Weld Procedure Template

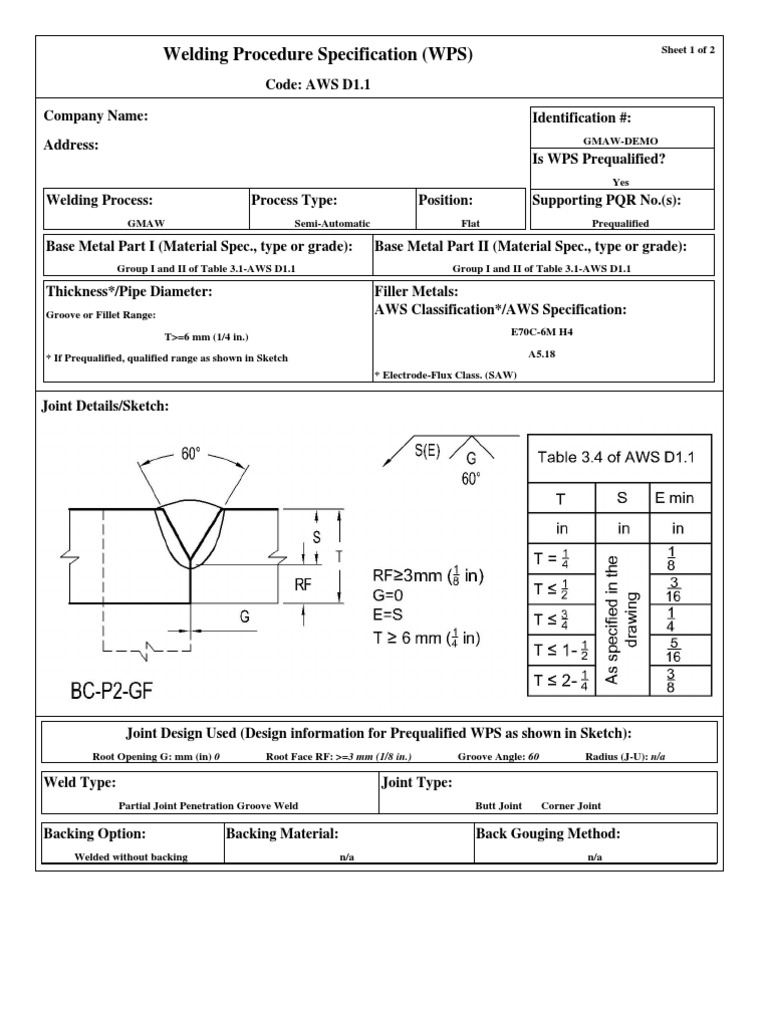

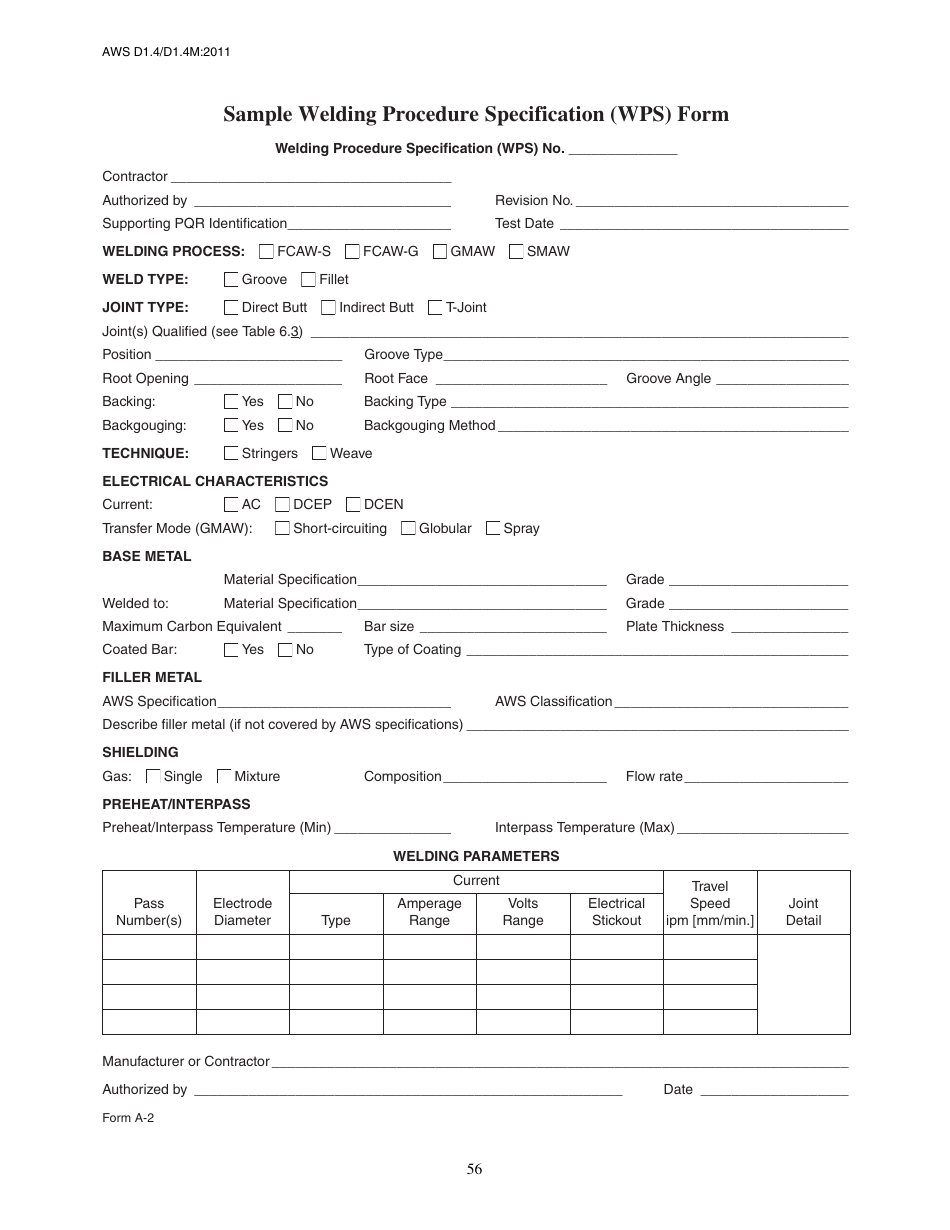

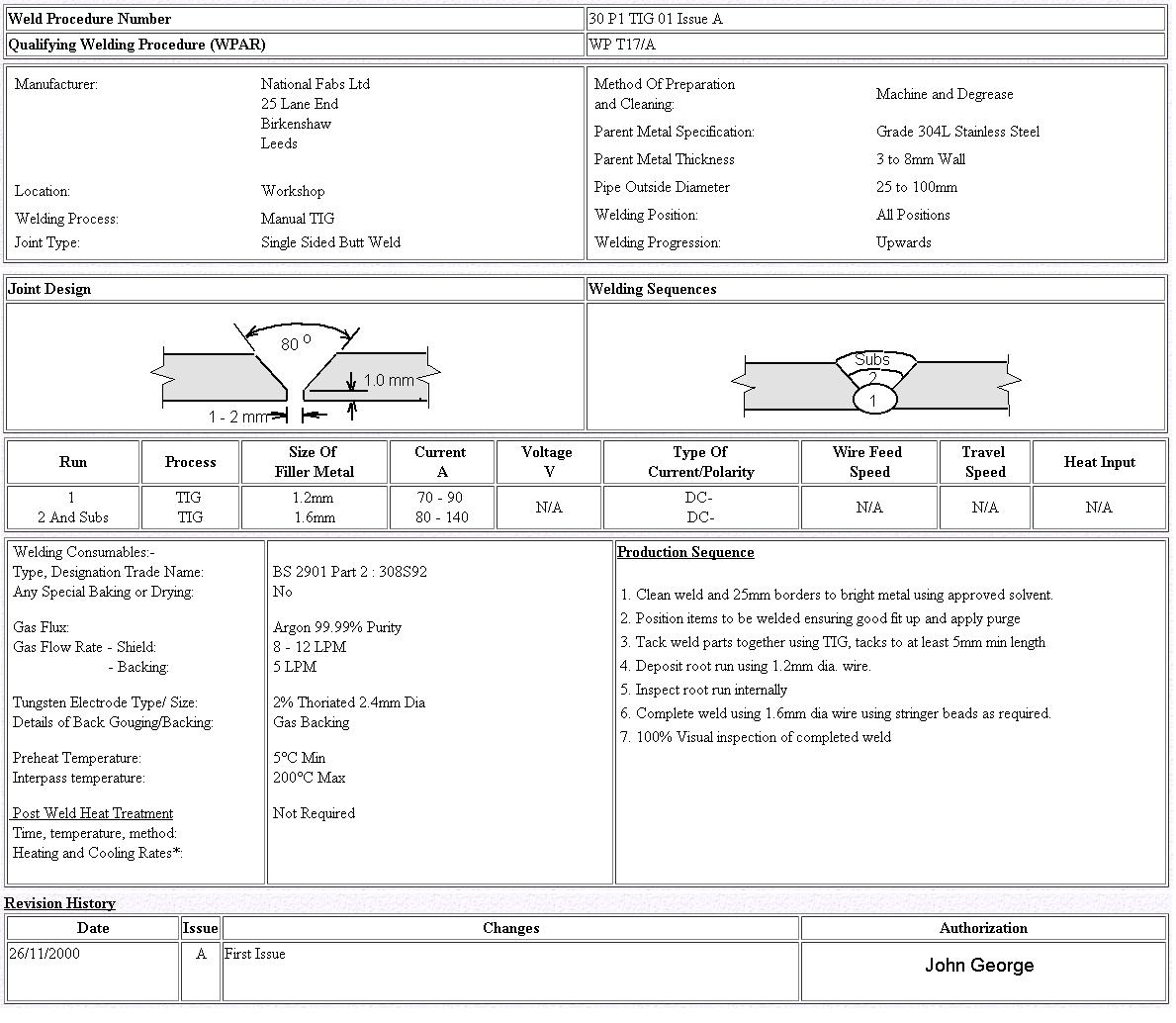

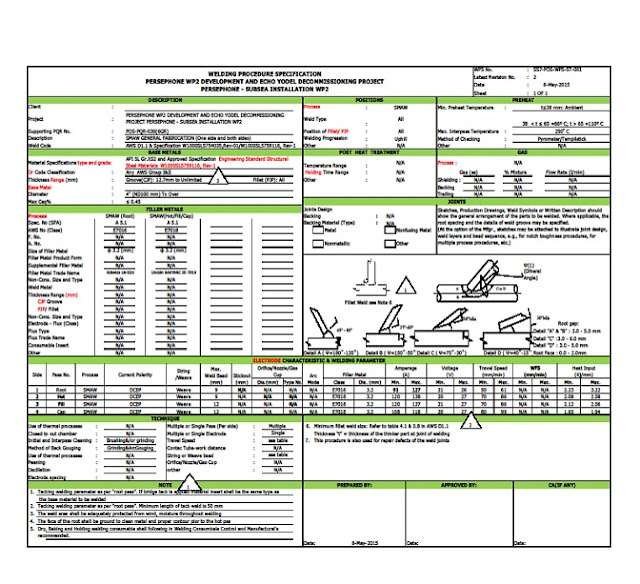

Weld Procedure Template - Web create a wps in minutes! Web this welding procedure specification outlines the parameters for welding, including the welding process, filler material size, current and voltage ranges, travel speed, heat input, gas flow rates, tungsten electrode type, preheat. Asme also offers a wps template. Welders use wpss to produce welds consistently and repeatably, ensuring they meet the required quality standards. Web the sample welding procedure specification (wps) form is used to document the details and requirements of a welding procedure. Web too often, i see welding procedures documented using the templates available from the various codes or jurisdictions responsible for compliance. All positions for plate or pipe. It provides instructions on how to perform a specific welding process, including information about the materials, equipment, and parameters to be used. Web ðï ࡱ á> þÿ s u. The intense heat generated with this arc melts the base metal and allows the joining of two components. Asme ix (for all of these methods: It explains a prescribed description of the welding process, gases and flow rates, the joint design and geometry, the base materials used, welding position including various variables. Asme also offers a wps template. The intense heat generated with this arc melts the base metal and allows the joining of two components. (including ranges,. It contains all the necessary parameters viz. Where applicable, the root details of the weld groove may be specified. Web ðï ࡱ á> þÿ s u. 1.fit up 2.welding*/cleaning 3.visual inspection 4.ndt(rt,ut,pt,mt)**. Web welding procedure specification (wps) is a written and detailed document for welding operations. Asme ix (for all of these methods: These settings are not visible to the welder with the hood down. The intense heat generated with this arc melts the base metal and allows the joining of two components. Asme also offers a wps template. Web ðï ࡱ á> þÿ s u. It contains all the necessary parameters viz. R 1⁄4” instructor and done in test position. Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual process. Web wps qualified range (asme ix guideline): Web the sample welding procedure specification. Web wps qualified range (asme ix guideline): Web ðï ࡱ á> þÿ s u. Web figure f.2—example of a welding procedure specification joint details sketches, production drawings, welding symbols, or written description should show the general arrangement of the parts to be welded. Web create a wps in minutes! Web this welding procedure specification outlines the parameters for welding, including. Web ðï ࡱ á> þÿ s u. It explains a prescribed description of the welding process, gases and flow rates, the joint design and geometry, the base materials used, welding position including various variables. Web welding procedure specification (wps) is a written and detailed document for welding operations. Welding parameters and ranges are (including ranges, if any) under which the. Web the sample welding procedure specification (wps) form is used to document the details and requirements of a welding procedure. (including ranges, if any) under which the welding process must be performed. All positions for plate or pipe. Web a welding procedure data sheet (wpds) is a document, used in conjunction with a wps, detailing the welding parameters and ranges. (including ranges, if any) under which the welding process must be performed. Web the sample welding procedure specification (wps) form is used to document the details and requirements of a welding procedure. Web aws d1.1/d1.1m:2010 annex n 355 welding procedure specification (wps) yes prequalified _____ qualified by testing _____ or procedure qualification records (pqr) yes The intense heat generated with. Where applicable, the root details of the weld groove may be specified. Web a welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). It provides instructions on how to perform a specific welding process, including information about the materials, equipment, and parameters to be used. Web figure f.2—example of a welding procedure specification. Web welding procedure specification examples and templates can be found in annex n of aws d1.1 or annex o of aws d1.5. Web the sample welding procedure specification (wps) form is used to document the details and requirements of a welding procedure. Web wps qualified range (asme ix guideline): Pass process filler metal current (asme sec iic) heat input (kj/mm). Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual process. 1.fit up 2.welding*/cleaning 3.visual inspection 4.ndt(rt,ut,pt,mt)**. Web sample (www.weldingandndt.com) welding procedure specification (wps) sample (www.weldingandndt.com) date: All positions for plate or pipe. The intense heat generated with this arc melts the base metal and allows the joining of two components. Web welding procedure specification examples and templates can be found in annex n of aws d1.1 or annex o of aws d1.5. Web ðï ࡱ á> þÿ s u. Where applicable, the root details of the weld groove may be specified. These settings are not visible to the welder with the hood down. Web a welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). It contains all the necessary parameters viz. Web the sample welding procedure specification (wps) form is used to document the details and requirements of a welding procedure. Web a welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. No grinding on cover pass α 70 degrees 2. Groove & fillet welds, corrosion resistant & hardfacing overlay welds, tube to tubesheet joints, lap & stud welds), aws d1.1, aws d1.2, aws d1.5 (for all of these methods: Welders use wpss to produce welds consistently and repeatably, ensuring they meet the required quality standards.

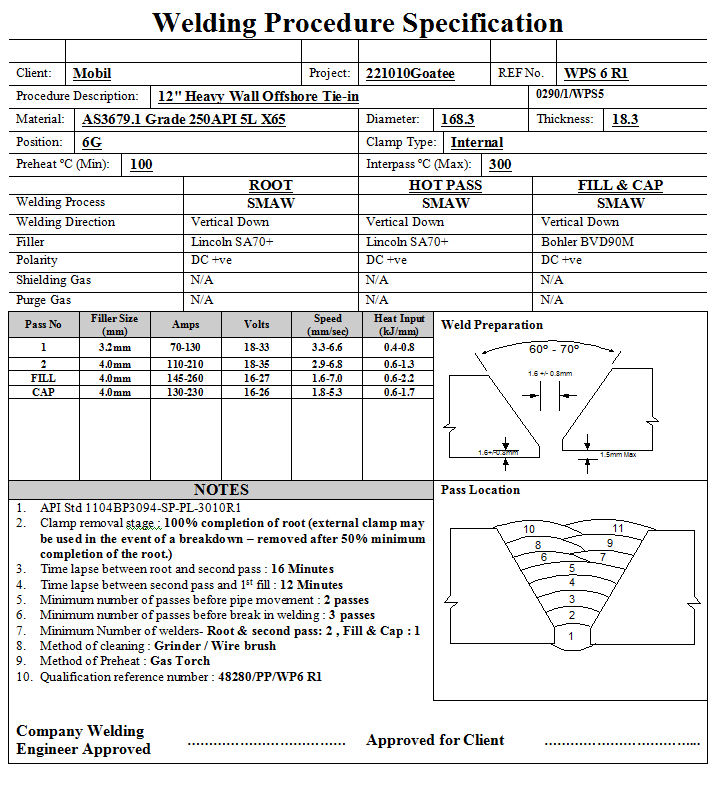

Sample Welding Procedure Specification (Wps) Form Fill Out, Sign

SMAWFilletAWS20D1.1 Welding Industrial Processes

Welding Procedure Metallurgy for Dummies

Welding Procedure Specification Template

Welding Procedure Specification Format Welding Construction

Introduction Download Welding Procedures

Guide reading welding procedure Specification WPS (Welding procedure

Welding Procedure Specification Sample

Welding Procedure Metallurgy for Dummies

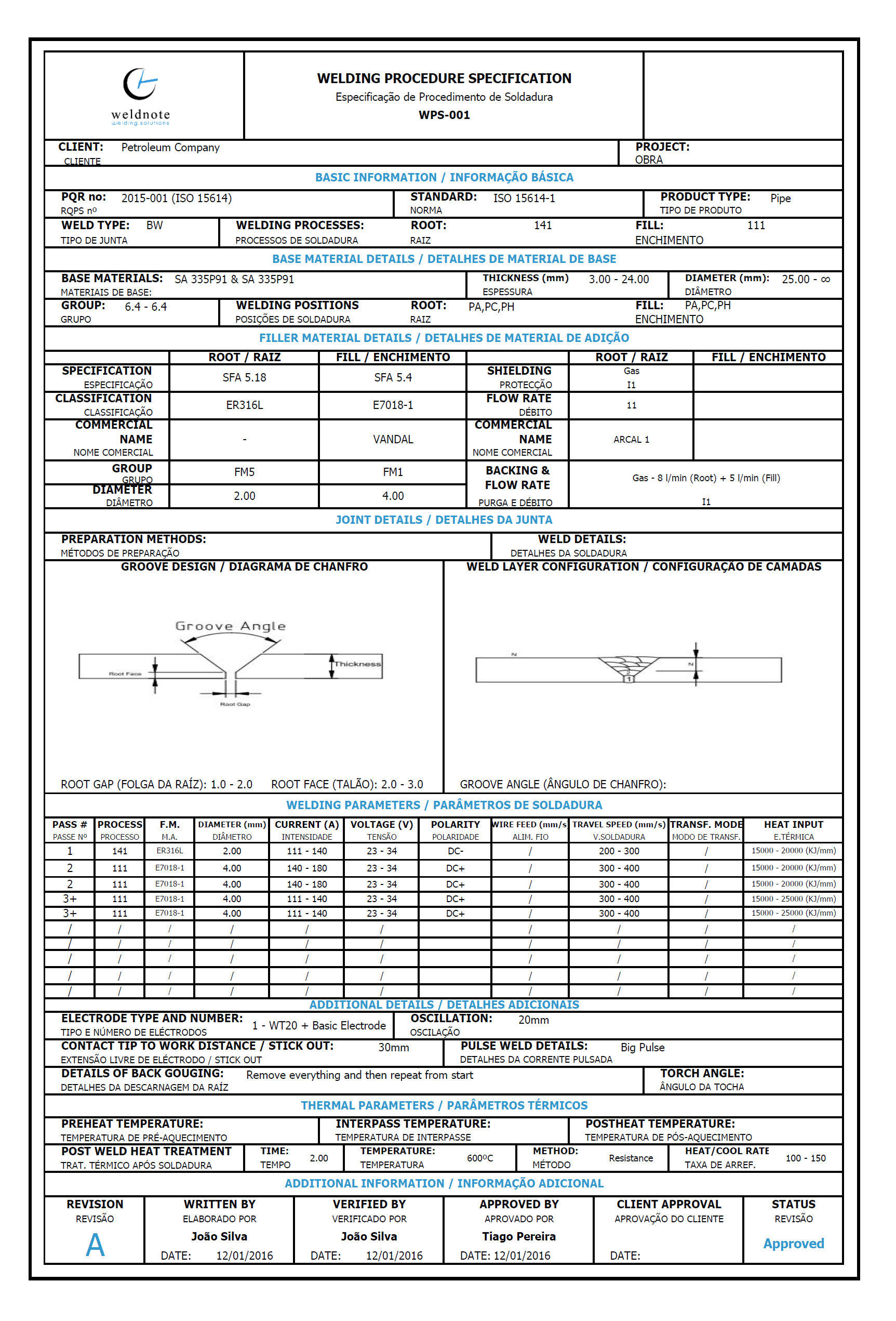

WeldNote Welding Management Software

Asme Also Offers A Wps Template.

Web Figure F.2—Example Of A Welding Procedure Specification Joint Details Sketches, Production Drawings, Welding Symbols, Or Written Description Should Show The General Arrangement Of The Parts To Be Welded.

It Explains A Prescribed Description Of The Welding Process, Gases And Flow Rates, The Joint Design And Geometry, The Base Materials Used, Welding Position Including Various Variables.

(Including Ranges, If Any) Under Which The Welding Process Must Be Performed.

Related Post: