Table Saw Push Stick Pattern

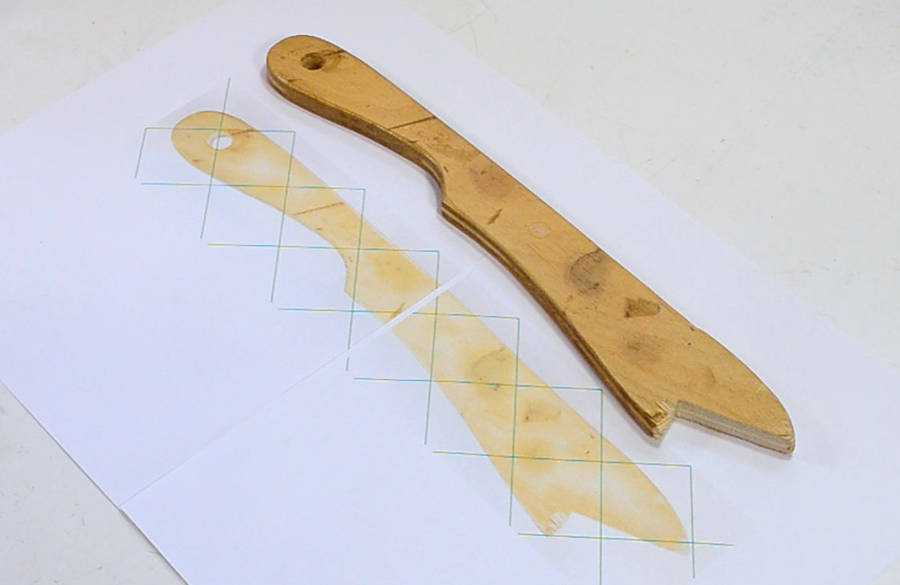

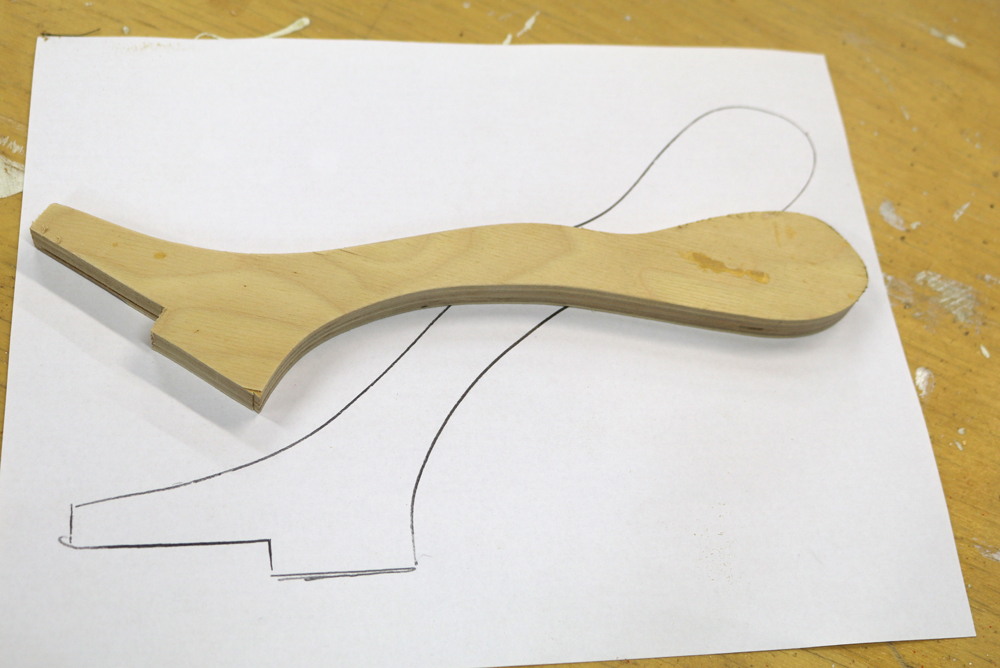

Table Saw Push Stick Pattern - Web it’s a basic process, but it involves many moving parts, such as footwork, hand placement, and pressure. Learn how to build a diy push stick, here. Cut the base in the table saw and the curved parts on the scroll saw. The key is controlling the workpiece through the cut, and that’s where push sticks and push pads come into play. Web push stick is a safety device that helps you to control movement of working piece when operate on some of the machines, especially when working on table saw, jointer, router table or a band saw. Draw the table saw push stick outline on the plywood. Web put them to good use and they’ll do you proud too. Use sandpaper to smooth out. They are made of birch plywood. You can download the plans for free here. Push stick keeps your hands away from machine cutting zone, it also helps to produce a smoother cuts. Table saw jigs for safety. Web push stick templates, can be made using scrap wood. It keeps the workpiece under control and it provides a protective barrier between your hand and the saw blade. Web this is a very simple template for. Web a notched push stick is a secondary protection to a push block while using a table saw. Web push sticks can come in different shapes and sizes, they can be made out of wood or plastic, and they can be made at home or purchased from a store too. Web the push stick you use with your table saw. Web this is a very simple template for push sticks. Safety is the most important thing in the workshop. Push sticks are used to push stock through your table saw without getting your fingers and hands near the spinning blade. It's a simple and effective design that keeps your wood stock firmly attached to the table saw surface. Workshop push. Draw the table saw push stick outline on the plywood. Web a notched push stick is a secondary protection to a push block while using a table saw. Learn how to build a diy push stick, here. Web a push stick keeps your hands away from sawblades and cutterheads and allows you to hold workpieces securely. It's a simple and. This is an easy one. Push sticks are used to push stock through your table saw without getting your fingers and hands near the spinning blade. Web push stick templates, can be made using scrap wood. Web this push stick is styled to look like a short handsaw, with a notch at the back to help push material through the. I traced one of my push sticks and made a pattern for you, it can be downloaded here: Web this version is designed with a comfortable, practical handle and a replaceable body. Web push stick is a safety device that helps you to control movement of working piece when operate on some of the machines, especially when working on tablesaw,. Use sandpaper to smooth out. Web if using a table saw is a little intimidating to you, you’re not alone! The key is controlling the workpiece through the cut, and that’s where push sticks and push pads come into play. Workshop push sticks and blocks. Check out the video on how to make it and here are some images and. For narrow cuts, i recommend using a push stick. Safety is the most important thing in the workshop. Push stick keeps your hands away from machine cutting zone, it also helps to produce a smoother cuts. Draw the table saw push stick outline on the plywood. Web i'm a big fan of using push sticks on the table saw, and. Web this is a very simple template for push sticks. Workshop push sticks and blocks. As such, don't take the lowly push stick for granted. Using a plywood push stick can help keep your fingers out of the way and give you more confidence. And why these are the best push sticks and sanding blocks. Using a plywood push stick can help keep your fingers out of the way and give you more confidence. Check out the video on how to make it and here are some images and the stencil that you can print out, trace and replicate. Draw the table saw push stick outline on the plywood. Here are two options for building.. I start by finding a hand saw that has a handle that i like and feels good in my hand. Table saw jigs for safety. We were all beginners once! The scrap plywood i had happened to be large enough for making two push sticks. The first step in making your new table saw push stick is to draw out the design onto your plywood. I start by printing the template and pasting it onto a piece of plywood: And why these are the best push sticks and sanding blocks. Web this is a very simple template for push sticks. Glue it on the plywood sheet. Workshop push sticks and blocks. As such, don't take the lowly push stick for granted. The new plywood 'blade' for this push stick is a thin 6mm, allowing great stability over a long reach, and the narrowness allows it to pass through the table saw even when the. I’ve been using this kind of push stick for a long time time, and i go into a few of the benefits of this type in the video at the bottom of the page. Here are two options for building. Web i'm a big fan of using push sticks on the table saw, and i usually use two of them to guide the work past the blade. It's a simple and effective design that keeps your wood stock firmly attached to the table saw surface.

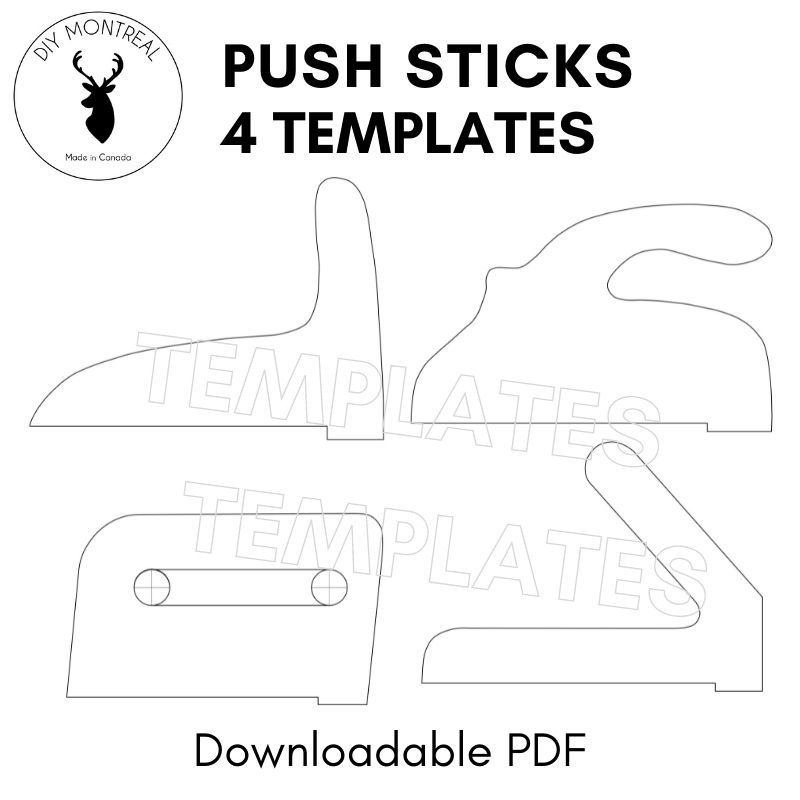

Push Sticks Printable Templates 4 Designs DIY Montreal

How To Make A Push Stick YouTube

50 Extreme Table Saw Push Stick Safest Design FREE PLANS YouTube

Making table saw push sticks

Woodworking Plans Table Saw Push Stick Pattern PDF Plans

Table saw push stick DIY » Famous Artisan

Woodworking Template Table Saw Push Sticks Kurt's Blog

Table Saw Push Stick CNC Router Files Printable Templates Push Stick

Woodworking Template Table Saw Push Sticks Kurt's Blog

PushStick for Table Saw Free Design Plans Jon Peters

Push Sticks Are Used To Push Stock Through Your Table Saw Without Getting Your Fingers And Hands Near The Spinning Blade.

Web Push Sticks Can Come In Different Shapes And Sizes, They Can Be Made Out Of Wood Or Plastic, And They Can Be Made At Home Or Purchased From A Store Too.

Use Sandpaper To Smooth Out.

Push Stick Keeps Your Hands Away From Machine Cutting Zone, It Also Helps To Produce A Smoother Cuts.

Related Post: