Solder Temp Chart

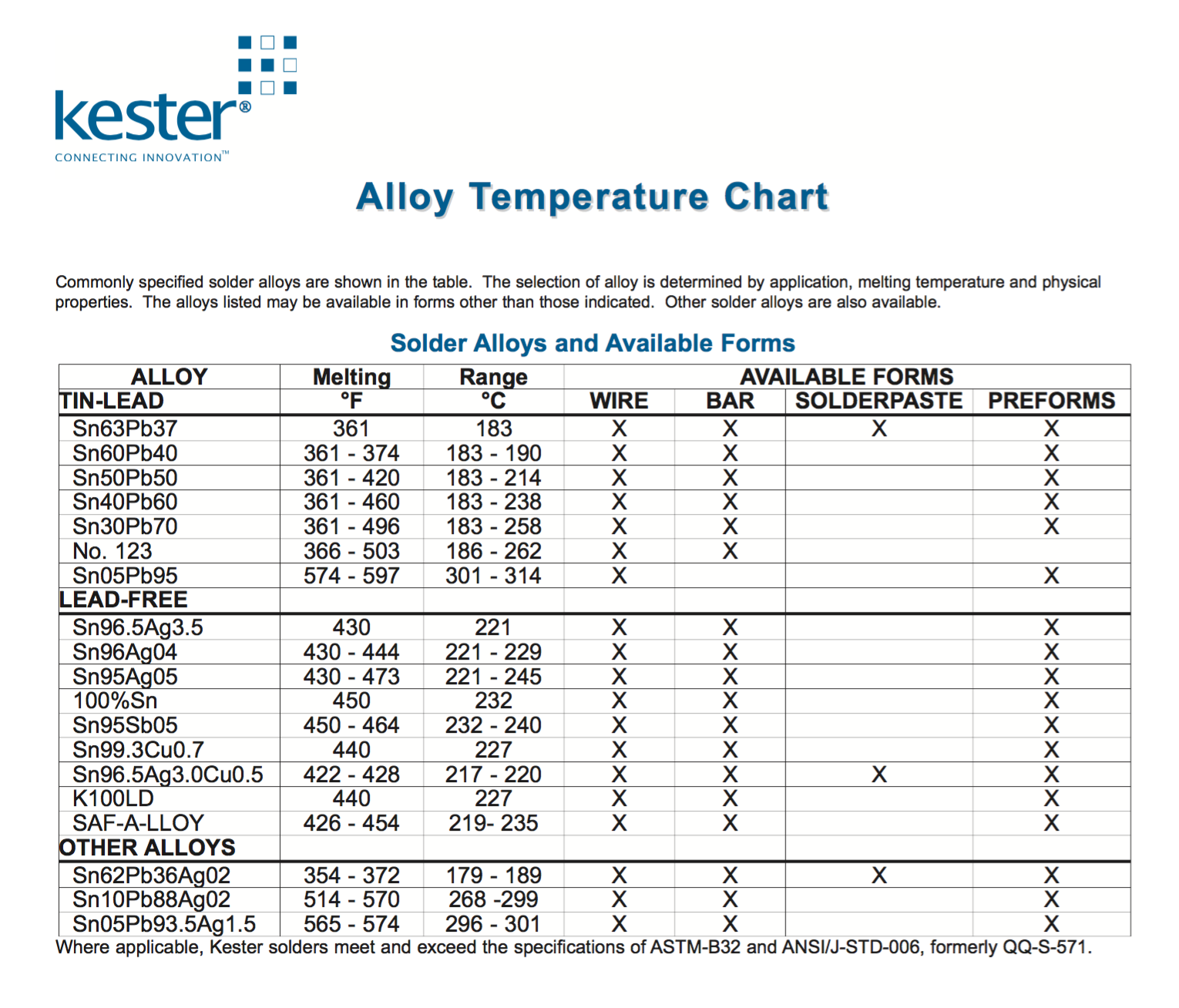

Solder Temp Chart - The choice of specific solder alloys depends on their melting point, chemical reactivity, mechanical. There is no standard about the temperature for the board, because it is only 3 seconds when the tin contact. Commonly specified solder alloys are shown in the table. Web the alloy temperature chart lists the alloys that are available from kester. This temperature chart shows the different solders that are available and their melting temperatures. Web solder is a metallic material that is used to connect metal workpieces. Web which soldering temperature goes with which solder? Web when soldering surface mount components, a small tip and 600f (315c) should be sufficient to quickly solder the joint well without overheating the component. This chart includes the alloy’s melting temperature and lists the available forms for each alloy. Web solder with a composition of 60% tin and 40% lead has a varying melting range but will begin turning into liquid at 361.4°f (183°c), then completely turn into liquid at 375.8°f. These are the more commonly used alloys. This type of solder has a melting point of around 190 °c. Web the melting temperature for alloy solder, which is the most common type of solder, is around 360 to 370 degrees fahrenheit (or 180 to 190 degrees celsius, if. Web which soldering temperature goes with which solder? Web when soldering surface. Commonly specified solder alloys are shown in the table. Web the alloy temperature chart lists the alloys that are available from kester. A 60/40 solder is an alloy of 60 % tin and 40 % lead measured by weight. The selection of alloy is determined by application, melting temperature and physical. Web kester's alloy temperature chart for commonly specified solder. Please note that the alloys listed on the chart are our most commonly used. These are the more commonly used alloys. Lead solders usually melt between 180 and 190. Commonly specified solder alloys are shown in the table. The melting point of the solder depends mostly on its alloy formulation. Web solder is a metallic material that is used to connect metal workpieces. Web the alloy temperature chart lists the alloys that are available from kester. Lead solders usually melt between 180 and 190. Please note that the alloys listed on the chart are our most commonly used. Web tensile strength (p.s.i.) of soft solders at elevated and below zero. Solder alloys offered in a range of. This type of solder has a melting point of around 190 °c. The selection of alloy is determined by application, melting temperature and physical. This chart includes the alloy’s melting temperature and lists the available forms for each alloy. Web when soldering surface mount components, a small tip and 600f (315c) should be. These are the more commonly used alloys. Web which soldering temperature goes with which solder? A 60/40 solder is an alloy of 60 % tin and 40 % lead measured by weight. Commonly specified solder alloys are shown in the table. This type of solder has a melting point of around 190 °c. This type of solder has a melting point of around 190 °c. Web solder with a composition of 60% tin and 40% lead has a varying melting range but will begin turning into liquid at 361.4°f (183°c), then completely turn into liquid at 375.8°f. These are the more commonly used alloys. Web kester's alloy temperature chart for commonly specified solder. Solder alloys offered in a range of. These are the more commonly used alloys. Web solder with a composition of 60% tin and 40% lead has a varying melting range but will begin turning into liquid at 361.4°f (183°c), then completely turn into liquid at 375.8°f. Web solder is a metallic material that is used to connect metal workpieces. The. Web turn on the soldering iron and set temperature above the melting point of your solder. The melting point of the solder depends mostly on its alloy formulation. A 60/40 solder is an alloy of 60 % tin and 40 % lead measured by weight. Web as a general rule of thumb, the optimal soldering temperature should be high enough. This type of solder has a melting point of around 190 °c. Web kester's alloy temperature chart for commonly specified solder alloys. Lead solders usually melt between 180 and 190. This chart includes the alloy’s melting temperature and lists the available forms for each alloy. Web solder is a metallic material that is used to connect metal workpieces. Web solder is a metallic material that is used to connect metal workpieces. This temperature chart shows the different solders that are available and their melting temperatures. A 60/40 solder is an alloy of 60 % tin and 40 % lead measured by weight. Web the melting temperature for alloy solder, which is the most common type of solder, is around 360 to 370 degrees fahrenheit (or 180 to 190 degrees celsius, if. Web which soldering temperature goes with which solder? Web for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short freezing range leads. These are the more commonly used alloys. Web as a general rule of thumb, the optimal soldering temperature should be high enough so that when making a solder connection, the solder is approximately 50°c above its. Solder alloys offered in a range of. Web kester's alloy temperature chart for commonly specified solder alloys. Commonly specified solder alloys are shown in the table. Web when soldering surface mount components, a small tip and 600f (315c) should be sufficient to quickly solder the joint well without overheating the component. The selection of alloy is determined by application, melting temperature and physical. Web tensile strength (p.s.i.) of soft solders at elevated and below zero temperatures. Web solder with a composition of 60% tin and 40% lead has a varying melting range but will begin turning into liquid at 361.4°f (183°c), then completely turn into liquid at 375.8°f. The selection of alloy is determined by application, melting temperature and physical.

Solder Melting Temperature Chart

Sterling Silver Solder 3 Pack . One Foot Each of Easy Medium and Hard

TemperatureChart Preforms Solder Materials for Assembly Solutions

Silver Solder Melting Temperature Chart

Solder Iron Temperature Chart

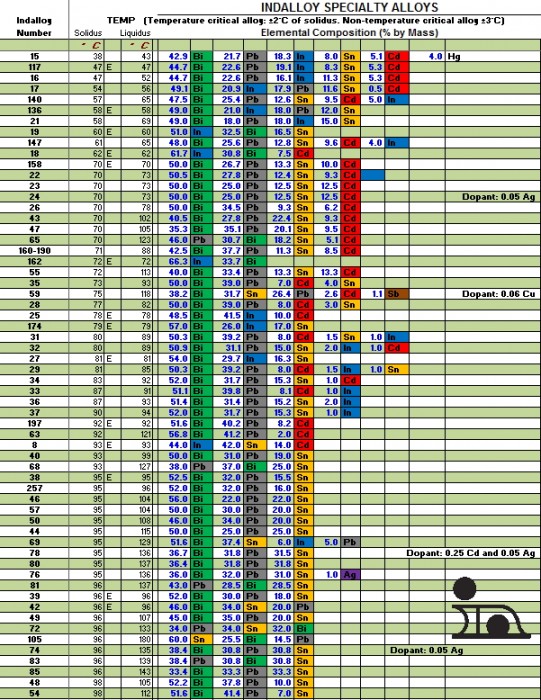

soldering Bismuth or Indium solder how do they compare?

Solder Melting Temperature Chart

Solder Melting Point Chart

Silver Solder Melting Temperature Chart

Solder Melting Temperature Chart

Please Note That The Alloys Listed On The Chart Are Our Most Commonly Used.

Lead Solders Usually Melt Between 180 And 190.

Web Turn On The Soldering Iron And Set Temperature Above The Melting Point Of Your Solder.

Web The Alloy Temperature Chart Lists The Alloys That Are Available From Kester.

Related Post: