Spi Finish Chart

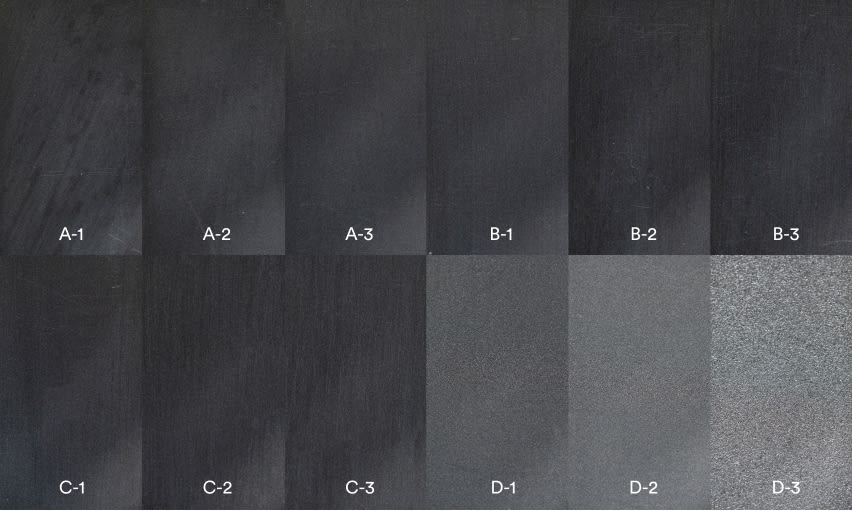

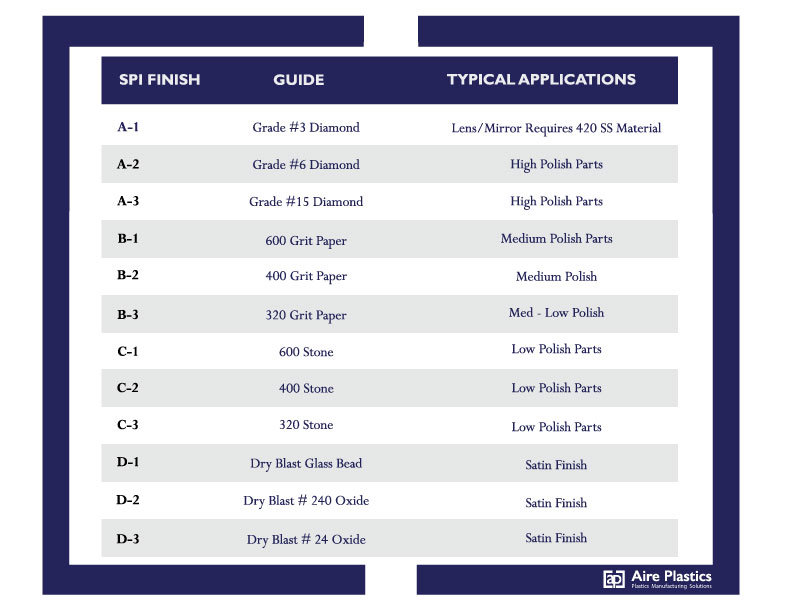

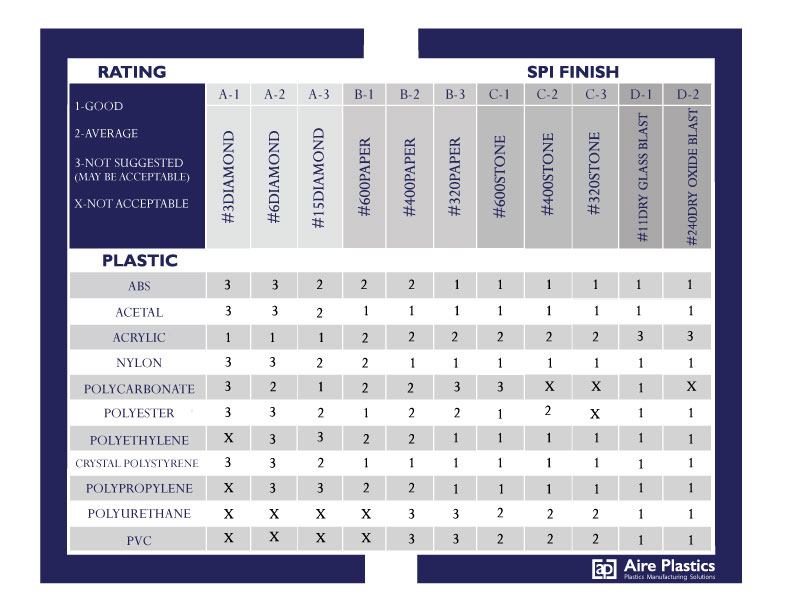

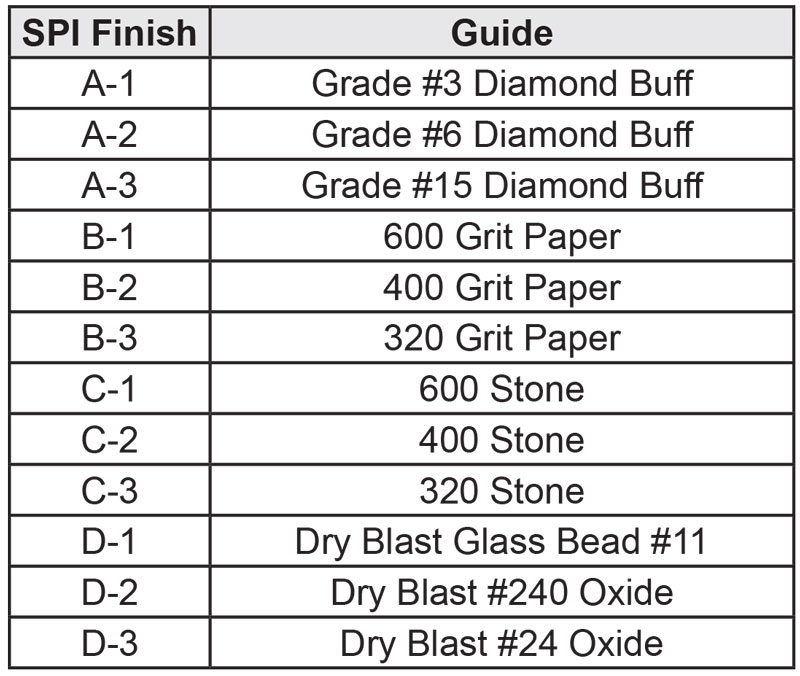

Spi Finish Chart - What’s the right material for each spi surface finish? Injection mould toolmakers, manufacturers and design engineers worldwide recognise these three standards and pia standards are marginally more common and widely known as “ spi grades “. If you want to check what the physical textures look like, the best way is to get our spi finish card. Each grade has different requirements for allowable deviation from perfect, with lower numbers allowing for less deviation and higher The tables below detail how to select the right mold finish and materials for your specific application. Web spi surface finish chart. Web spi surface finish standards the spi is that society of the plastics industry sets standard for plastics industry in the united states that identifies the cosmetic quality of plastics, upmold uses the spi standard to define finish of plastic injection molded parts. Web let’s take a closer look at the 12 different injection molding spi surface finishes and their corresponding optimal materials. Web spi mold finish guide, spi mold finish standards, plastic surface finish standards, spi surface finish chart, plastic injection molded parts surface finishes, surface roughness Web the spi surface finish standard covers 12 spi grades of polish finishes split across four categories: Web the complete spi finish standard covers 12 grades from spi a1 to d3. Spi surface finish recommendations for plastic part. Web spi surface finish chart. Each grade has different requirements for allowable deviation from perfect, with lower numbers allowing for less deviation and higher Web spi mold finish guide, spi mold finish standards, plastic surface finish standards, spi surface. Each grade has different requirements for allowable deviation from perfect, with lower numbers allowing for less deviation and higher What’s the right material for each spi surface finish? The spi mold finish chart below describes all twelve spi surface finishes, including the finishing method and typical surface roughness. Web there are twelve grades of finishes specified by the spi in. Spi surface finish recommendations for plastic part. The tables below detail how to select the right mold finish and materials for your specific application. Web let’s take a closer look at the 12 different injection molding spi surface finishes and their corresponding optimal materials. There are twelve grades of finishes specified by the spi in four categories If you want. Web spi surface finish chart. Spi surface finish recommendations for plastic part. Injection mould toolmakers, manufacturers and design engineers worldwide recognise these three standards and pia standards are marginally more common and widely known as “ spi grades “. The below chart shows the spi finish along with the finish method and surface roughness values. Web let’s take a closer. Injection mould toolmakers, manufacturers and design engineers worldwide recognise these three standards and pia standards are marginally more common and widely known as “ spi grades “. The spi mold finish chart below describes all twelve spi surface finishes, including the finishing method and typical surface roughness. The below chart shows the spi finish along with the finish method and. What’s the right material for each spi surface finish? The spi mold finish chart below describes all twelve spi surface finishes, including the finishing method and typical surface roughness. Web the spi surface finish standard covers 12 spi grades of polish finishes split across four categories: Web spi mold finish guide, spi mold finish standards, plastic surface finish standards, spi. What’s the right material for each spi surface finish? Web spi surface finish chart for roughness technology. Web spi surface/mold finishes produce different results depending on the material you use for injection molding components. Injection mould toolmakers, manufacturers and design engineers worldwide recognise these three standards and pia standards are marginally more common and widely known as “ spi grades. Each grade has different requirements for allowable deviation from perfect, with lower numbers allowing for less deviation and higher Injection mould toolmakers, manufacturers and design engineers worldwide recognise these three standards and pia standards are marginally more common and widely known as “ spi grades “. Spi mold finish look, feel, and quality depends on the thermoplastic material’s mechanical properties. Web spi surface finish chart. Web spi surface/mold finishes produce different results depending on the material you use for injection molding components. Web there are twelve grades of finishes specified by the spi in four categories that range from shiny to dull. Injection mould toolmakers, manufacturers and design engineers worldwide recognise these three standards and pia standards are marginally more. Spi mold finish look, feel, and quality depends on the thermoplastic material’s mechanical properties and part color. There are twelve grades of finishes specified by the spi in four categories At below spi finish chart, we use surface roughness ra (μm), finishing methods, recommended steels as references to show each grade’s finish. Spi surface finish recommendations for plastic part. Web. Web the spi surface finish standard covers 12 spi grades of polish finishes split across four categories: At below spi finish chart, we use surface roughness ra (μm), finishing methods, recommended steels as references to show each grade’s finish. Web spi surface/mold finishes produce different results depending on the material you use for injection molding components. What’s the right material for each spi surface finish? Each grade has different requirements for allowable deviation from perfect, with lower numbers allowing for less deviation and higher Spi surface finish recommendations for plastic part. Web spi mold finish guide, spi mold finish standards, plastic surface finish standards, spi surface finish chart, plastic injection molded parts surface finishes, surface roughness Web spi surface finish chart. Injection mould toolmakers, manufacturers and design engineers worldwide recognise these three standards and pia standards are marginally more common and widely known as “ spi grades “. Web the complete spi finish standard covers 12 grades from spi a1 to d3. There are twelve grades of finishes specified by the spi in four categories Web spi surface finish chart for roughness technology. Spi mold finish look, feel, and quality depends on the thermoplastic material’s mechanical properties and part color. Web there are twelve grades of finishes specified by the spi in four categories that range from shiny to dull. The below chart shows the spi finish along with the finish method and surface roughness values. The spi mold finish chart below describes all twelve spi surface finishes, including the finishing method and typical surface roughness.

Spi Surface Finish Chart

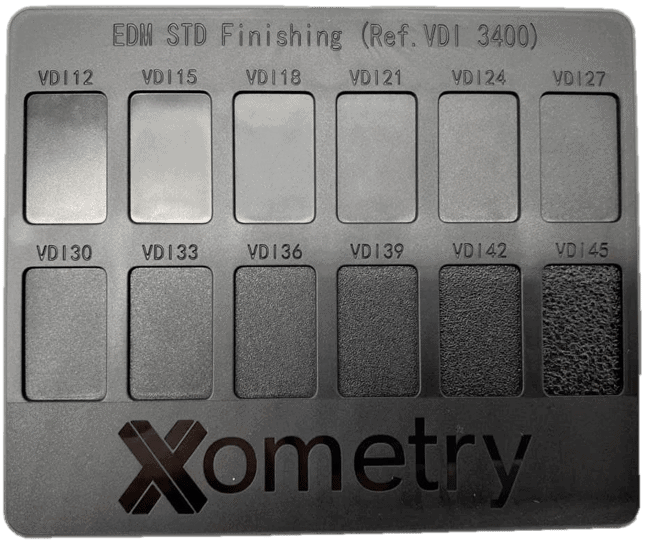

Surface finish (polishing and texture) Sositar

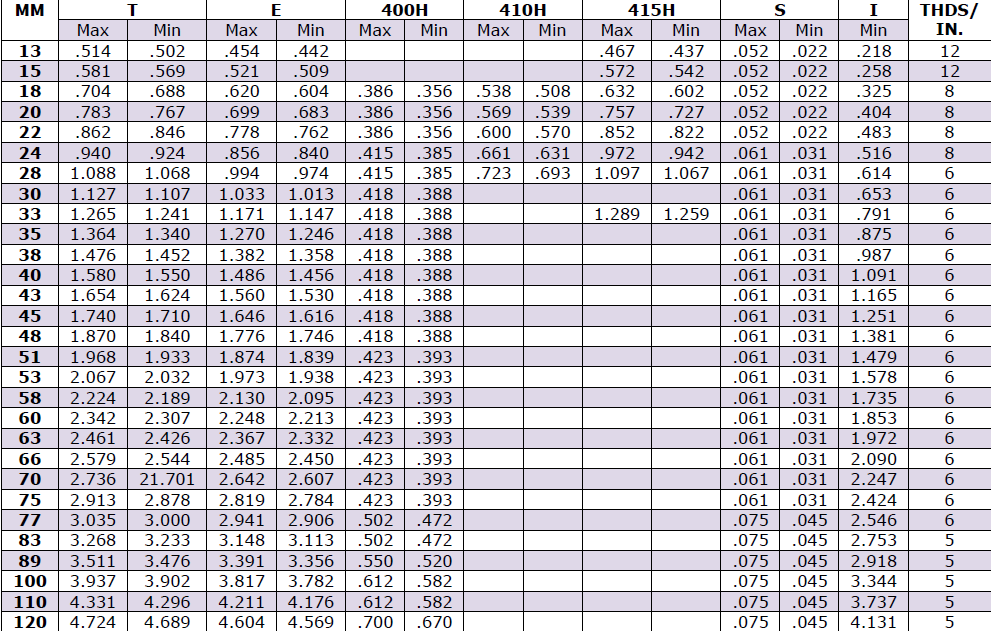

Neck Finish Information MJS Packaging

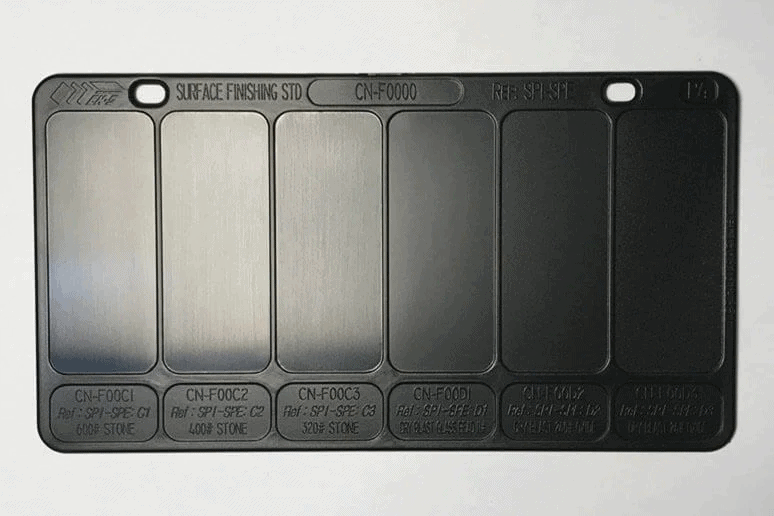

SPI surface finish standard with metal scale SPI Surface Finish

Spi Surface Finish Chart

SPI Surface Finish Chart SPI Surface Finish, 41 OFF

Spi Surface Finish Chart

SPI Mold Finish Guide and Guidelines Injection Molding Texas

Spi Surface Finish Chart

Spi Surface Finish Chart Spi Surface Finish vrogue.co

Web Let’s Take A Closer Look At The 12 Different Injection Molding Spi Surface Finishes And Their Corresponding Optimal Materials.

If You Want To Check What The Physical Textures Look Like, The Best Way Is To Get Our Spi Finish Card.

The Tables Below Detail How To Select The Right Mold Finish And Materials For Your Specific Application.

Web Spi Surface Finish Standards The Spi Is That Society Of The Plastics Industry Sets Standard For Plastics Industry In The United States That Identifies The Cosmetic Quality Of Plastics, Upmold Uses The Spi Standard To Define Finish Of Plastic Injection Molded Parts.

Related Post: