Torque Pattern 20 Bolt Flange

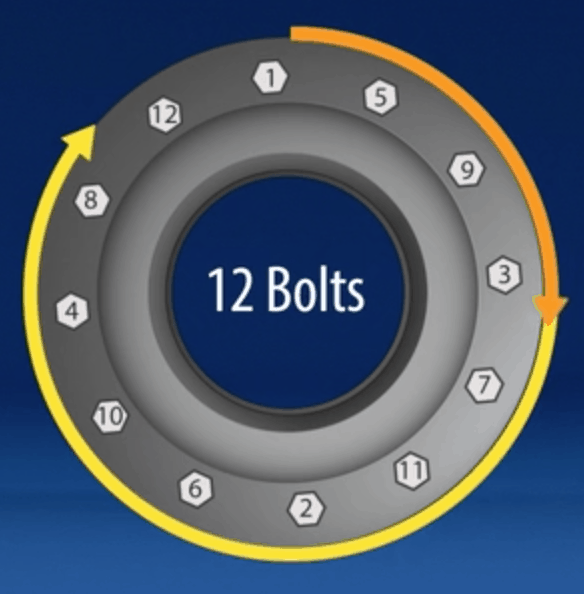

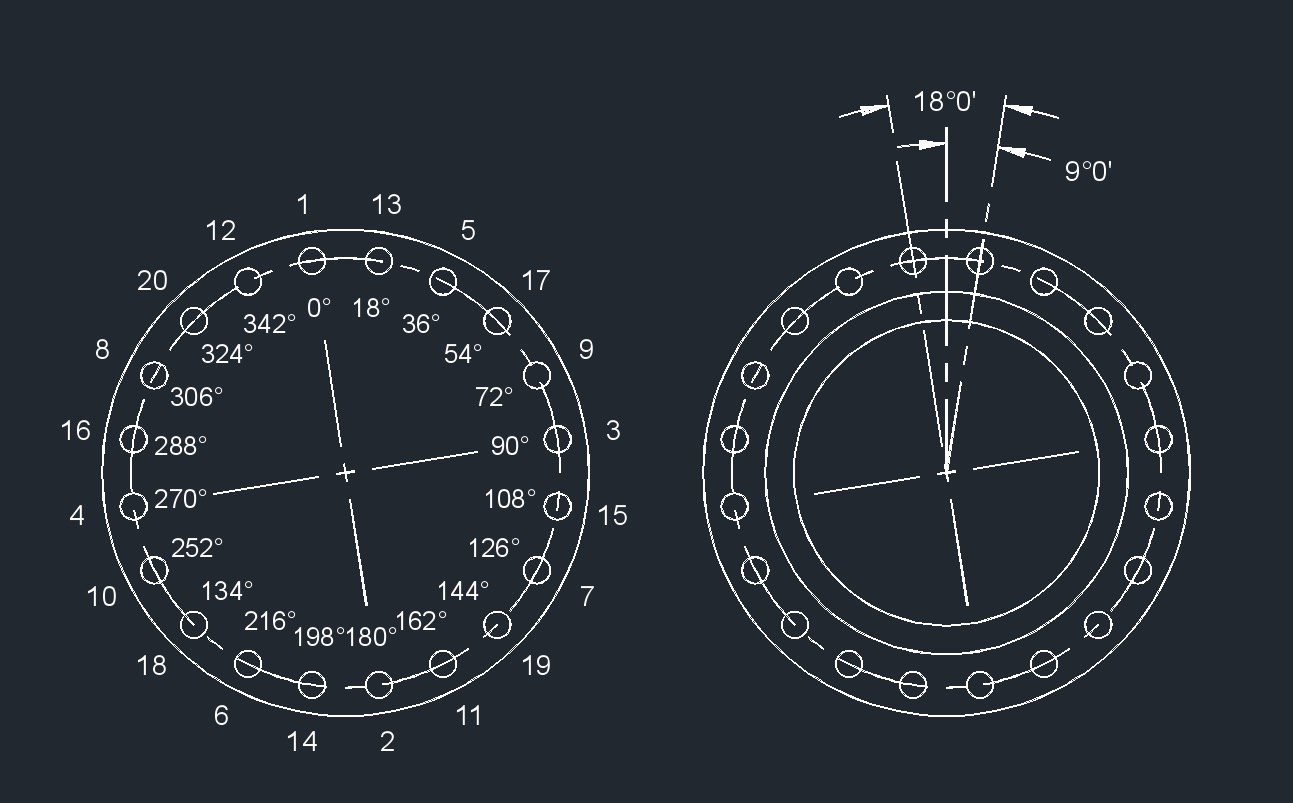

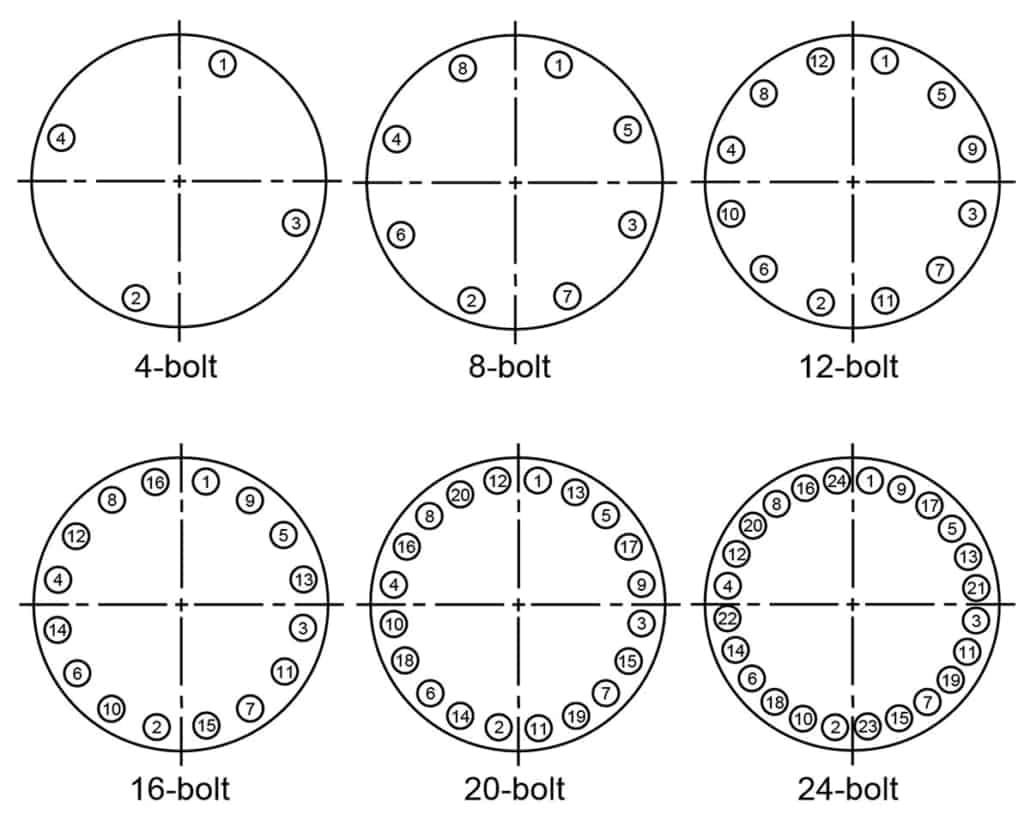

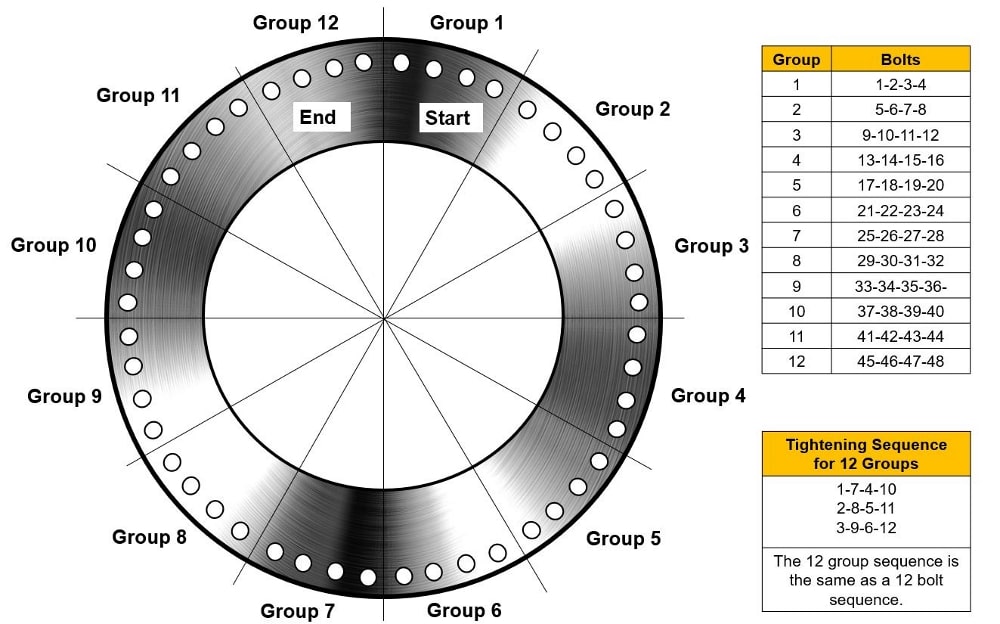

Torque Pattern 20 Bolt Flange - Web the flange bolt torque calculator simplifies the task of determining the correct torque for flange bolt tightening, helping to ensure the integrity and safety of critical connections in. Web recommended torque values lubricated stud bolts w/0.15 friction value. 1, 17, 9, 5, 13, 3, 19, 11, 7, 15, 2, 18, 10, 6, 14, 4, 20, 12, 8, 16. Garlock sealing technologies an enpro industries company. Web ses 75% of the yield strength. The torques given are based on using a. The following charts indicate the approximate bolt torque required to seal flanged joints against internal pressure. Tighten to 20% to 30% of target torque usind cross pattern. In addition to choosing the correct gasketing material, proper installation is crucial to. View all gasket materials here. Web flange bolt torque sequence. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Before using a given torque table, these assumptions should be verified to insure they are. Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect. Lookup flange bolt torque patterns on your phone in seconds. The torques given are based on using a. The following charts indicate the approximate bolt torque required to seal flanged joints against internal pressure. World wide metric offers an extensive selection of flanges in din, jis and ansi standards, including: Web these bolt torque values are intended for use as. Web the motor and reducer are secured to the base with bolts. Based on using weldneck flanges &. The torques given are based on using a. Web garlock sealing technologies an enpro industries company. Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated. Web recommended torque values lubricated stud bolts w/0.15 friction value. Tighten to 50% to 70% of target torque. Tighten to 20% to 30% of target torque usind cross pattern. The interactive tool provides users a way to easily. View all gasket materials here. Web ses 75% of the yield strength. The torques given are based on using a. Tighten to 20% to 30% of target torque usind cross pattern. In addition to choosing the correct gasketing material, proper installation is crucial to. Web the torque tables are built on specific assumptions regarding bolt and nut factor. The interactive tool provides users a way to easily. Web flange bolt torque sequence. World wide metric offers an extensive selection of flanges in din, jis and ansi standards, including: Tighten to 50% to 70% of target torque. Based on using weldneck flanges &. The flange distributes pressure, so you don't need a washer. 14 12 1 320 340 14 20 1 1/4 450 470 14 20 1 3/8 820 840. The torques given are based on using a. In addition to choosing the correct gasketing material, proper installation is crucial to. Web recommended torque values lubricated stud bolts w/0.15 friction value. Check flange gap around circumference for uniformity. Web the motor and reducer are secured to the base with bolts. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Web garlock sealing technologies an enpro industries company. The flange distributes pressure, so you don't need a washer. The torques given are based on using a. Based on using weldneck flanges &. The flange distributes pressure, so you don't need a washer. Web the torque tables are built on specific assumptions regarding bolt and nut factor. Check flange gap around circumference for uniformity. Garlock sealing technologies an enpro industries company. Web ses 75% of the yield strength. The flange distributes pressure, so you don't need a washer. Web the torque tables are built on specific assumptions regarding bolt and nut factor. 1, 17, 9, 5, 13, 3, 19, 11, 7, 15, 2, 18, 10, 6, 14, 4, 20, 12, 8, 16. The flange distributes pressure, so you don't need a washer. Lookup flange bolt torque patterns on your phone in seconds. Web recommended torque values lubricated stud bolts w/0.15 friction value. Garlock sealing technologies an enpro industries company. Based on using weldneck flanges &. Web the flange bolt torque calculator simplifies the task of determining the correct torque for flange bolt tightening, helping to ensure the integrity and safety of critical connections in. Web ses 75% of the yield strength. World wide metric offers an extensive selection of flanges in din, jis and ansi standards, including: 14 12 1 320 340 14 20 1 1/4 450 470 14 20 1 3/8 820 840. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Web the motor and reducer are secured to the base with bolts. Tighten to 50% to 70% of target torque. Web the torque tables are built on specific assumptions regarding bolt and nut factor. Web garlock sealing technologies an enpro industries company. Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according. The interactive tool provides users a way to easily.

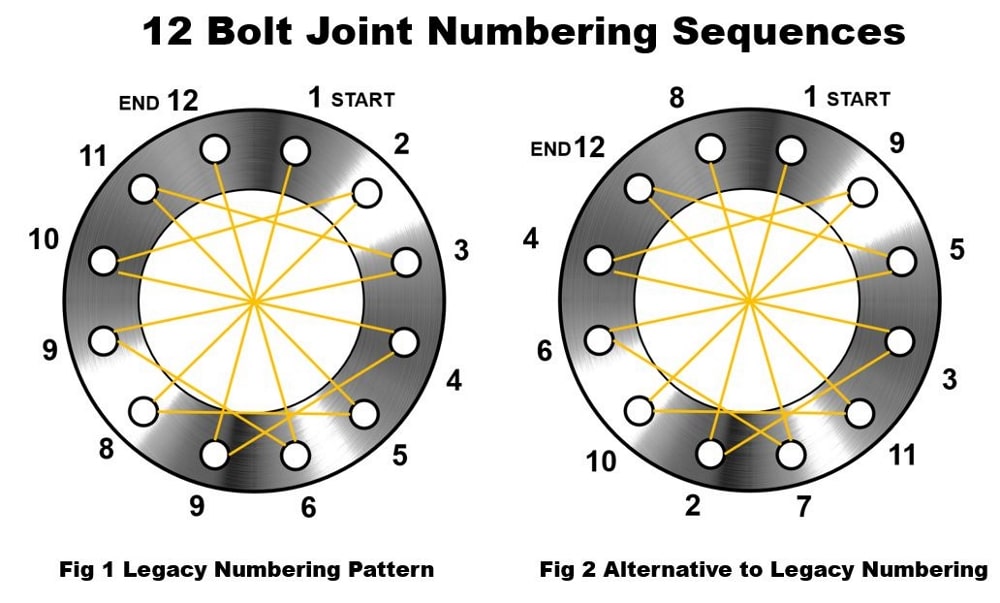

FlangeBoltingPatterns Industrial Bolting and Torque Tools

20 Bolt Torque Pattern

Bolt Tightening Procedure

Flange Bolt Torque Sequence UIP International Premium Industrial

Bolt Tightening Procedure

Flange Bolt Torque Sequence UIP International Premium, 41 OFF

Torque Charts Industrial Bolting and Torque Tools

20 Bolt Flange Torque Pattern PDF

Pipe Flange Bolt Torque Chart

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

Before Using A Given Torque Table, These Assumptions Should Be Verified To Insure They Are.

1 Shows The Dimensions Of The Specimens Considering The Impact Of The Bolt Preload On Both The Inner And Cover Plates, And In Conjunction With The Available Equipment And.

The Following Charts Indicate The Approximate Bolt Torque Required To Seal Flanged Joints Against Internal Pressure.

Check Flange Gap Around Circumference For Uniformity.

Related Post: