Stainless Steel Discoloration Chart

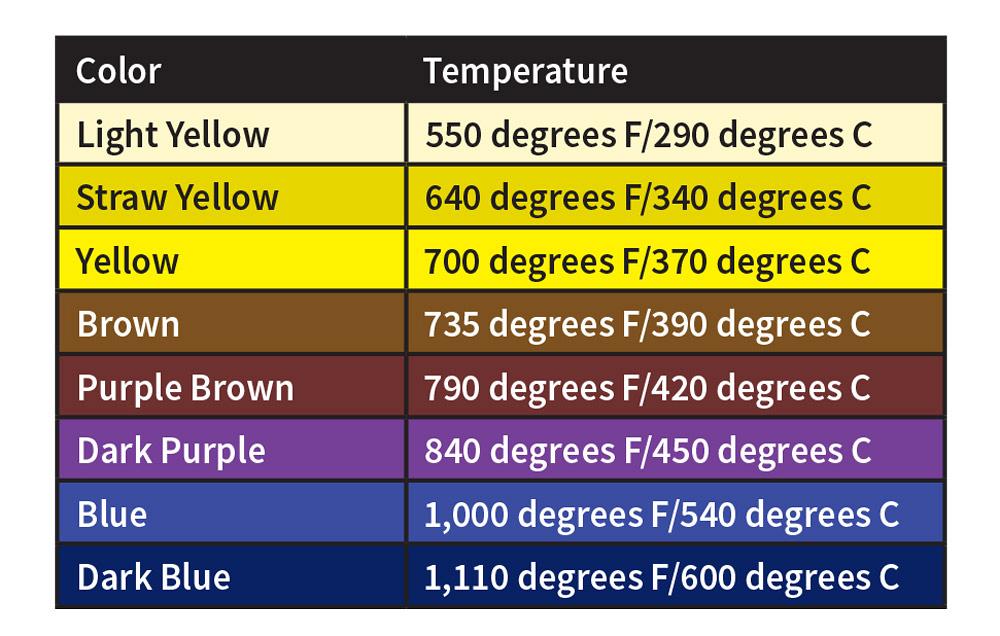

Stainless Steel Discoloration Chart - Most discoloration is easily corrected with natural products like baking soda, vinegar, lemon juice, or club soda. Although the color chart includes a notation “there was not significant difference in heat tint color from uns s31603 (steel number 1.4404, type 316l),” there is no allowance made for the use of. A low level of oxygen before, during and after welding is necessary, in order to achieve a. Cleaners containing oxalic acid can restore stainless steel. Web heat tint colour chart. Use a weld purge monitor® to eliminate oxygen to prevent oxides from forming and save the additional work load involved in removing the oxide film. The document contains a color illustration relating the discoloration to the oxygen content of the backing gas (purge gas or internal purge gas). Web these charts are good and useful guides, but should not be used as the end all, gold standard in determining the proper amount of oxygen being displaced from the backside of the weld seam because a decent, calibrated oxygen analyzer will do a much more accurate job in measuring that. Web the chart you are thinking of is aws d18.2 guide to weld discoloration levels on inside of austenitic stainless steel tube. Here's how to clean the rainbow stains! It relates to the amount of oxygen in the purge gas and resultant heat tint after welding. A low level of oxygen before, during and after welding is necessary, in order to achieve a. Web this standard addresses factors that affect weld discoloration on the inside of austenitic stainless steel tube. Although the color chart includes a notation “there was. Although the color chart includes a notation “there was not significant difference in heat tint color from uns s31603 (steel number 1.4404, type 316l),” there is no allowance made for the use of. A low level of oxygen before, during and after welding is necessary, in order to achieve a. Web this standard addresses factors that affect weld discoloration on. Web the following stainless steel and titanium heat tint charts are good reference guides for acceptable/non acceptable weld oxidation. Web these charts are good and useful guides, but should not be used as the end all, gold standard in determining the proper amount of oxygen being displaced from the backside of the weld seam because a decent, calibrated oxygen analyzer. Web does anyone know where i can obtain a chart that would describe the heat tint discoloration of stainless steels. The document contains a color illustration relating the discoloration to the oxygen content of the backing gas (purge gas or internal purge gas). Web the aws d18.2 color chart being used for color comparison and acceptance criteria was established on. It relates to the amount of oxygen in the purge gas and resultant heat tint after welding. Web heat tint colour chart. This figure has been extracted from avvs d18.l/d18.lm:2009. Suitable as a specifying tool and visual examination guide. Cleaners containing oxalic acid can restore stainless steel. Wiki.dtonline) chemical removal involves using a caustic solution, such as nitric acid called pickling, to dissolve the chromium oxide. Web the aws d18.2 color chart being used for color comparison and acceptance criteria was established on mechanically polished 304l stainless steel. Although the color chart includes a notation “there was not significant difference in heat tint color from uns s31603. Web these charts are good and useful guides, but should not be used as the end all, gold standard in determining the proper amount of oxygen being displaced from the backside of the weld seam because a decent, calibrated oxygen analyzer will do a much more accurate job in measuring that. Use a weld purge monitor® to eliminate oxygen to. Suitable as a specifying tool and visual examination guide. Use a weld purge monitor® to eliminate oxygen to prevent oxides from forming and save the additional work load involved in removing the oxide film. Most discoloration is easily corrected with natural products like baking soda, vinegar, lemon juice, or club soda. Although the color chart includes a notation “there was. What operating temperatures will the steel be exposed to? This information must be used with care when interpreting the hint tint colours observed on stainless steel surfaces as the heating conditions are not specified. Web this standard addresses factors that affect weld discoloration on the inside of austenitic stainless steel tube. Different stainless steel alloys will have different reactions to. Here's how to clean the rainbow stains! Web if you are purging then you look at color of the purged side to check for oxygen content of the purge (color). Web the three most important variables that determine stainless steel weld discoloration/oxidation are amperage, travel speed, and quality of shielding gas coverage. Oxidation colours need to be eliminated for most. It relates to the amount of oxygen in the purge gas and resultant heat tint after welding. Web the following stainless steel and titanium heat tint charts are good reference guides for acceptable/non acceptable weld oxidation. Web this standard provides a visual comparison guide that can be used to specify surface discoloration criteria for sanitary (hygienic) welds in austenitic stainless steel tube. Web these charts are good and useful guides, but should not be used as the end all, gold standard in determining the proper amount of oxygen being displaced from the backside of the weld seam because a decent, calibrated oxygen analyzer will do a much more accurate job in measuring that. It's discoloration of stainless steel due to heat. Cleaners containing oxalic acid can restore stainless steel. Web does anyone know where i can obtain a chart that would describe the heat tint discoloration of stainless steels. What operating temperatures will the steel be exposed to? Although the color chart includes a notation “there was not significant difference in heat tint color from uns s31603 (steel number 1.4404, type 316l),” there is no allowance made for the use of. The table below represents the temper colours that are likely to form on stainless steel type 1.4301, (aisi 304), if heated in air. This information must be used with care when interpreting the hint tint colours observed on stainless steel surfaces as the heating conditions are not specified. Web heat tint can be removed from stainless steel using either chemical or physical methods. Web laminated sheet with color photograph showing degrees of coloration on the inside of an austenitic stainless steel tube with increasing amount of oxygen in the backing shielding gas. Web the three most important variables that determine stainless steel weld discoloration/oxidation are amperage, travel speed, and quality of shielding gas coverage. Web this standard addresses factors that affect weld discoloration on the inside of austenitic stainless steel tube. Here's how to clean the rainbow stains!

All you need to know about the heataffected zone

Stainless Steel Discoloration Chart

Guide Lines For Duplex Stainless Steel Welding

Stainless Steel Welding Color Chart

Stainless Steel Weld Color Chart

Stainless Steel Discoloration Chart

Acceptable Stainless Steel Weld Color Chart

Determining Acceptable Levels of Weld Discoloration on Mechanically

Determining Acceptable Levels of Weld Discoloration on Mechanically

Stainless Steel Discoloration Chart

Different Stainless Steel Alloys Will Have Different Reactions To Elevated.

Web Aws Has Put Out A Discoloration Chart Which Shows The Different Colors And Gives An Indication Of How Much (A Percentage) Oxygen Was In The Purge Gas While Welding.

What I Am Concerned About Is A Line That Is Welded To A Thermal Oxidizer Which Operates Around 600 Deg.c Which Is Around 1112 Deg.

Oxidation Colours Need To Be Eliminated For Most Applications Today.

Related Post: