V Belt Tensioning Chart

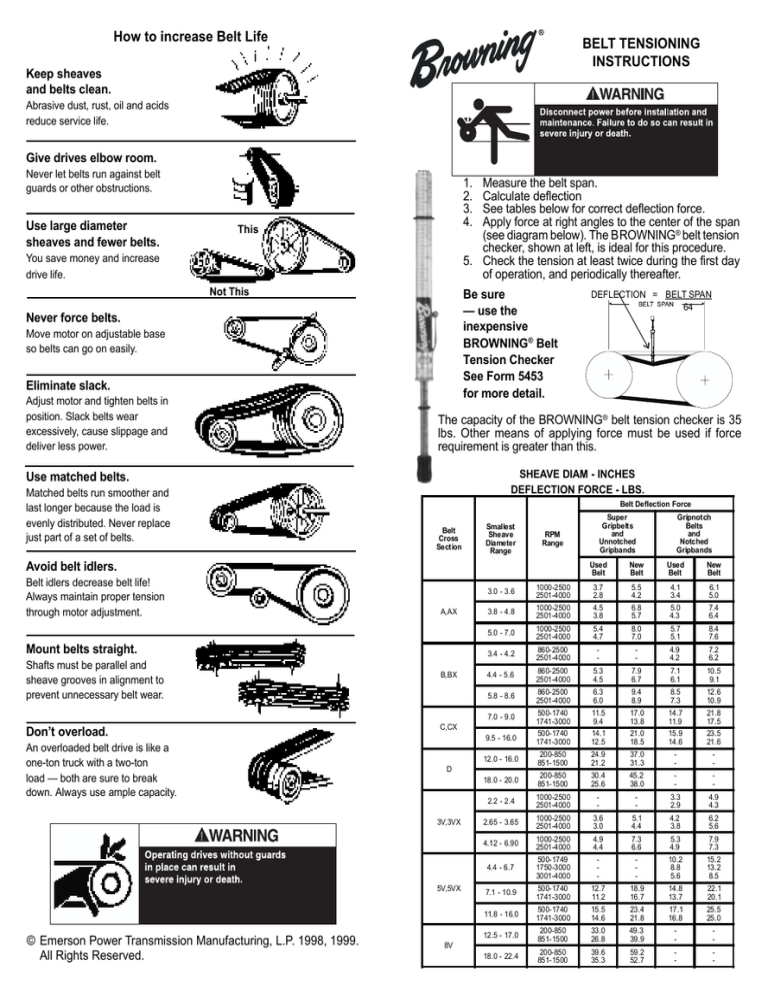

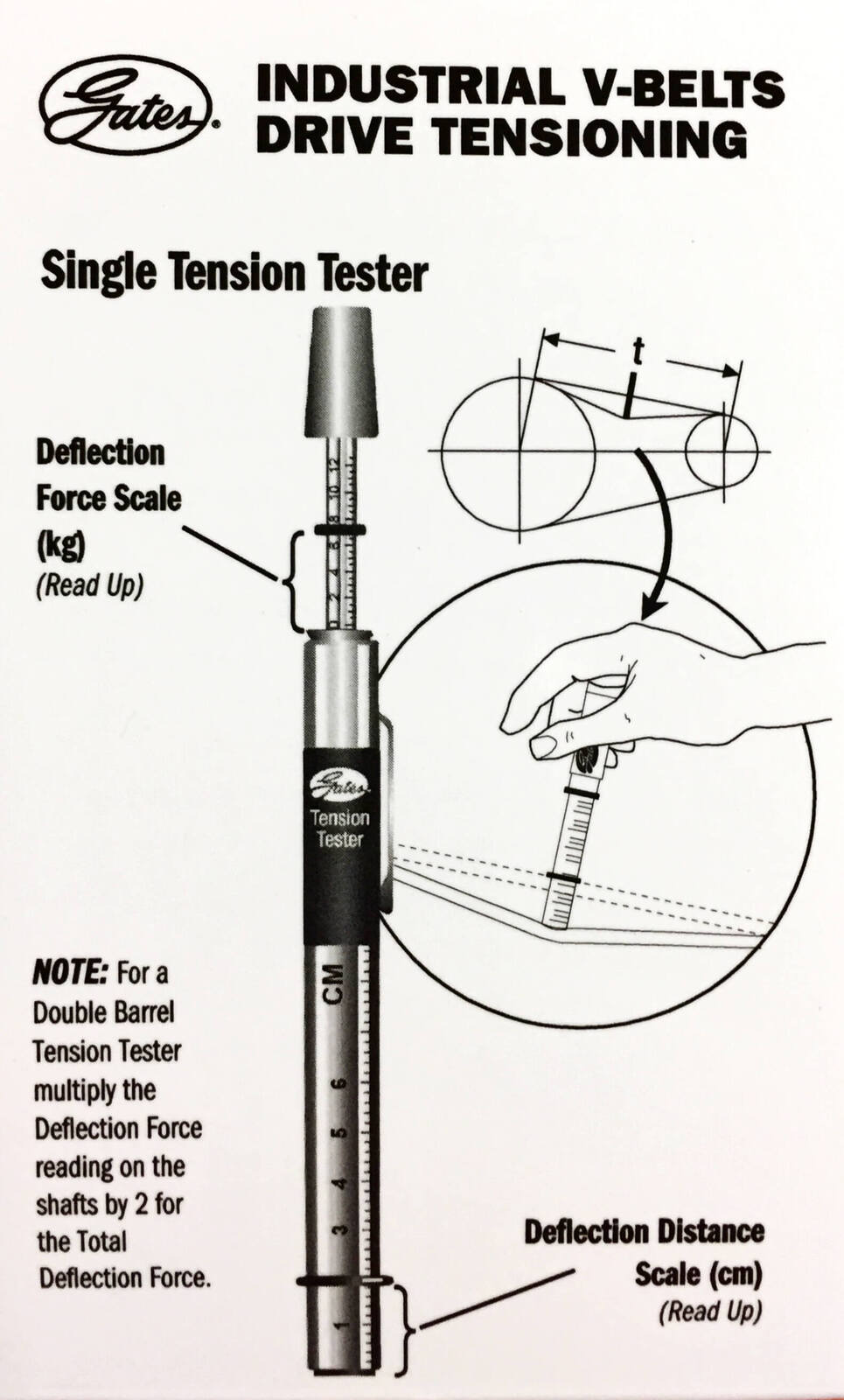

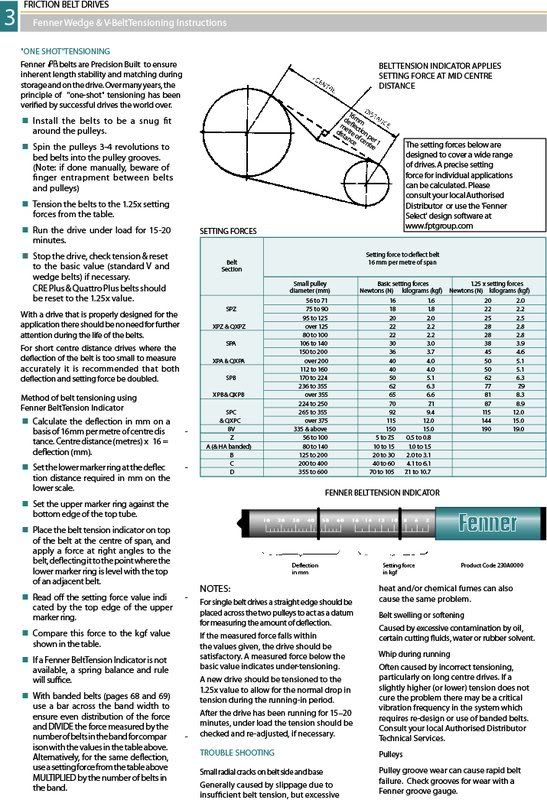

V Belt Tensioning Chart - Shop best sellersdeals of the dayread ratings & reviewsshop our huge selection Web v belt tension methods & instructions. After seating the belts in the groove and adjusting. Web belt drive design is key in obtaining optimum performance and durability in transmission systems. Tight side tension (pounds) hp : Jk fenner has developed an online calculator to simplify this for you. This information is crucial for achieving optimal. Web table 1 gives general tensioning values for a particular belt cross section in relation to the pulley diameter. Top brandsbuyer protection programdaily deals>80% items are new Web calculate your gates powergrip belt drive tension to determine the proper center distance, tension force, deflection distance and more to improve your belt system efficiency. This information is crucial for achieving optimal. Incorrect belt tension (as well as pulley misalignment) adversely affects belt drive reliability and efficiency. To check the tension of a v. Top brandsbuyer protection programdaily deals>80% items are new First, the effective belt tension (te) must be calculated. Small sheave initial diameter range (inches) retensioning maximum minimum Htb, standard and metric timing belts should be installed to fit pulleys snugly, neither too tight nor too loose. See tables below for correct deflection force. The friction is multiplied by the mechanical advantage of the wedging principle. Web table 1 gives general tensioning values for a particular belt cross section. Ideal tension is the lowest tension at which the belt will not slip under peak. When you install a new set of belts, use the gauge to establish correct. Apply force at right angles to the center of the span (see diagram. Jk fenner has developed an online calculator to simplify this for you. Small sheave initial diameter range (inches). Web table 1 gives general tensioning values for a particular belt cross section in relation to the pulley diameter. Te is the sum of the tension required to move the empty belt (tc), the tension required to. Web belt drive design is key in obtaining optimum performance and durability in transmission systems. (calculates the force exerted by an endless belt. See tables below for correct deflection force. After seating the belts in the groove and adjusting. First, the effective belt tension (te) must be calculated. Too little tension will result in slippage, causing rapid belt and. Htb, standard and metric timing belts should be installed to fit pulleys snugly, neither too tight nor too loose. Web v belt tension methods & instructions. First, the effective belt tension (te) must be calculated. (calculates the force exerted by an endless belt on a pulley, i.e., the force of two belt strands) we recommend stretching most unreinforced round belts. Incorrect belt tension (as well as pulley misalignment) adversely affects belt drive reliability and efficiency. See tables below for. Web table 1 gives general tensioning values for a particular belt cross section in relation to the pulley diameter. See tables below for correct deflection force. Web belt drive design is key in obtaining optimum performance and durability in transmission systems. After seating the belts in the groove and adjusting. The friction is multiplied by the mechanical advantage of the. Web table 1 gives general tensioning values for a particular belt cross section in relation to the pulley diameter. Te is the sum of the tension required to move the empty belt (tc), the tension required to. Small sheave initial diameter range (inches) retensioning maximum minimum First, the effective belt tension (te) must be calculated. Too little tension will result. Web proper belt tension is a critical step when installing a belt. (calculates the force exerted by an endless belt on a pulley, i.e., the force of two belt strands) we recommend stretching most unreinforced round belts. When you install a new set of belts, use the gauge to establish correct. Te is the sum of the tension required to. Ideal tension is the lowest tension at which the belt will not slip under peak. Web belt drive design is key in obtaining optimum performance and durability in transmission systems. The friction is multiplied by the mechanical advantage of the wedging principle. Too little tension will result in slippage, causing rapid belt and. Htb, standard and metric timing belts should. Jk fenner has developed an online calculator to simplify this for you. After seating the belts in the groove and adjusting. Web a belt will still operate satisfactorily within a wide range of tension. First, the effective belt tension (te) must be calculated. Web v belt tension methods & instructions. Incorrect belt tension (as well as pulley misalignment) adversely affects belt drive reliability and efficiency. Htb, standard and metric timing belts should be installed to fit pulleys snugly, neither too tight nor too loose. When you install a new set of belts, use the gauge to establish correct. Web table 1 gives general tensioning values for a particular belt cross section in relation to the pulley diameter. This information is crucial for achieving optimal. Te is the sum of the tension required to move the empty belt (tc), the tension required to. Apply force at right angles to the center of the span (see diagram. See tables below for correct deflection force. Small sheave initial diameter range (inches) retensioning maximum minimum Tight side tension (pounds) hp : Arc of contact (°) tight side tension t1 = 41,250 x hp fa x v t1 :

V Belt Tension Chart

Vbelt Tension Gauge Chart Wholesale Store saratov.myhistorypark.ru

V Belt Tension Gauge Chart

Fenner V Belt Tension Chart

Gates Pocket VBelt Tension Guide

Fenner V Belt Tension Chart A Visual Reference of Charts Chart Master

V Belt Tension Chart

V Belt Tension Chart Pdf

V Belt Tension Gauge Chart

V Belt Tensioning Chart

(Calculates The Force Exerted By An Endless Belt On A Pulley, I.e., The Force Of Two Belt Strands) We Recommend Stretching Most Unreinforced Round Belts.

To Check The Tension Of A V.

Web Proper Belt Tension Is A Critical Step When Installing A Belt.

The Friction Is Multiplied By The Mechanical Advantage Of The Wedging Principle.

Related Post: