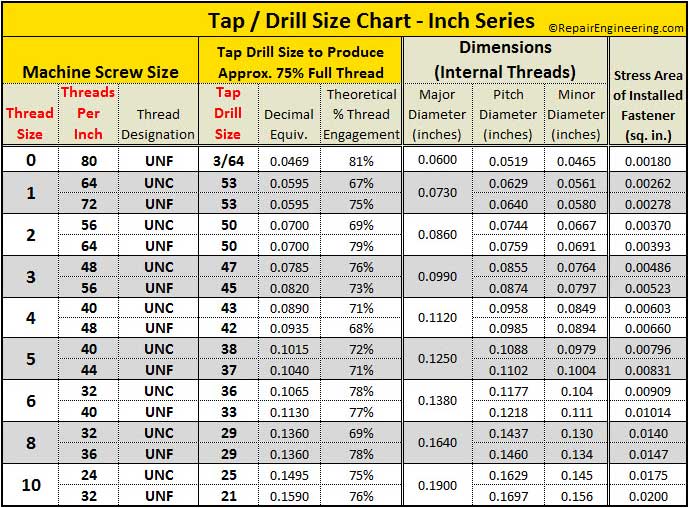

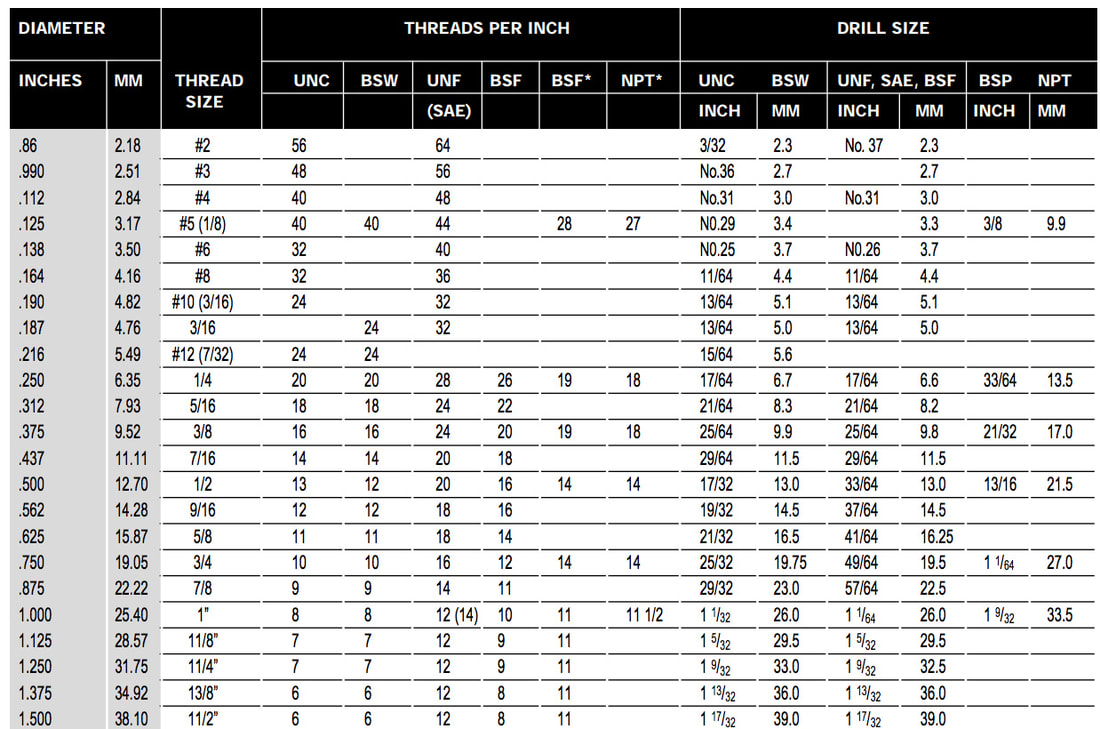

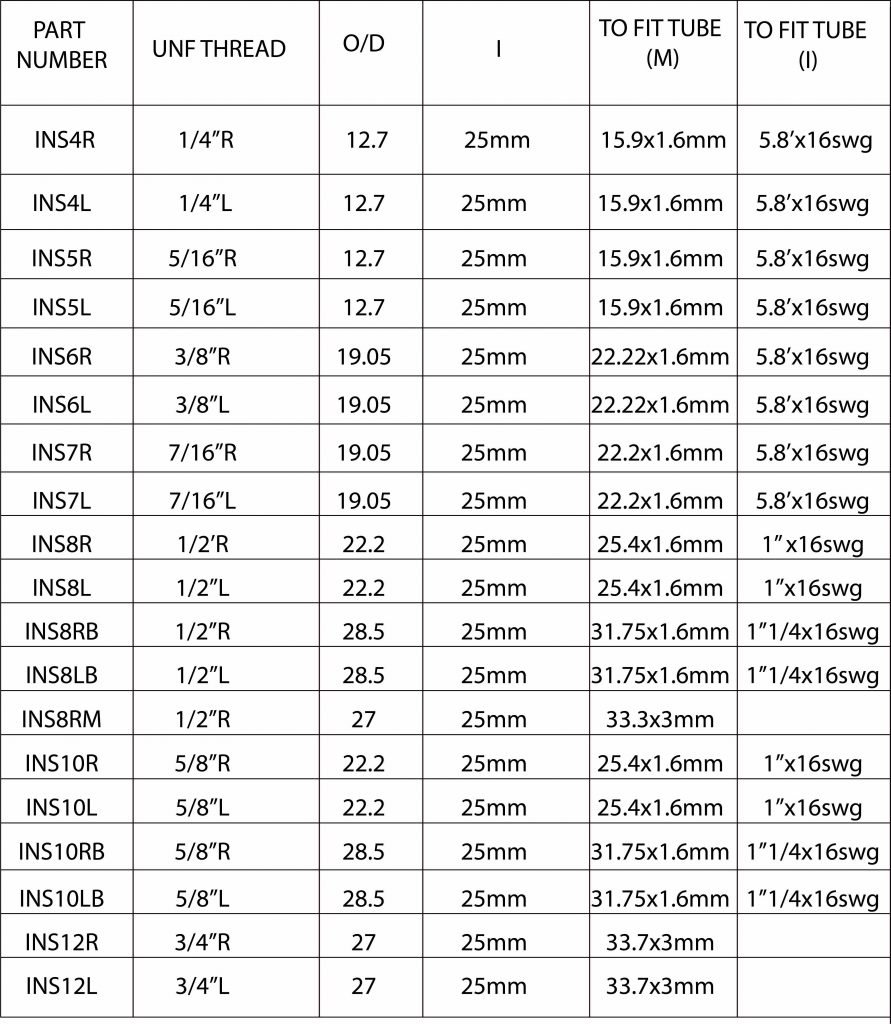

Threaded Insert Drill Size Chart

Threaded Insert Drill Size Chart - Web threaded inserts are available with a range of thread sizes for compatibility with differently sized screws and bolts. Web installing threaded inserts typically involves the following steps: The hole should be the correct size to accommodate the body of the insert and should be as straight as possible. Whether inserted into wood or metal, a threaded insert needs to match the diameter and threading of the screw or bolt that it will host. Web to install thread inserts, first, drill a hole in the desired location, ensuring the hole is the correct size for the insert. Refer to the manufacturer’s guidelines for the recommended drill bit size. Start by selecting the appropriate drill bit size based on the thread size and insert dimensions. Web choose a drill bit that matches the external thread size of the insert to ensure a proper fit. The hole diameter should be slightly smaller than the outer diameter of the insert threads for a secure grip. Then, using a threading tool, screw the insert into the hole until it is flush with the surface. Web threaded inserts are available with a range of thread sizes for compatibility with differently sized screws and bolts. Whether inserted into wood or metal, a threaded insert needs to match the diameter and threading of the screw or bolt that it will host. The hole diameter should be slightly smaller than the outer diameter of the insert threads for. Web choose a drill bit that matches the external thread size of the insert to ensure a proper fit. The hole diameter should be slightly smaller than the outer diameter of the insert threads for a secure grip. Start by selecting the appropriate drill bit size based on the thread size and insert dimensions. Web to begin, you’ll need to. Then, using a threading tool, screw the insert into the hole until it is flush with the surface. The hole diameter should be slightly smaller than the outer diameter of the insert threads for a secure grip. Simply drill a hole sized for the body of the insert, and screw it into place. Start by selecting the appropriate drill bit. Web to install thread inserts, first, drill a hole in the desired location, ensuring the hole is the correct size for the insert. Whether inserted into wood or metal, a threaded insert needs to match the diameter and threading of the screw or bolt that it will host. Simply drill a hole sized for the body of the insert, and. Web to install thread inserts, first, drill a hole in the desired location, ensuring the hole is the correct size for the insert. Refer to the manufacturer’s guidelines for the recommended drill bit size. The hole diameter should be slightly smaller than the outer diameter of the insert threads for a secure grip. Then, using a threading tool, screw the. Web to begin, you’ll need to drill a pilot hole, which will serve as a guide for the threaded insert. Simply drill a hole sized for the body of the insert, and screw it into place. Web to install thread inserts, first, drill a hole in the desired location, ensuring the hole is the correct size for the insert. Web. The hole diameter should be slightly smaller than the outer diameter of the insert threads for a secure grip. The hole should be the correct size to accommodate the body of the insert and should be as straight as possible. Web to install thread inserts, first, drill a hole in the desired location, ensuring the hole is the correct size. The hole should be the correct size to accommodate the body of the insert and should be as straight as possible. The hole diameter should be slightly smaller than the outer diameter of the insert threads for a secure grip. Web to install thread inserts, first, drill a hole in the desired location, ensuring the hole is the correct size. Web installing threaded inserts typically involves the following steps: The hole diameter should be slightly smaller than the outer diameter of the insert threads for a secure grip. Start by selecting the appropriate drill bit size based on the thread size and insert dimensions. Refer to the manufacturer’s guidelines for the recommended drill bit size. The first step is to. The first step is to drill a pilot hole in the material where you want to install the threaded insert. Web to install thread inserts, first, drill a hole in the desired location, ensuring the hole is the correct size for the insert. Whether inserted into wood or metal, a threaded insert needs to match the diameter and threading of. Simply drill a hole sized for the body of the insert, and screw it into place. Web threaded inserts are available with a range of thread sizes for compatibility with differently sized screws and bolts. The first step is to drill a pilot hole in the material where you want to install the threaded insert. The hole diameter should be slightly smaller than the outer diameter of the insert threads for a secure grip. Web installing threaded inserts typically involves the following steps: Web choose a drill bit that matches the external thread size of the insert to ensure a proper fit. Web to begin, you’ll need to drill a pilot hole, which will serve as a guide for the threaded insert. Refer to the manufacturer’s guidelines for the recommended drill bit size. Whether inserted into wood or metal, a threaded insert needs to match the diameter and threading of the screw or bolt that it will host. Start by selecting the appropriate drill bit size based on the thread size and insert dimensions.

Threaded Insert Drill Size Chart

Threaded Insert Size Chart

CNC Kitchen Official Threaded Inserts

Threaded Insert Drill Size Chart

Threaded Inserts for Plastic, Wood, Injection & Rotomolding Cross Tools Co

Threaded Insert Drill Size Chart

Threaded Insert Drill Size Chart A Visual Reference of Charts Chart

Threaded Insert Size Chart

Threaded Inserts The Wood Works Book & Tool Co.

Threaded Insert Drill Size Chart

Web To Install Thread Inserts, First, Drill A Hole In The Desired Location, Ensuring The Hole Is The Correct Size For The Insert.

The Hole Should Be The Correct Size To Accommodate The Body Of The Insert And Should Be As Straight As Possible.

Then, Using A Threading Tool, Screw The Insert Into The Hole Until It Is Flush With The Surface.

Related Post: