Torch Tip Size Chart

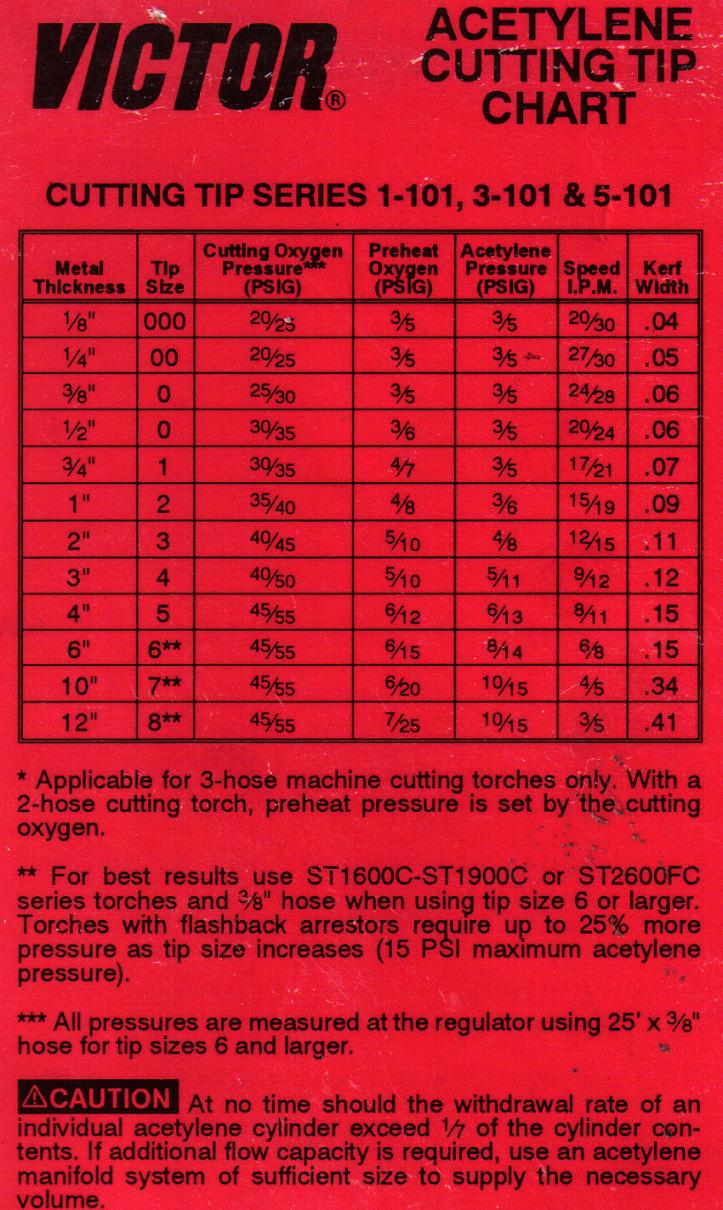

Torch Tip Size Chart - This guide will walk you through the process and factors to consider for optimal brazing results. Heating tips are matched by btu output using the intended fuel gas. Consult charts, understand joint design, brazing alloy, and heat input. **for best results use st 1600c / st 1900c or st 2600fc series torches and 3/8 hose when using tip size 6 or larger. Web here are the tips: Web here we will discuss the various types of cutting torch tips and the best sizes for each job. When using tip size 6 or above, you need to use 3/8 inches hose in order to get the best results in the shortest period of time. With a two hose cutting torch, preheat pressure is set by the cutting oxygen. Web ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Torches with flashback arrestors require up to 25% more pressure as tip size increases. With a two hose cutting torch, preheat pressure is set by the cutting oxygen. Determine the metal thickness you want to cut. Torches with flashback arrestors require up to 25% more pressure as tip size increases. Web cutting tip series gpn, hpn. ** for best results use st2600fc series torches and 3/8 hose when using tip size 6 or larger. Web here are the tips: ** for best results use st2600fc series torches and 3/8 hose when using tip size 6 or larger. Web choosing the right tip for your application will provide smoother cuts, protect you and your torch, and eliminate any downtime from tip or torch damage. Select the tip size rated to cut that thickness or beyond.. Consult charts, understand joint design, brazing alloy, and heat input. Additional matters and processes to consider are the torches of suitable capacity for stated metal thickness. * applicable for three hose machine torch only. Web cutting tip series gpn, hpn. ** for best results use st2600fc series torches and 3/8 hose when using tip size 6 or larger. Web here we will discuss the various types of cutting torch tips and the best sizes for each job. Torches with flashback arrestors require up to 25% more pressure as tip size increases. Web longest lasting cutting tip for dependable performance. Web looking to select the perfect tip size for your brazing torch? Web here are the tips: Web choosing the right tip for your application will provide smoother cuts, protect you and your torch, and eliminate any downtime from tip or torch damage. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the most common torch tip questions. Cuts up to 3/16 in. With a two hose. Additional matters and processes to consider are the torches of suitable capacity for stated metal thickness. Web looking to select the perfect tip size for your brazing torch? Web here we will discuss the various types of cutting torch tips and the best sizes for each job. Consult charts, understand joint design, brazing alloy, and heat input. Web here are. This guide will walk you through the process and factors to consider for optimal brazing results. Web each tip size is suitable for metal thickness as specified in the chart. When using tip size 6 or above, you need to use 3/8 inches hose in order to get the best results in the shortest period of time. ** for best. Determine the metal thickness you want to cut. The welder must check the amount of fuel gas required to run the tip and be sure to provide sufficient gas to run the tip without backfires and overheating. Web choosing the right tip for your application will provide smoother cuts, protect you and your torch, and eliminate any downtime from tip. Web cutting tip series gpn, hpn. The welder must check the amount of fuel gas required to run the tip and be sure to provide sufficient gas to run the tip without backfires and overheating. Consult charts, understand joint design, brazing alloy, and heat input. This guide will walk you through the process and factors to consider for optimal brazing. This guide will walk you through the process and factors to consider for optimal brazing results. Heating tips are matched by btu output using the intended fuel gas. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the most common torch tip questions. With a two hose cutting torch, preheat. Heating tips are matched by btu output using the intended fuel gas. **for best results use st 1600c / st 1900c or st 2600fc series torches and 3/8 hose when using tip size 6 or larger. Web welding tips from different manufacturers can be matched by orifice size; When using tip size 6 or above, you need to use 3/8 inches hose in order to get the best results in the shortest period of time. Torches with flashback arrestors require up to 25% more pressure as tip size increases. Consult charts, understand joint design, brazing alloy, and heat input. Web here we will discuss the various types of cutting torch tips and the best sizes for each job. * applicable for three hose machine torch only. Web choosing the right tip for your application will provide smoother cuts, protect you and your torch, and eliminate any downtime from tip or torch damage. Web each tip size is suitable for metal thickness as specified in the chart. The welder must check the amount of fuel gas required to run the tip and be sure to provide sufficient gas to run the tip without backfires and overheating. Web ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. This guide will walk you through the process and factors to consider for optimal brazing results. Select the tip size rated to cut that thickness or beyond. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the most common torch tip questions. ** for best results use st2600fc series torches and 3/8 hose when using tip size 6 or larger.

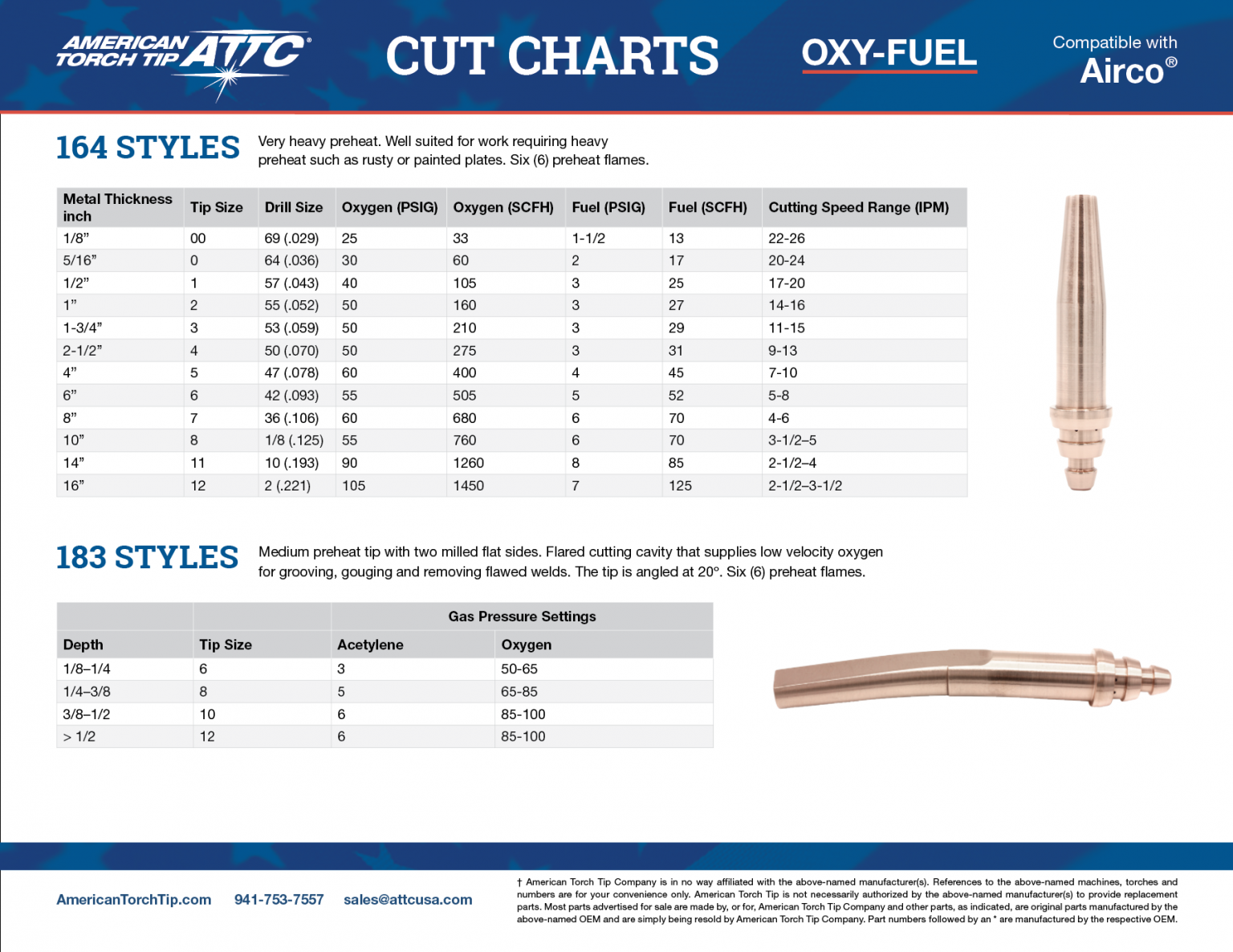

Welding Cut Charts American Torch Tip Cut Charts

Victor Tip Size Chart Printable Templates Free

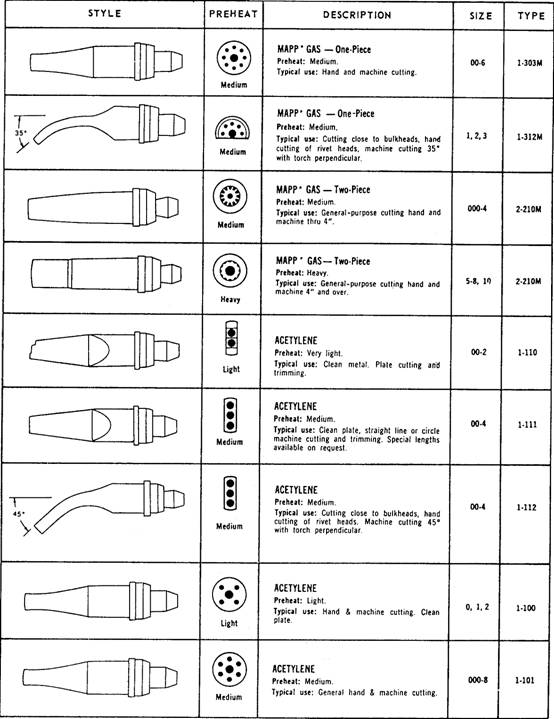

Cutting Torch Tip Size Guide

Welding, Brazing Tip w/ Gas Mixer Style W1 ArcZone

Cutting Torch Tip Chart

Harris Torch Tip Chart

Selecting the Right Cutting Tip RonSon's Torch Repairs & Sales Ltd.

Cutting Torch Guide

airco cutting tip chart Bamil

Propane Cutting Torch Tip Size Chart

With A Two Hose Cutting Torch, Preheat Pressure Is Set By The Cutting Oxygen.

Additional Matters And Processes To Consider Are The Torches Of Suitable Capacity For Stated Metal Thickness.

Cuts Up To 3/16 In.

Web Cutting Tip Series Gpn, Hpn.

Related Post: