Taguchi Design Of Experiments

Taguchi Design Of Experiments - We showed two taguchi arrays for this case: Web an orthogonal array design based on taguchi optimization is used to execute the experiments effectively. Similar content being viewed by others. Material removal rate (mrr) and surface roughness (sr) are monitored and statistically analyzed as a consequence of the responses. Web experimental design in the taguchi method. It is a statically approach where we develop the mathematical models through experimental trial runs to predict the possible output on the basis of the given input data or parameters. Web taguchi’s main purpose is to reduce the variability around the target value of product properties via a systematic application of statistical experimental design which called robust design. Design of experiments (doe) is a powerful approach for investigating the optimal combination of process. Taguchi built on the work of plackett and burman by combining statistics and engineering to achieve rapid improvements in product designs and manufacturing processes. Robust design is an important technique for. Web experimental design in the taguchi method. タグチメソッド) are statistical methods, sometimes called robust design methods, developed by genichi taguchi to improve the quality of manufactured goods, and more recently also applied to engineering, biotechnology, marketing and advertising. Design of experiments (doe) is a powerful approach for investigating the optimal combination of process. This is achieved through the use of. Web orthogonal arrays (often referred to taguchi methods) are often employed in industrial experiments to study the effect of several control factors. For example, consider an experiment with 3 parameters and 3 levels of each parameter (p = 3 and l = 3), as discussed in a previous learning module. This is achieved through the use of an orthogonal matrix,. Design of experiment is the method, which is used at a very large scale to study the experimentations of industrial processes. Critique of experimental design and the taguchi method. These uncontrollable factors are called noise factors. The taguchi method is a statistical approach for optimizing complex systems and is widely used in engineering, manufacturing, marketing, and other fields to improve. Web genichi taguchi applied the statistical methods and the design of experiments concepts, (that he used in communication theory and practiced in department of a japanese company and in laboratory of electrical communications and telegraphs), to the product and process design. Web the taguchi method is a robust design of experiments technique that allows for the systematic evaluation of multiple. Products and processes can be designed to function with less variation and with less sensitivity t. The overall objective of the method is to produce high quality product at low cost to the manufacturer. Web we’ll walk you through the entire process of implementing the taguchi method for robust design, from problem definition to verification and validation, in this comprehensive. Web the chapter introduces taguchi method of experimental design and several common experimental designs such as the completely randomized design, the randomized block design, and the latin square design. Design of experiment is the method, which is used at a very large scale to study the experimentations of industrial processes. Web orthogonal arrays (often referred to taguchi methods) are often. This is achieved through the use of an orthogonal matrix, which facilitates the identification of main effects and interactions between factors [ 75 ]. Web orthogonal arrays (often referred to taguchi methods) are often employed in industrial experiments to study the effect of several control factors. Parameter design in the taguchi method. Taguchi of nippon telephones and telegraph company, japan. Web design of experiments is a statistically based, structured approach to product or process improvement that will quickly yield significant increases in product quality and subsequent decreases in cost. Design of experiments (doe) is a powerful approach for investigating the optimal combination of process. Web taguchi’s main purpose is to reduce the variability around the target value of product properties. Web design of experiments is a statistically based, structured approach to product or process improvement that will quickly yield significant increases in product quality and subsequent decreases in cost. Products and processes can be designed to function with less variation and with less sensitivity t. For example, consider an experiment with 3 parameters and 3 levels of each parameter (p. The overall objective of the method is to produce high quality product at low cost to the manufacturer. This is achieved through the use of an orthogonal matrix, which facilitates the identification of main effects and interactions between factors [ 75 ]. You can group runs into blocks to distinguish the original runs from the. Web an orthogonal array design. But taguchi provides either no information or insufficient information on the methods that were used to construct these arrays. Similar content being viewed by others. His efforts led to a subset of screening experiments commonly referred to the taguchi techniques or the taguchi method®. Web the chapter introduces taguchi method of experimental design and several common experimental designs such as the completely randomized design, the randomized block design, and the latin square design. Taguchi of nippon telephones and telegraph company, japan has developed a method based on orthogonal array experiments which gives much reduced variance for the experiment with optimum settings of control parameters. Web design of experiments is a statistically based, structured approach to product or process improvement that will quickly yield significant increases in product quality and subsequent decreases in cost. Instead of having to test all possible combinations like the factorial design, the taguchi method tests pairs of combinations. The taguchi method is a statistical approach for optimizing complex systems and is widely used in engineering, manufacturing, marketing, and other fields to improve product quality and performance. Web the experimental design proposed by taguchi involves using orthogonal arrays to organize the factors affecting the process and the levels at which they should be set. Web experimental design in the taguchi method. Design of experiment is the method, which is used at a very large scale to study the experimentations of industrial processes. Material removal rate (mrr) and surface roughness (sr) are monitored and statistically analyzed as a consequence of the responses. Taguchi built on the work of plackett and burman by combining statistics and engineering to achieve rapid improvements in product designs and manufacturing processes. It was developed by japanese statistician and engineer genichi taguchi. Products and processes can be designed to function with less variation and with less sensitivity t. Web orthogonal arrays (often referred to taguchi methods) are often employed in industrial experiments to study the effect of several control factors.

Classic Taguchi Design of Experiment Download Scientific Diagram

! Design Of Experiments Using Taguchi Approach.pdf Analysis Of

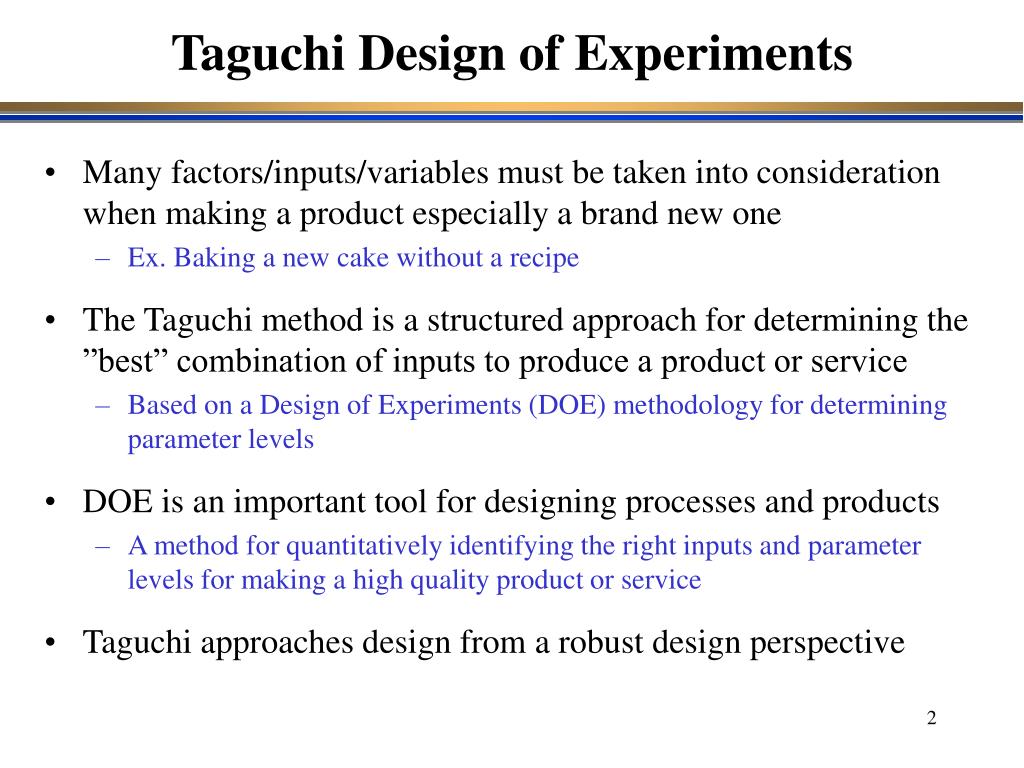

Taguchi Design of Experiments Many factorsinputsvariables must be

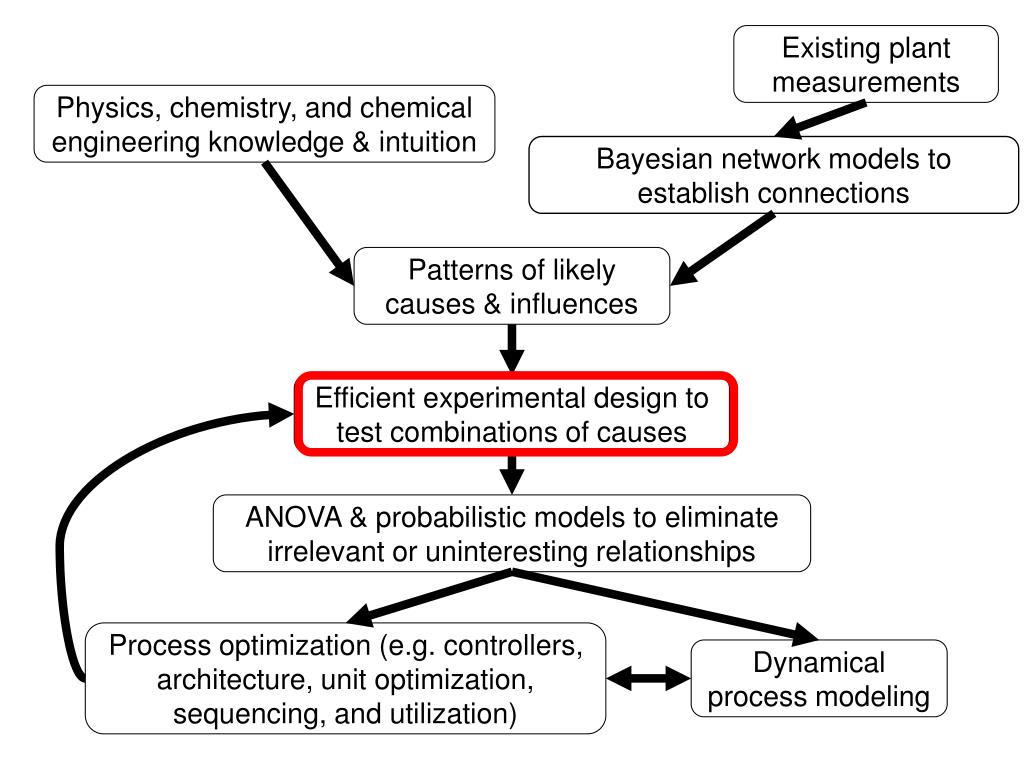

PPT Design of Experiments Taguchi Methods By Peter Woolf (pwoolf

Introduction To Robust Parameter Taguchi Design of Experiments Analysis

Steps of Taguchi design method Download Scientific Diagram

Flow chart of design of experiment by Taguchi method Download

PPT Robust Design The Taguchi Philosophy PowerPoint Presentation

Taguchi Design of Experiments Many factorsinputsvariables must be

Taguchi metho ppt Design Of Experiments Experiment

Robust Design Is An Important Technique For.

Web The Taguchi Method Is A Robust Design Of Experiments Technique That Allows For The Systematic Evaluation Of Multiple Parameter Combinations With A Small Number Of Experiments.

Design Of Experiments (Doe) Is A Powerful Approach For Investigating The Optimal Combination Of Process.

Taguchi’s Original Target Population Was Manufacturing Engineers, But His Techniques Are Readily Applied To Many Management Problems.

Related Post: