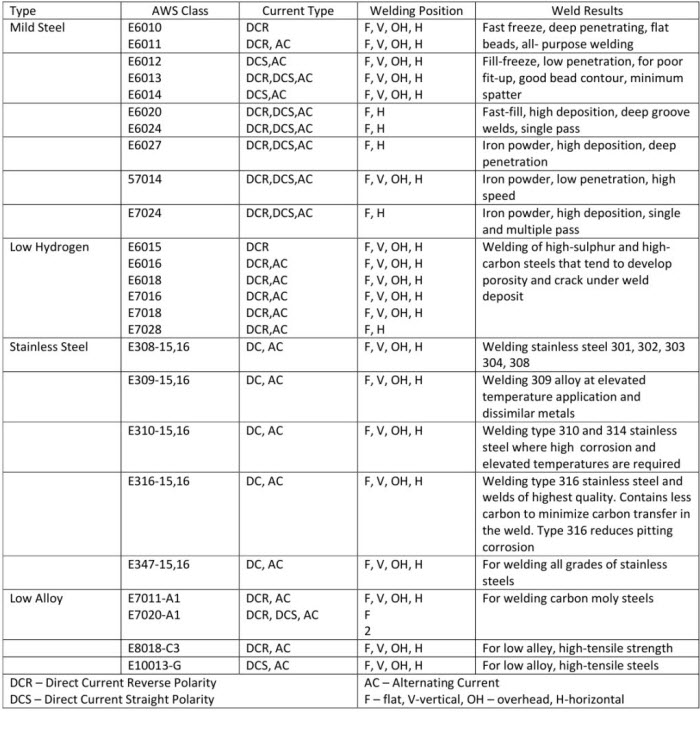

Arc Welding Rods Guide

Welding Rod Chart

Ac Welding Rod Chart

Welding Electrode Chart and Selection Weld Guru

Welding Rod Chart

Welding Rod Chart

Stainless Steel Welding Rod Chart

Welding Rod Sizes, Amperage & Metal Thickness Chart Kings of Welding

Arc Welding Rods Guide

Types Of Welding Rod Chart

Let’s Delve Deeper Into The Importance Of Selecting The Correct Rod Size.

The Most Common Diameter For General Purpose Welding Is 3/32, 1/8 Inch, And 5/32 Inch.

Instead, You Would Choose The Largest Electrode To Give You A Perfect 1/8″ Fillet Weld.

E Indicates Electrode For Arc Welding.

Related Post: