Tig Welder Settings Chart

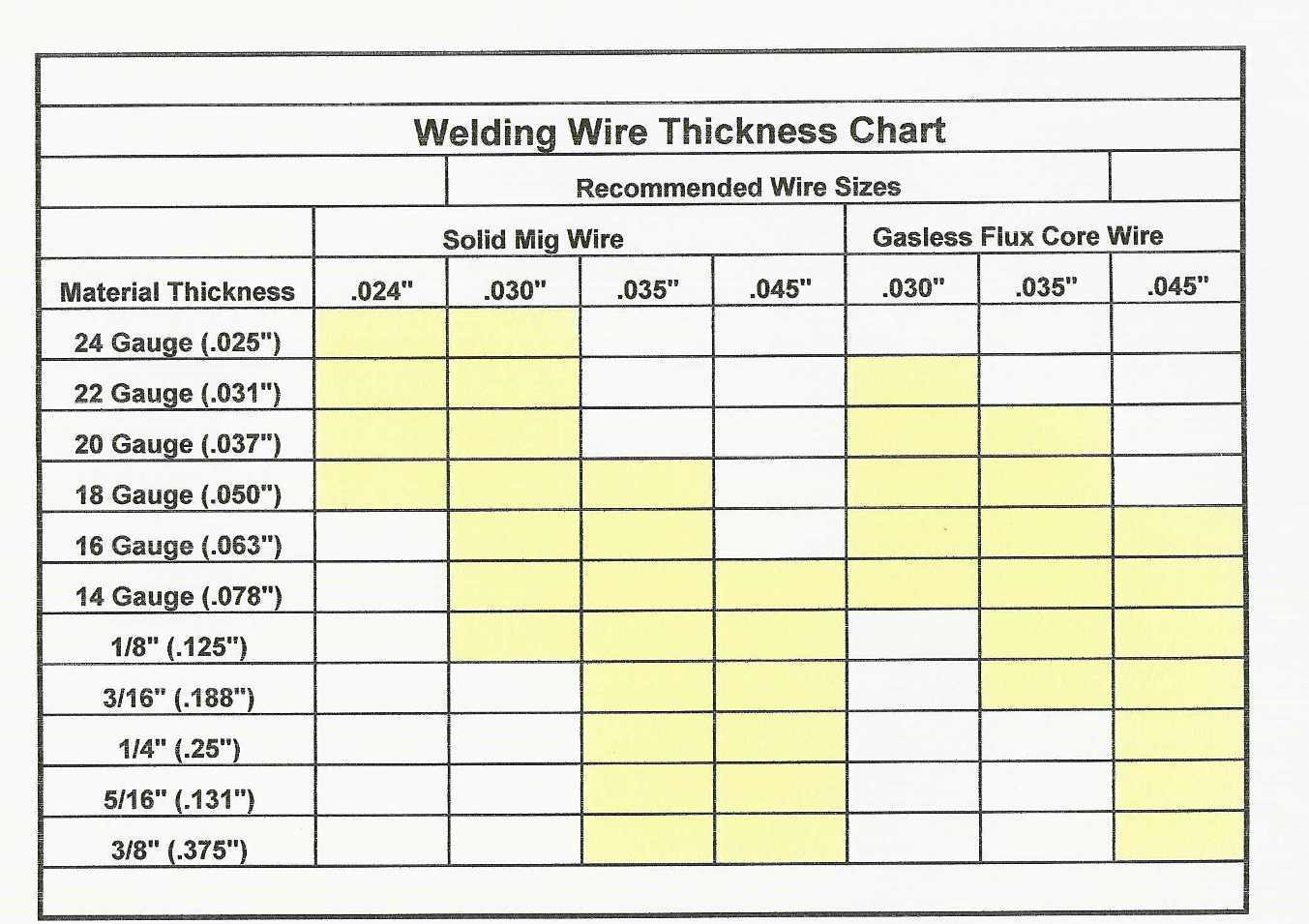

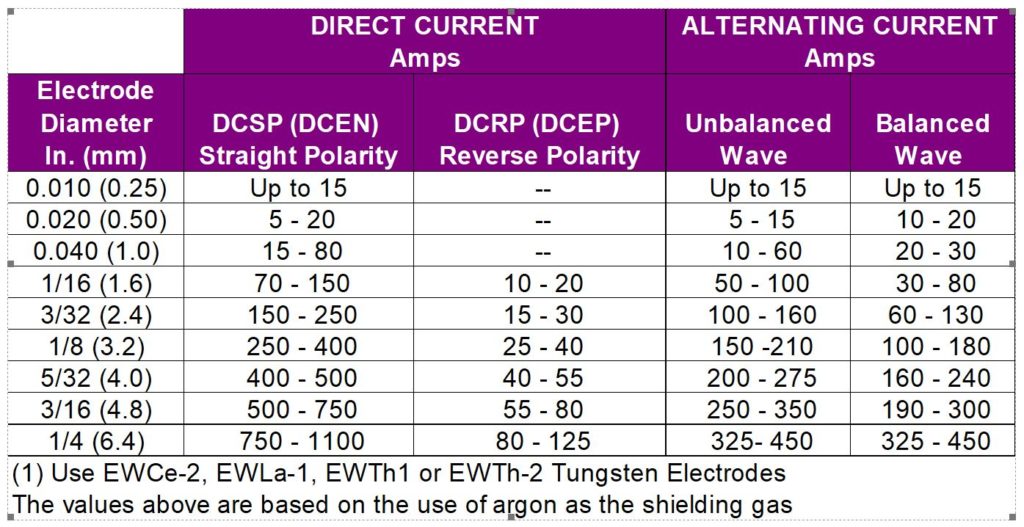

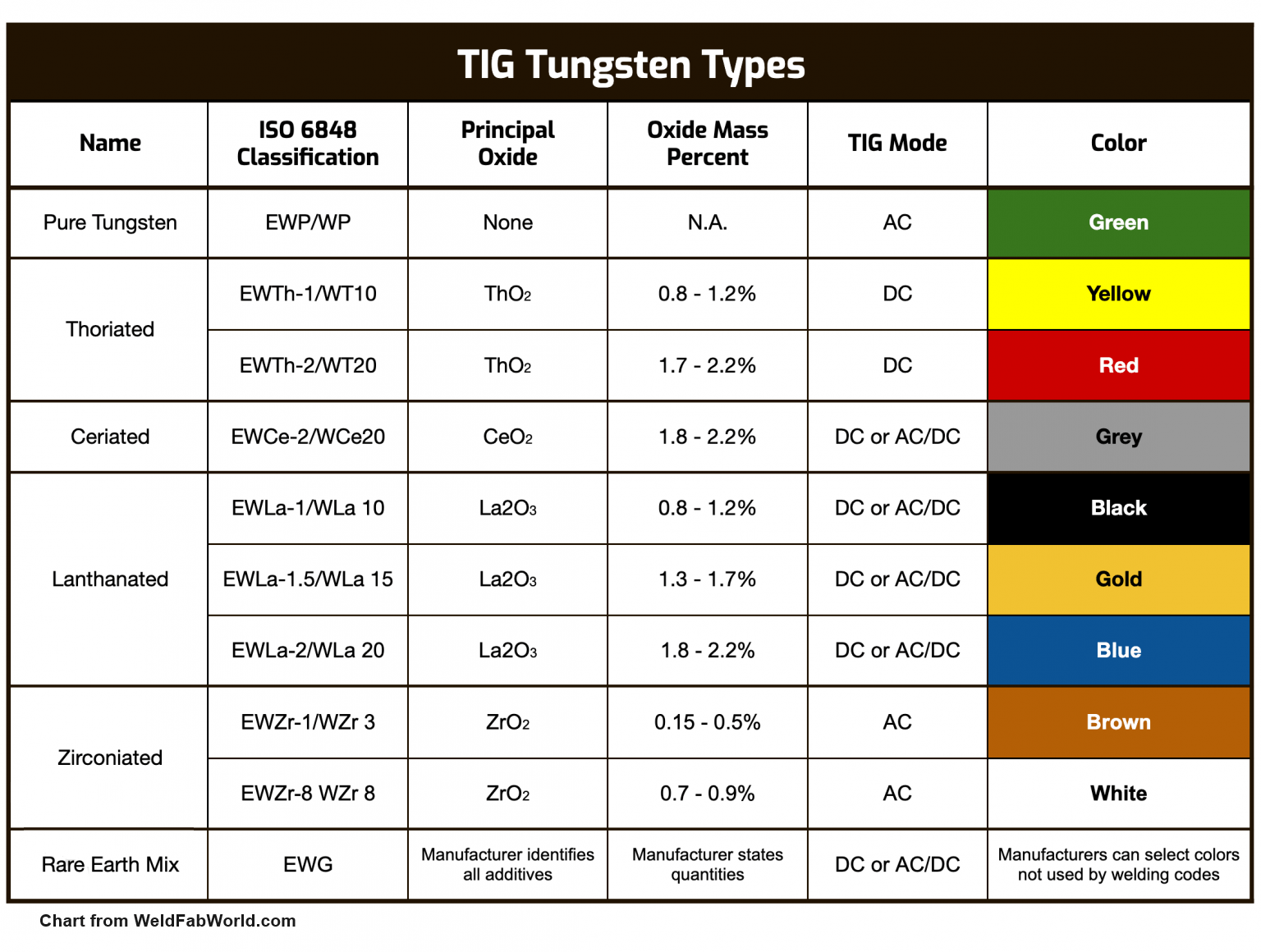

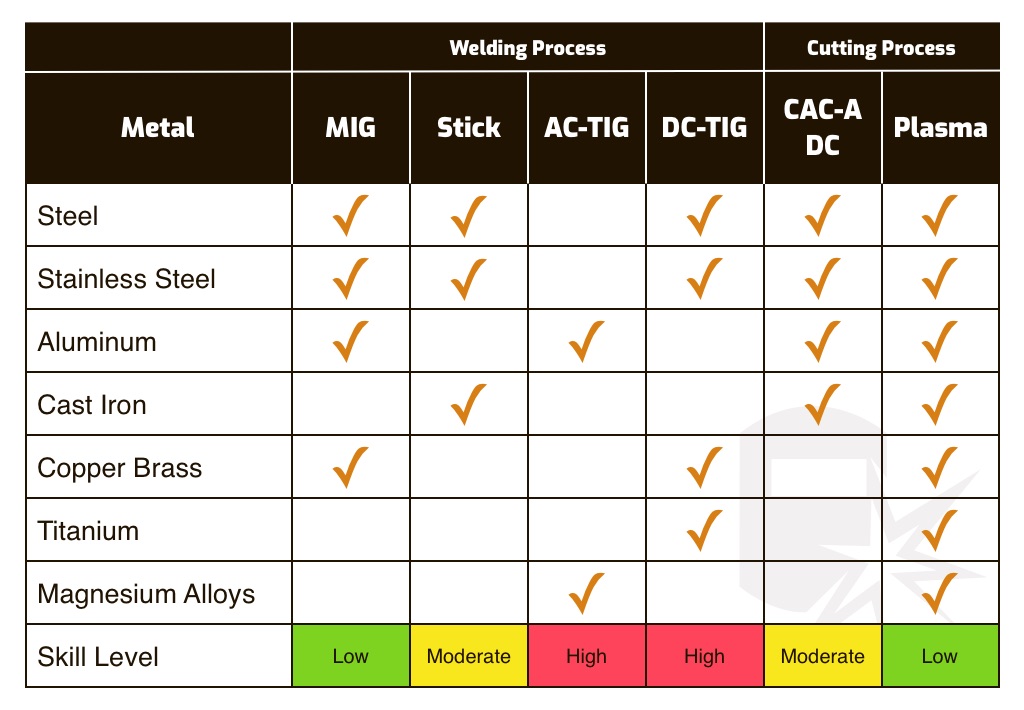

Tig Welder Settings Chart - Web browse suggested weld parameter settings for tig welding. We need a lot less flow in tig welding. Web see the chart below for current ranges of all sizes. Web a tig welding settings chart is an indispensable tool for welders, offering a roadmap to the ideal settings for various materials and thicknesses. Tungsten diameter and cup size. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web tig welding chart based on material and shielding gas. • amperage —pretty straightforward.but there is a simple rule of thumb that holds true up to about.125 thick metal. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. It. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. • amperage —pretty straightforward.but there is a simple rule of thumb that holds true up to about.125 thick metal. The three main types of metals typically worked on with a tig welder include steel, stainless steel,. Web a tig welding settings chart is an indispensable tool for welders, offering a roadmap to the ideal settings for various materials and thicknesses. Tungsten diameter and cup size. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web browse suggested weld parameter settings for tig welding. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Web a tig. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. It outlines the optimal settings based on material thickness and joint type. • amperage —pretty straightforward.but there is a simple rule of thumb that holds true up to about.125 thick metal. Let’s dive into how travel speed and temperature control work in harmony to elevate. Web browse suggested weld parameter settings for tig welding. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Web tig welding chart based on material and shielding gas. A. It outlines the optimal settings based on material thickness and joint type. Web tig welding chart based on material and shielding gas. Web see hundreds of quick 30 second videos showing tig welder settings for all types of welds. Web see the chart below for current ranges of all sizes. A flow of 15 to 25 cfh will cover most. Tungsten diameter and cup size. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. Web browse suggested weld parameter settings for tig welding. Web see the chart below for current ranges of. Web see hundreds of quick 30 second videos showing tig welder settings for all types of welds. We need a lot less flow in tig welding. Tungsten diameter and cup size. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Let’s dive into how travel. • amperage —pretty straightforward.but there is a simple rule of thumb that holds true up to about.125 thick metal. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Web see the chart below for. A flow of 15 to 25 cfh will cover most applications. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Tungsten diameter and cup size. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Web see the chart below for current ranges of all sizes. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. • amperage —pretty straightforward.but there is a simple rule of thumb that holds true up to about.125 thick metal. Let’s dive into how travel speed and temperature control work in harmony to elevate your tig welding prowess. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Web tig welding chart based on material and shielding gas. We need a lot less flow in tig welding. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. It outlines the optimal settings based on material thickness and joint type.

Aluminum Tig Welding Settings Chart

instructions on welding in auto floor pan Grumpys Performance Garage

a table with the names and colors of different types of electrical

Tig Welding Settings Chart Pdf

Tig Weld Amp Chart

Shielding Gas Selection Chart Welding tips, Welding, Tig welding

Tungsten Electrodes For TIG (with Color Chart) Welding Fabrication World

Tig Welding Settings Chart

Tig Welder Settings Chart

How To Choose the Right Welder for Your Needs (MIG, Stick, and TIG

Web A Tig Welding Settings Chart Is An Indispensable Tool For Welders, Offering A Roadmap To The Ideal Settings For Various Materials And Thicknesses.

Web See Hundreds Of Quick 30 Second Videos Showing Tig Welder Settings For All Types Of Welds.

Web Browse Suggested Weld Parameter Settings For Tig Welding.

Adequate Gas Flow For Gmaw Typically Ranges From 35 To 50 Cubic Feet Per Hour.

Related Post: