Twist Damascus Pattern

Twist Damascus Pattern - It is almost a must to grind the outside smooth before further forging. It will give a slight variation on the pattern but if you try to do a tight twist it will keep the corners from tearing apart and having to grind them or forge them back into the billet. A bar of the desired number of layers is forged into a square and the corners are forged down slightly. There are many different types of damascus steel patterns, each with its own unique characteristics. The cruforge v etches darkly, and its wear resistance and high working hardness make it ideal for culinary knives. Watch this full build 👇🏼 episode: Web believe it or not, i wanted to end up with a twist pattern in each layer count at each layer ratio so i could see what the different effects/looks might be. There are multiple variants of twist patterns in damascus steel. Web this rod is then twisted which is what creates that amazing twist pattern. First, the metal worker needs to decide how many layers they want to use. Web fireball is one of those damascus patterns that transforms while you work it. Web this is an interesting damascus pattern with lots of nuances so come check it out. The twist pattern features twisted and swirling lines that run along the length of the blade. Web this is an in depth tutorial on how to make a twist damascus. If you’re looking for a twist patterned blade to add to your collection, then twist damascus knives are worth considering. It creates a visually striking and dynamic pattern. 1 • making twisted w damascus. Web this is an in depth tutorial on how to make a twist damascus pattern. The cruforge v etches darkly, and its wear resistance and high. It will give a slight variation on the pattern but if you try to do a tight twist it will keep the corners from tearing apart and having to grind them or forge them back into the billet. Web fireball is one of those damascus patterns that transforms while you work it. Here are a few photos of as far. Damascus steel is a metal that is steeped in history. Web types of damascus steel patterns. Basic patterns like random patterns, twist patterns, ladder patterns, and raindrop patterns can be achieved with different techniques. The two steel sheets are welded together to form a twisted pattern on the knife. It is almost a must to grind the outside smooth before. If you’re looking for a twist patterned blade to add to your collection, then twist damascus knives are worth considering. Forging damascus is one of my favorites things! For a ladder or raindrop pattern, 200 to 300 layers are ideal and, with a good etch, will give a holographic effect to the blade. The twist pattern features twisted and swirling. Web this is an in depth tutorial on how to make a twist damascus pattern. There are multiple variants of twist patterns in damascus steel. 1 • making twisted w damascus. Basic patterns like random patterns, twist patterns, ladder patterns, and raindrop patterns can be achieved with different techniques. Web this rod is then twisted which is what creates that. There are multiple variants of twist patterns in damascus steel. Here are a few photos of as far as i got. Web twisted damascus is a knife that is made from two different types of steel. Damascus steel is a metal that is steeped in history. Web believe it or not, i wanted to end up with a twist pattern. There are multiple variants of twist patterns in damascus steel. For a ladder or raindrop pattern, 200 to 300 layers are ideal and, with a good etch, will give a holographic effect to the blade. First, the metal worker needs to decide how many layers they want to use. Web the twisted damascus pattern: The result is a spiral pattern. First, the metal worker needs to decide how many layers they want to use. Web this is an in depth tutorial on how to make a twist damascus pattern. Web types of damascus steel patterns. The distinct twists and designs that are revealed during shaping add an extra layer of distinctness to your project. Basic patterns like random patterns, twist. It is almost a must to grind the outside smooth before further forging. I look forward to following your explorations! He is ready to up his game so he scheduled in with. It will give a slight variation on the pattern but if you try to do a tight twist it will keep the corners from tearing apart and having. Here are a few photos of as far as i got. Web 25% off original merch using code: Web twisted damascus is a knife that is made from two different types of steel. The cruforge v etches darkly, and its wear resistance and high working hardness make it ideal for culinary knives. Web this is an interesting damascus pattern with lots of nuances so come check it out. The bar is heated until it is close to welding temperature, and then twisted. It is almost a must to grind the outside smooth before further forging. The two steel sheets are welded together to form a twisted pattern on the knife. Web making twisted w damascus steel for a beautiful set of five knives. Web this rod is then twisted which is what creates that amazing twist pattern. For a ladder or raindrop pattern, 200 to 300 layers are ideal and, with a good etch, will give a holographic effect to the blade. This pattern is created by twisting the billet of steel before it is forged. Web believe it or not, i wanted to end up with a twist pattern in each layer count at each layer ratio so i could see what the different effects/looks might be. Web try not to twist a tapered bar unless you have an assistant with a torch to keep the heat where you need it for uniform twisting. A bar of the desired number of layers is forged into a square and the corners are forged down slightly. There are many different types of damascus steel patterns, each with its own unique characteristics.

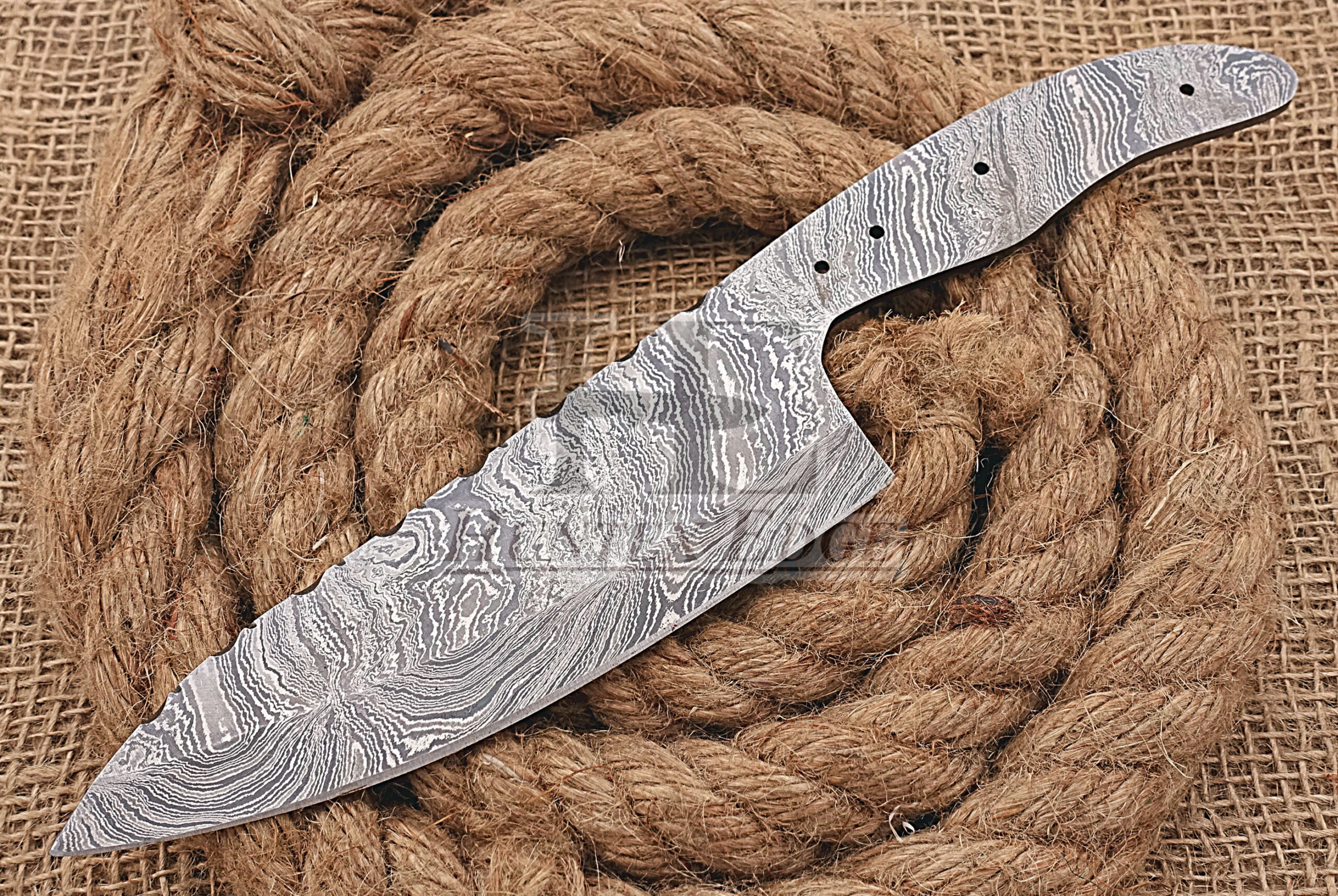

HUNTEX Brand New Custom Handmade Twist Pattern Damascus 380 mm Long

As Twisted Pattern Damascus Steel Owen Bush Bushfire

As Twisted Pattern Damascus Steel Owen Bush Bushfire

HUNTEX Brand New Custom Handmade Twist Pattern Damascus 254 mm Long DIY

Custom Handmade Damascus steel Twist pattern shef for Etsy

8 Azure Chef Knife; Twist Pattern Damascus

Twist Damascus Pattern Welded Blade Basics American Bladesmith

In Depth Tutorial on How to Make a Twist Damascus Pattern YouTube

HUNTEX Brand New Custom Handmade Twist Pattern Damascus 330 mm Long

Damascus Patterns And How To Make Them Olson Heather

Web The Bottom Line Is That Twist Damascus Knives Are Unique And Beautiful Pieces.

Some Of The Most Common Types Include:

I Am Teaching Bob Earhart Who Recently Received His Journeyman Stamp!

The Twisting Method Is Also Done By Heating Multiple Damascus Steel, Twisting, And Forge Welding Them Together.

Related Post: