Steel Material Hardness Chart

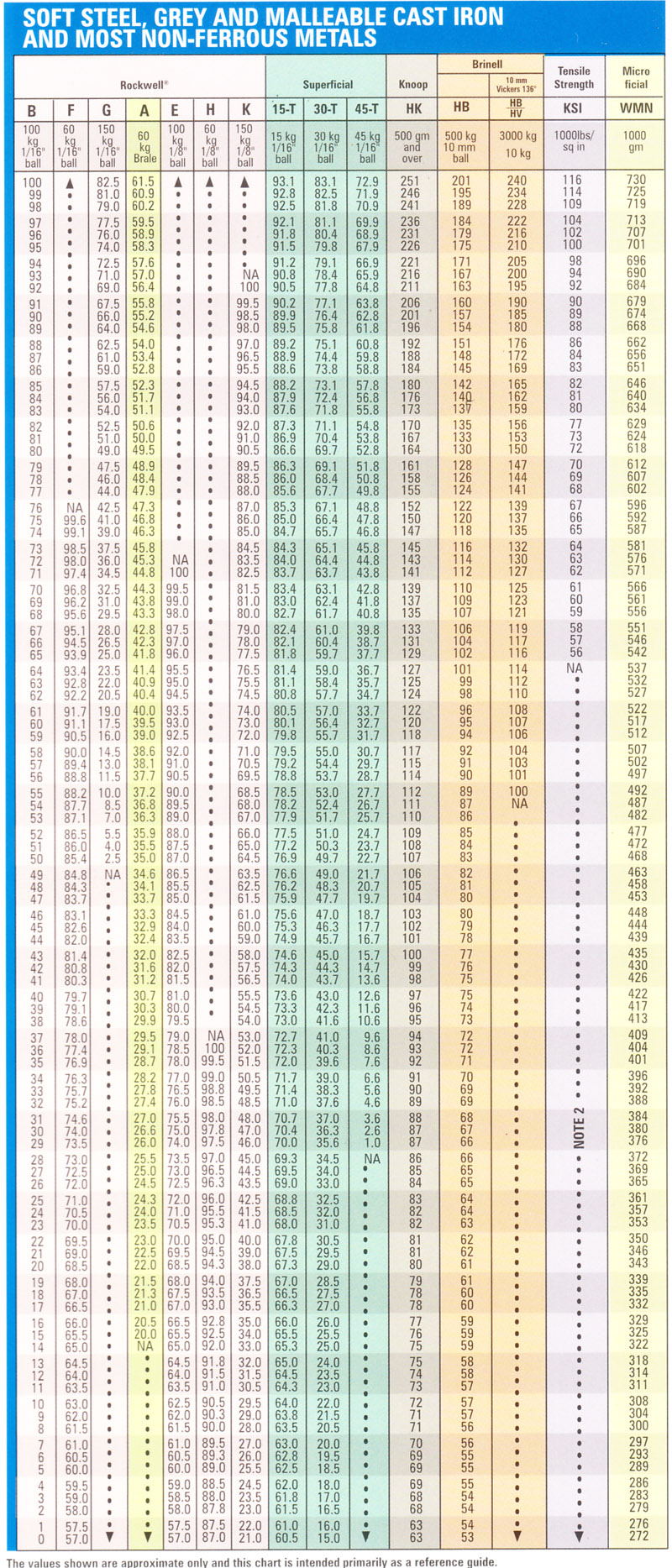

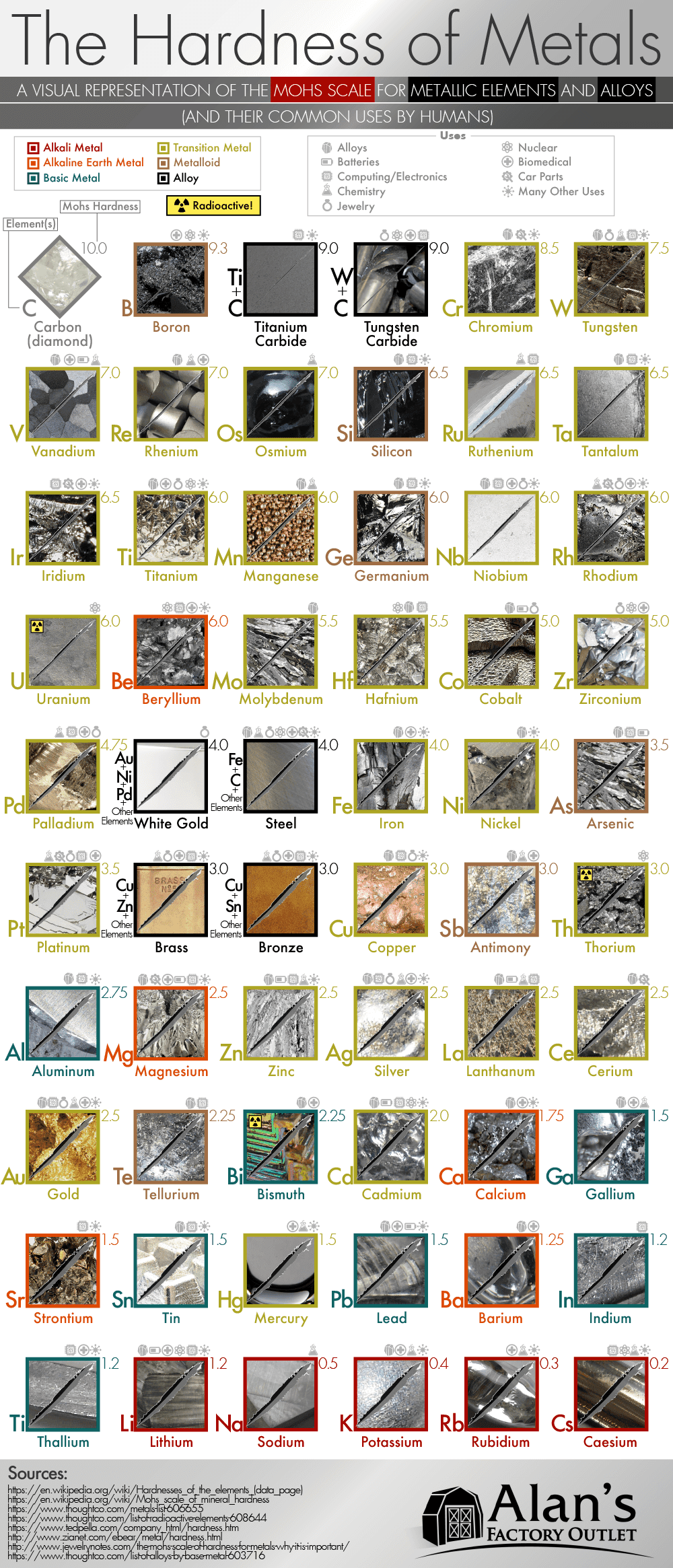

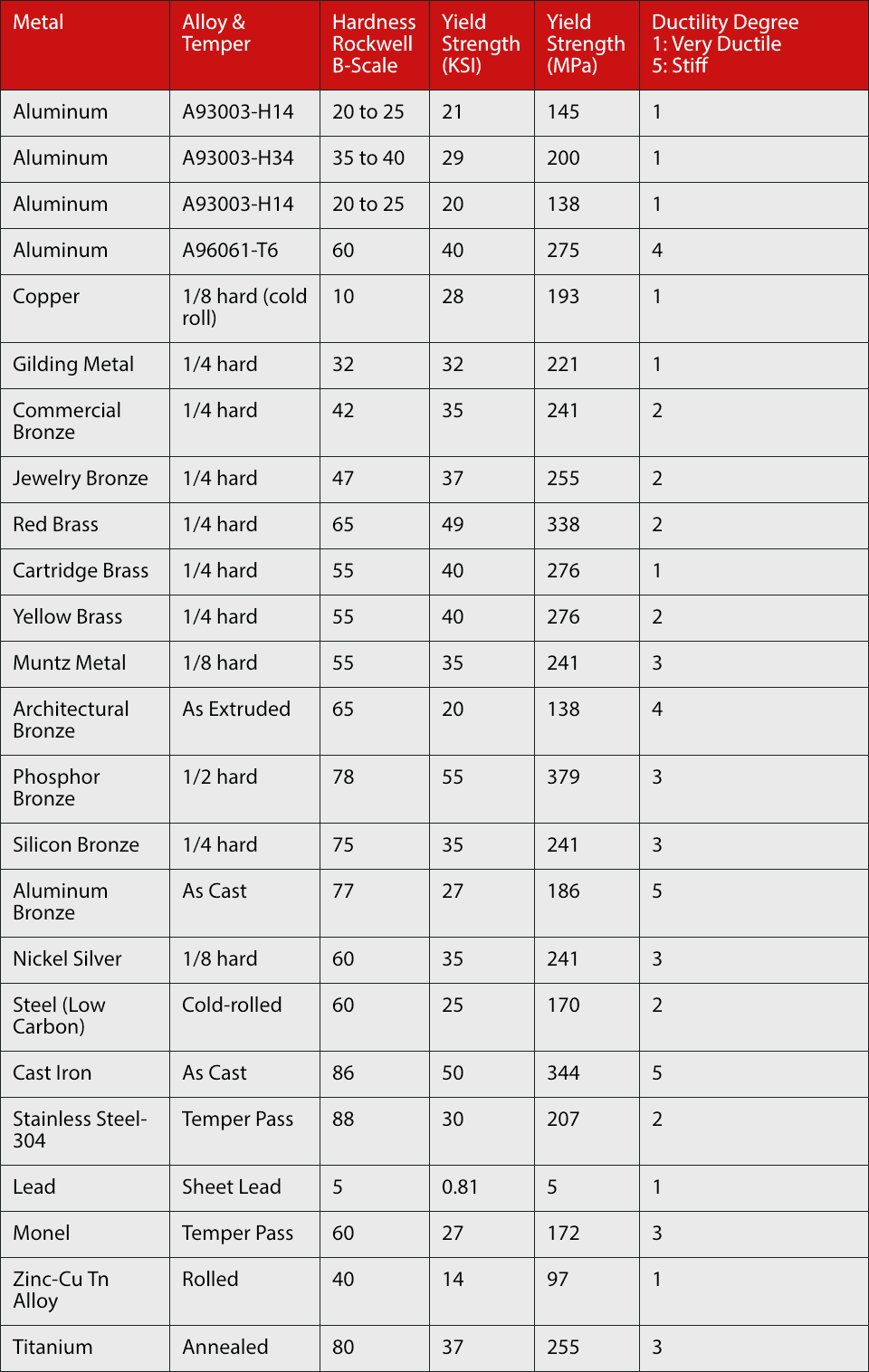

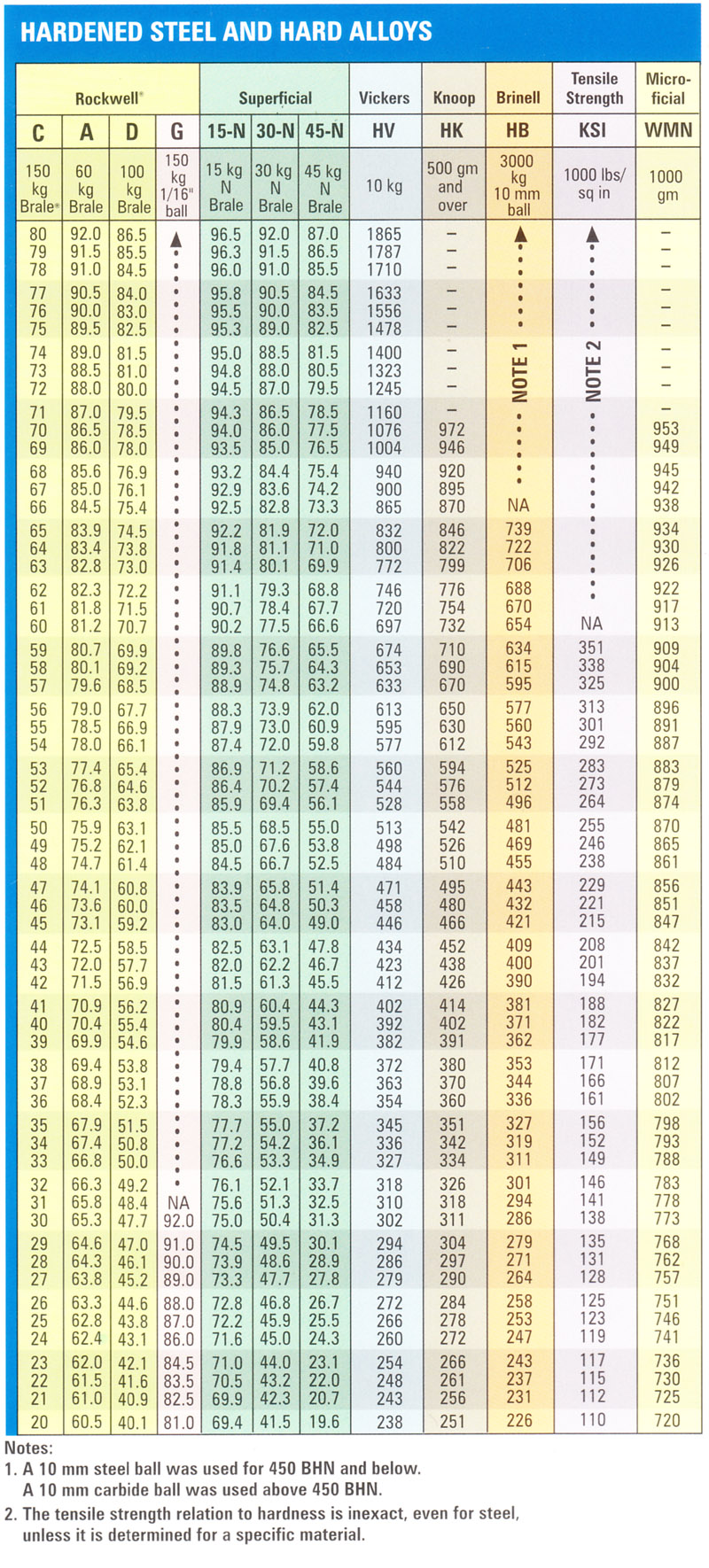

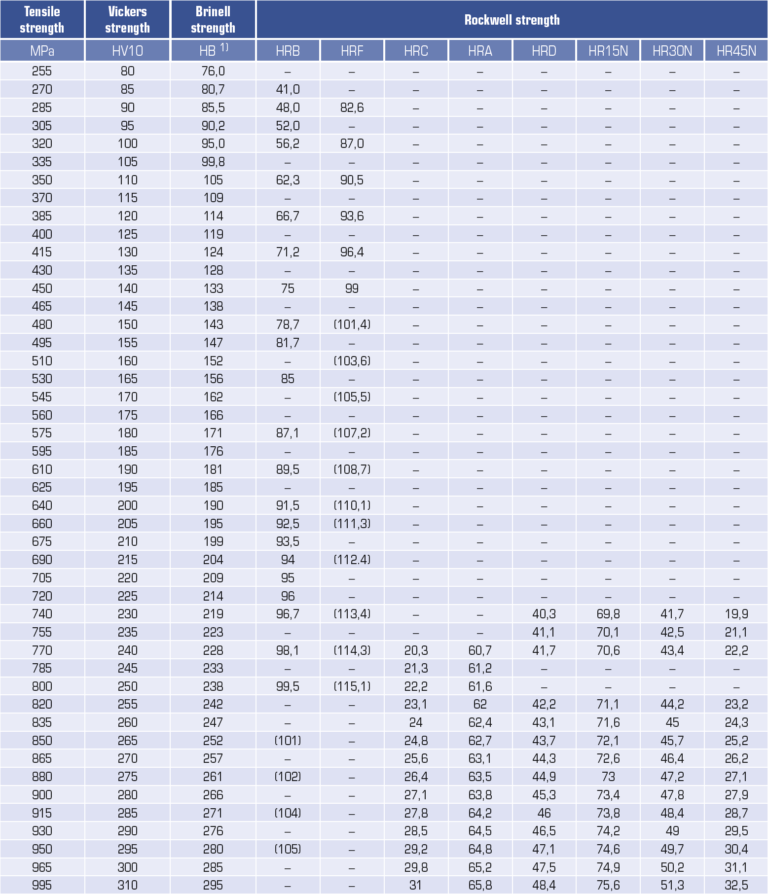

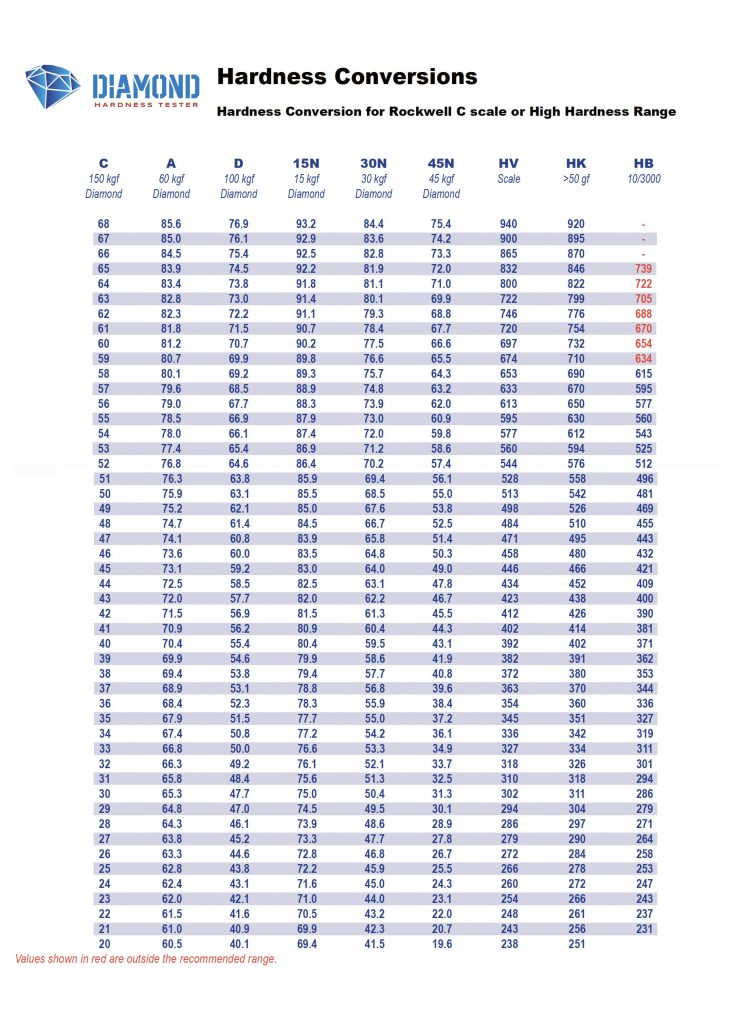

Steel Material Hardness Chart - Metals and materials table of contents. A 10 mm steel ball was used for 450 bhn and below. Web the hardness of a metal refers to its ability to resist local deformation, particularly plastic deformation, indentations, or scratches. Sus 304 stainless steel is widely used in various household appliances due to its excellent corrosion resistance, durability, and aesthetic appeal. Web refer to the “hardness comparison table” below for converting different hardness values of steel. Scratch hardness is the measure of how resistant a sample is to permanent plastic deformation due to friction from a sharp object. Web do you have the best type of steel for your project? The below chart is useful for determining which metals will be impervious to scratching and dinging, as it relates to the rockwell scale and ductility. The following table compares the various hardness scales. In 2020, the world produced 1878 million tons of steel, dwarfing the production of all other metals. The table values are guide values. The comparison is fraught with uncertainties and should therefore be limited as far as possible to the unavoidable cases. The table chart below gives typical mechanical characteristics for selected properties. According to the german standard din50150, the following table compares the tensile strength of commonly used steel materials with vickers hardness, brinell hardness, and. Web hardness conversion chart with standards including brinell, rockwell b scale, rockwell c scale, vickers and others. Metals and materials table of contents. They are also a little more sensitive and demanding to sharpen. The tensile strength relation to hardness is inexact, even for steel, unless it is determined for a specific material. Rockwell scale rockwell superficial brinnell tensile strength. Assumptions are that the metal tested is homogeneous to a. Web comparative hardness scales for steel table. The comparison is fraught with uncertainties and should therefore be limited as far as possible to the unavoidable cases. The table values are guide values. The table values are guide values. Scratch hardness is the measure of how resistant a sample is to permanent plastic deformation due to friction from a sharp object. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. A 10 mm carbide ball was used above 450 bhn. Assumptions are that the metal tested is homogeneous to a. Web. Web there are three main types of hardness measurements: Rockwell scale rockwell superficial brinnell tensile strength psi rcd custom machinery Web do you have the best type of steel for your project? Use our chart to help & learn more about the various steel grades, their applications, & astm standards. A 10 mm carbide ball was used above 450 bhn. Web there are three main types of hardness measurements: Scratch hardness is the measure of how resistant a sample is to permanent plastic deformation due to friction from a sharp object. The table chart below gives typical mechanical characteristics for selected properties. Use our chart to help & learn more about the various steel grades, their applications, & astm standards.. Hardness testing measures the resistance of a material to deformation, or hardness, and is an important physical property in manufacturing as it directly correlates to material strength. A 10 mm steel ball was used for 450 bhn and below. For all critical applications, verify to the applicable industry or requisite material / steel standard. A variety of hardness testing methods. Web in this captivating blog post, we dive into the fascinating realm of metal hardness comparison. Web this article offers a comprehensive chart comparing brinell, rockwell, and vickers hardness values for different steel materials. A variety of hardness testing methods are available including the brinell and rockwell tests. Aluminum is a distant second at 65.3 million tons. Web on the. The table chart below gives typical mechanical characteristics for selected properties. Uncover the secrets behind vickers, brinell, and rockwell scales, as our expert mechanical engineer guides you through the intricacies of this essential topic. For all critical applications, verify to the applicable industry or requisite material / steel standard. Web there are three main types of hardness measurements: The most. The following table compares the various hardness scales. There are two main types of. A 10 mm steel ball was used for 450 bhn and below. Web in this captivating blog post, we dive into the fascinating realm of metal hardness comparison. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. A variety of hardness testing methods are available including the brinell and rockwell tests. Web modern steels of powder metallurgy rank highest on the rockwell scale and boast hardness around 64 and 68 hrc. Web on the tensile strength and hardness of sus 304 material. The table chart below gives typical mechanical characteristics for selected properties. Web do you have the best type of steel for your project? The table values are guide values. Steel grading, hardness, yield strength, and alloys. Web here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common metals of different grades for your reference. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. Web metal hardness chart. Web comparative hardness scales for steel table. The comparison is fraught with uncertainties and should therefore be limited as far as possible to the unavoidable cases. Hardness testing measures the resistance of a material to deformation, or hardness, and is an important physical property in manufacturing as it directly correlates to material strength. Web this article offers a comprehensive chart comparing brinell, rockwell, and vickers hardness values for different steel materials. The below chart is useful for determining which metals will be impervious to scratching and dinging, as it relates to the rockwell scale and ductility. According to the german standard din50150, the following table compares the tensile strength of commonly used steel materials with vickers hardness, brinell hardness, and rockwell hardness.

Steel types, hardness and thickness Download Table

21 STEEL MATERIAL HARDNESS TABLE * Materials

Metal Hardness Scale A Chart of the Mohs Scale of Hardness

Stainless Steel Hardness Scale Steel Choices

Hardness Chart Of Materials

Metal Hardness Zahner — Innovation and Collaboration to Achieve the

Hardness Conversion Chart Rockwell "C" Hardness Range

Hardness comparison table WS STAHL

Rockwell Steel Hardness Chart

Steel Hardness Conversion Table Les tests Ingénierie de produits

Aluminum Is A Distant Second At 65.3 Million Tons.

Vickers, Brinell And Rockwell Hardness As Well As Tensile Strength In Steel And Cast Steel.

Assumptions Are That The Metal Tested Is Homogeneous To A.

The Following Table Compares The Various Hardness Scales.

Related Post: