Smaw Welding Electrode Chart

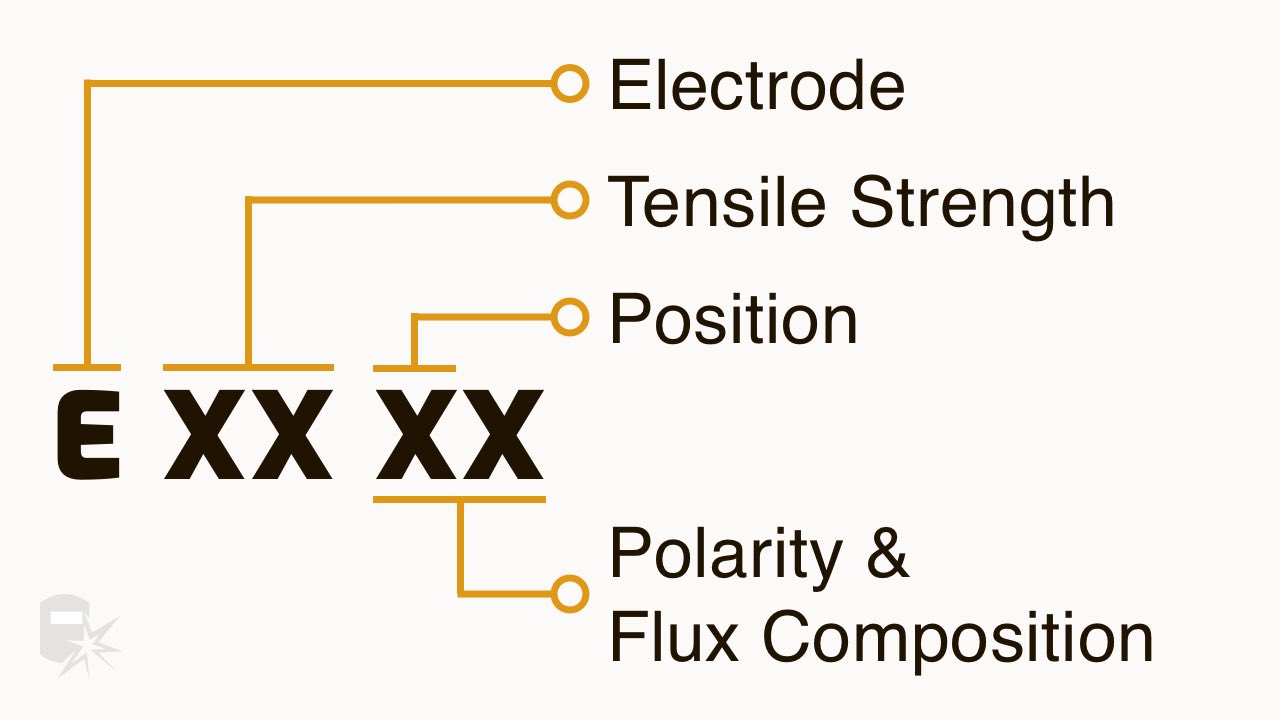

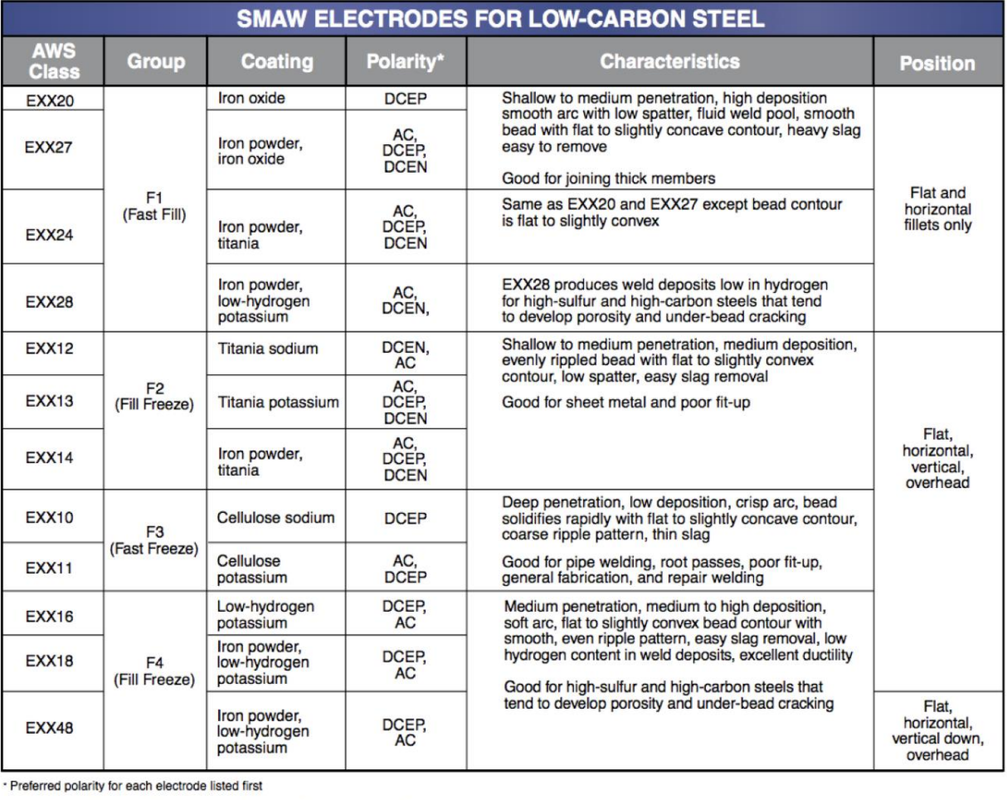

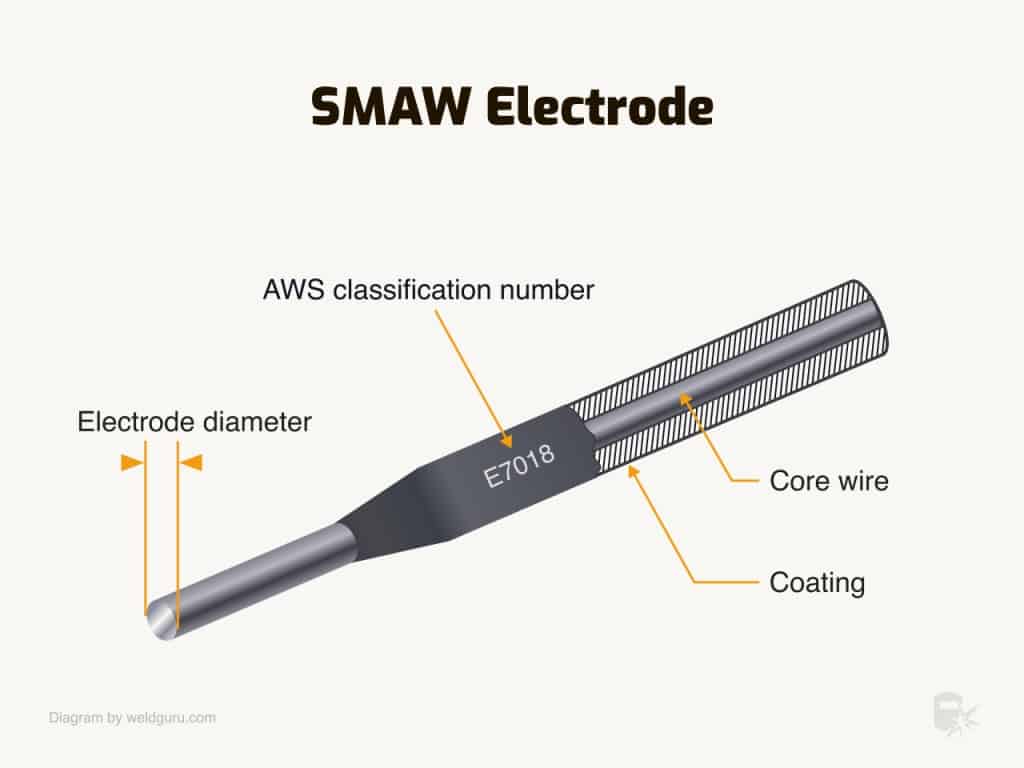

Smaw Welding Electrode Chart - Low hydrogen electrodes (for carbon steel & low alloy steel welding) e.g., e7018, e8018, & e10018. Use the charts provided to help you choose the best setup for each application. The input power circuit and machine internal circuits are also. Web what is stick welding (smaw)? Deep penetration and ideal for welding light to medium amounts of dirty, rusty or painted materials; The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low amperage on thinner metal. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Web our powerful calculator let's you easily determine which stick electrode you need. The below chart gives very detailed guidelines for stick welding (smaw) or equivalent tig/mig filler wires for different types of stainless steel welding. However, there are many different ones. Live when power is on. The arc melts the base and electrode metals. The below chart gives very detailed guidelines for stick welding (smaw) or equivalent tig/mig filler wires for different types of stainless steel welding. Web how to select stick welding rod type, size, and amperage. What is it & how to choose? Web here are the most popular stick welding (smaw) electrodes: Plus a chart with rod size and amperage per metal thickness in inches and mm. Web for material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice. Below is a chart that will give you a starting point for choosing the correct welding rod. Plus you'll get the most complete welding rod chart on the internet in pdf! Anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm). Web however, stick welding is the most commonly used arc welding process, making use of an electrode (sometimes called a filler. Good for working on surfaces that are oily, rusted, or has dirt. Web what is stick welding (smaw)? For smaw process, weaving shall be 3 times core dia. Web the electrode and work circuit is electrically live whenever the output is on. Use the charts provided to help you choose the best setup for each application. Aws welding electrode classification for smaw mild steel coated electrodes. Stick welding is a manual process that partially melts and joins metals of the same type. Web welding electrode selection chart for carbon steel to stainless steel, all stainless steel. For smaw process, weaving shall be 3 times core dia. Plus you'll get the most complete welding rod chart on. Web how to select stick welding rod type, size, and amperage. Aws welding electrode classification for smaw mild steel coated electrodes. Web our powerful calculator let's you easily determine which stick electrode you need. These electrodes have good welding properties for aluminum and are suitable for thin sections. Web the welding electrodes’ design offers the simplicity, portability, and versatility of. Web how to select stick welding rod type, size, and amperage. Used for carbon and galvanized steel; (with chart) last updated on jan 30 2023. Web welding electrodes classification for shielded metal arc welding (smaw) by american welding society (aws) is as follows. Low hydrogen electrodes (for carbon steel & low alloy steel welding) e.g., e7018, e8018, & e10018. The arc melts the base and electrode metals. Web how to select stick welding rod type, size, and amperage. Stick welding (smaw) aws class position polarity usage. Web in this article, we will discuss the various factors responsible for choosing the right welding electrode for the shielded metal arc welding process (smaw) for carbon steels. Web in this blog post,. Good for working on surfaces that are oily, rusted, or has dirt. These electrodes have good welding properties for aluminum and are suitable for thin sections. Web here are the most popular stick welding (smaw) electrodes: Low hydrogen electrodes (for carbon steel & low alloy steel welding) e.g., e7018, e8018, & e10018. Stick welding (smaw) aws class position polarity usage. Good for working on surfaces that are oily, rusted, or has dirt. In semiautomatic or automatic wire welding, the wire, wire reel, drive roll housing, and all metal parts touching the welding wire are electrically live. Aws welding electrode classification for smaw mild steel coated electrodes. Web some common stick welding (smaw) welding electrodes types (welding rod types) include: Stick. The electrode is melted and flows into the weld puddle, providing both filler material and shielding gas. These electrodes have good welding properties for aluminum and are suitable for thin sections. Web how to select stick welding rod type, size, and amperage. Used for carbon and galvanized steel; However, there are many different ones. Web the electrode and work circuit is electrically live whenever the output is on. In semiautomatic or automatic wire welding, the wire, wire reel, drive roll housing, and all metal parts touching the welding wire are electrically live. Stick welding is a manual process that partially melts and joins metals of the same type. Anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm). Stick welding (smaw) aws class position polarity usage. Live when power is on. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. After reading this article, you will learn about their characteristics, categories, and uses. The input power circuit and machine internal circuits are also. The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low amperage on thinner metal. Plus you'll get the most complete welding rod chart on the internet in pdf!

Welding Electrodes Understanding The SMAW Electrode, 41 OFF

Selection and Use of Electrodes for SMAW of Low Carbon Steel PAKTECHPOINT

Stick(SMAW) Welding Basics Welding electrodes, Smaw

![[ IMG] Smaw welding, Welding rods, Shielded metal arc welding](https://i.pinimg.com/736x/b4/ce/59/b4ce5957208c66caceec3c81b15825d2.jpg)

[ IMG] Smaw welding, Welding rods, Shielded metal arc welding

Welding electrodes Understanding the SMAW electrode symbols Welding

Smaw Electrode Chart vrogue.co

SMAW Welding Class

Smaw Electrode Chart vrogue.co

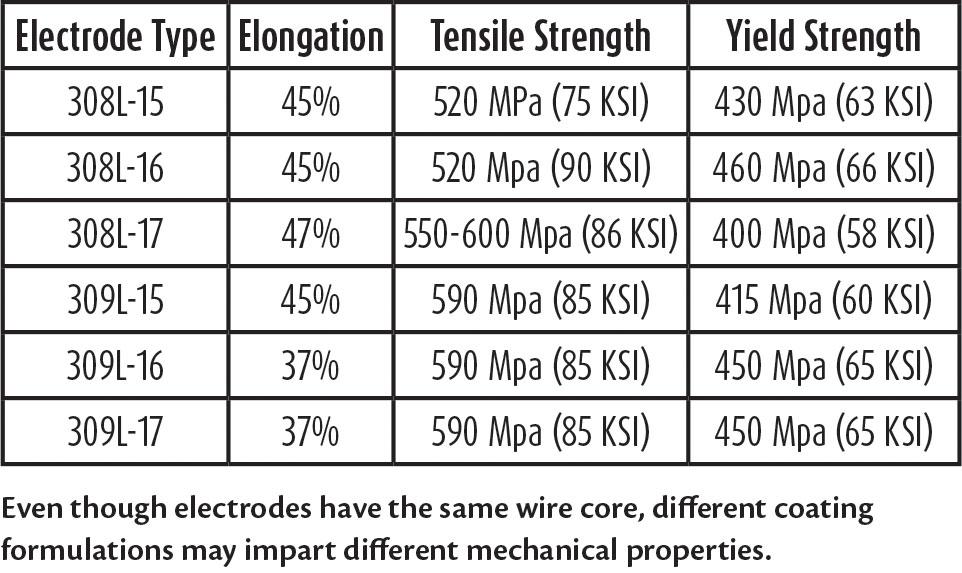

Mastering stainless SMAW electrodes

Welding Rod Sizes How To Choose the Right Electrode Weld Guru

Below Is A Chart That Will Give You A Starting Point For Choosing The Correct Welding Rod Size.

Web Different Types Of Carbon Steel Electrodes Used In Shielded Metal Arc Welding (Smaw) Explained In This Article.

Web However, Stick Welding Is The Most Commonly Used Arc Welding Process, Making Use Of An Electrode (Sometimes Called A Filler Rod Or Just A Stick) And Electric Power To Fuse Metals Together And Fill In The Joint.

Web In This Article, We Will Discuss The Various Factors Responsible For Choosing The Right Welding Electrode For The Shielded Metal Arc Welding Process (Smaw) For Carbon Steels.

Related Post: