Silage Bag Capacity Chart

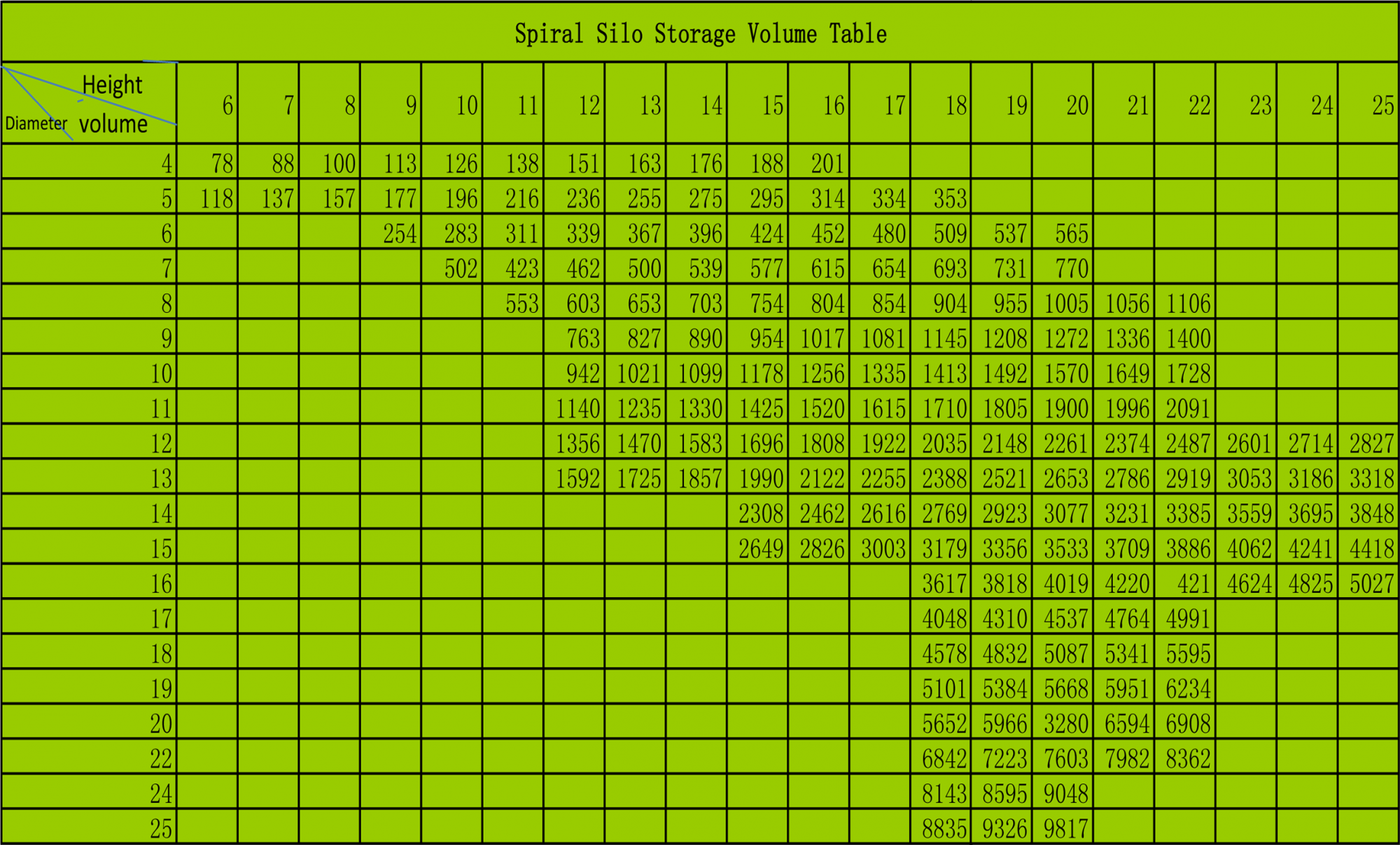

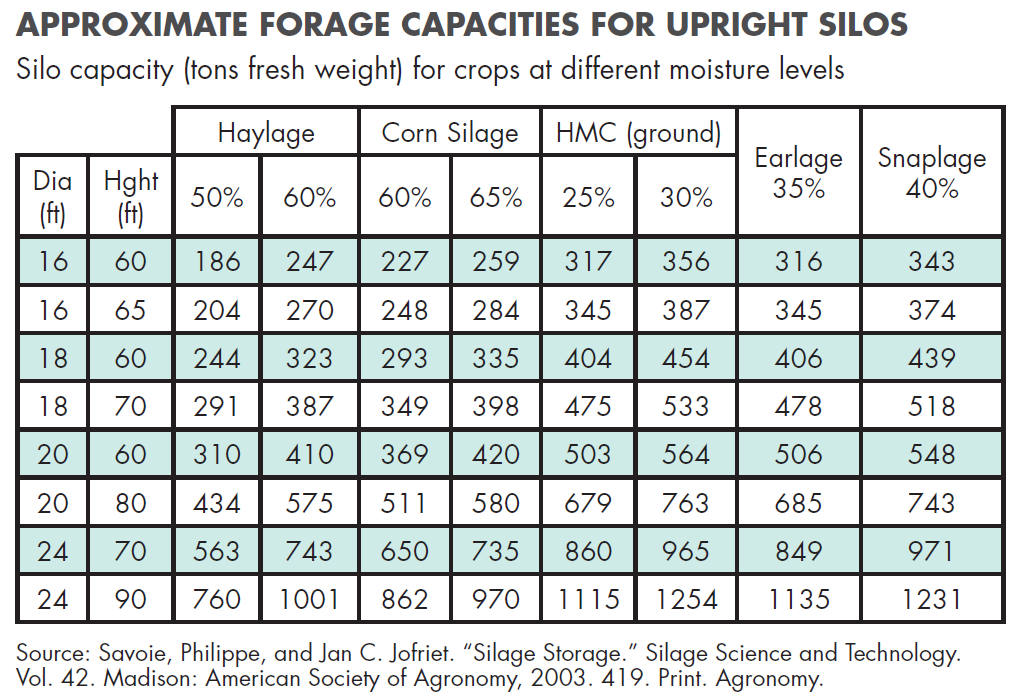

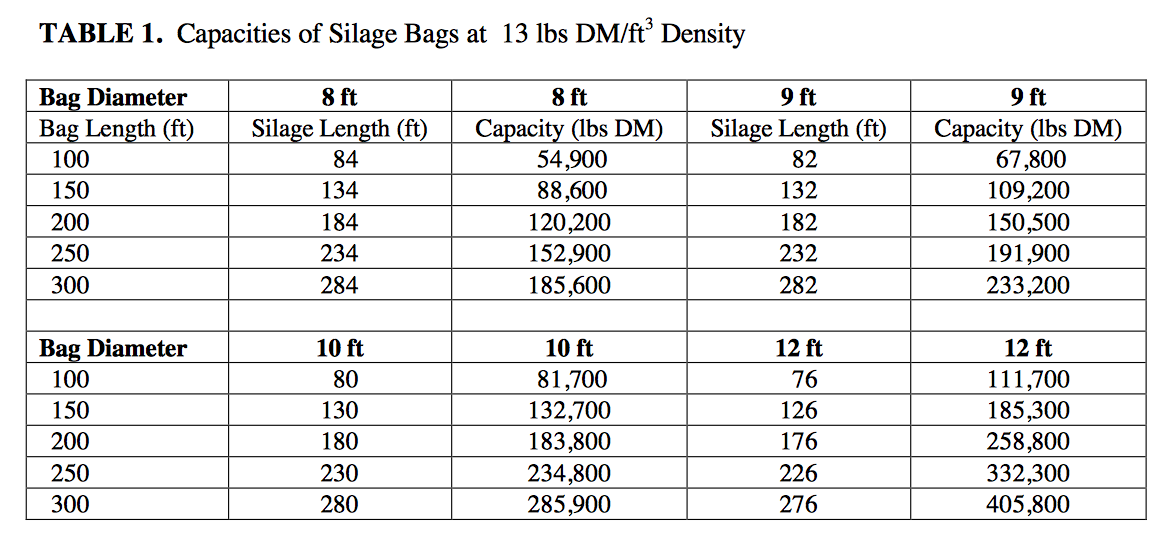

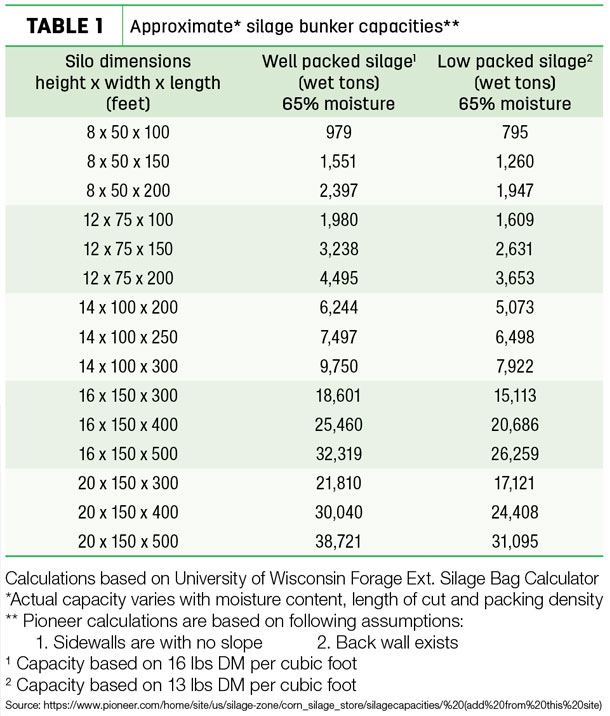

Silage Bag Capacity Chart - The best way to measure total capacity is weighing each load before storing forage or grain. Web we frequently get questions about the amount of silage in a silo bag. Web below is a handy pile sizing chart based on the width that determines the height at the center, the volume of feed per ft. *actual capacity varies with moisture content, length of cut and packing density. 430,000 lbs af = 150,500 lbs dm/0.35 when packed at 13 lbs dm/ft3 density. Web this spreadsheet was developed to determine the number and size of silage storage bags and a pad upon which to place them for hay crop, whole plant corn crop and ground high moisture corn. Divide this value by 2000 lbs/t to obtain. Web marketing silage is limited due to high transportation costs and susceptibility to spoilage. Pioneer referenced the university of wisconsin saying that a 9'x200' should hold 236 tons of low packed silage. Web the 8 foot silage bag holds just under 2000 lbs per foot. Web with these designs, longer bags can potentially be used. Web use this decision tool to estimate the storage capacity for grain bins, bales storage, water and fuel tanks. 1 capacity based on 16 lbs. Pioneer referenced the university of wisconsin saying that a 9'x200' should hold 236 tons of low packed silage. Web approximate silage bunker, pile and bag. Pioneer referenced the university of wisconsin saying that a 9'x200' should hold 236 tons of low packed silage. Table 1 has been developed to show silo bag capacity based on the following assumptions. Web the silage bag capacity guide from the university of wisconsin can help you determine potential capacity of various sizes (bag diameter and length) and packing densities.. Exact tons or bushels are based on length of cut, moisture, variety, and pack density. A good rule of thumb for corn silage is 1 and 1 1/2 tons (wet basis) per running foot for 9 and 10 foot diameter bags, respectively. *actual capacity varies with moisture content, length of cut and packing density. The best way to measure total. Web the dry matter density can vary from bag to bag and is based on machine type and adjustment as well as forage type. T feed rations cab be blended and balanced. The best way to measure total capacity is weighing each load before storing forage or grain. Web this spreadsheet was developed to determine the number and size of. The total we have taken out of a 9 by 300 is 287 metric tonnes. This tool along with moisture levels, length of the cut, and crop variety are ways to ensure you are managing your forage crop in the best possible way. Calculations based on university of wisconsin forage ext. These numbers are estimated values only to provide a. 1 capacity based on 16 lbs. Speed up your grain harvest by filling an agflex bag in the field instead of trucking grain long distances for storage. Silage pile (without side walls) attributes based on a 1:3 pitch The amount of specific silages that can be stored in each bag varies with forage species, dry matter content and bag capacity.. T feed rations cab be blended and balanced. 2 capacity based on 13 lbs. Web marketing silage is limited due to high transportation costs and susceptibility to spoilage. Web the dry matter density can vary from bag to bag and is based on machine type and adjustment as well as forage type. Web use this decision tool to estimate the. Web this flow chart uses major decision points to direct you toward a given type of storage. Silage pile (without side walls) attributes based on a 1:3 pitch Calculations based on university of wisconsin forage ext. Recycling silo bags and other agricultural plastic films Exact tons or bushels are based on length of cut, moisture, variety, and pack density. Silage pile (without side walls) attributes based on a 1:3 pitch Then when we start the bag we lose a few feet and when we stop at the end we lose a couple more. Web the dry matter density can vary from bag to bag and is based on machine type and adjustment as well as forage type. Begin sampling. Web approximate silage bunker, pile and bag capacities. If you need to know the capacity in lbs of silage as fed, divide the table value by the dry matter content. Other considerations (personal preferences, financial constraints, existing facilities/labor/management, etc.) may influence your decision to select a storage other than what the flow chart suggests. Silage pile (without side walls) attributes. Recycling silo bags and other agricultural plastic films T feed rations cab be blended and balanced. Calculations based on university of wisconsin forage ext. Web marketing silage is limited due to high transportation costs and susceptibility to spoilage. Web below is a handy pile sizing chart based on the width that determines the height at the center, the volume of feed per ft. Our 9 foot holds 2200 lbs per foot. Table 1 has been developed to show silo bag capacity based on the following assumptions. *actual capacity varies with moisture content, length of cut and packing density. The best way to measure total capacity is weighing each load before storing forage or grain. Then when we start the bag we lose a few feet and when we stop at the end we lose a couple more. This fact sheet provides management tips for properly locating, constructing and managing a bunker silo to obtain the maximum benefit in both feed quality and quantity. Of length, and the necessary silage bunker cover width. Web this flow chart uses major decision points to direct you toward a given type of storage. The amount of specific silages that can be stored in each bag varies with forage species, dry matter content and bag capacity. Brian holmes (emeritus), is designed to help producers estimate the quantity of forage in a bag silo. Web this spreadsheet was developed to determine the number and size of silage storage bags and a pad upon which to place them for hay crop, whole plant corn crop and ground high moisture corn.

Silage Corn FOUNDATION ORGANIC SEEDS & FOUNDATION DIRECT SEEDS

Tower Silo Capacity Chart

Approximate Silage Bunker, Pile and Bag Capacities

Calculating forage inventory Hubbard Feeds

Silage Bag Capacity

Silage Inform Nutrition

Up North Plastics Grain Bags Bag Man, LLC Agricultural Sales

Up North Plastics Silage Bags Bag Man, LLC Agricultural Sales

Details 54+ silage bags vs bunkers latest in.cdgdbentre

Up North Plastics Silage Bags Bag Man, LLC Agricultural Sales

A Good Rule Of Thumb For Corn Silage Is 1 And 1 1/2 Tons (Wet Basis) Per Running Foot For 9 And 10 Foot Diameter Bags, Respectively.

Other Considerations (Personal Preferences, Financial Constraints, Existing Facilities/Labor/Management, Etc.) May Influence Your Decision To Select A Storage Other Than What The Flow Chart Suggests.

1 Capacity Based On 16 Lbs.

One Way To Estimate This Value Is To Calculate The Volume In The Bag And Multiply By Its Density.

Related Post: