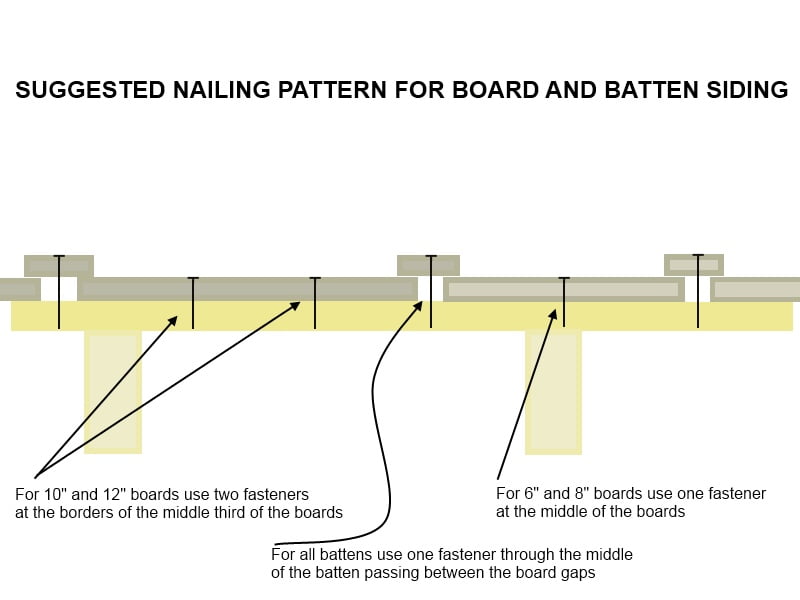

T111 Siding Nailing Pattern

T111 Siding Nailing Pattern - Web it will swell at every spot a nail pierces. Space nails 6 to 8 inches apart along the edges and 12 inches apart along. What nails should you use for t1. I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or. Every 6” on the sides and every 12” on the studs located in between, the edges. The process of pressure treating it injects rosin and other chemicals into the wood fibers, under. The minimum nail length is 2 to 2 1/2 inches, and the. Web most of the nailing pattern is 6 on edges and 12 in the field. I was going to first put some construction glue on the studs, then nail the siding in the grooves with. Follow these guidelines for a proper nailing pattern: What nails should you use for t1. The process of pressure treating it injects rosin and other chemicals into the wood fibers, under. The minimum nail length is 2 to 2 1/2 inches, and the. I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or. Every 6” on the sides and every 12”. Web most of the nailing pattern is 6 on edges and 12 in the field. You can attach them with exterior screws or galvanized nails. Web nail type and size. With relatively blunt tips and thin shanks, siding nails. Although i have seen it on 4 edge nailing shear panels. I was going to first put some construction glue on the studs, then nail the siding in the grooves with. The minimum nail length is 2 to 2 1/2 inches, and the. I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or. Follow these guidelines for a proper nailing pattern: The best one. The process of pressure treating it injects rosin and other chemicals into the wood fibers, under. The minimum nail length is 2 to 2 1/2 inches, and the. With relatively blunt tips and thin shanks, siding nails. I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or. Web it will swell at every. With relatively blunt tips and thin shanks, siding nails. The process of pressure treating it injects rosin and other chemicals into the wood fibers, under. Smooth shank will suffice, ring shank will hold better. It’s made by laminating layers of wood veneer together, creating a durable and weather. Wash surface with mold/mildew remover as per label instructions. I know the stuff does not hold up very well. Every 6” on the sides and every 12” on the studs located in between, the edges. These nails should be long enough to penetrate the siding, plywood sheathing, and securely fasten into the wall. Web it will swell at every spot a nail pierces. The process of pressure treating it. It’s made by laminating layers of wood veneer together, creating a durable and weather. Web nail type and size. The best one is described as all wood. Get an estimate of costs and make an informed decision. The process of pressure treating it injects rosin and other chemicals into the wood fibers, under. It needs n o finish and will last indefinitely. Follow these guidelines for a proper nailing pattern: The best one is described as all wood. Web nail type and size. I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or. Every 6” on the sides and every 12” on the studs located in between, the edges. Web it will swell at every spot a nail pierces. The process of pressure treating it injects rosin and other chemicals into the wood fibers, under. The best one is described as all wood. It’s made by laminating layers of wood veneer together, creating. Get an estimate of costs and make an informed decision. Web by selecting the right nail gun, nails, and following these steps, you’ll achieve a neat and secure finish that enhances the beauty and durability of your siding project. I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or. Space nails 6 to. I was going to first put some construction glue on the studs, then nail the siding in the grooves with. The best one is described as all wood. It needs n o finish and will last indefinitely. I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or. Get an estimate of costs and make an informed decision. The minimum nail length is 2 to 2 1/2 inches, and the. With relatively blunt tips and thin shanks, siding nails. Smooth shank will suffice, ring shank will hold better. What nails should you use for t1. Web by selecting the right nail gun, nails, and following these steps, you’ll achieve a neat and secure finish that enhances the beauty and durability of your siding project. Although i have seen it on 4 edge nailing shear panels. Web most of the nailing pattern is 6 on edges and 12 in the field. These nails should be long enough to penetrate the siding, plywood sheathing, and securely fasten into the wall. Every 6” on the sides and every 12” on the studs located in between, the edges. It’s made by laminating layers of wood veneer together, creating a durable and weather. Web it will swell at every spot a nail pierces.

Board and Batten Siding Install

How to Install T111 or LP SmartSide Siding on a Shed (T111 or LP

Warped T111 siding, can this be nailed back in? Home Improvement

Top 10 Best Nails For T1 11 Siding Reviews With Scores VarietyPick

How to DIY Install T111 Plywood Siding One Hundred Acres Home

Nail Types for T111 Panels Hunker

Drip Cap Placement With T111 Siding? Windows and Doors DIY

Shed Door Plans StepByStep Construct101

How to Install T111 or LP SmartSide Siding on a Shed (T111 or LP

How to Install Shed Siding (T111 and LP SmartSide Panel Installation

Web Nail Type And Size.

Space Nails 6 To 8 Inches Apart Along The Edges And 12 Inches Apart Along.

Next, Install A Ledger Board Or Temporary.

Follow These Guidelines For A Proper Nailing Pattern:

Related Post: