Welding Rod Number Chart

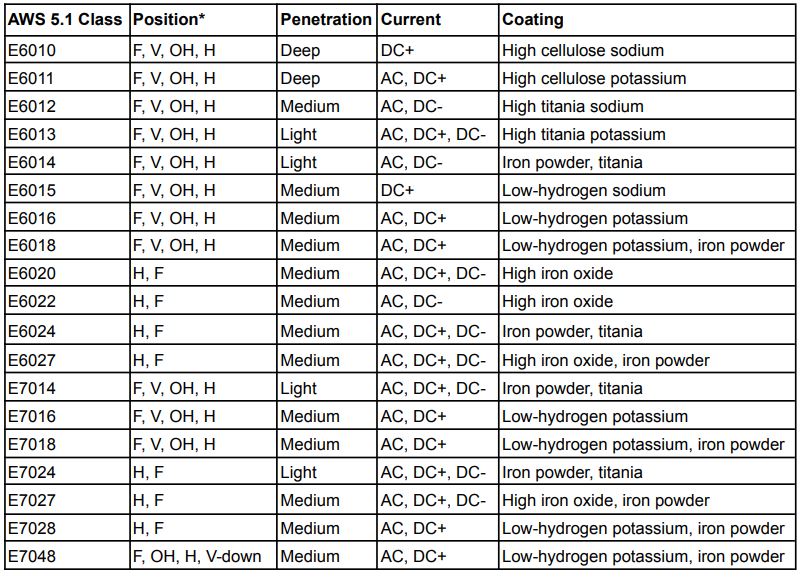

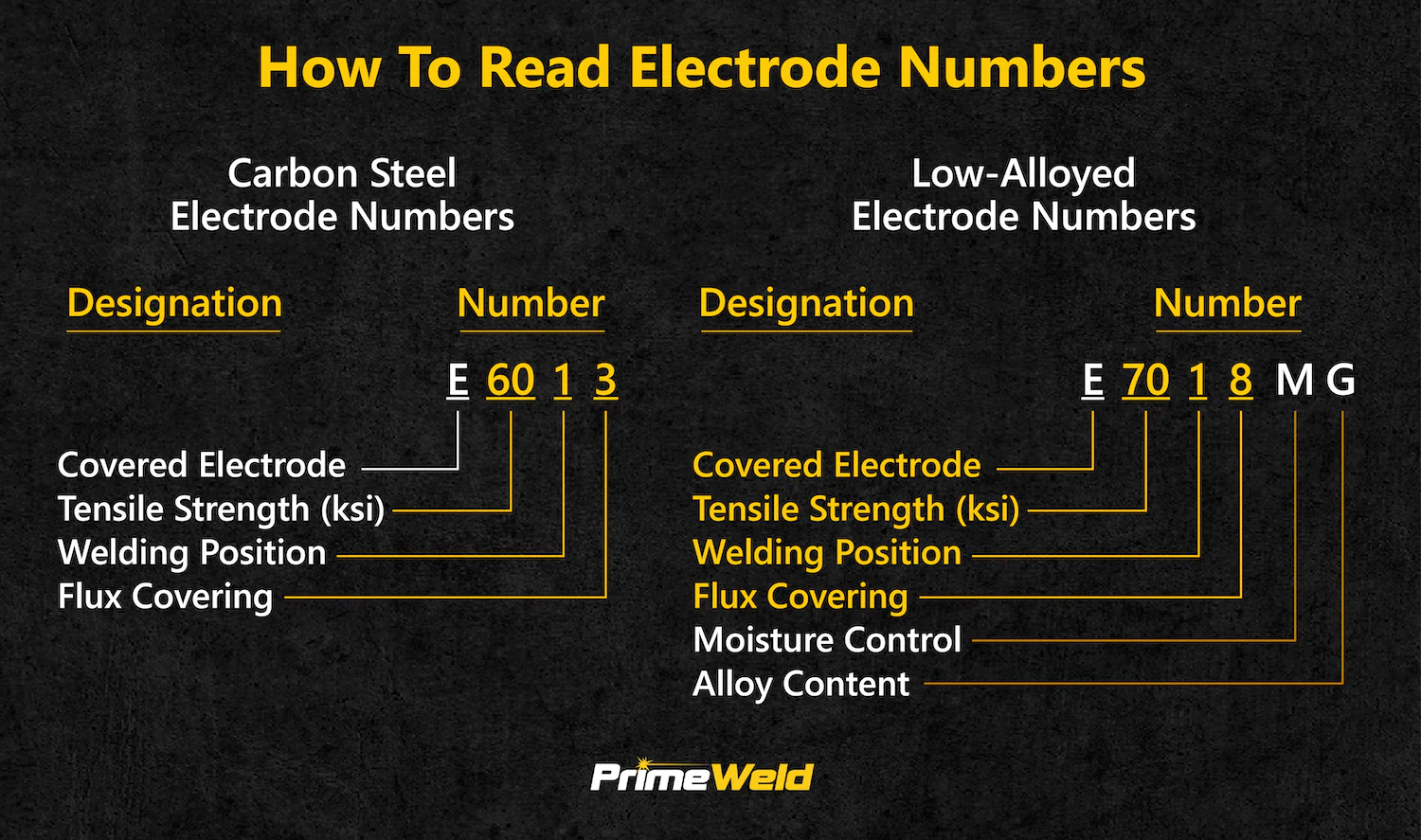

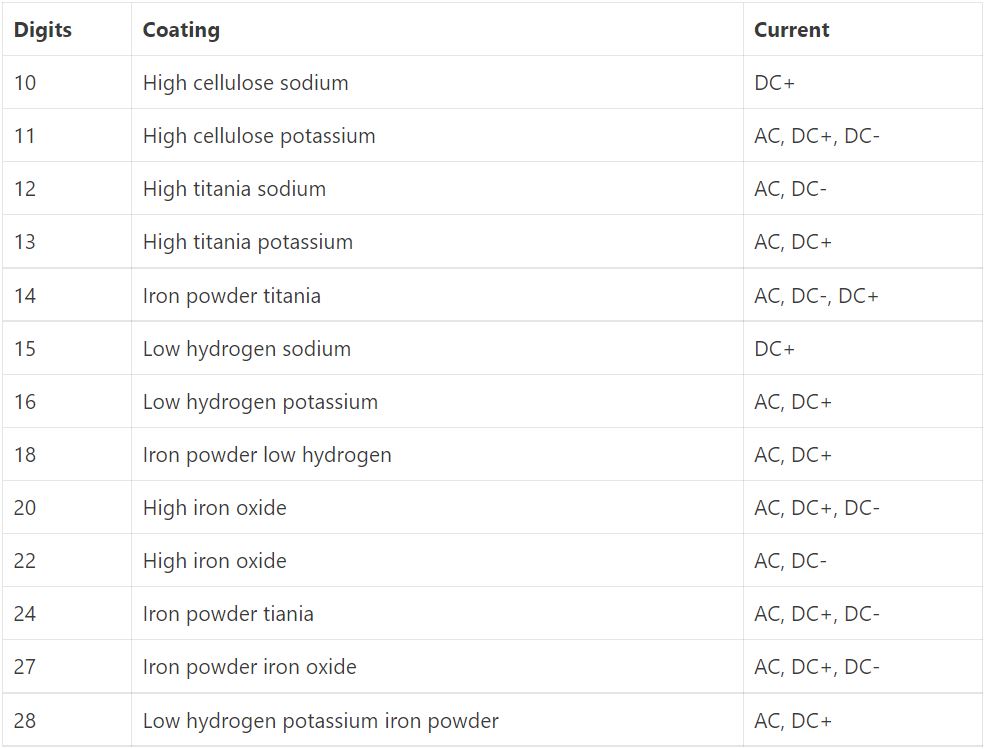

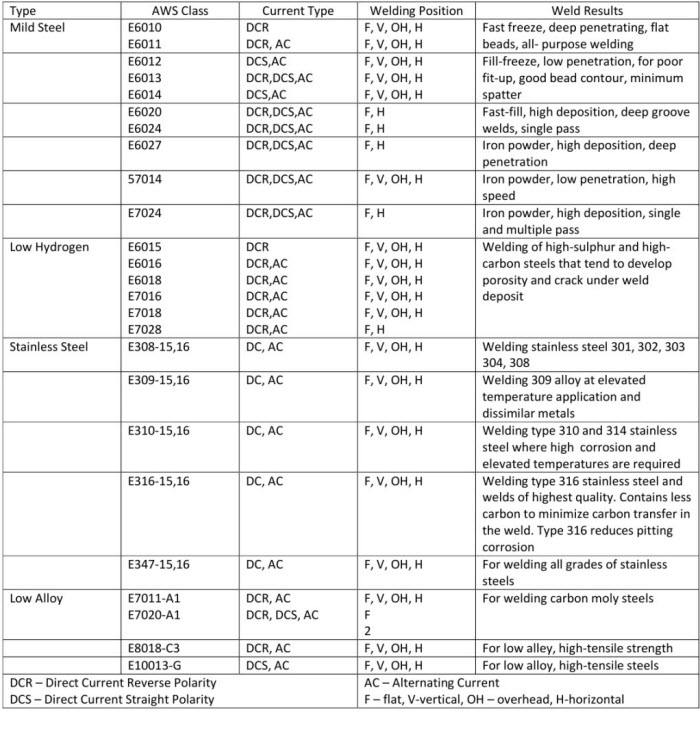

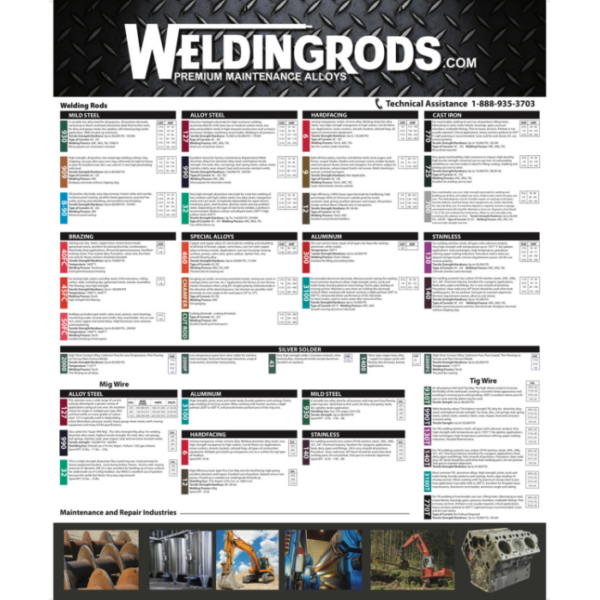

Welding Rod Number Chart - Let’s delve deeper into the importance of selecting. Web this chart provides valuable information on which rod size to use for different metal thicknesses and welding positions. Web learn how to choose the right welding rod size for different materials and applications. See a chart of common electrode types, coatings, positions, currents, and. In this article, you will learn. The first letter stands for “electrode,” the consumable, conductive part of the welding circuit creating the arc. Web find the best stick welding electrode for any metal with the calculator and the pdf chart. The numbers on a welding rod represent the tensile strength of the rod, measured in pounds per square inch (psi). 1/8” and 5/32” are also very common. For example, a rod with the number “60” has a tensile. Which is best suited for welding mild steel, carbon steel and low alloy steel. Learn about the types, sizes, amperage, and other features of over 220 electrodes. Web home » mechanical engineering » different types of welding rods & their uses [explained] pdf. What to consider before selecting a stick welding rod type? Once you’ve chosen your welding rod diameter,. Let’s delve deeper into the importance of selecting. In this article, you will learn. 1/8” and 5/32” are also very common. The american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between stick electrodes. The numbers in the classification refer to the properties of the electrode and how it can. In this article, you will learn. Gain valuable insights into the different types of electrodes,. 1/8” and 5/32” are also very common. Web you will see welding rods with numbers like these: Web home » mechanical engineering » different types of welding rods & their uses [explained] pdf. Web if you are a beginner in the welding industry, you may be confused upon looking at the welding rod classification, for you would readily notice that the welding rod chart have. Large selectiongreat customer reviewspopular brandssatisfaction guaranteed As per aws designation, the first two, and in some cases three numbers on the welding rod refer to the tensile strength,. Web the first 2 numbers. Web for example, if the part you’re working on calls for a 1/8″ (3.2 mm) fillet weld, but the material is 1/2″ (12.7 mm) thick, you would not want to use a 5/32″ (4 mm) electrode. Web the numbers on welding rods indicate the aws classification and refer to the composition, tensile strength, and other. Learn about the types, sizes, amperage, and other features of over 220 electrodes. Web find out how to choose the right welding rod for different materials, thicknesses and positions with charts and tables. Let’s delve deeper into the importance of selecting. Which is best suited for welding mild steel, carbon steel and low alloy steel. What to consider before selecting. They also explain whether power is ac or dc and what polarity you should. As per aws designation, the first two, and in some cases three numbers on the welding rod refer to the tensile strength, i.e., the ability to resist being. Web the stamped numbers describe properties like tensile strength, welding position, and flux composition. Web this chart provides. Large selectiongreat customer reviewspopular brandssatisfaction guaranteed Learn about the features, benefits and drawbacks of. What to consider before selecting a stick welding rod type? The american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between stick electrodes. 1/8” and 5/32” are also very common. Large selectiongreat customer reviewspopular brandssatisfaction guaranteed July 31, 2022 by yousef. Which is best suited for welding mild steel, carbon steel and low alloy steel. What to consider before selecting a stick welding rod type? Once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for. Web home » mechanical engineering » different types of welding rods & their uses [explained] pdf. Large selectiongreat customer reviewspopular brandssatisfaction guaranteed Web the numbers on welding rods indicate the aws classification and refer to the composition, tensile strength, and other characteristics of the electrode. Which is best suited for welding mild steel, carbon steel and low alloy steel. The. Web find the best stick welding electrode for any metal with the calculator and the pdf chart. 1/8” and 5/32” are also very common. Once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that. Web the first 2 numbers. The numbers on a welding rod represent the tensile strength of the rod, measured in pounds per square inch (psi). Large selectiongreat customer reviewspopular brandssatisfaction guaranteed Web the stamped numbers describe properties like tensile strength, welding position, and flux composition. For example, a rod with the number “60” has a tensile. Web the most popular welding rods for hobbyists are 3/32” rods. In this article, you will learn. Web this chart provides valuable information on which rod size to use for different metal thicknesses and welding positions. Web learn how to choose the right welding rod size for different materials and applications. Web explore the world of welding electrode types and understand the meaning and classification of welding rod numbers. Huge selectionfree shipping over $50multiple payment optionsfree shipping available Web find out how to choose the right welding rod for different materials, thicknesses and positions with charts and tables. The numbers in the classification refer to the properties of the electrode and how it can be used for the best performance.

Welding Rod Number Chart

WHAT DO WELDING ROD NUMBERS MEAN? WeldingMart

Welding Rod Chart

Welding Rod Number Meaning & Welding Rod Chart Kings of Welding

Welding Rod Number Meaning & Welding Rod Chart Kings of Welding

Arc Welding Rods Guide

Welding Rod Chart

Types Of Welding Rod Chart

Welding Rod Number Chart

Welding Rod Chart

See A Chart Of Common Electrode Types, Coatings, Positions, Currents, And.

Web For Example, If The Part You’re Working On Calls For A 1/8″ (3.2 Mm) Fillet Weld, But The Material Is 1/2″ (12.7 Mm) Thick, You Would Not Want To Use A 5/32″ (4 Mm) Electrode.

What To Consider Before Selecting A Stick Welding Rod Type?

They Also Explain Whether Power Is Ac Or Dc And What Polarity You Should.

Related Post: