Tolerance H7 Chart

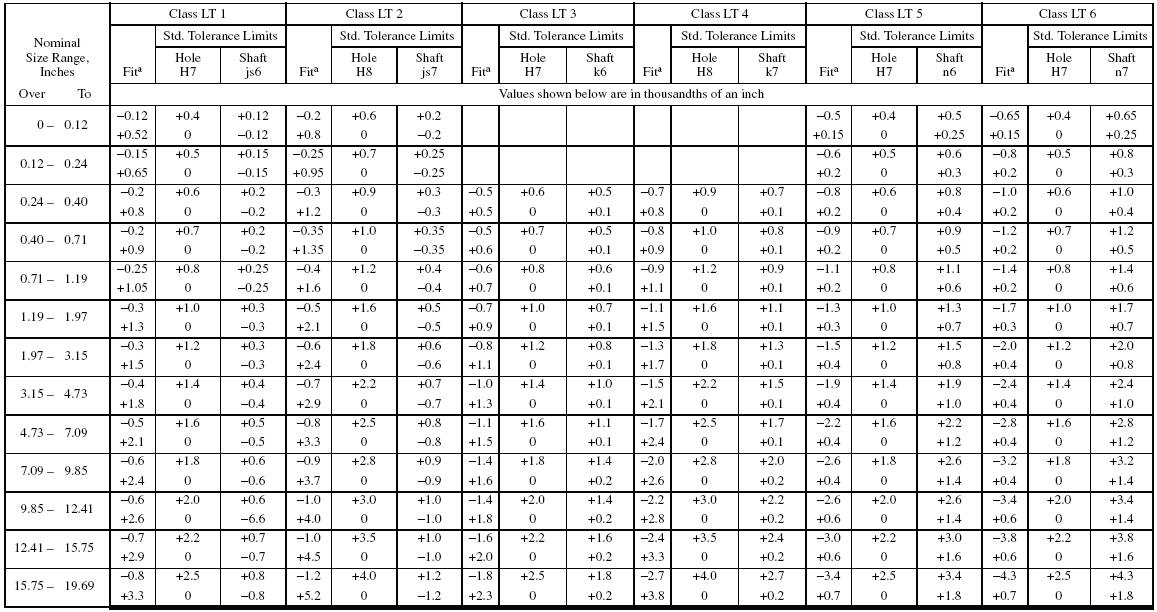

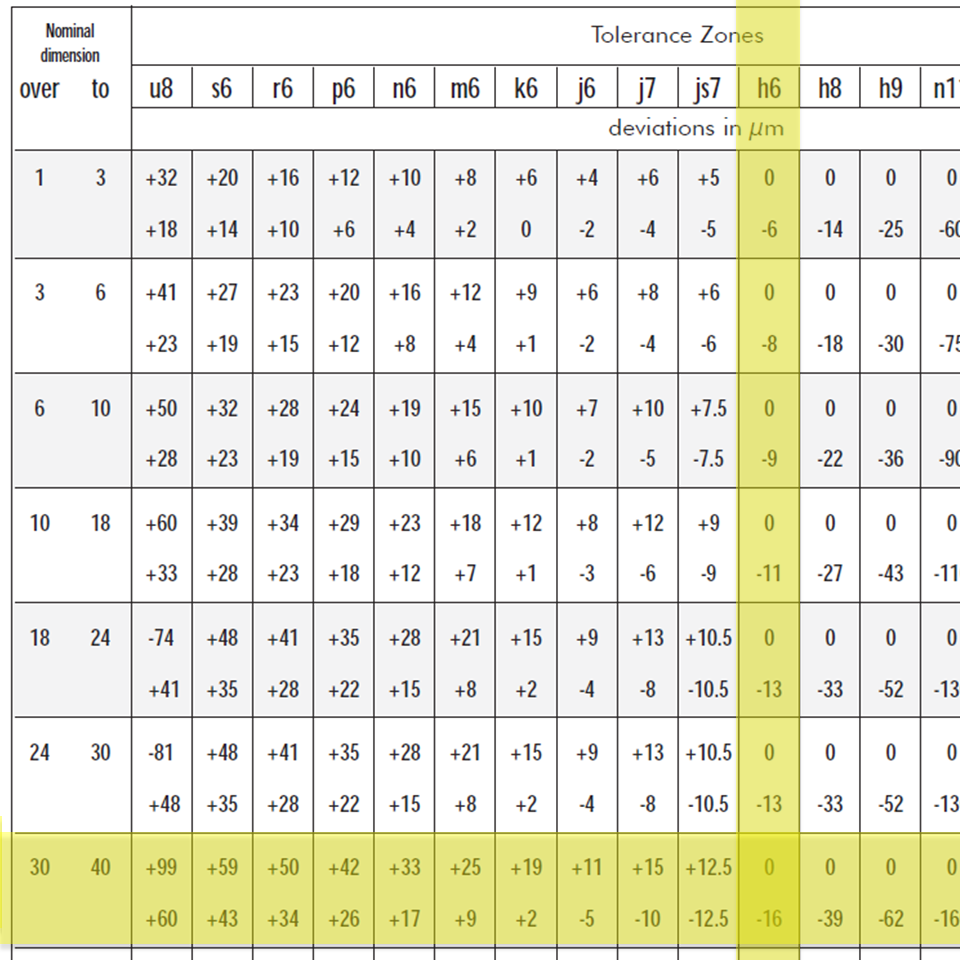

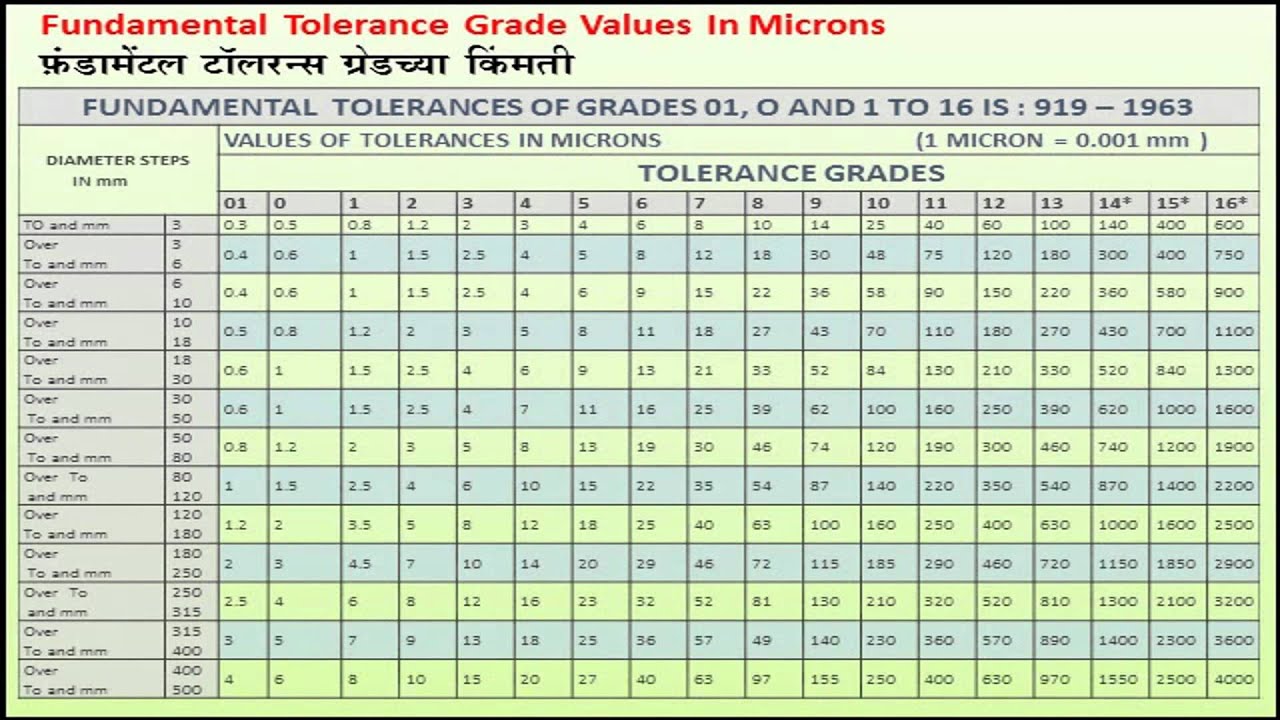

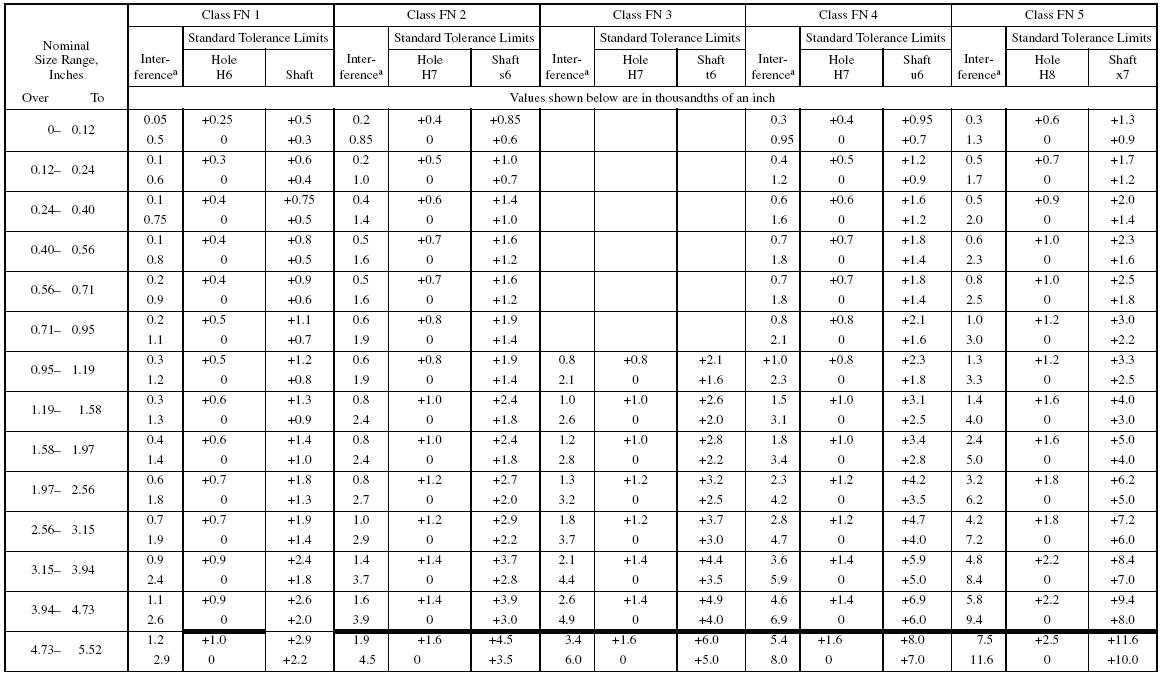

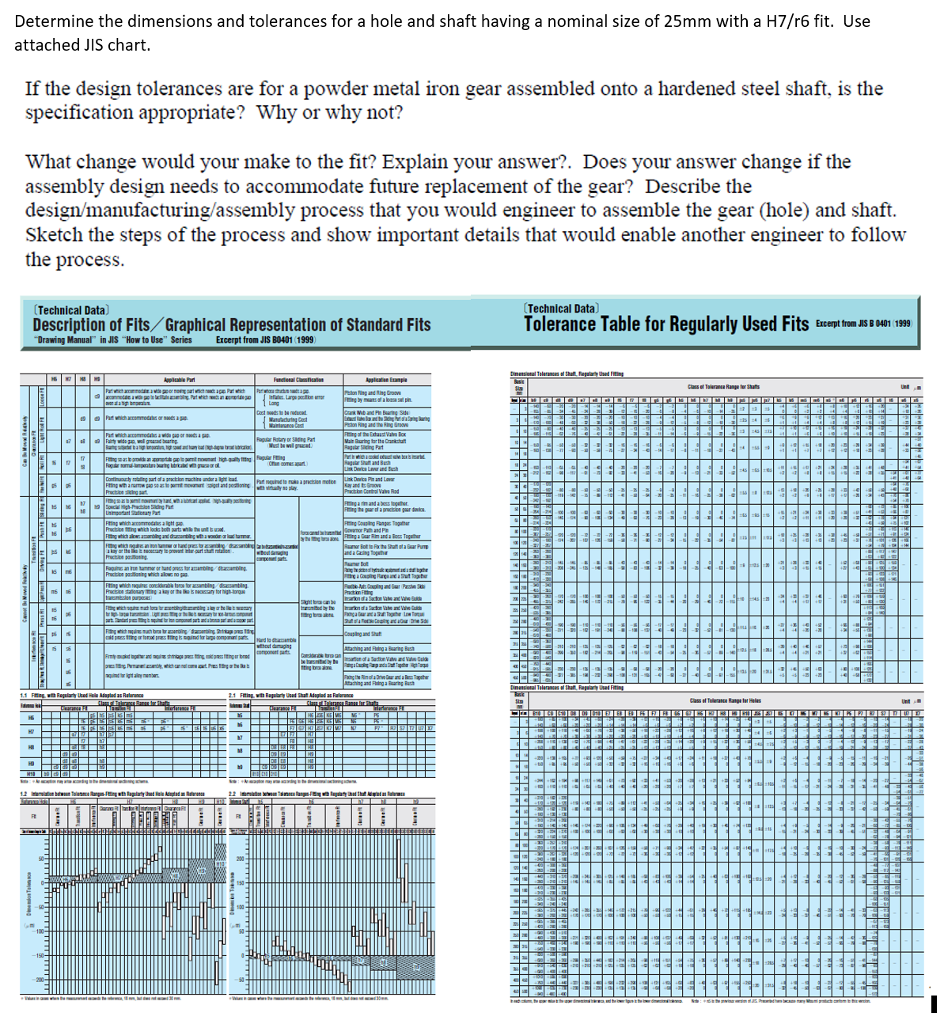

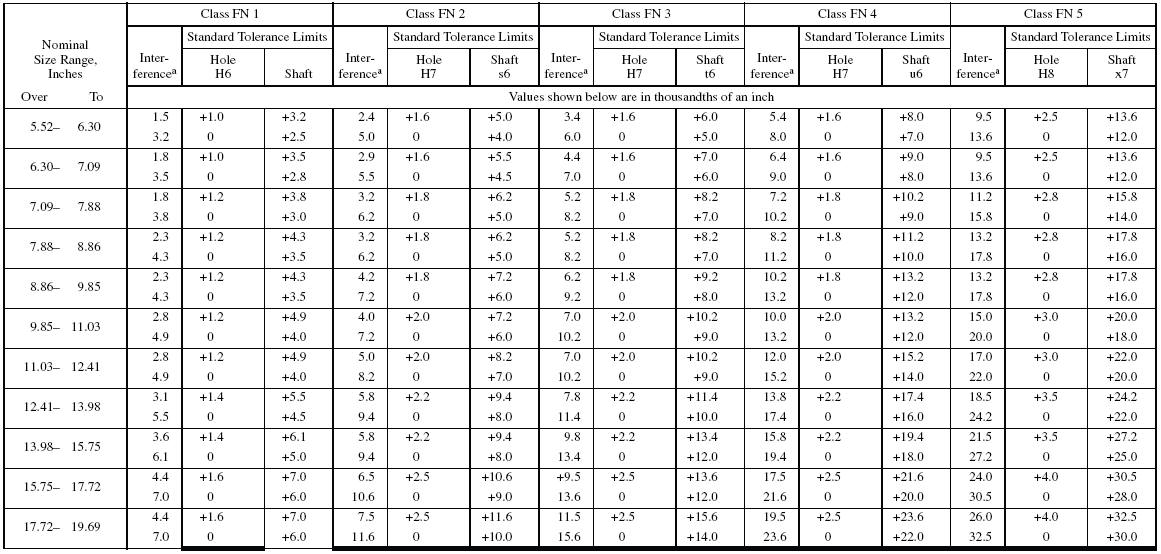

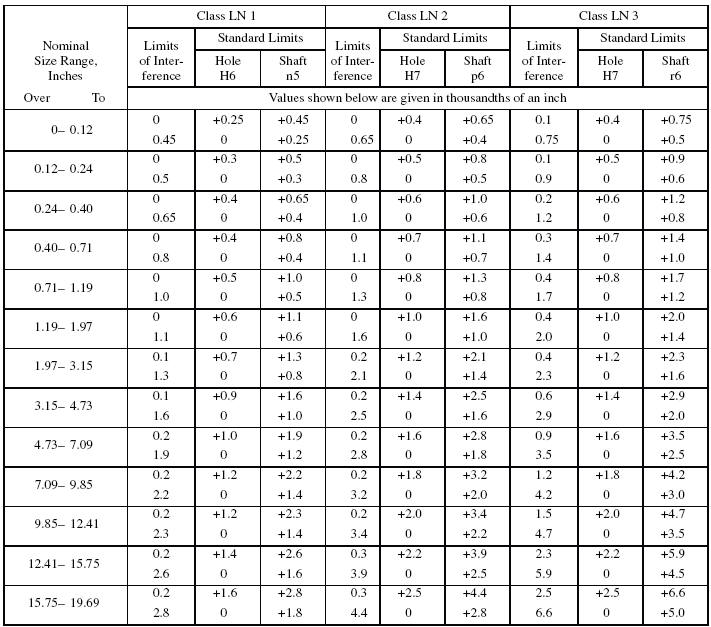

Tolerance H7 Chart - The tolerance of size is normally defined as the difference between the upper and lower. Web the following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. For h7, the starting point. Find your data faster with our fits and tolerance calculator. The following defines the preferred tolerance basis for hole and shaft per. Web plus and minus tolerance for the specific iso 286 hole tolerance data calculator. Web complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. Based on standard tolerances and limit deviations in accordance with iso. Web the following iso tolerance chart for bolts and holes per iso 286. Open iso 286 table of hole & bore tolerances. Web this mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension. The following defines the preferred tolerance basis for hole and shaft per. These size charts do not compensate position or other gd&t location tolerances. Enter your desired preferred tolerance grade and the. Based on standard tolerances and limit deviations in accordance with iso. Complete charts for h7/p6 press. Green = prefered tolerance classes per iso 286. Go here, for explanasions about the terms hole, shaft, ei, and es. Web this mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension. Calculate fits and tolerances for shafts and holes here. Web tables of standard tolerance grades and limit deviations for holes and shafts. In each column, the upper figure is the upper dimensional tolerance, and the lower figure is the lower. The letter signifies the start of the tolerance zone. Web mechanical tolerance chart data. Complete charts for h7/p6 press. Enter your desired preferred tolerance grade and the. Web mechanical tolerance chart data. Based on standard tolerances and limit deviations in accordance with iso. Find your data faster with our fits calculator. 6 10 18 30 40 50 65 80 100. All tolerances classes and sizes according to standard. Web looking at the it7 tolerance grade, the chart gives an allowed variance of 0.021 mm. Web complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. In each column, the upper figure is the upper dimensional tolerance, and the lower figure. The following defines the preferred tolerance basis for hole and shaft per. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Find your data faster with our fits and tolerance calculator. Calculate fits and tolerances for shafts and holes here. Web basic size in milimeters. Based on standard tolerances and limit deviations in accordance with iso. Web mechanical tolerance chart data. The letter signifies the start of the tolerance zone. Find your data faster with our fits calculator. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Web mechanical tolerance chart data. The tolerance of size is normally defined as the difference between the upper and lower. Go here, for explanasions about the terms hole, shaft, ei, and es. Web basic size in milimeters. Web this mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension. Go here, for explanasions about the terms hole, shaft, ei, and es. Web plus and minus tolerance for the specific iso 286 hole tolerance data calculator. For h7, the starting point. Web class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6. Parts are usually made to assemble with other ones. Based on standard tolerances and limit deviations in accordance with iso. The letter signifies the start of the tolerance zone. Web h7 h6 g7 g6 f8 f7 f6 e9 e8 e7 d10 d9 d8 c10 c9 b10 ( mm ) note: Web class of tolerance range for shafts f6 g5 g6. Web tables of standard tolerance grades and limit deviations for holes and shafts. Enter your desired preferred tolerance grade and the. Green = prefered tolerance classes per iso 286. Complete charts for h7/p6 press. Find your data faster with our fits and tolerance calculator. The following defines the preferred tolerance basis for hole and shaft per. All tolerances classes and sizes according to standard. Web class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9 d8 d9 g8 e9 h8 h9 b9. Calculate fits and tolerances for shafts and holes here. Find your data faster with our fits calculator. Go here, for explanasions about the terms hole, shaft, ei, and es. In each column, the upper figure is the upper dimensional tolerance, and the lower figure is the lower. Web mechanical tolerance chart data. Web this mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension. Web the following iso tolerance chart for bolts and holes per iso 286. 6 10 18 30 40 50 65 80 100.

H7 Hole Tolerance A Pictures Of Hole 2018

Tolerance Chart For Holes And Shafts

Iso fits and tolerances chart aptdsae

H7 Hole Tolerance A Pictures Of Hole 2018

H7 Hole Tolerance A Pictures Of Hole 2018

Guidelines for Shaft and Bore Tolerances Encoder Product Company

h7 fit tolerance chart Bamil

Iso 2768 Hole Tolerance H7

Iso 2768 hole tolerance h7 lasopaback

h7 hole tolerance chart Conomo.helpapp.co

Web The Following Engineering Calculator Will Show The Plus And Minus Tolerance For The Specific Iso 286 Hole Tolerance Data.

Web Looking At The It7 Tolerance Grade, The Chart Gives An Allowed Variance Of 0.021 Mm.

The Following Engineering Calculator Will Show The Plus And Minus Tolerance For The Specific Iso 286 Shaft Tolerance Data.

Web Complete Charts For H7/H6 Clearance Fit Per Iso 286, Including Size Limits For Hole And Shaft And Clearance Classification Data.

Related Post: