Tooling Design

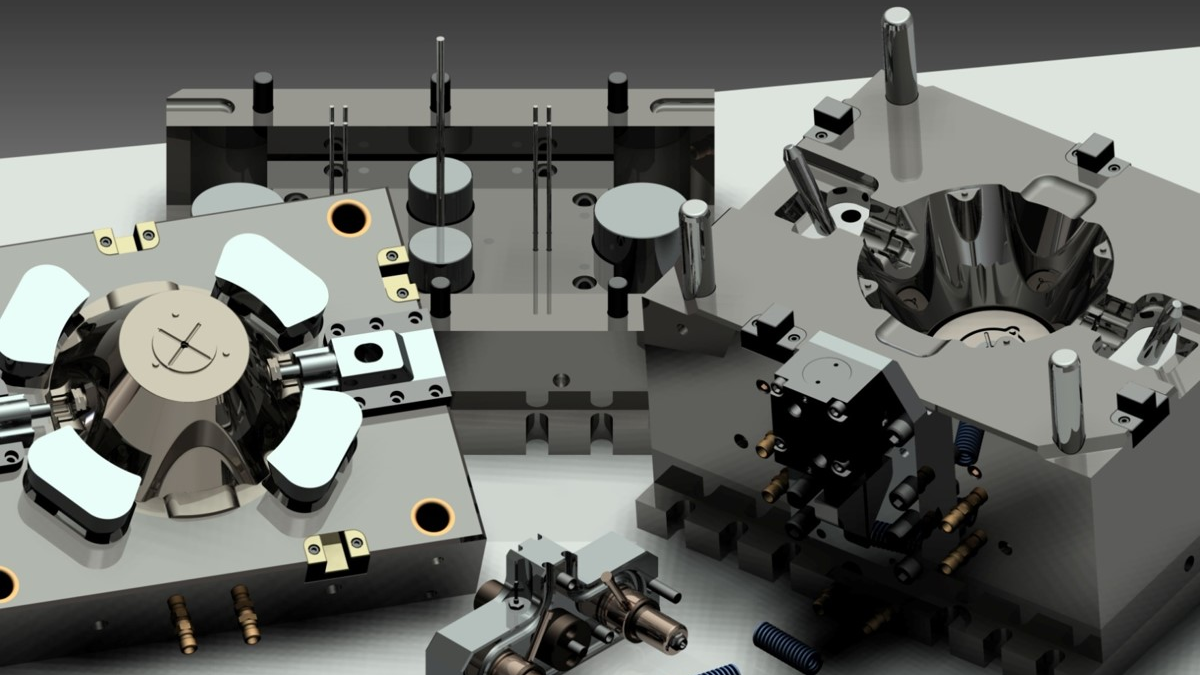

Tooling Design - Since tool design and construction are complex, fabrication requires significant capital investment and enough lead time to create an effective tool. Web master tooling design with star rapid's guide. Web tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Web throughout this article, we will cover different fundamental principles of tooling design, including the diverse types of tools, common tooling design errors, essential facets of the tooling design process, and variables to consider during manufacturing tool design. Learn the basics to kickstart your project successfully and efficiently. It also explains the general process of designing tools and stresses the importance of. This involves the use of jigs, molds, patterns, fixtures, and cutting tools to cut, shape, and form the parts. This article will discuss die design and tooling, including their uses, processes, and types. Accelerate the mold development process using advanced tools to validate part design, tool design and motion. Web explore the powerful design capabilities for tooling and fixtures: Since tool design and construction are complex, fabrication requires significant capital investment and enough lead time to create an effective tool. Web tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Web we would like to show you a description here but the site won’t allow us.. Since tool design and construction are complex, fabrication requires significant capital investment and enough lead time to create an effective tool. Web explore the powerful design capabilities for tooling and fixtures: Web tooling, commonly referred to as machine tooling, is the process of shaping or forming materials to produce tolerance parts. Configure the mold structure using libraries of standard parts,. Configure the mold structure using libraries of standard parts, component systems and mold bases. Since tool design and construction are complex, fabrication requires significant capital investment and enough lead time to create an effective tool. This involves the use of jigs, molds, patterns, fixtures, and cutting tools to cut, shape, and form the parts. Web master tooling design with star. This article will discuss die design and tooling, including their uses, processes, and types. Web effective die design and tooling are fundamental to achieving consistency, accuracy, and productivity in manufacturing operations. Web tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. High quantity and quality parts require. Accelerate the mold development process using advanced tools to validate part design, tool design and motion. Web effective die design and tooling are fundamental to achieving consistency, accuracy, and productivity in manufacturing operations. Learn the basics to kickstart your project successfully and efficiently. Since tool design and construction are complex, fabrication requires significant capital investment and enough lead time to. Web effective die design and tooling are fundamental to achieving consistency, accuracy, and productivity in manufacturing operations. This article will discuss die design and tooling, including their uses, processes, and types. 5/5 (6,433 reviews) Accelerate the mold development process using advanced tools to validate part design, tool design and motion. Web explore the powerful design capabilities for tooling and fixtures: Configure the mold structure using libraries of standard parts, component systems and mold bases. Accelerate the mold development process using advanced tools to validate part design, tool design and motion. Web throughout this article, we will cover different fundamental principles of tooling design, including the diverse types of tools, common tooling design errors, essential facets of the tooling design process,. Configure the mold structure using libraries of standard parts, component systems and mold bases. Since tool design and construction are complex, fabrication requires significant capital investment and enough lead time to create an effective tool. High quantity and quality parts require proper tooling. Accelerate the mold development process using advanced tools to validate part design, tool design and motion. Web. Accelerate the mold development process using advanced tools to validate part design, tool design and motion. It also explains the general process of designing tools and stresses the importance of. High quantity and quality parts require proper tooling. Learn the basics to kickstart your project successfully and efficiently. Web explore the powerful design capabilities for tooling and fixtures: High quantity and quality parts require proper tooling. Web tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Web we would like to show you a description here but the site won’t allow us. This involves the use of jigs, molds, patterns, fixtures, and cutting tools to. Accelerate the mold development process using advanced tools to validate part design, tool design and motion. This article will discuss die design and tooling, including their uses, processes, and types. Web we would like to show you a description here but the site won’t allow us. Since tool design and construction are complex, fabrication requires significant capital investment and enough lead time to create an effective tool. 5/5 (6,433 reviews) It also explains the general process of designing tools and stresses the importance of. Web tooling, commonly referred to as machine tooling, is the process of shaping or forming materials to produce tolerance parts. Web explore the powerful design capabilities for tooling and fixtures: Configure the mold structure using libraries of standard parts, component systems and mold bases. Learn the basics to kickstart your project successfully and efficiently. Web throughout this article, we will cover different fundamental principles of tooling design, including the diverse types of tools, common tooling design errors, essential facets of the tooling design process, and variables to consider during manufacturing tool design. Web master tooling design with star rapid's guide.

Leather working patterns, Leather pattern, Leather tooling

Tool Design (Design & Analysis of Press Tools) Behance

Pin on 模具

Leather tooling / carving Patterns / stencils. Two Sheridan Etsy

Product and Tool Design Services Tooling Technologies, Inc.

Tool And Die Design Process Cornwell Himiland

Tooling Design • TengamTengam

Tooling Design

Tooling & Fixture Design Siemens Software

Tooling What it means in manufacturing and design Shape Products

This Involves The Use Of Jigs, Molds, Patterns, Fixtures, And Cutting Tools To Cut, Shape, And Form The Parts.

Web Effective Die Design And Tooling Are Fundamental To Achieving Consistency, Accuracy, And Productivity In Manufacturing Operations.

High Quantity And Quality Parts Require Proper Tooling.

Web Tooling, Also Known As A Mold, Refers To The Negative Cavity Space Where Molten Plastic Resin Is Injected To Create A Part.

Related Post: