Socket Set Size Chart

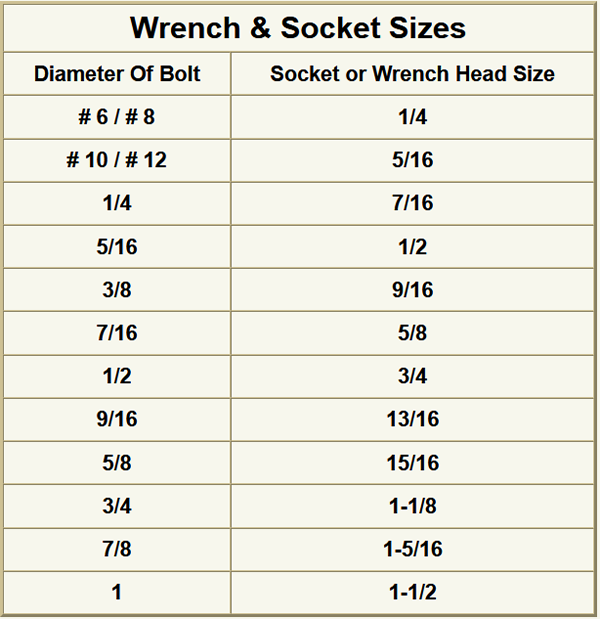

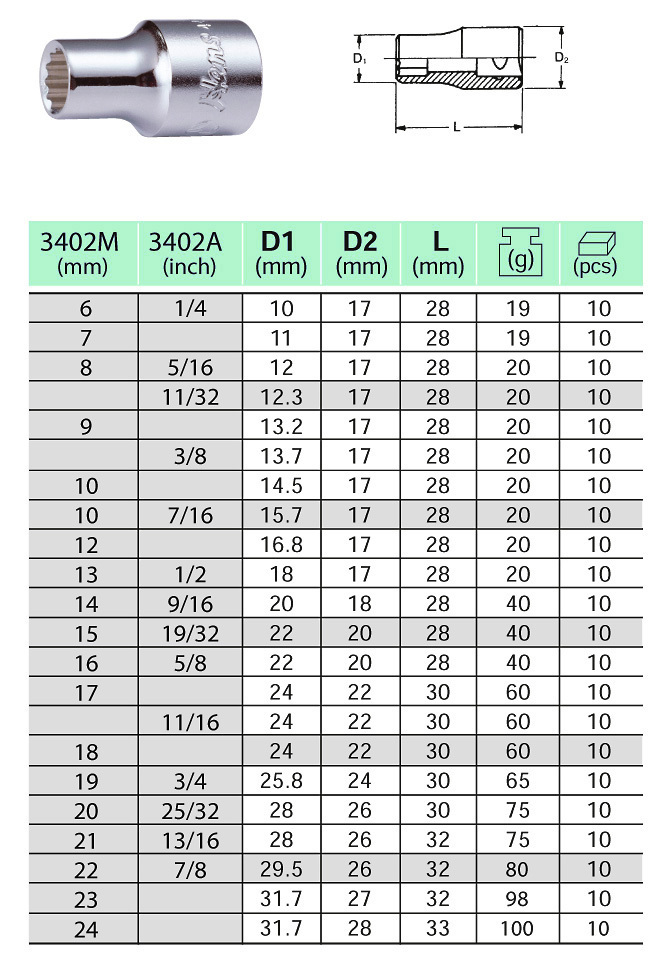

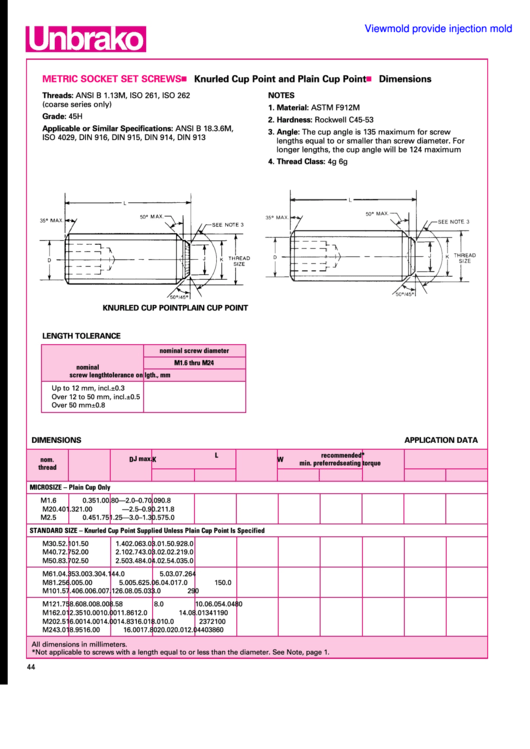

Socket Set Size Chart - Web the three most common drive size types are 1/4″, 3/8″, and 1/2″. Find our best fitting sockets for your vehicle and enjoy free next day delivery or same day pickup at a store near you! Web here you can find the socket sizes in order from the smallest to the largest you are most likely to use in the home or on your vehicle (and a complete socket set). Commonly used standard sae sizes for sockets and wrenches in order: Web answer 1 of 3: Lists of top rated socket sets on amazon. Some sets may also include larger sockets for specialty jobs, such as. Each is suited for different torque levels and applications. A socket tool is one that attaches to a rachet or wrench to allow much more efficient work while you turn a nut or a bolt. Web this socket size chart will help you whether you just got your first socket set, or you want to know which sizes you’re missing in your toolset, like maybe a 10mm? Metric socket sizes in order. But you don’t require all the socket size sockets, and you just require those that you will work with. You can quickly use the conversion chart to check your metric socket size against your sae socket size and vice versa. Within those sizes, you can expect to find sockets ranging from 4mm up to 24mm. Metric socket sizes in order. This article will discover the socket sizes in order from smaller to larger. Web get the job done with the right part, at the right price. Web if you have bought a socket set, you can use our chart to find out which size sockets are missing from your new set. Learn more about the. Web here you can find the socket sizes in order from the smallest to the largest you are most likely to use in the home or on your vehicle (and a complete socket set). Within those sizes, you can expect to find sockets ranging from 4mm up to 24mm and beyond. You can use this later or refer to the. Learn more about the different socket sets, their benefits, and their uses, too. Web answer 1 of 8: Web this page will help you discover the precise order of metric and standard socket sizes, for each set and type, and ensure your sockets are organized and ready to work. This article will discover the socket sizes in order from smaller. Sae to metric conversion chart. Learn more about the different socket sets, their benefits, and their uses, too. Do you know the classification of socket sizes from smallest to largest? You can use this later or refer to the sae to metric conversion chart toward the end of the guide. Socket sizes in order from smallest to largest. Check the socket size chart to know what size your sockets are. Web this page will help you discover the precise order of metric and standard socket sizes, for each set and type, and ensure your sockets are organized and ready to work. Web this socket size chart will help you whether you just got your first socket set, or. Web the most common socket set sizes are 1/4 inch, 3/8 inch, and 1/2 inch. Some sets may also include larger sockets for specialty jobs, such as. Sae socket sizes in order. Additionally, trial and error can be used to confirm the correct fit before applying torque. Web this page will help you discover the precise order of metric and. You can quickly use the conversion chart to check your metric socket size against your sae socket size and vice versa. Web whether you just got your first socket set, want to know which sizes you’re missing in your socket organizer, or simply need a quick reference to see if a metric size converts to sae, check out the tables. Web this socket size chart will help you whether you just got your first socket set, or you want to know which sizes you’re missing in your toolset, like maybe a 10mm? Check out the table of contents below to quickly find the chart you need. You can quickly use the conversion chart to check your metric socket size against. Web get the job done with the right part, at the right price. But you don’t require all the socket size sockets, and you just require those that you will work with. This article will discover the socket sizes in order from smaller to larger. Web answer 1 of 3: Web need some quick work done with nuts and bolts? This particular guide will show the proper arrangement of sockets based on their measurements. But you don’t require all the socket size sockets, and you just require those that you will work with. Web here you can find the socket sizes in order from the smallest to the largest you are most likely to use in the home or on your vehicle (and a complete socket set). Check out the table of contents below to quickly find the chart you need. Each is suited for different torque levels and applications. Sae socket sizes in order. You can learn more about drive types here. You can quickly use the conversion chart to check your metric socket size against your sae socket size and vice versa. Lists of top rated socket sets on amazon. Web this socket size chart will help you whether you just got your first socket set, or you want to know which sizes you’re missing in your toolset, like maybe a 10mm? You can quickly use the conversion chart to check your metric socket size against your sae socket size and vice versa. Sorry i know its a boring question but will i need to buy an adapter to plug in my hair straightners / chargers/ hair dryer etc, if so what kind should i buy? Socket size chart for metric. Web contents [ hide] most common drive sizes. Web the three most common drive size types are 1/4″, 3/8″, and 1/2″. Web a socket set typically includes a variety of socket sizes.

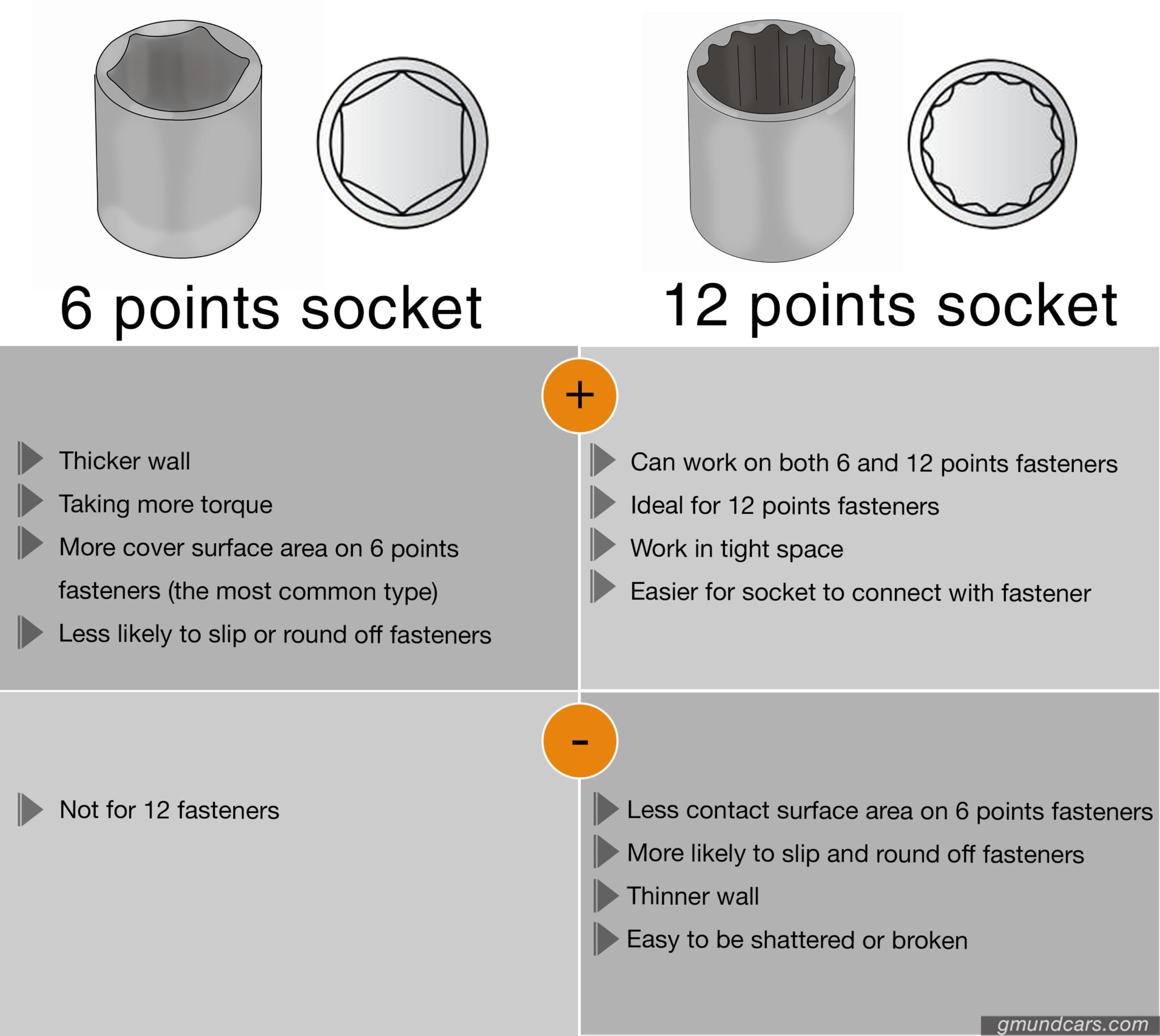

AZ Socket guide & Top 10 socket sets review 2021 Gmund Cars

Printable Socket Size Chart In Order

Standard Socket Set Size Chart

Craftsman Socket Size Chart

Printable Socket Size Chart Metric And Standard

Socket Set Sizes Chart

Standard Socket Sizes Chart

Sae Socket Size In Order Printable Chart

Printable Socket Size Chart

Printable Socket Size Chart Metric And Standard

Just Down Below, You Will Find Reference Charts So You Can Quickly Find Out Which Socket Sizes You Are Missing.

Check The Socket Size Chart To Know What Size Your Sockets Are.

Additionally, Trial And Error Can Be Used To Confirm The Correct Fit Before Applying Torque.

A Socket Tool Is One That Attaches To A Rachet Or Wrench To Allow Much More Efficient Work While You Turn A Nut Or A Bolt.

Related Post: