Weld Groove Design

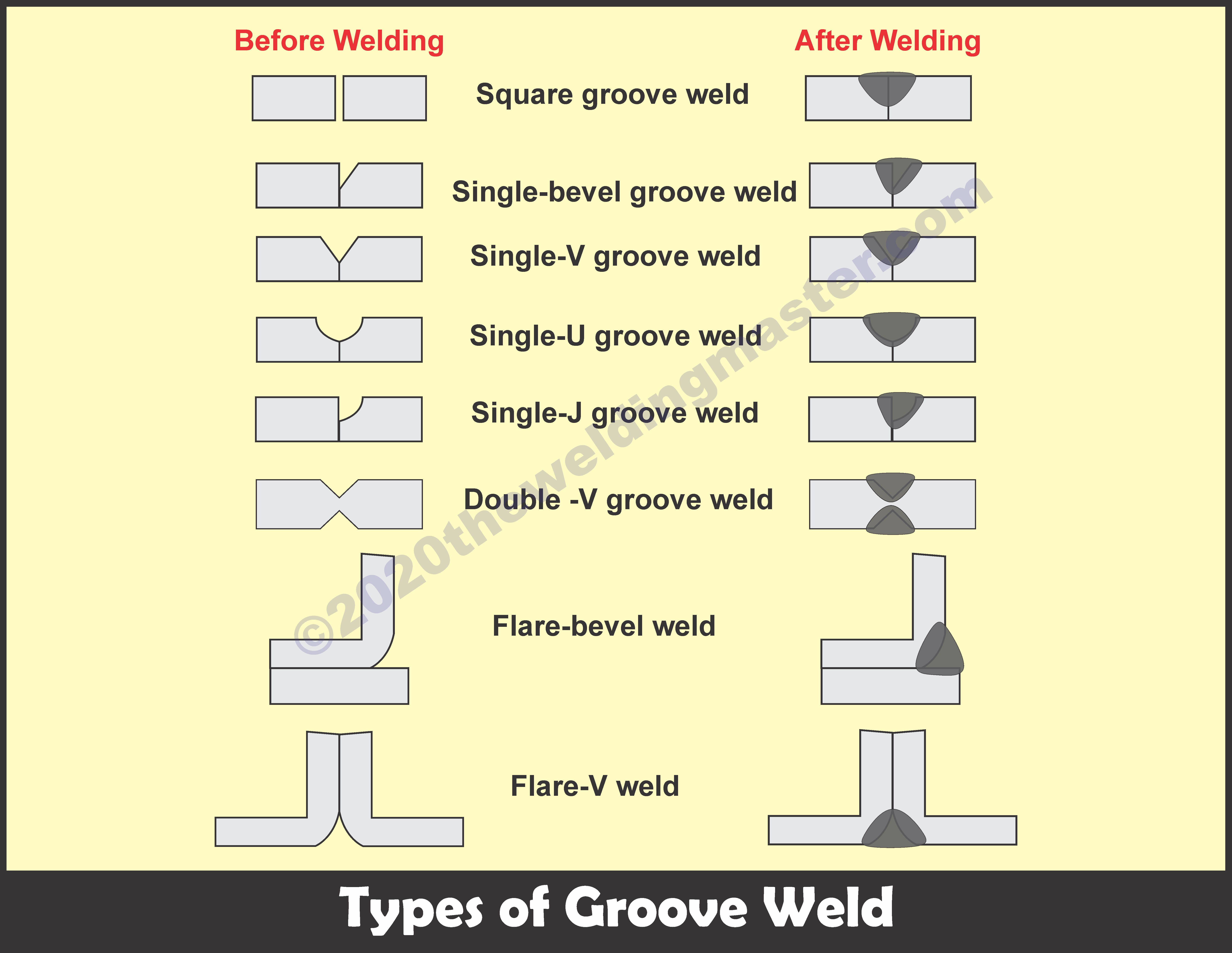

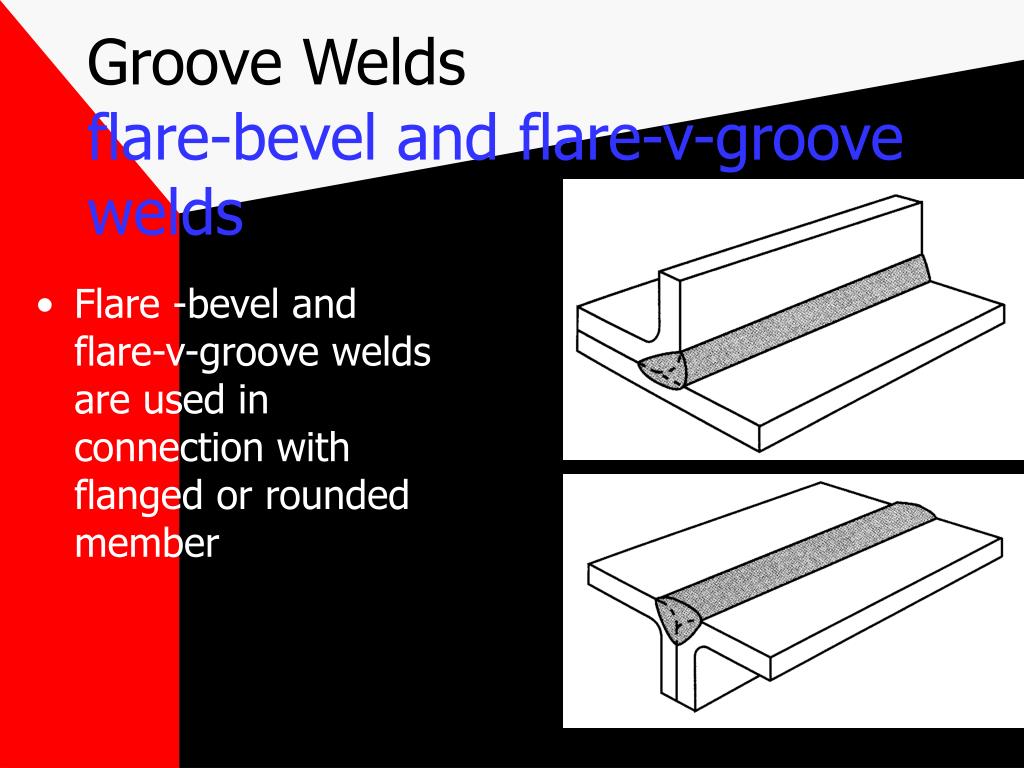

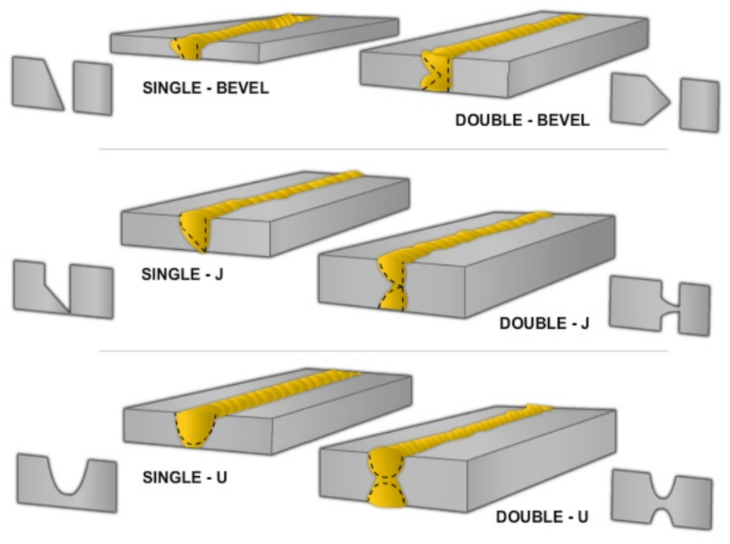

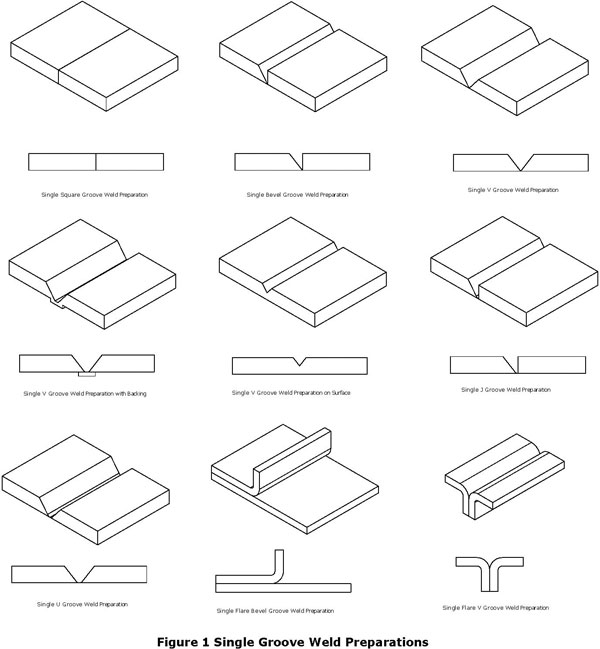

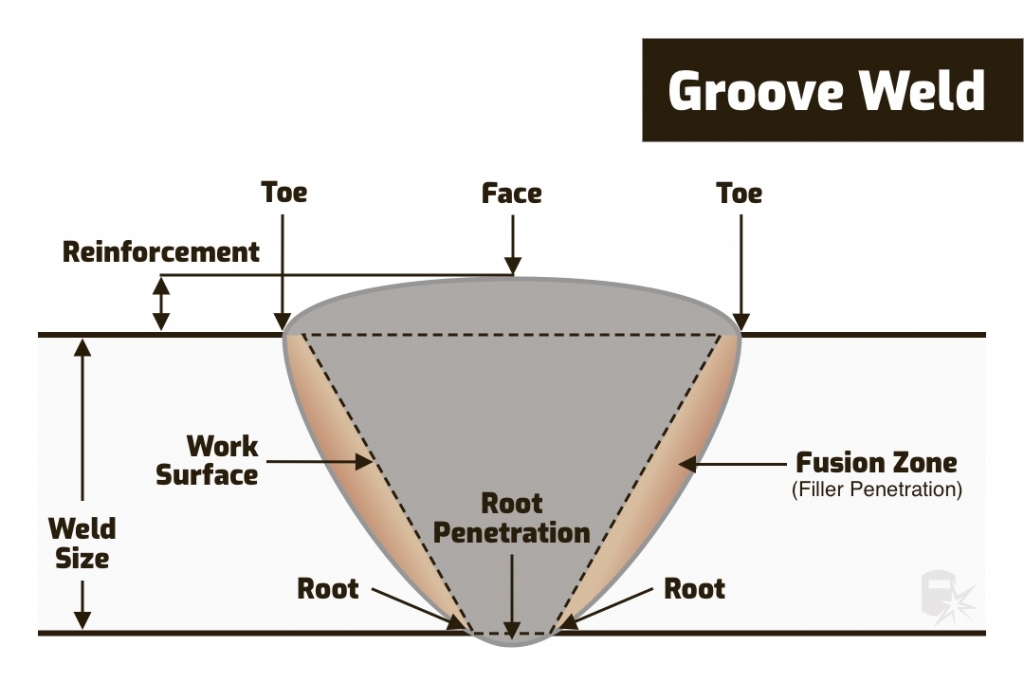

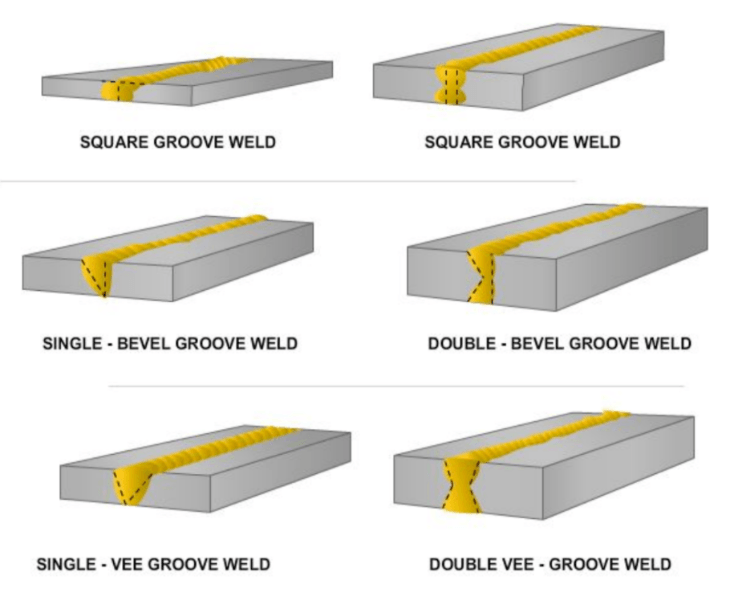

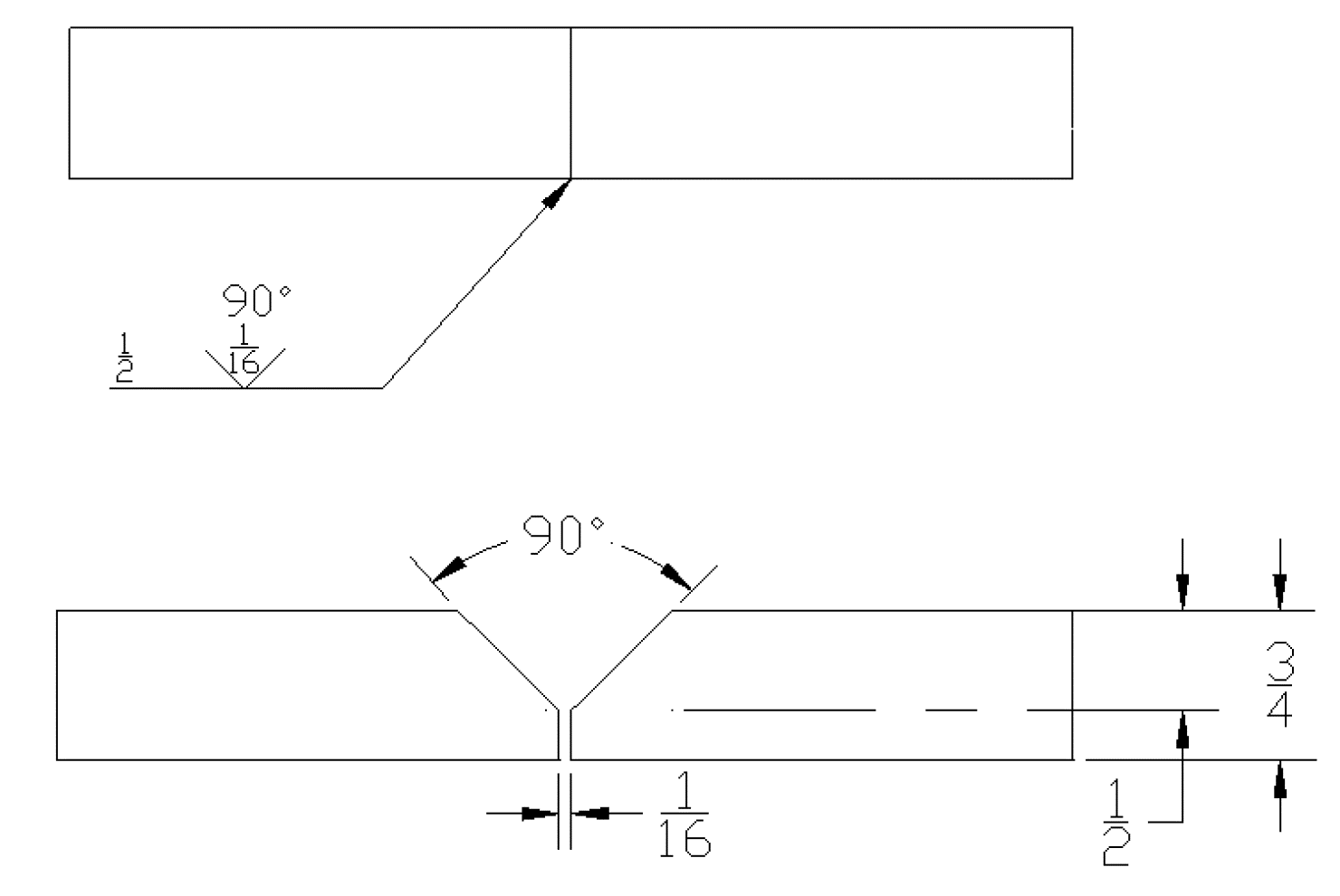

Weld Groove Design - The welding classes at southern technical college offers more than just the technical skills to become a welder. The following 8 steps will make it easier to interpret welding symbols for groove welds. This section covers the requirements for the design of welded connections. This type of weld is often used in small weld thickness applications, because it is productive, good quality and reliable. Web a groove weld, also known as a butt weld is a type of weld joint configuration that is created by depositing weld material into a groove (of different shapes, as we will see later in this post) that has been machined into the two. Web the term “weld joint design” refers to the way pieces of metal are put together or aligned with each other. Web design of welded connections. Provides complete fusion, low stress, and 100% penetration. Additional design aspects of the weld joints have also been presented. Web design of welded connections. Groove weld or butt weld can be the same when butting members have grooves made on them. Lap joints, which require fillet welds; Determine the type of joint and joint preparation needed. Pros of groove joint design. Additional design aspects of the weld joints have also been presented. Direct loading applications and eccentrically loaded applications are covered. Additional design aspects of the weld joints have also been presented. Preparation for making a connection where the individual components, suitably prepared and assembled, are joined by welding or brazing. Web the design, shape, and dimensions of the groove depend on a number of factors, including material type and thickness, welding. Groove weld or butt weld can be the same when butting members have grooves made on them. The following are to links of welding engineering and design equation, tips and specifications. Additional design aspects of the weld joints have also been presented. Web part 2 provides the essential information on analysis and design of welded joints. Lap joints, which require. Web groove design & bevel preparation. These are determined by the joint geometry. The section covers the two main types of welded connections, fillet welds and groove welds, as they make up nearly 95% of all welded joints used in mechanical applications. Web the term “weld joint design” refers to the way pieces of metal are put together or aligned. Butt joints requiring a groove weld; The following are to links of welding engineering and design equation, tips and specifications. And corner joints, which can be fillet or groove welds. Web the design, shape, and dimensions of the groove depend on a number of factors, including material type and thickness, welding position, welding process, and joint configuration. Web groove weld. Pros of groove joint design. This section covers the design requirements of nontubular and tubular welded connections, regardless of the product form or the type of loading. Web groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. Web groove weld is one of the types of weld joint (. Selecting the most appropriate joint design for a welding job requires special attention and skill. Pros of groove joint design. These are determined by the joint geometry. Provides complete fusion, low stress, and 100% penetration. Web design of welded connections. The section covers the two main types of welded connections, fillet welds and groove welds, as they make up nearly 95% of all welded joints used in mechanical applications. Web weld process and joint design and engineering formula menu. Web part 2 provides the essential information on analysis and design of welded joints. Preparation for making a connection where the. Butt joints requiring a groove weld; Lap joints, which require fillet welds; Web weld process and joint design and engineering formula menu. Web groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. These are determined by the joint geometry. Web unlike fillet welds where there is no variation, there are many different types of groove welds. Butt joints requiring a groove weld; Welds shrink evenly and are less likely to distort. Web a weld groove is defined as “a channel in the surface of a workpiece or an opening between two joint members providing space to contain weld metal.”. The welding classes at southern technical college offers more than just the technical skills to become a welder. This section covers the design requirements of nontubular and tubular welded connections, regardless of the product form or the type of loading. The optimal groove weld depth, at a safety factor of 3.5, ranges from 20 to 50 mm. Web design of welded connections. Selecting the most appropriate joint design for a welding job requires special attention and skill. Additional design aspects of the weld joints have also been presented. Preparation for making a connection where the individual components, suitably prepared and assembled, are joined by welding or brazing. Butt joints requiring a groove weld; Understand weld anatomy to optimize costs. Pros of groove joint design. Cons of groove joint design. And corner joints, which can be fillet or groove welds. Part a—common requirements of nontubular and tubular connections. These are determined by the joint geometry. Web the joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. Web a groove weld, also known as a butt weld is a type of weld joint configuration that is created by depositing weld material into a groove (of different shapes, as we will see later in this post) that has been machined into the two.

How to Read Welding Blueprints Like a Pro

Types of groove weld

PPT Weld Joint Geometry and Welding Symbols PowerPoint Presentation

Design of butt weld (Groove weld) YouTube

Guide to Welding Joint Types and Parts WelditU

Understanding Weld symbols The groove weld Meyer Tool & Mfg.

Parts of A Weld Weld Components with Diagram Weld Guru

Types of Welding Joints and Welds Color Graphics • WelditU

What is the design criteria of Groove Joints? Explain in details step

Groove Welding Symbols Interpretation of Metal Fab Drawings

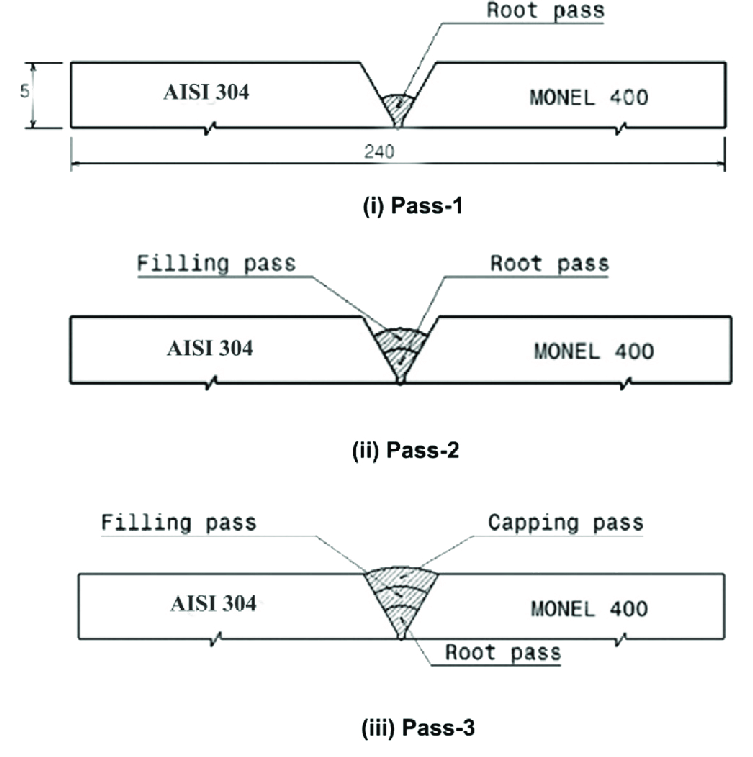

Web This Chapter Describes The Factors Affecting The Selection Of Suitable Groove Geometry For Edge Preparation And Influence Of Welding Parameters On Weld Bead Geometry.

Each Joint’s Design Affects The Quality And Cost Of The Completed Weld.

Web Get An Overview Of Fillet Welds And Groove Welds And How They're Used, Both Commonly Found On Structural Steel Jobsites.

Web The Design, Shape, And Dimensions Of The Groove Depend On A Number Of Factors, Including Material Type And Thickness, Welding Position, Welding Process, And Joint Configuration.

Related Post: