Stainless Steel Bolt Torque Chart

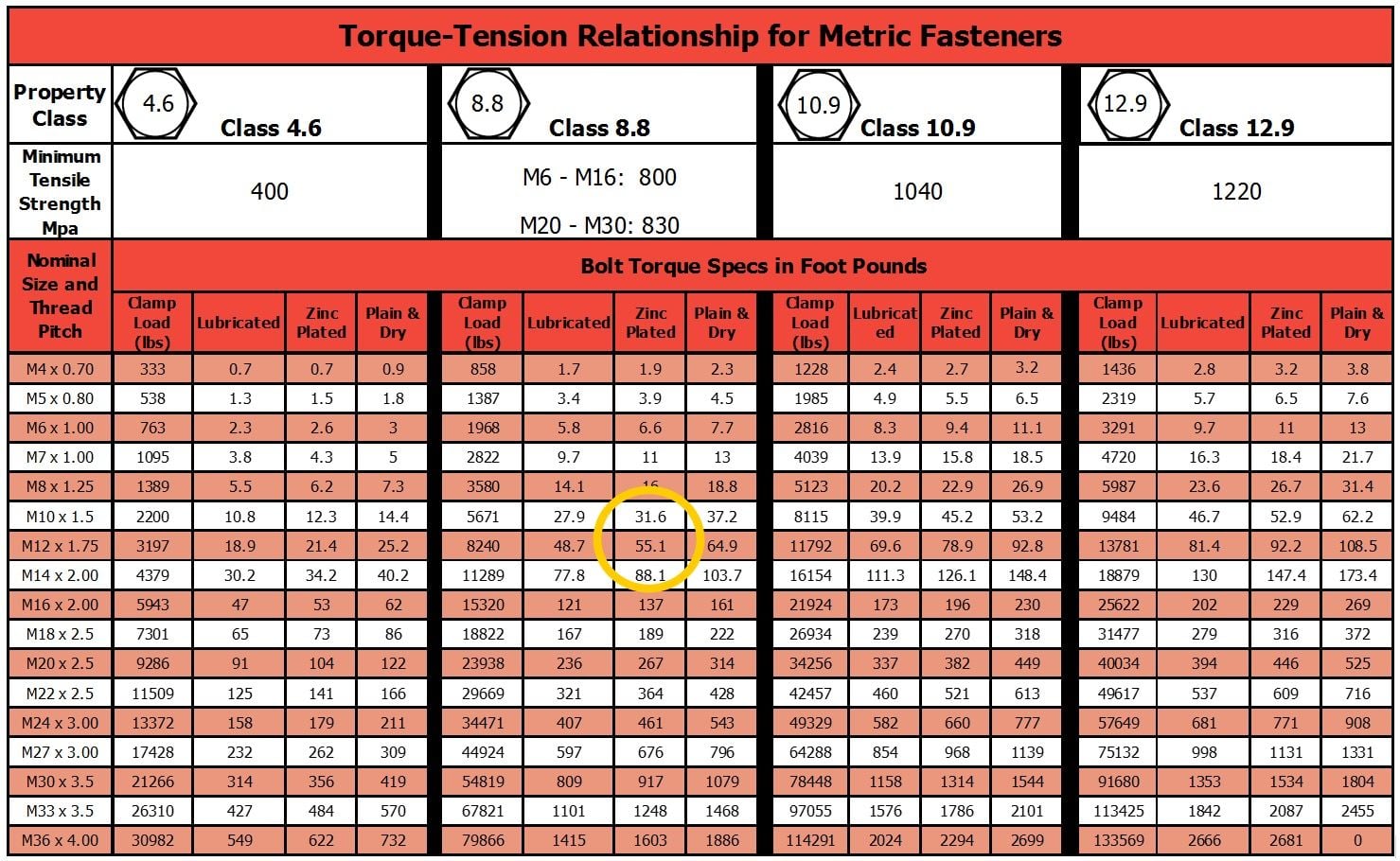

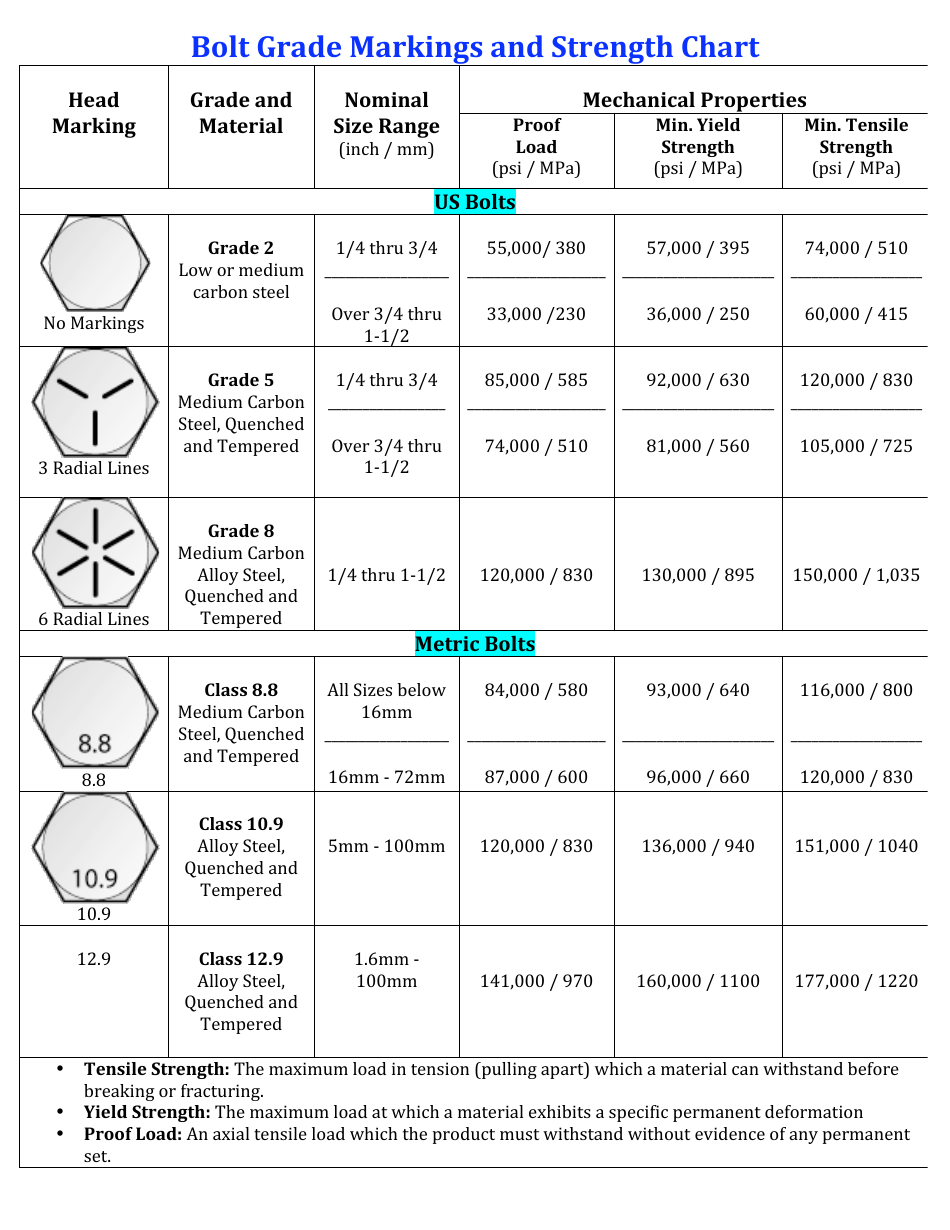

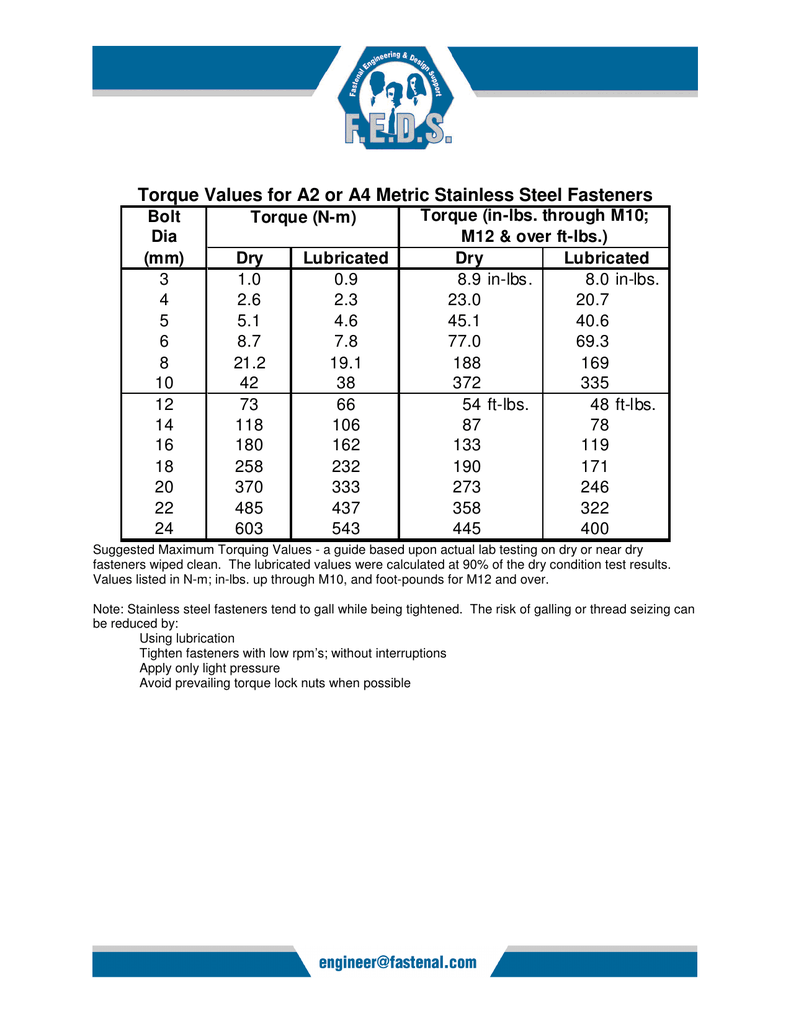

Stainless Steel Bolt Torque Chart - Keep in mind that this is only an estimated value. To construct a securely assembled joint using bolts or machine screws, the fasteners must be tightened to develop the proper amount of clamping force. The following data tables are designed to be used as general guidance when installing stainless steel fasteners. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. Web stainless steel bolt and machine screw torque reference. Therefore, using the correct installation torque is. Web torque values for a2 or a4 metric stainless steel fasteners. It may provide satisfactory performance. Every application needs to be evaluated on its own to determine the optimum torque for each application. To construct a securely assembled joint using bolts or machine screws, the fasteners must be tightened to develop the proper amount of clamping force. Web torque chart for stainless steel cap screws. Web values given represent the torque required to induce a tension in the bolt corresponding to approximately 65% of its proof load. It may provide satisfactory performance. Recommended. Therefore, using the correct installation torque is. Web stainless steel bolt and machine screw torque reference. Web ‘the values listed above are for clean and dry parts free of lubricants and thread lockers. The following data tables are designed to be used as general guidance when installing stainless steel fasteners. Web the torque values can only be achieved if nut. Web ‘the values listed above are for clean and dry parts free of lubricants and thread lockers. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near dry fasteners. * this table is recommended for use as a guide only. Recommended bolt torque values for stainless steel and nonferrous fasteners (inch series).. It may provide satisfactory performance. The lubricated values were calculated at 90% of the dry condition test results. Web torque chart for stainless steel cap screws. Web 5)stainless steel fasteners tend to gall while being tightened. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. It may provide satisfactory performance. Recommended bolt torque values for stainless steel and nonferrous fasteners (inch series). Web ‘the values listed above are for clean and dry parts free of lubricants and thread lockers. Imperial has made a concerted effort to provide accurate information in its catalog and on its web site, however imperial assumes no responsibility for the accuracy. Every application needs to be evaluated on its own to determine the optimum torque for each application. The calculator is generic an can used for imperial and metric units as long as the use of units are consistent. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near dry fasteners. To construct. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. Because of these existing variables, the only way to determine the correct torque is through experimentation under actual joint and assembly conditions. Aft fasteners is your trusted source for fastener information. The lubricated values were calculated at 90% of the. Even perfect input torque can give a variation of preload by as much as 25%. Because of these existing variables, the only way to determine the correct torque is through experimentation under actual joint and assembly conditions. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near dry fasteners. Web torque values. It may provide satisfactory performance. * this table is recommended for use as a guide only. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. Web torque values stainless steel bolt table chart. Using lubrication, tightening fasteners with low rpms and without interruptions, applying only light pressure, and avoiding. Therefore, using the correct installation torque is. Web torque chart for stainless steel cap screws. Web stainless steel bolt and machine screw torque reference. It may provide satisfactory performance. Iling torque fasteners, impact drivers, and lack of lubrication. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: The following torque values are suggested maximums based upon actual lab testing on clean and dry or near dry fasteners. Iling torque fasteners, impact drivers, and lack of lubrication. Web the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. Web 5)stainless steel fasteners tend to gall while being tightened. The following data tables are designed to be used as general guidance when installing stainless steel fasteners. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. Web torque values stainless steel bolt table chart. Web ‘the values listed above are for clean and dry parts free of lubricants and thread lockers. Web check bolt torque chart online, view bolt torque chart stainless steel and m30 stainless steel bolt torque. Web bolt torque chart reference guides include grade 2, b7, a307, a325, grade 8, a490, and grade 5. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near dry fasteners. This shows torque values in nm for property classes 50, 70 and 80 as shown in the table below. Keep in mind that this is only an estimated value. Using lubrication, tightening fasteners with low rpms and without interruptions, applying only light pressure, and avoiding prevailing torque lock nuts Therefore, using the correct installation torque is.

Stainless Steel Stud Bolt Torque Chart Torque Values, 55 OFF

Stainless Steel Torque Guidelines A2 & A4 Grampian Fasteners Nut

ISO Metric Bolt Torque Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word

Bolt Torque Chart For Stainless Steel

Metric Bolt Torque Chart Stainless Steel IMAGESEE

Stainless Steel Bolt Torque Chart

Stainless Steel Bolt Shear Strength Chart

Torque Values for Stainless Steel and NonFerrous Fasteners

Stainless Steel Metric Bolt Torque Chart Best Picture vrogue.co

While All Care Has Been Taken With Its Preparation, No Responsibility Is Accepted For The

The Calculator Is Generic An Can Used For Imperial And Metric Units As Long As The Use Of Units Are Consistent.

Because Of These Existing Variables, The Only Way To Determine The Correct Torque Is Through Experimentation Under Actual Joint And Assembly Conditions.

Even Perfect Input Torque Can Give A Variation Of Preload By As Much As 25%.

Related Post: