Tube Heat Exchanger Design

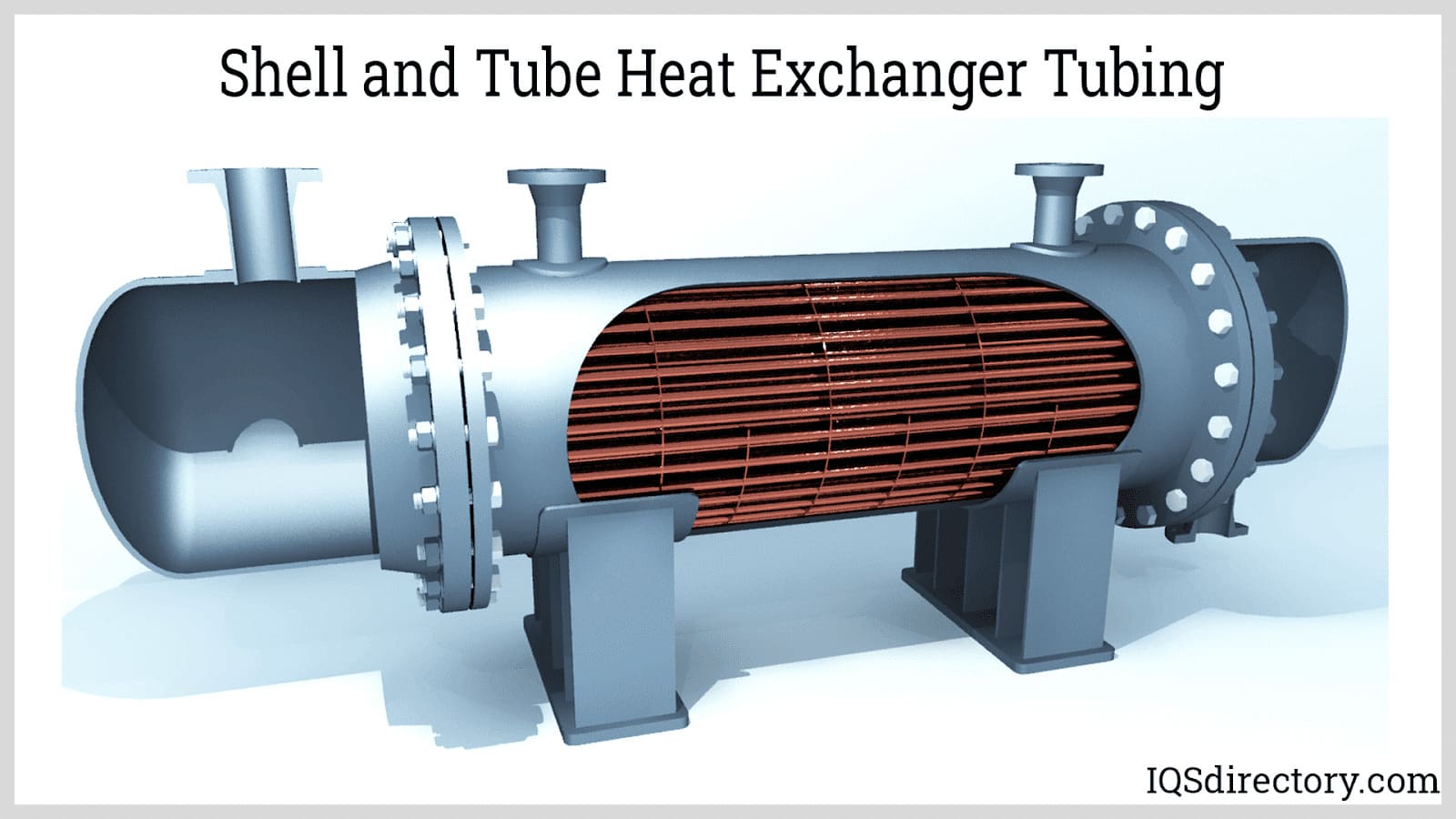

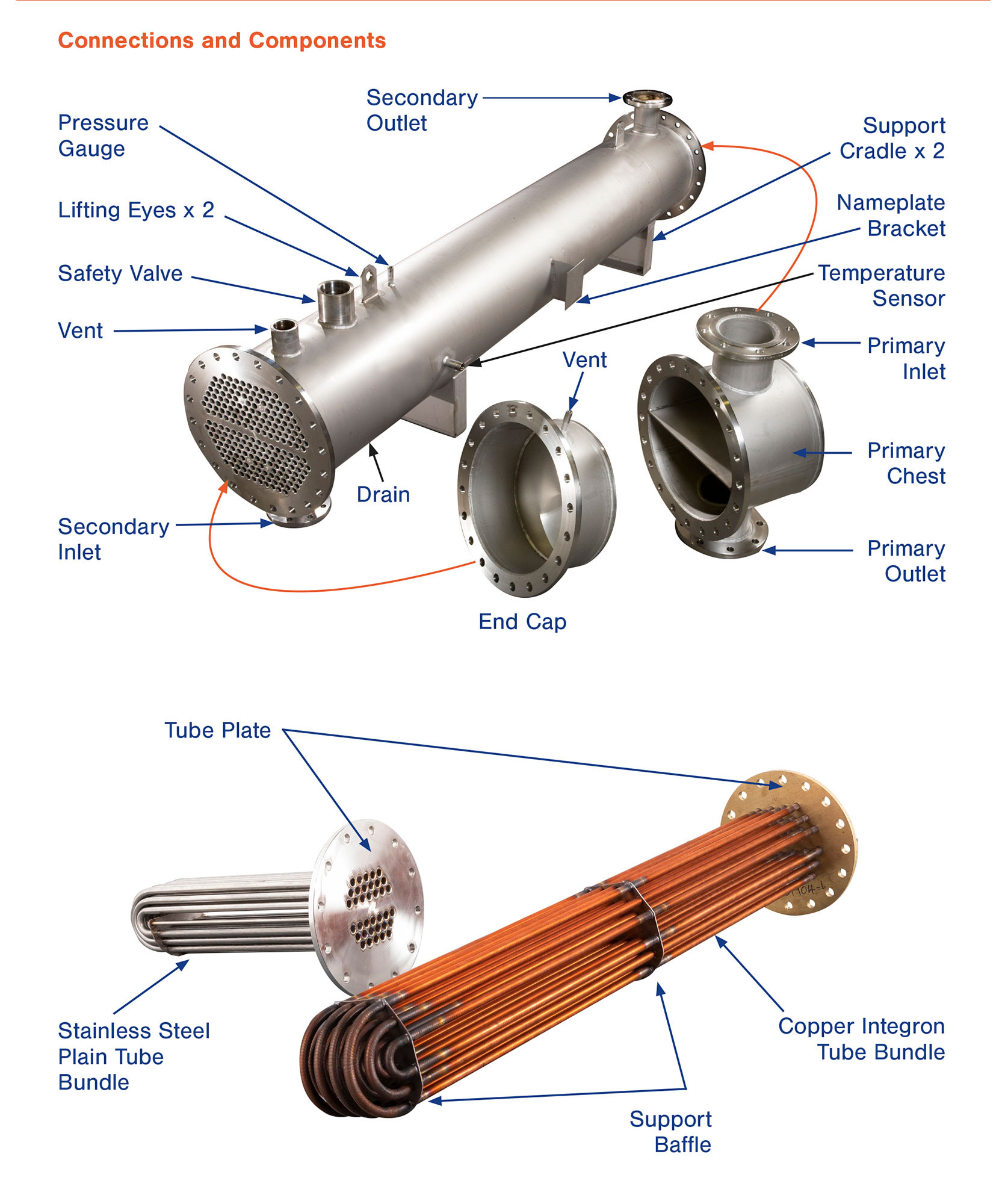

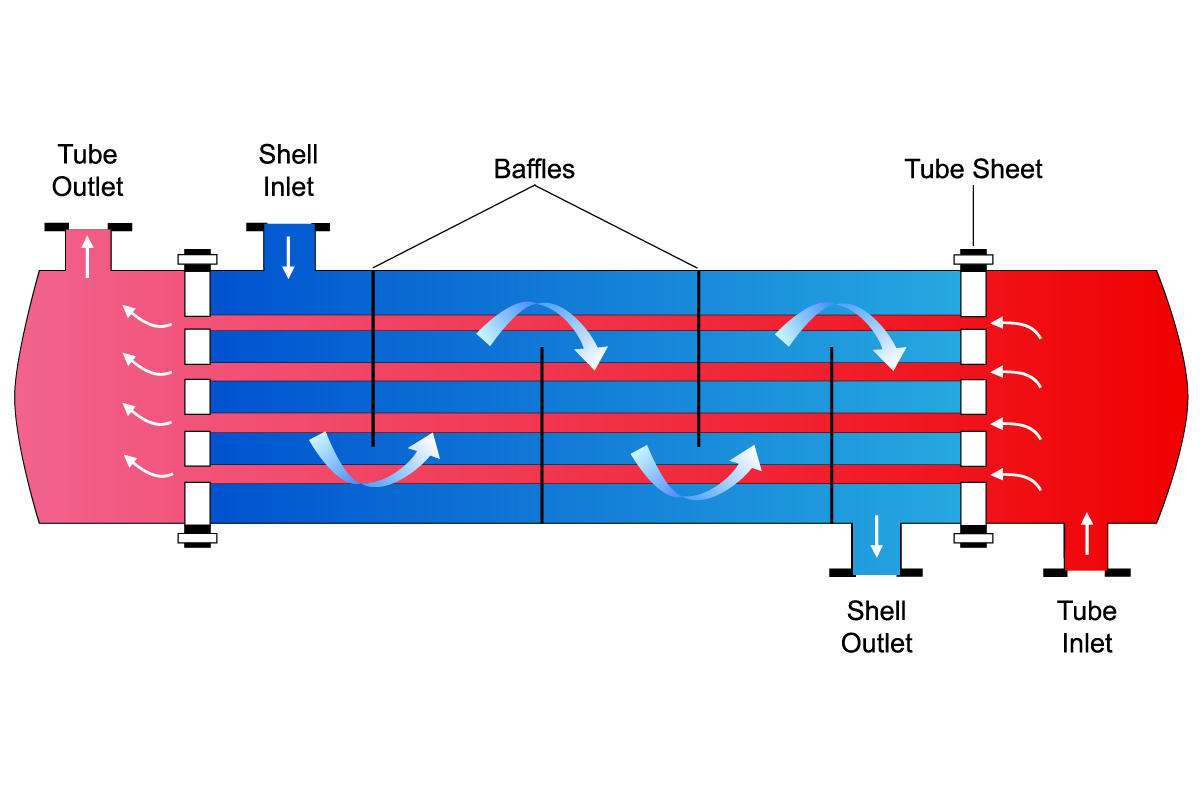

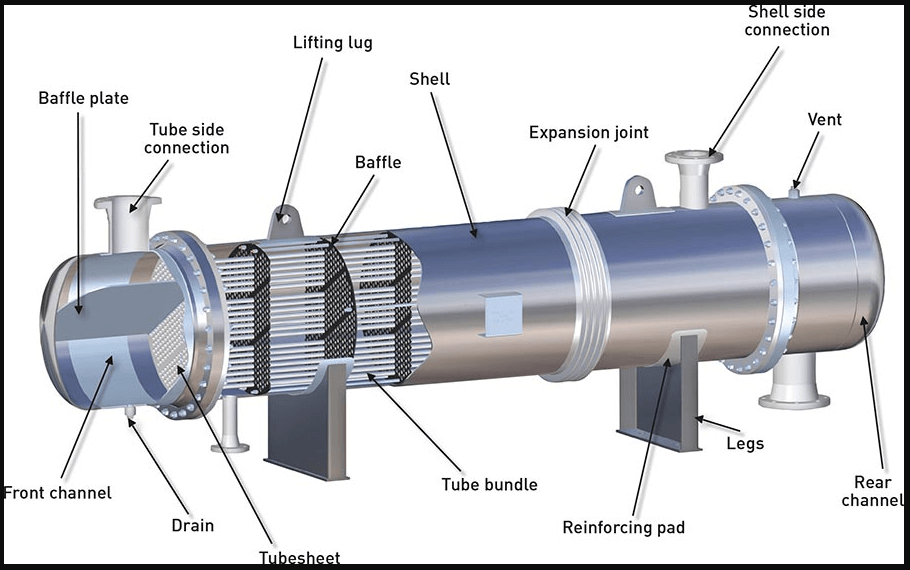

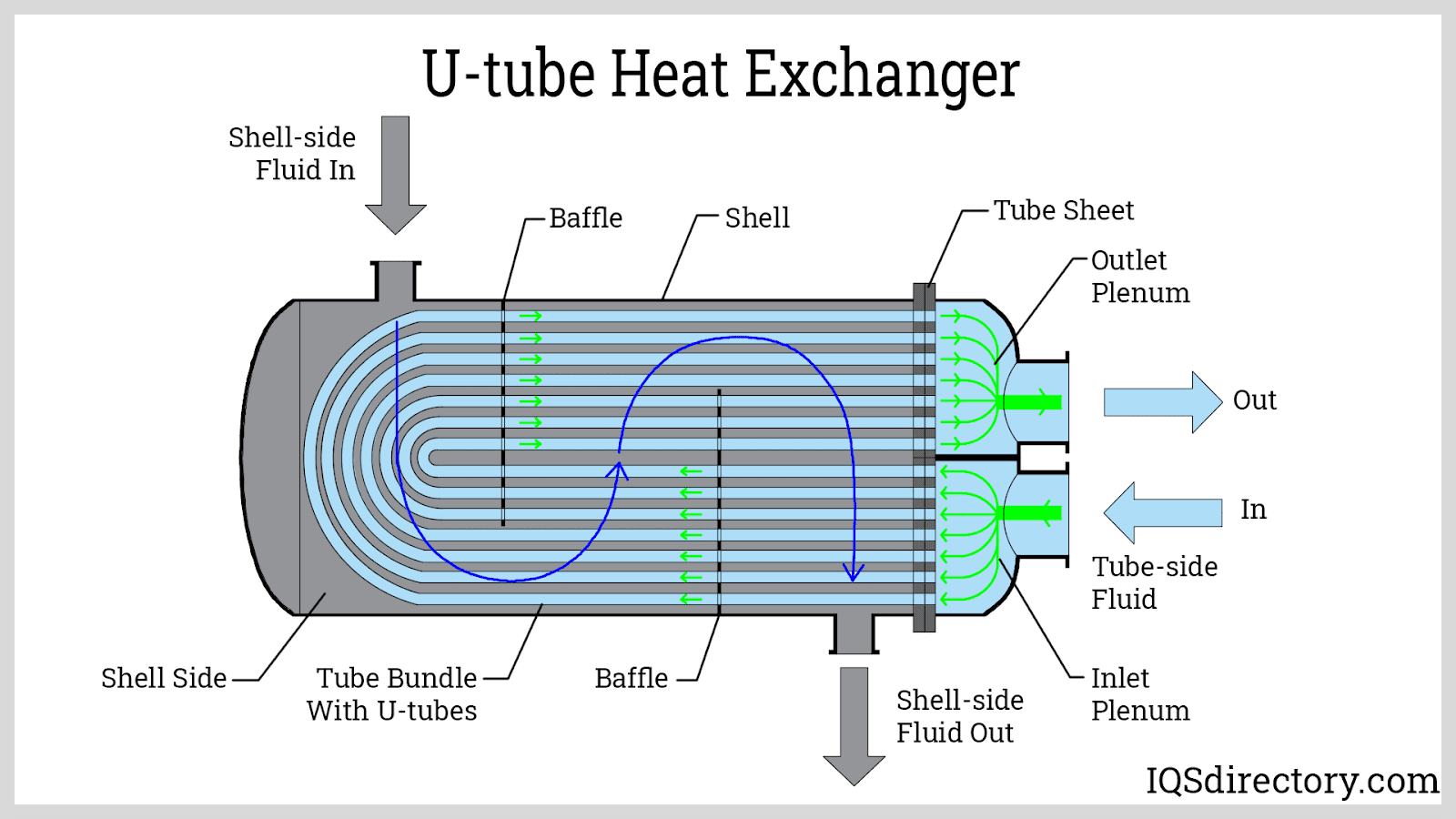

Tube Heat Exchanger Design - It is also important to remember that if your process simulator does not support zoned analysis (such as chemcad iii), you should model each zone with a separate heat exchanger. When designing a shell and tube heat exchanger, it’s important to be familiar with the general steps, assumptions, and key variables to consider. Also, more emphasis is placed on analysis and less on empiricism. The design and arrangement of the tubes within these exchangers are fundamental to their operation and effectiveness. Web heat exchanger design guide: Web the shell and tube heat exchangers with helical baffles have clear advantages in enhancing heat transfer and reducing pressure drop, although the acoustic characteristics are not very. Web the optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can be summarized as follows: Guidelines for selecting the exchanger core construction and surface geometry are presented in. Web discover the steps and considerations in designing a shell and tube heat exchanger with altex industries. We will mainly look at finalizing the process parameters of a new shell & tube exchanger and preparing the process specification sheet for the new exchanger. Setting shell side and tube side pressure drop design. By examining these parameters, the study investigates their effects on the heat transfer performance in microchannels and coated microtubes. Primary emphasis is placed on fundamental concepts and applications. They are used in many alternative energy applications including ocean, thermal and geothermal. Web shell & tube heat exchanger design. Web tube od of ¾ and 1‟‟ are very common to design a compact heat exchanger. We will mainly look at finalizing the process parameters of a new shell & tube exchanger and preparing the process specification sheet for the new exchanger. 3d design is done in autodesk inventor. Web how to calculate the heat transfer coefficient and exchange area. Process fluid assignments to shell side or tube side. Web tube od of ¾ and 1‟‟ are very common to design a compact heat exchanger. Before turning to radiation (last topic) we Web shell and tube heat exchanger (sthe) is the most widely used heat exchanger and is among the most effective means of heat exchange. It is also important. Learn how to optimize your heat exchanger design. Web discover the steps and considerations in designing a shell and tube heat exchanger with altex industries. Guidelines for selecting the exchanger core construction and surface geometry are presented in. Web the review encompasses a wide range of parameters including fluid flow rate, wall heat flux, surface roughness, tube diameter, and tube. Rajiv mukherjee, engineers india ltd. We will mainly look at finalizing the process parameters of a new shell & tube exchanger and preparing the process specification sheet for the new exchanger. It is also important to remember that if your process simulator does not support zoned analysis (such as chemcad iii), you should model each zone with a separate heat. Also, more emphasis is placed on analysis and less on empiricism. Selection of stream temperature specifications. How can we use fundamental heat transfer to understand real devices like heat exchangers? Defining zones is one of the most important aspects of heat exchanger design. Rajiv mukherjee, engineers india ltd. Defining zones is one of the most important aspects of heat exchanger design. Process fluid assignments to shell side or tube side. Web discover the steps and considerations in designing a shell and tube heat exchanger with altex industries. The following sequence is used to design a shell tube heat exchanger knowing the characteristics of the fluid on both sides. It is also important to remember that if your process simulator does not support zoned analysis (such as chemcad iii), you should model each zone with a separate heat exchanger. Tubes, baffles, shell size, tie rods, sealing strips, skid bars, etc.). A shell and tube heat exchanger is a device where two working fluids exchange heat by thermal contact using. Web heat exchanger modeling, sizing, and design professor faith morrison department of chemical engineering michigan technological university © faith a. Prototype design & model of shell and tube heat exchanger made for a study. Setting shell side and tube side pressure drop design. Web discover the steps and considerations in designing a shell and tube heat exchanger with altex industries.. Also, more emphasis is placed on analysis and less on empiricism. Web heat exchanger design guide: Web to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. Web tube od of ¾ and 1‟‟ are very common to design a compact heat exchanger. Defining zones is one of the most important aspects of. Setting shell side and tube side pressure drop design. The design and arrangement of the tubes within these exchangers are fundamental to their operation and effectiveness. When designing a shell and tube heat exchanger, it’s important to be familiar with the general steps, assumptions, and key variables to consider. We will mainly look at finalizing the process parameters of a new shell & tube exchanger and preparing the process specification sheet for the new exchanger. Selection of stream temperature specifications. Web tube od of ¾ and 1‟‟ are very common to design a compact heat exchanger. We shall focus on sensible heat transfer, and make extensive use of chapter 11 in perry’s handbook(3). Defining zones is one of the most important aspects of heat exchanger design. Web the optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can be summarized as follows: By examining these parameters, the study investigates their effects on the heat transfer performance in microchannels and coated microtubes. Process fluid assignments to shell side or tube side. Also, more emphasis is placed on analysis and less on empiricism. Guidelines for selecting the exchanger core construction and surface geometry are presented in. Chemical engineering progress • february 1998. Web some clients prefer that the epc firm process and/or mechanical engineers do extensive work on exchanger design to fully specify the exchanger (e.g. Selection of stream temperature specifications.

Shell and Tube Heat Exchanger What Is It? Types, Process

Shell and Tube Heat Exchanger Explained saVRee saVRee

Shell and Tube Heat Exchanger Explained saVRee saVRee

Shell & Tube Heat Exchangers for process applications Ormandy Rycroft

Shell and Tube Heat Exchanger What Is It? Types, Process

Plate Heat Exchanger (For Dummies) Rasmussen Mechanical

Design Optimization Shell & Tube Heat Exchanger Bronswerk

Types of Heat Exchanger according to construction The piping talk

Shell and Tube Heat Exchanger What Is It? Types, Process

All About Shell And Tube Heat Exchangers What You Need To Know

Web How To Calculate The Heat Transfer Coefficient And Exchange Area Of A Shell Tube Heat Exchanger ?

Web Shell & Tube Heat Exchanger Design.

A Shell And Tube Heat Exchanger Is A Device Where Two Working Fluids Exchange Heat By Thermal Contact Using Tubes Housed Within A Cylindrical Shell.

They Are Used In Process Industries, In Conventional And Nuclear Power Stations, Steam Generators, Etc.

Related Post: