Welder Settings Chart

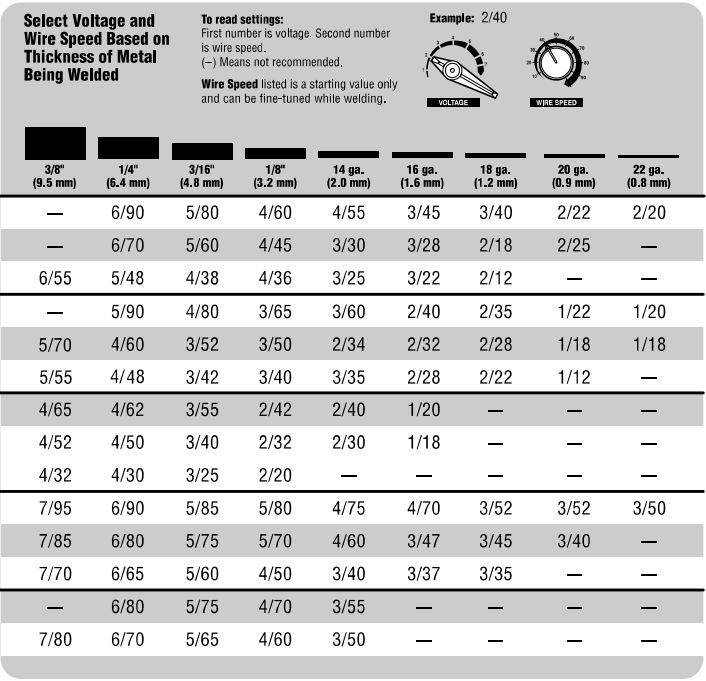

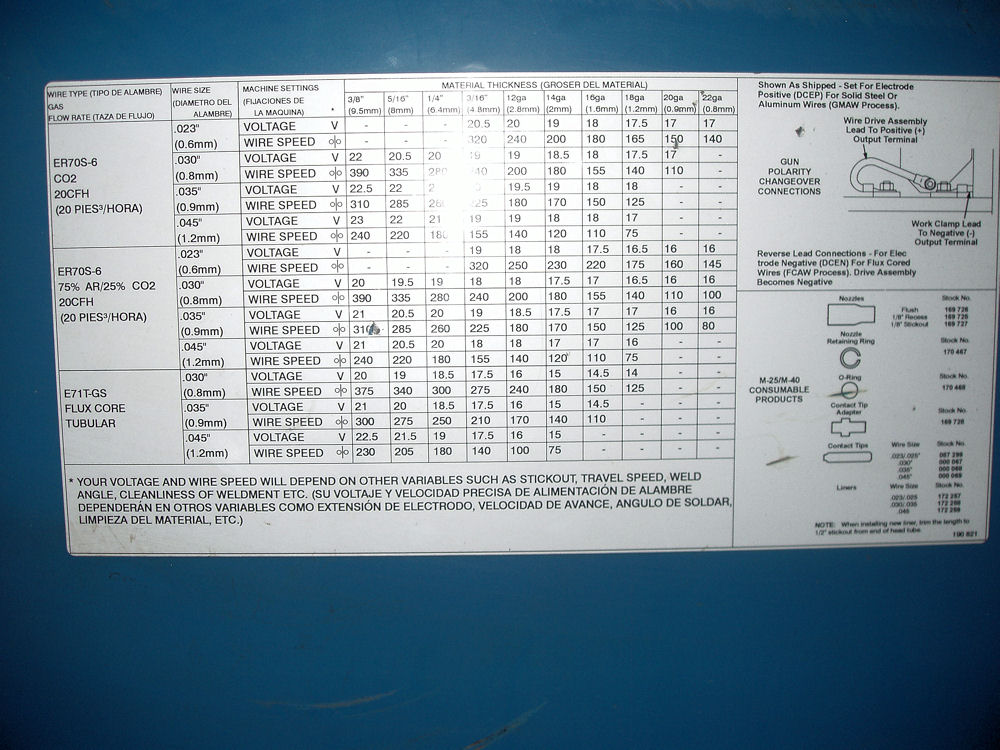

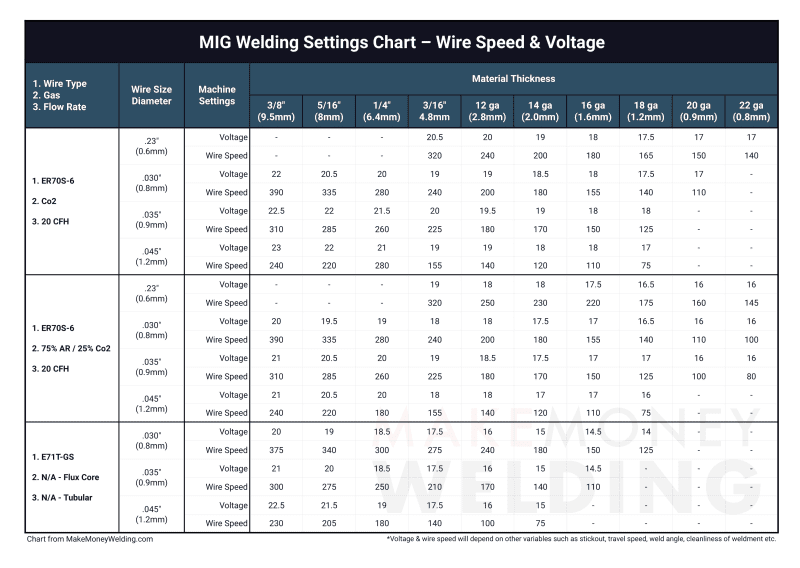

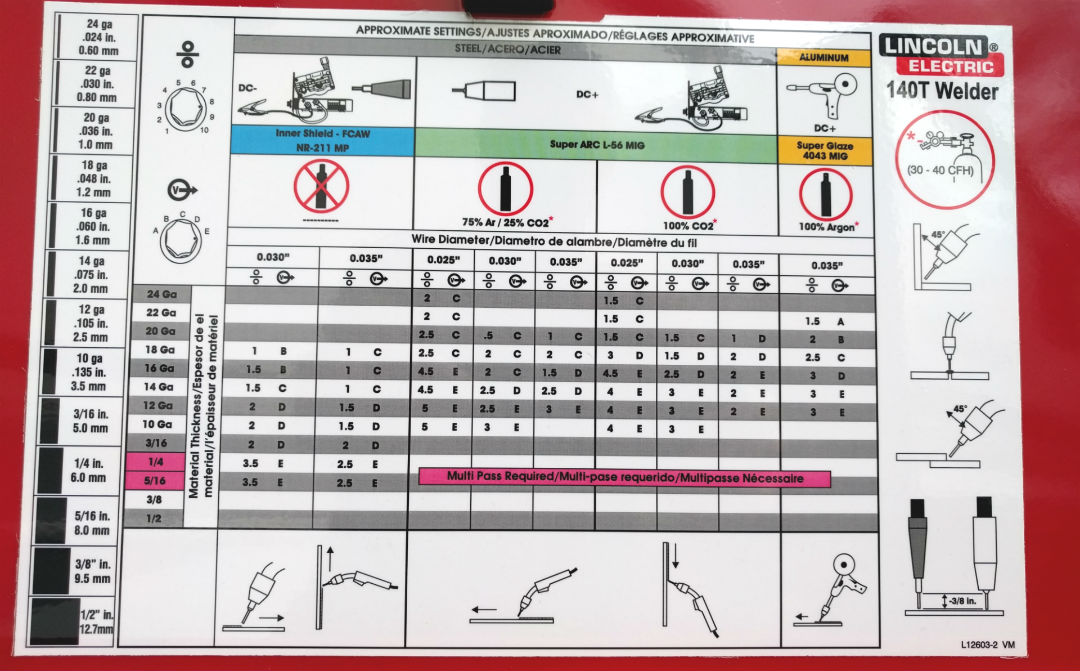

Welder Settings Chart - When you’re looking for the right settings for your lincoln 140 mig welder. Browse suggested weld parameter settings for stick welding. Web setting up your mig welder for the first time. But before using these values, we suggest. Voltage, wire feed speed, and gas flow rate. They control the weld’s heat and the gas transfer type depending on. Web learn how to identify the parent material, select the filler metal, choose the shielding gas, and adjust the gas quantity and welder settings for mig/mag welding. Web miller mig welding settings charts. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web there are 3 main controls that set the welder: Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. If you have a project that involves metals you might have to use mig welding. Web are you working with a plate thickness of 5/16 in? Web aluminum mig welding settings charts. Always test your settings on a scrap piece of metal. When you’re looking for the right settings for your lincoln 140 mig welder. You may need to dial them in, depending on your setup. Web setting up your mig welder for the first time. Web there are 3 main controls that set the welder: Web there are 3 main controls that set the welder: Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. But before using these values, we suggest. Web learn how to identify the parent material, select the filler metal, choose the shielding gas, and adjust the gas quantity and welder settings for mig/mag. Web learn how to set up your mig welder for different materials, thicknesses, and shielding gases. Web setting up your mig welder for the first time. You may need to dial them in, depending on your setup. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal.. Web the following basic mig welding settings are for welding steel with solid wire. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web lincoln mig welding settings charts. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web there are 3 main controls. Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Web are you working with a plate thickness of 5/16 in? Web what material are you welding? Web learn how to set up your mig welder for different materials, thicknesses, and shielding gases. Web the most important. Then use 120 amps while working with a dc polarity. Voltage, wire feed speed, and gas flow rate. These settings determine the heat, wire deposition rate, and. Joint design, position and other factors affect results and settings. Web aluminum mig welding settings charts. If you have a project that involves metals you might have to use mig welding. Then use 120 amps while working with a dc polarity. Read and understand the safety data sheets. These settings determine the heat, wire deposition rate, and. Web the following basic mig welding settings are for welding steel with solid wire. Now that you’ve grasped the basics of how mig welding works and how to protect yourself using personal protective. Web aluminum mig welding settings charts. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web learn how to set up your mig welder for different materials, thicknesses, and shielding gases. Find out. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Always test your settings on a scrap piece of metal. When you’re looking for the right settings for your lincoln 140 mig welder. Now that you’ve grasped the basics of how mig welding works and how to. Here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. Voltage, wire feed speed, and gas flow rate. If you have a project that involves metals you might have to use mig welding. Web what material are you welding? Read and understand the safety data sheets. Always test your settings on a scrap piece of metal. Web the following basic mig welding settings are for welding steel with solid wire. Find out how voltage, wire speed, and gas flow affect the weld quality. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. You may need to dial them in, depending on your setup. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. When you’re looking for the right settings for your lincoln 140 mig welder. Web miller mig welding settings charts. Web aluminum mig welding settings charts. So that you know where start to get yourself a strong good looking. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:

Mig Welding Chart Settings

Mig Welding Settings Chart

How To MIG Weld Aluminum Beginners Guide (with Chart)

Mig Welding Settings Chart Metric Pdf

Mig Welding Setting Chart

How To Set Up a MIG Welder Welder Settings, Gasses and Electrodes

MIG Welder Settings Explained (with Chart) Weld Guru

Important MIG Welder Settings You Need to Know (with Chart)

Lincoln Mig Welder Settings Chart

Mig Welding Chart Settings And Guides

There Are Many Mig Setting Charts Available From Manufacturers That All Vary.

Joint Design, Position And Other Factors Affect Results And Settings.

But Before Using These Values, We Suggest.

These Settings Determine The Heat, Wire Deposition Rate, And.

Related Post: