Weld Weave Patterns

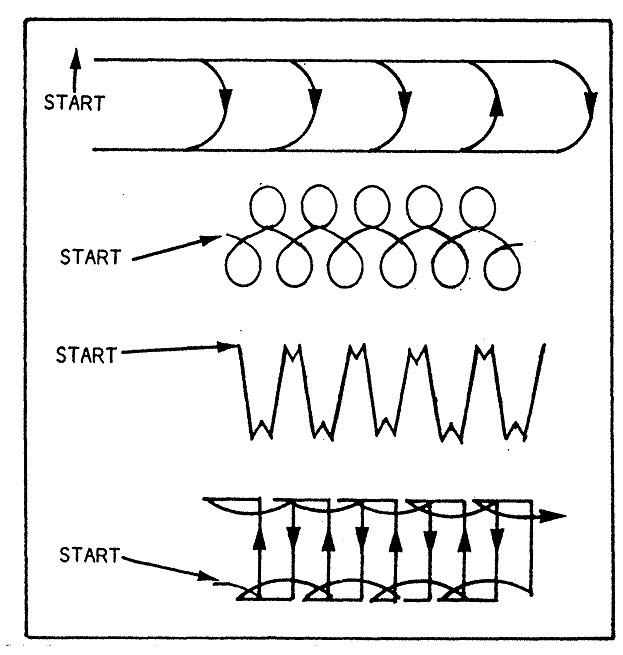

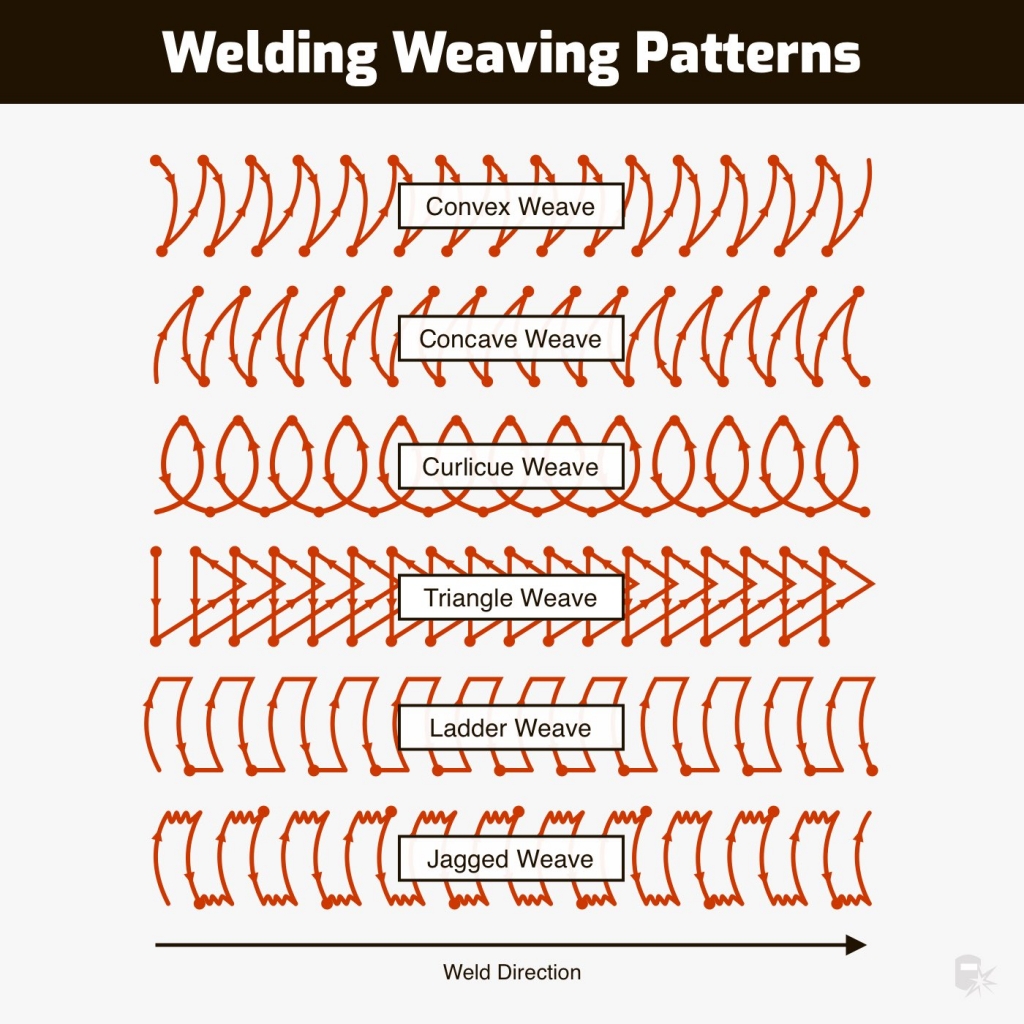

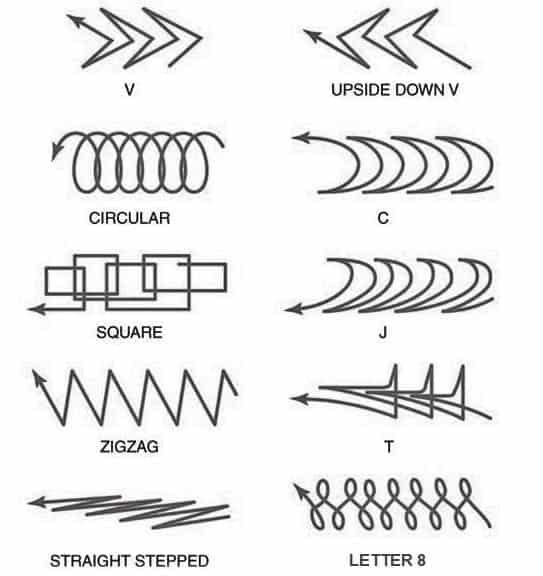

Weld Weave Patterns - Common welding patterns and their uses. Web you can weld thicker materials by weaving because it evenly distributes the heat and ensures optimal penetration. Use a wire brush or grinder to remove. With this comprehensive guide, you'll be an adept welder quickly. You use this motion to make cover. These patterns significantly impact the final. This is the most basic and straightforward pattern, involving a simple linear motion. Web circular weave patterns are often found in pipe welding applications. You will make a weaving pattern in order to cover a larger area. Weave pattern beads are beneficial when you’ve got a broader joint to weld, as they will result in a nice wide bead. Weave bead welding is exactly as it sounds; Web weldpundit has a detailed article on how to stick weld vertically, including rod amperage charts, and weave patterns for cellulosic rods. Web there are basically two ways to weave a tig weld: These patterns significantly impact the final. Web weave welding is achieved by offsetting the motion of the weld arc. Web there are basically two ways to weave a tig weld: The stringer bead, crescent weave pattern bead,. Web weave patterns offer several advantages in mig welding and find extensive applications in various welding scenarios: Web circular weave patterns are often found in pipe welding applications. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern,. Walking the cup and freehand. 349k views 8 years ago welding. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. Weave bead welding is exactly as it sounds; Web straight line pattern: Walking the cup and freehand. It’s often used for thin materials or when a quick, strong. The weaving technique is about more than just moving up and down. Weave bead welding is exactly as it sounds; Web weldpundit has a detailed article on how to stick weld vertically, including rod amperage charts, and weave patterns for cellulosic rods. Web you can weld thicker materials by weaving because it evenly distributes the heat and ensures optimal penetration. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. This motion allows you to make cover welds over stringer beads,. Web weave patterns offer several advantages in mig. While stick welding may be the most forgiving process on dirty or rusty metal, you should still clean the material. Common welding patterns and their uses. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. Pbz manufacturing is familiar with all the common welding patterns and. This motion allows you to make cover welds over stringer beads,. The weaving technique is about more than just moving up and down. Web weave welding is achieved by offsetting the motion of the weld arc as it moves along the weld path, making it ideal for filling wide, flat joints or welding thick. Pbz manufacturing is familiar with all. Mig (metal inert gas) welding is an arc welding process used widely for versatile welding, creating solid and durable welds. Web there are basically two ways to weave a tig weld: Weave bead welding is exactly as it sounds; The stringer bead, crescent weave pattern bead,. This motion allows you to make cover welds over stringer beads,. Web there are basically two ways to weave a tig weld: Walking the cup and freehand. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. It’s often used for thin materials or when a quick, strong. With this comprehensive guide, you'll be an adept welder quickly. Web weaving welding technique pattern. Web weave welding is achieved by offsetting the motion of the weld arc as it moves along the weld path, making it ideal for filling wide, flat joints or welding thick. Mig (metal inert gas) welding is an arc welding process used widely for versatile welding, creating solid and durable welds. Creates smooth and durable. Pbz manufacturing is familiar with all the common welding patterns and how to use them effectively for your projects. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. You use this motion to make cover. Weave pattern beads are beneficial when you’ve got a broader joint to weld, as they will result in a nice wide bead. Web straight line pattern: Web weave patterns offer several advantages in mig welding and find extensive applications in various welding scenarios: Walking the cup and freehand. It’s often used for thin materials or when a quick, strong. These patterns significantly impact the final. This is the most basic and straightforward pattern, involving a simple linear motion. Mig (metal inert gas) welding is an arc welding process used widely for versatile welding, creating solid and durable welds. Web circular weave patterns are often found in pipe welding applications. Weaves are used for wider welds and range from a tight side to side motion that can be a stringer bead to welds that are. The stringer bead, crescent weave pattern bead,. Web you can weld thicker materials by weaving because it evenly distributes the heat and ensures optimal penetration. Web weldpundit has a detailed article on how to stick weld vertically, including rod amperage charts, and weave patterns for cellulosic rods.

MIG Welding Weave Patterns Super Helpful Guide & Review

MIG Welding Weave Patterns Super Helpful Guide & Review

Welding Techniques

Welding Beads What Are They? & Different Types

6 Essential MIG Welding Patterns To Master

DIFFERENT TYPES OF WEAVING USED IN THE PROCESS OF WELDING Nikit

Mig Welding Weave Patterns Pattern.rjuuc.edu.np

Weaving in welding A comprehensive guide to weave patterns

What is Welding Bead and their Different Types with Uses?

Weaving in welding A comprehensive guide to weave patterns

Use A Wire Brush Or Grinder To Remove.

For Example, You Can Use The.

You Will Make A Weaving Pattern In Order To Cover A Larger Area.

Creates Smooth And Durable Welds On Thicker Materials, Versatile For All Weld Positions, Ideal.

Related Post: