Solder Melting Point Chart

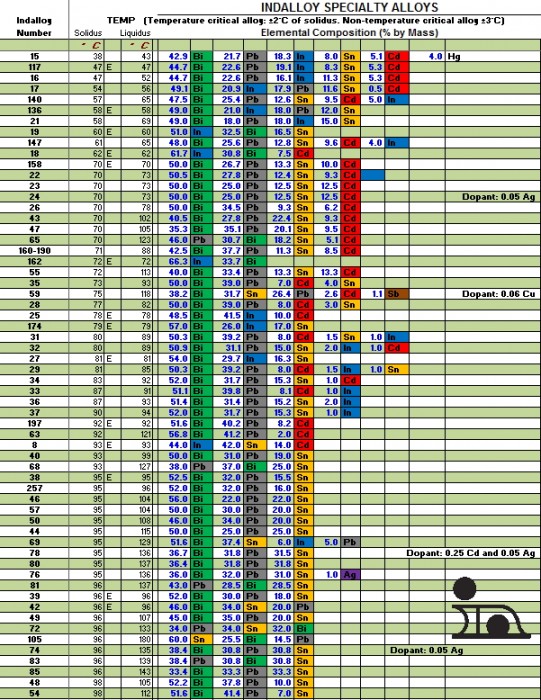

Solder Melting Point Chart - This temperature chart shows the different solders that are available and their melting temperatures. The chart includes paste, wire, preforms and bar forms for each alloy. Web kester's alloy temperature chart for commonly specified solder alloys. Web learn how to successfully solder your jewelry with the help of soldering: Web learn the difference between high vs. Web phase diagrams are widely used in the electronics industry to determine the existence of intermetallic compounds, alloy melting points, and the solubility of elements at different. Web find the melting temperature of various kester solder alloys in °c and °f. Commonly specified solder alloys are shown in the table. Web the melting point of most solder is in the region of 188°c (370°f) and the iron tip temperature is typically 330°c to 350°c (626°f to 662°f). Solder with a composition of 60% tin and 40% lead has a varying melting range but will begin turning. Explore our blog for insights on electronic assembly and soldering. 360 to 720 k), and is commonly used in electronics, plumbing, and sheet metal work. Commonly specified solder alloys are shown in the table. Web find the melting temperature of various kester solder alloys in °c and °f. Web learn how to successfully solder your jewelry with the help of. The selection of alloy is determined by application, melting temperature and physical. Web phase diagrams are widely used in the electronics industry to determine the existence of intermetallic compounds, alloy melting points, and the solubility of elements at different. Web solder is a metallic material that is used to connect metal workpieces. This temperature chart shows the different solders that. Web kester's alloy temperature chart for commonly specified solder alloys. The choice of specific solder alloys depends on their melting point, chemical reactivity, mechanical. Under $10>80% items are newmake money when you sellfeatured collections Web the melting point of most solder is in the region of 188°c (370°f) and the iron tip temperature is typically 330°c to 350°c (626°f to. Web learn the difference between high vs. Web solder is a metallic material that is used to connect metal workpieces. Web learn about the melting point of solder, how to measure it, and the different types of solder and their melting points. Find out how to choose the right solder for your project and. Web kester's alloy temperature chart for. 360 to 720 k), and is commonly used in electronics, plumbing, and sheet metal work. Its composition varies depending upon the type. Commonly specified solder alloys are shown in the table. Web the melting point of solder varies depending on its composition. Web solder is a metallic material that is used to connect metal workpieces. Commonly specified solder alloys are shown in the table. The selection of alloy is determined by application, melting temperature and physical. Attention should be paid to poor wetting and fatigue. Gold & silver melting points & more from interweave. Web bright solder joints, improved wetting. Web phase diagrams are widely used in the electronics industry to determine the existence of intermetallic compounds, alloy melting points, and the solubility of elements at different. Commonly specified solder alloys are shown in the table. Web bright solder joints, improved wetting. Its composition varies depending upon the type. Low temperature solder types and their melting points. Web find the melting temperature of various kester solder alloys in °c and °f. Commonly specified solder alloys are shown in the table. Under $10>80% items are newmake money when you sellfeatured collections Web learn why the melting point of solder matters, how it varies by alloy composition and flux, and how to measure it accurately. Web phase diagrams are. Web learn how to successfully solder your jewelry with the help of soldering: Web kester's alloy temperature chart for commonly specified solder alloys. Explore our blog for insights on electronic assembly and soldering. Web bright solder joints, improved wetting. 360 to 720 k), and is commonly used in electronics, plumbing, and sheet metal work. Low temperature solder types and their melting points. The selection of alloy is determined by application, melting temperature and physical. Commonly specified solder alloys are shown in the table. The choice of specific solder alloys depends on their melting point, chemical reactivity, mechanical. Web learn why the melting point of solder matters, how it varies by alloy composition and flux,. Web if you do not know the solder alloy that you need, please use the form below to help find the solder alloy that meets your criteria. Web phase diagrams are widely used in the electronics industry to determine the existence of intermetallic compounds, alloy melting points, and the solubility of elements at different. Commonly specified solder alloys are shown in the table. * identify your preferred melting temperature,. Gold & silver melting points & more from interweave. 360 to 720 k), and is commonly used in electronics, plumbing, and sheet metal work. The choice of specific solder alloys depends on their melting point, chemical reactivity, mechanical. Web learn how to successfully solder your jewelry with the help of soldering: The chart includes paste, wire, preforms and bar forms for each alloy. Web the melting point of most solder is in the region of 188°c (370°f) and the iron tip temperature is typically 330°c to 350°c (626°f to 662°f). The selection of alloy is determined by application, melting temperature and physical. Commonly specified solder alloys are shown in the table. Solder with a composition of 60% tin and 40% lead has a varying melting range but will begin turning. Attention should be paid to poor wetting and fatigue. Web one key characteristic of solder alloys is their melting point, which influences the soldering process and the temperatures to which electronic components. This temperature chart shows the different solders that are available and their melting temperatures.

Solder Melting Point Chart

Solder Melting Temperature Chart

Solder Melting Temperature Chart

Silver Solder Melting Temperature Chart

Solder Melting Point Chart

Solder Melting Temperature Chart

Solder Melting Point Chart

Solder Melting Point Chart

soldering Bismuth or Indium solder how do they compare?

Solder Melting Point Chart

Web The Melting Point Of Solder Varies Depending On Its Composition.

Web Find The Melting Temperature Of Various Kester Solder Alloys In °C And °F.

Find Out How To Choose The Right Solder For Your Project And.

Web Learn About The Melting Point Of Solder, How To Measure It, And The Different Types Of Solder And Their Melting Points.

Related Post: