Welding Patterns

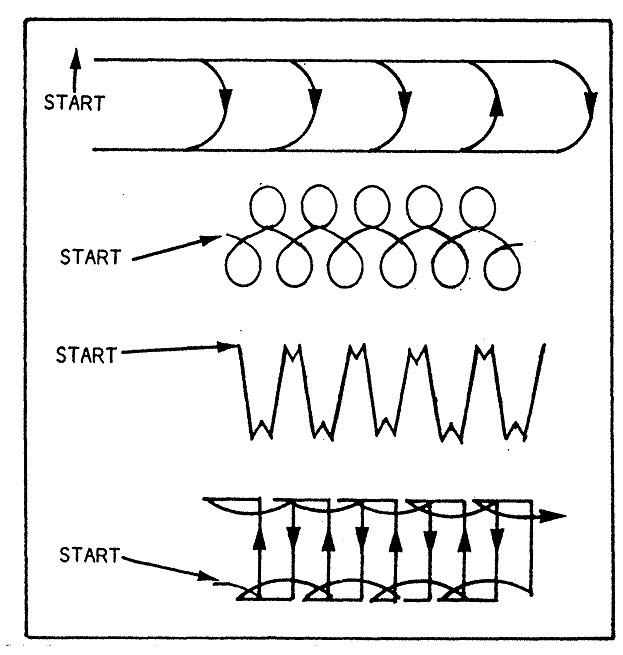

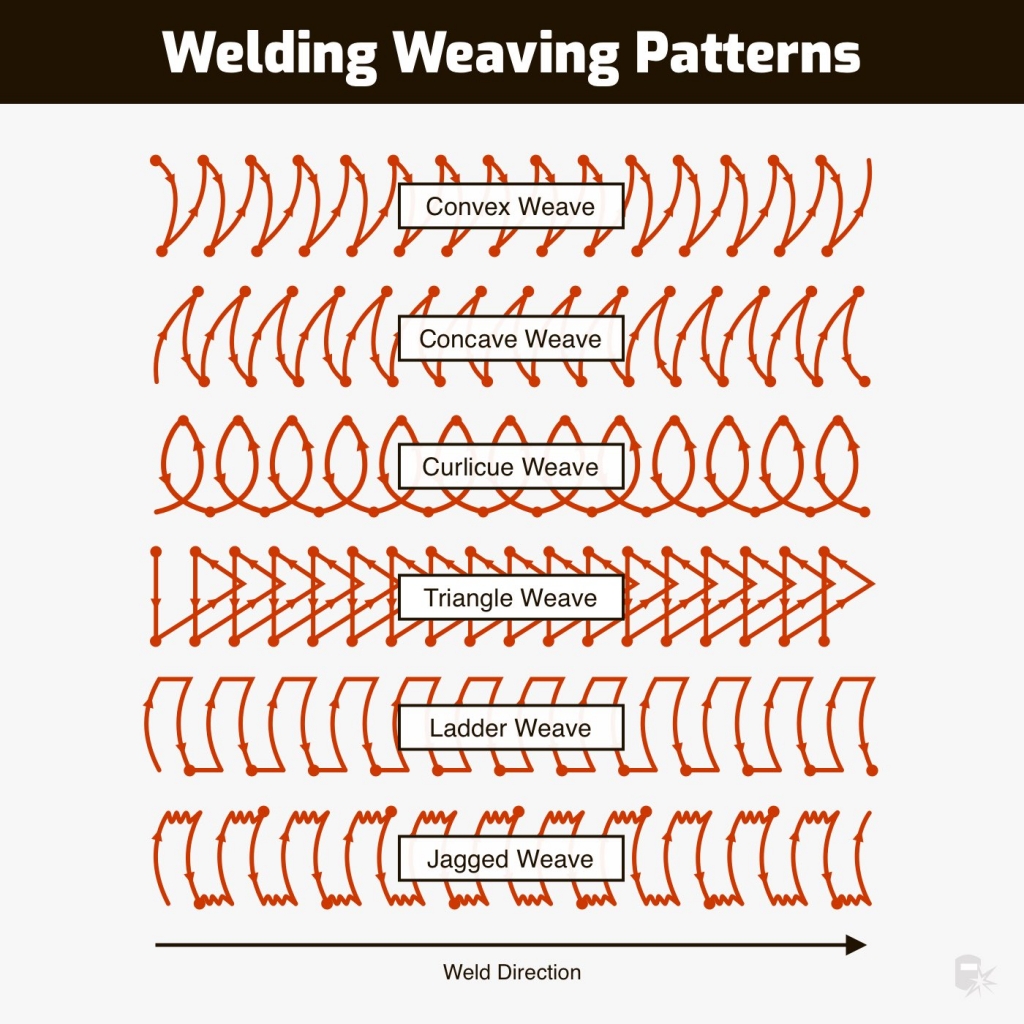

Welding Patterns - Web vertical welding is one of the four basic welding positions where the joint’s axis is vertical to the ground, at an angle ranging from 45° to 90°. Have fused edges and be smooth. Mig welding is a widely used welding method. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. Contact us to learn more. Web basic stick welding covering safety, joint preparation, rod selection, arc welding machine setup, and basic stick welding techniques in various positions. The iron or steel used must be contrasting so that they are optically different and. Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material. First, lets define what a good weld is. If it’s a butt joint with a. A good weld, whether it's a stringer bead or a weave bead will. Web what is a weld bead? Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material. Each pattern describes a specific movement or shape that the welder’s hand makes during the welding process. Mobile welding, repair. Walking the cup and freehand. Quickly access the aws standard welding procedure you need for use in pressure vessels and heat exchangers designed through shopfloor or compress. All patterns have pros and cons, difficulty levels, and the best situations to use them. The iron or steel used must be contrasting so that they are optically different and. We’ll hit on. There are several benefits of employing weaving patterns in. In this tutorial we will discus some of the most common techniques. Understanding and applying various mig welding patterns can significantly impact the quality of your welds, leading to stronger, more aesthetically pleasing results. Web welding beads can look different, and the outcome varies on the selected process and various torch. Brushing stainless steel clean with a wire brush. Web understanding mig welding patterns: First, lets define what a good weld is. Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material. It simply involves dragging the welding wire straight across the seam without any intricate weaving or movement. If you have a fillet weld in a tee or lap joint, it’s called a 3f position. Web welding beads can look different, and the outcome varies on the selected process and various torch movements. Each pattern describes a specific movement or shape that the welder’s hand makes during the welding process. Web 3351 laughlin road, zellwood, fl, 32798, united. Web how to mig weld in all positions using the proper techniques, travel patterns and electrode agles in the flat, horzintal, vertical and overhead positions. These patterns significantly impact the final weld bead's shape, size, and penetration depth. First, lets define what a good weld is. Let’s explain the welding beads, how they form, and the most common welding bead. Web there are basically two ways to weave a tig weld: Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material. We’ll hit on the latter in a bit, but right now let’s focus on the former. Common welding patterns and their uses. As you melt a filler material. If it’s a butt joint with a. Tig welding isn’t forgiving of dirty material. Web how to mig weld in all positions using the proper techniques, travel patterns and electrode agles in the flat, horzintal, vertical and overhead positions. Mig welding patterns are the varied ways in which the welding gun is manipulated to lay down the weld. Brushing stainless. A weld bead is created by depositing a filler material into a joint between two pieces of metal. Each pattern describes a specific movement or shape that the welder’s hand makes during the welding process. In this tutorial we will discus some of the most common techniques. Web how to mig weld in all positions using the proper techniques, travel. Web 3351 laughlin road, zellwood, fl, 32798, united states. It simply involves dragging the welding wire straight across the seam without any intricate weaving or movement. Web the four easiest mig welding patterns for beginners to learn and master are the steady motion pattern, the whipping pattern, the circle pattern, and the weave. Quickly access the aws standard welding procedure. Check asme ix compliance, purchase, download, and integrate seamlessly into efficient operations. Web the four easiest mig welding patterns for beginners to learn and master are the steady motion pattern, the whipping pattern, the circle pattern, and the weave. Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material. Contact us to learn more. Mig welding patterns are the varied ways in which the welding gun is manipulated to lay down the weld. A weld bead is created by depositing a filler material into a joint between two pieces of metal. Mobile welding, repair & fabrication in central florida. Web one of the essential aspects of becoming a skilled mig welder is mastering different mig welding pattern techniques. Web stringer welds are one of the easiest and quickest welding patterns to learn and perform. Let’s explain the welding beads, how they form, and the most common welding bead patterns. Web how to mig weld in all positions using the proper techniques, travel patterns and electrode agles in the flat, horzintal, vertical and overhead positions. Web there are basically two ways to weave a tig weld: All patterns have pros and cons, difficulty levels, and the best situations to use them. If it’s a butt joint with a. Pbz manufacturing is familiar with all the common welding patterns and how to use them effectively for your projects. Web 3351 laughlin road, zellwood, fl, 32798, united states.

Mig Welding Basics Patterns

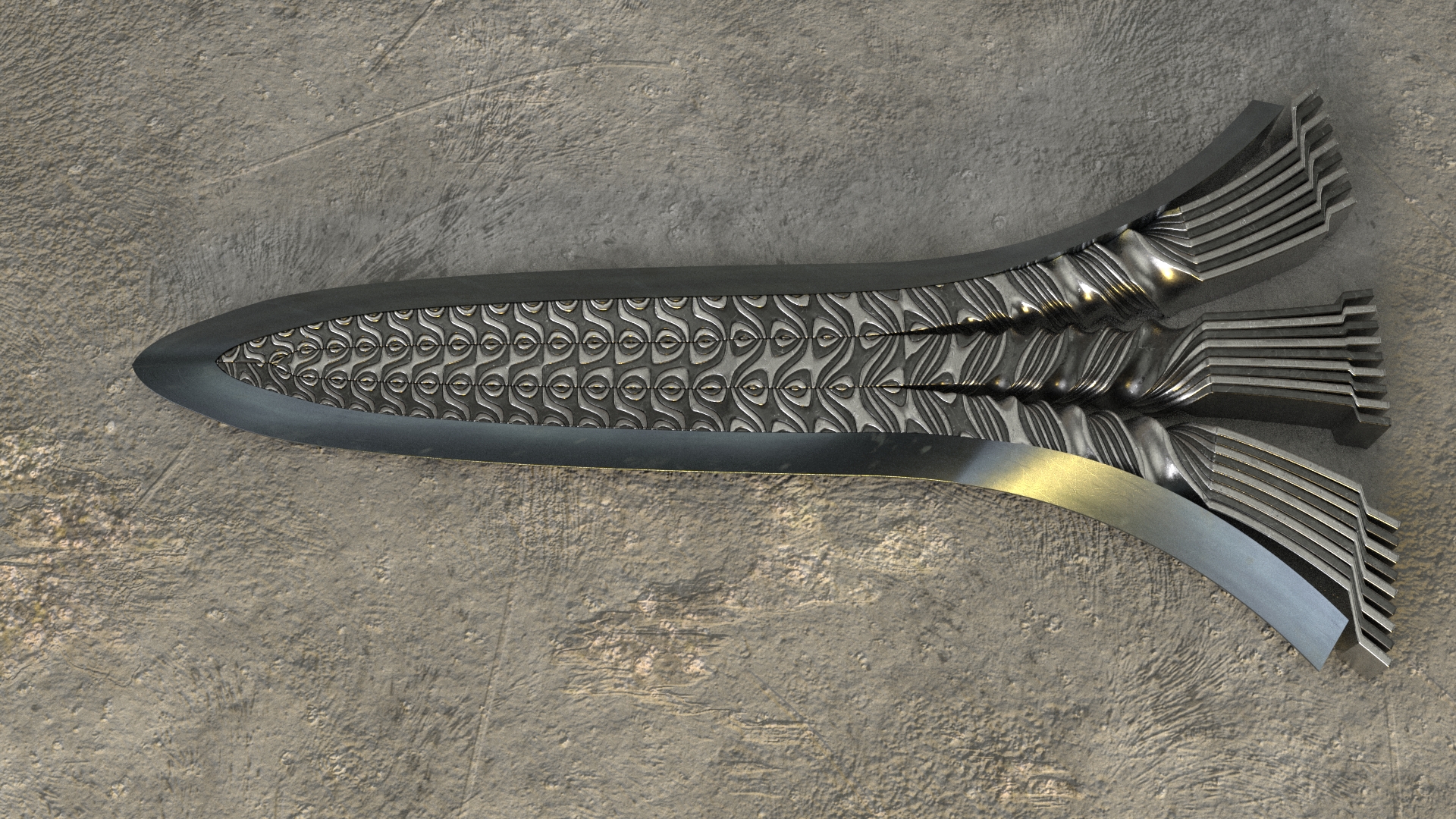

Pattern Welding Explained

Welding Techniques

6 Essential MIG Welding Patterns To Master

Tig weave Welding Cart, Welding Rigs, Mig Welding, Metal Welding

Weaving in welding A comprehensive guide to weave patterns

welding art projects for beginners Weldingart Welding art, Welding

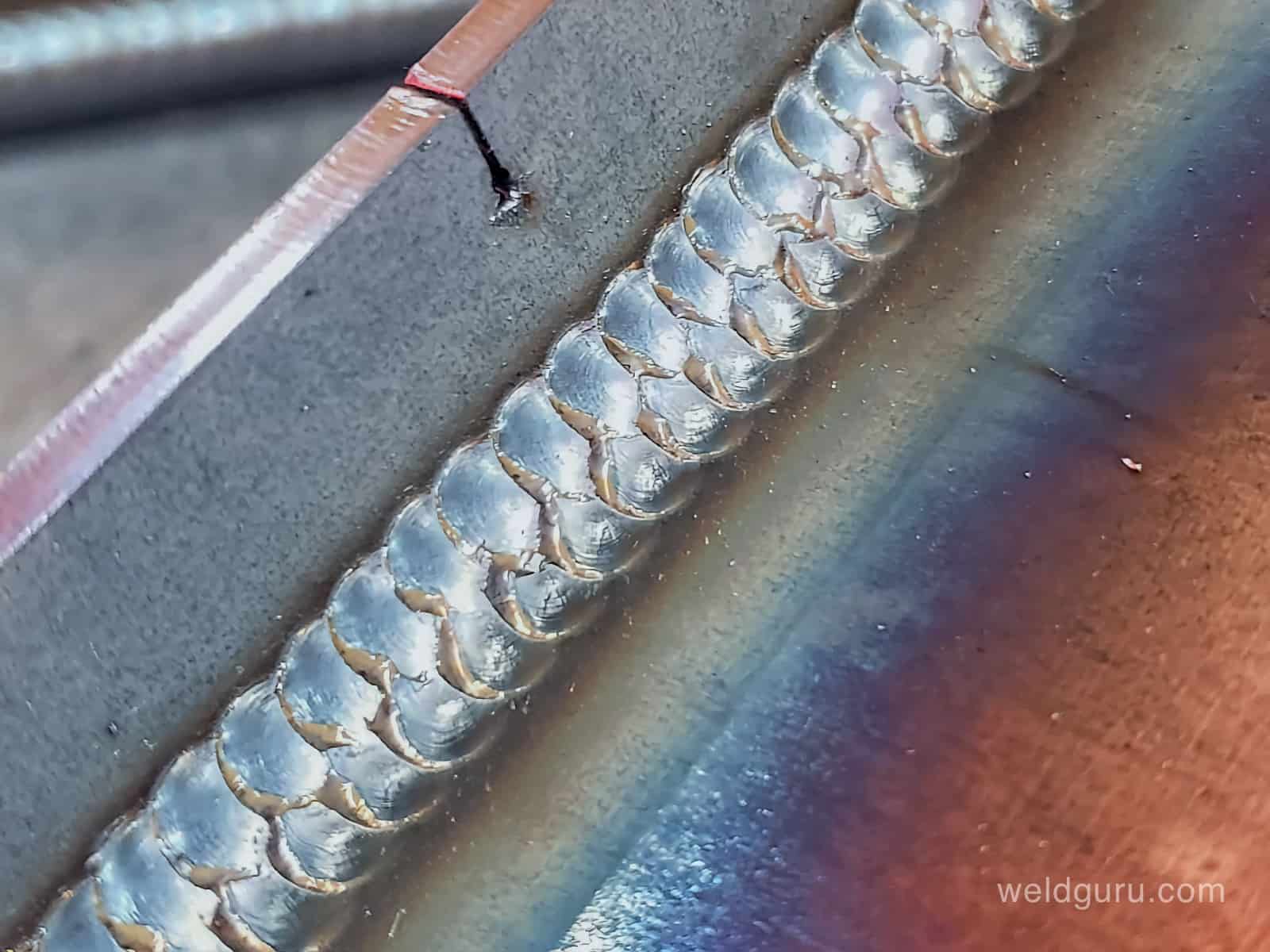

Welding Beads What Are They? & Different Types

Large Pictures 1 knives, Blacksmithing, Viking sword

Welder places interlocking patterns of molten metal between pipes Metal

You Must Always Take The Time To Remove Any Dirt, Dust, Oil, Grime, Or Other Contaminants From.

If You Have A Fillet Weld In A Tee Or Lap Joint, It’s Called A 3F Position.

Web What Is A Weld Bead?

Web Vertical Welding Is One Of The Four Basic Welding Positions Where The Joint’s Axis Is Vertical To The Ground, At An Angle Ranging From 45° To 90°.

Related Post: