Tig Welding Settings Chart

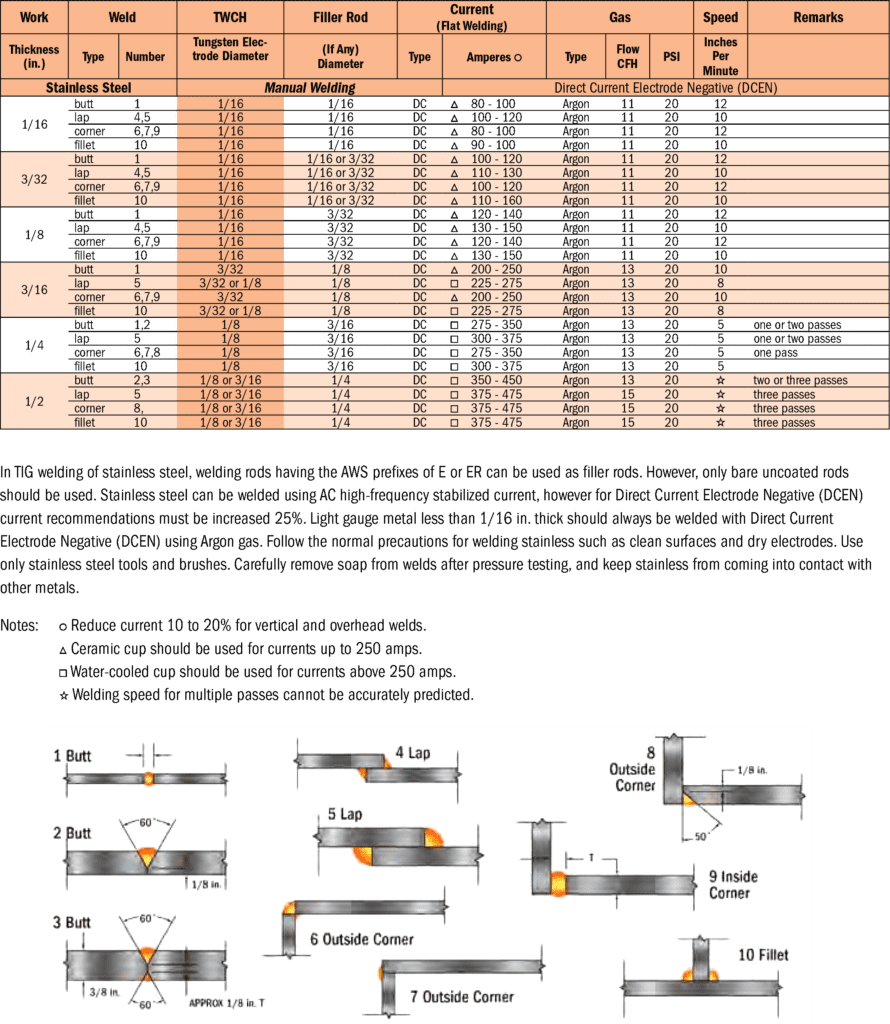

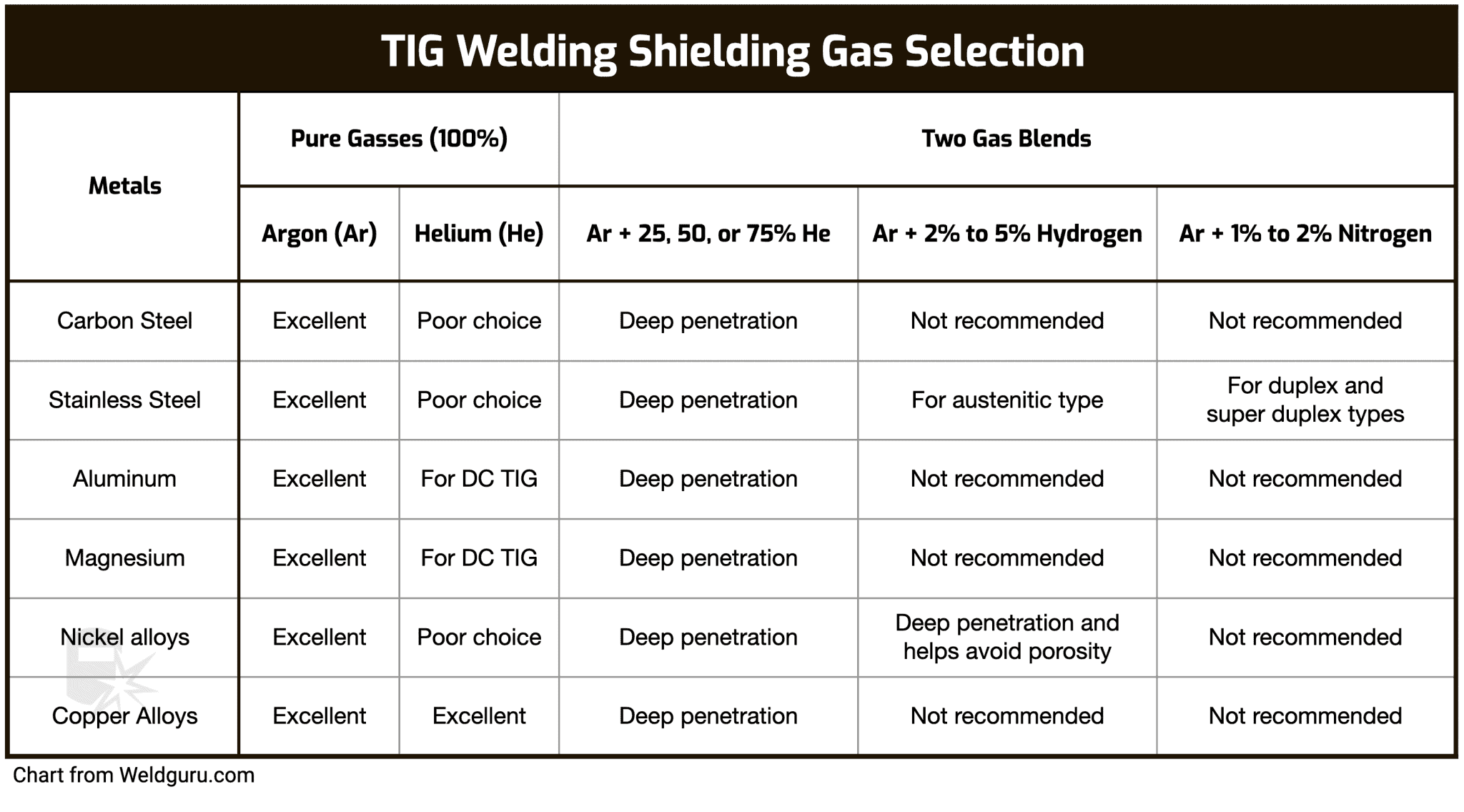

Tig Welding Settings Chart - Web tig setting, are these charts right?? Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. We need a lot less flow in tig welding. Get recommended weld settings based on metal type and thickness. All tig welders can stick weld, so you would switch to that setting if you attached an electrode holder to your machine. Web a tig welding settings chart is an indispensable tool for welders, offering a roadmap to the ideal settings for various materials and thicknesses. Dc tig welding is also the cleanest weld with no sparks or spatter. Tig welding can be used to weld aluminium, copper, titanium etc. Gas flow denotes how much shielding gas you employ in your welds, and it will depend on the actual conditions. Web understanding and adjusting the tig welding steel settings according to the specifics of the job at hand can significantly impact the quality of the welds. Some of the settings that you need to really get a handle on are: Watch hand and torch placement. In everything i've researched, you're supposed to weld aluminum hot and fast compared to mild steel, i'm also told stainless needs to be done quickly. Filler metal must be dry, free of. Web tig setting, are these charts right?? We need a lot less flow in tig welding. Filler metal can be either wire or rod and should be compatible with the base alloy. All tig welders can stick weld, so you would switch to that setting if you attached an electrode holder to your machine. It outlines the optimal settings based on material thickness and joint type. It. Web tig welding amperage chart. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. Get recommended weld settings based on metal type and thickness. Some of the settings that you need to really get a handle on are: Tungsten diameter and cup size. Watch hand and torch placement. Web how to weld the low ferrite austenitic stainless steels. Click here for helpful charts for tig welding based on amperage, materials, sizes, shielding gasses, and more. We need a lot less flow in tig welding. It can be used on thinner material if the tip is kept very sharp. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. Beginning tig welders often unintentionally produce a lot of scrap because they don’t practice basic hand placement and control before striking an arc on the base material.. Web tig welding offers the user the greatest amount of flexibility to weld the widest range of material and thickness and types. Web tig weld setting calculator. Web these are our welding process settings. Gas flow denotes how much shielding gas you employ in your welds, and it will depend on the actual conditions. Tungsten diameter and cup size. Tungsten brings us a high melting point, and also offers excellent electrical conductivity as you weld, so the tungsten electrode won’t ever burn up. 2 2mm is the transition between 1.0mm and 1.6mm filler rod. Web a tig welding settings chart is an indispensable tool for welders, offering a roadmap to the ideal settings for various materials and thicknesses. Get. Web from setup to troubleshooting, learn more about the basics of tig welding and get tips for tig welding success. Filler metal can be either wire or rod and should be compatible with the base alloy. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. Filler metal must be dry, free. Web tig weld setting calculator. Filler metal can be either wire or rod and should be compatible with the base alloy. Filler metal must be dry, free of. The guide is split into specific areas of welding and cutting and designed to give an understanding of these areas. Tungsten brings us a high melting point, and also offers excellent electrical. Web tig welding amperage chart. Get recommended weld settings based on metal type and thickness. Click here for helpful charts for tig welding based on amperage, materials, sizes, shielding gasses, and more. It can be used on thinner material if the tip is kept very sharp. Tungsten diameter and cup size. And even two dissimilar metals. Tungsten brings us a high melting point, and also offers excellent electrical conductivity as you weld, so the tungsten electrode won’t ever burn up. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Filler metal suggested for wrought stainless steels. We need a lot less flow in tig welding. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Click here for helpful charts for tig welding based on amperage, materials, sizes, shielding gasses, and more. Web guide to tig welding. Web understanding and adjusting the tig welding steel settings according to the specifics of the job at hand can significantly impact the quality of the welds. Web so let’s talk about the main tig welding inverter settings. Some of the settings that you need to really get a handle on are: Mma (manual metal arc) is also known as stick welding. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. It can be used on thinner material if the tip is kept very sharp. The guide is split into specific areas of welding and cutting and designed to give an understanding of these areas. 1 a 1.6mm tungsten is ok down to about 30 amps.

Tig Welder Settings Chart

Aluminum Tig Welding Settings Chart

Tig Welding Settings Chart

Tig Welder Settings Chart

Tig Welding Settings Chart

Tig Welding Settings Chart Pdf

TIG Welding Parameters Hobart Brothers

Tig Welding Settings Chart

Tig Welding Settings Chart

Tig Welding Settings Chart

Information About Default Weld Parameters And Settings

Get Recommended Weld Settings Based On Metal Type And Thickness.

Web Tig Setting, Are These Charts Right??

Web Tig Welding Offers The User The Greatest Amount Of Flexibility To Weld The Widest Range Of Material And Thickness And Types.

Related Post: