T1 11 Siding Nailing Pattern

T1 11 Siding Nailing Pattern - I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or screws. It might not be your first choice for building a home, but it could be ideal for finishing up a shed, chicken coop, or other outbuilding in an inexpensive, yet attractive way. Web nail type and size. Whether you’re a seasoned pro or a diy enthusiast, these guidelines will help you get the job done right. Follow these guidelines for a proper nailing pattern: Designed specifically for siding applications, this nail gun uses compressed air to drive nails. Web nail the trim to the corners of the house and around windows and doors with 8d galvanized finish nails. These nails should be long enough to penetrate the siding, plywood sheathing, and securely fasten into the wall studs or framing behind the siding. Web by selecting the right nail gun, nails, and following these steps, you’ll achieve a neat and secure finish that enhances the beauty and durability of your siding project. Every 6” on the sides and every 12” on the studs located in between, the edges at the sill and top plate should be nailed every 4” to seal tight against insects and air. Designed specifically for siding applications, this nail gun uses compressed air to drive nails. With relatively blunt tips and thin shanks, siding nails reduce splitting during installation. Hi all, i am building a large’ish shed; Space nails 6 to 8 inches apart along the edges and 12 inches apart along the studs. Whether you’re a seasoned pro or a diy. I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or screws. Hi all, i am building a large’ish shed; Space nails 6 to 8 inches apart along the edges and 12 inches apart along the studs. Woodgrain texture with attractive groove pattern. Plate nailing is also not good. Whether you’re a seasoned pro or a diy enthusiast, these guidelines will help you get the job done right. Follow these guidelines for a proper nailing pattern: In this guide, we’ll walk you through the steps to ensure a professional and secure installation. Space nails 6 to 8 inches apart along the edges and 12 inches apart along the studs.. Space the nails horizontally at intervals of 16 inches, starting from the top edge of the siding panel and continuing down. I have a couple of questions. Follow manufacturer guidelines for specific requirements. (778) questions & answers (281) hover image to zoom. Every 6” on the sides and every 12” on the studs located in between, the edges at the. I'm unsure whether it would be easier/better to use ring shank nails in a nail gun, or screws. Does it qualify as wall sheathing? These nails should be long enough to penetrate the siding, plywood sheathing, and securely fasten into the wall studs or framing behind the siding. Space nails 6 to 8 inches apart along the edges and 12. Space nails 6 to 8 inches apart along the edges and 12 inches apart along the studs. Would like to avoid buying an air compressor and framing nail gun if i. With relatively blunt tips and thin shanks, siding nails reduce splitting during installation. Does it qualify as wall sheathing? It is also common practice to trim the tops to. It might not be your first choice for building a home, but it could be ideal for finishing up a shed, chicken coop, or other outbuilding in an inexpensive, yet attractive way. Davidr8 | posted in construction techniques on september 25, 2006 07:23am. Web nail gun types. Designed specifically for siding applications, this nail gun uses compressed air to drive. Woodgrain texture with attractive groove pattern. Plate nailing is also not good. Web by selecting the right nail gun, nails, and following these steps, you’ll achieve a neat and secure finish that enhances the beauty and durability of your siding project. It is also common practice to trim the tops to the sheets, where the wall meets the soffit, and. Woodgrain texture with attractive groove pattern. Web by selecting the right nail gun, nails, and following these steps, you’ll achieve a neat and secure finish that enhances the beauty and durability of your siding project. Davidr8 | posted in construction techniques on september 25, 2006 07:23am. Get an estimate of costs and make an informed decision. Follow manufacturer guidelines for. Every 6” on the sides and every 12” on the studs located in between, the edges at the sill and top plate should be nailed every 4” to seal tight against insects and air. I have a couple of questions. Davidr8 | posted in construction techniques on september 25, 2006 07:23am. It’s a common choice due to its efficiency and. Rated for exterior use in construction. Space the nails horizontally at intervals of 16 inches, starting from the top edge of the siding panel and continuing down. Designed specifically for siding applications, this nail gun uses compressed air to drive nails. It’s a common choice due to its efficiency and precision. Follow these guidelines for a proper nailing pattern: Web nail type and size. These nails should be long enough to penetrate the siding, plywood sheathing, and securely fasten into the wall studs or framing behind the siding. Web the heading says it all. Hi all, i am building a large’ish shed; Next, install a ledger board or temporary ledger nails at the base of the shed wall that will serve as the ledge in which the siding panels will rest as you install them. It might not be your first choice for building a home, but it could be ideal for finishing up a shed, chicken coop, or other outbuilding in an inexpensive, yet attractive way. Davidr8 | posted in construction techniques on september 25, 2006 07:23am. Space nails 6 to 8 inches apart along the edges and 12 inches apart along the studs. Does it qualify as wall sheathing? It is also common practice to trim the tops to the sheets, where the wall meets the soffit, and the bottoms, where it meets the foundation. Whether you’re a seasoned pro or a diy enthusiast, these guidelines will help you get the job done right.

Nail Types for T111 Panels Hunker

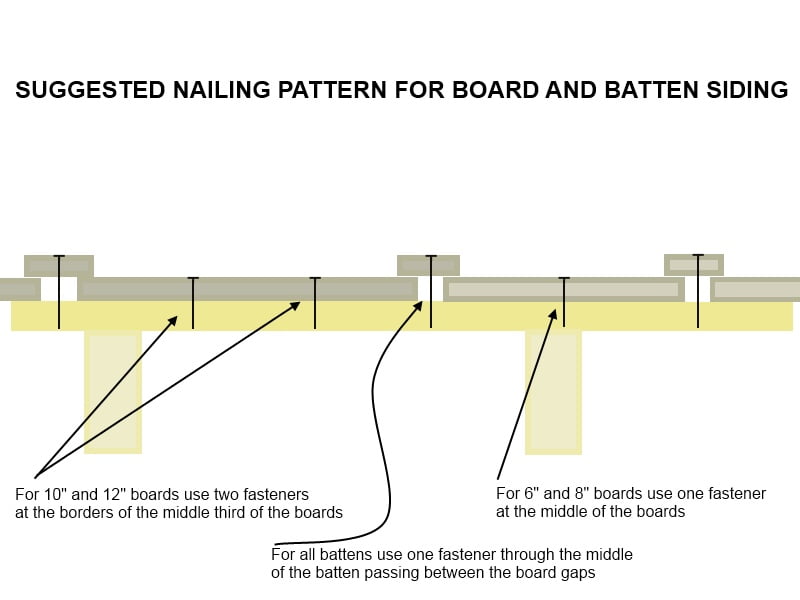

Board and Batten Siding Install

Shed Door Plans StepByStep Construct101

How to DIY Install T111 Plywood Siding One Hundred Acres Home

T111 Exterior Siding Panel CC Lumber Company Raleigh

How to Install Shed Siding (T111 and LP SmartSide Panel Installation

Top 10 Best Nails For T1 11 Siding Reviews With Scores VarietyPick

How to Install T111 or LP SmartSide Siding on a Shed (T111 or LP

How to Nail T111 Siding Hunker Exterior grade plywood, T1 11

How to Install T111 or LP SmartSide Siding on a Shed (T111 or LP

(778) Questions & Answers (281) Hover Image To Zoom.

Plate Nailing Is Also Not Good.

Get An Estimate Of Costs And Make An Informed Decision.

Woodgrain Texture With Attractive Groove Pattern.

Related Post: